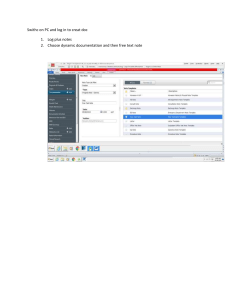

Mercury Vapor Monitor VM 3000 Operating Manual English Version 2.8 Manufacturer: Mercury Instruments GmbH Liebigstrasse 5 85757 Karlsfeld/Germany service@mercury-instruments.de © 2012 by Mercury Instruments GmbH, Karlsfeld (Germany) VM-3000 General information for safe operation C A U T I O N: While operating the VM-3000, parts of its interior are under high voltage and UV-beams are produced inside. If safety regulations are ignored physical and/or material damages could occur. Only qualified personal should be allowed to operate the VM-3000. Following conditions for correct function of the VM-3000 are to be held: careful and correct storage, proficient operation and maintenance. • Do not operate instrument if it is damaged. • When connecting the VM-3000 to a power source please note the related safety regulations. • The VM-3000 should be operated from the type of power source indicated on the rating plate. • Make sure that plugs and power cord are not damaged. • Regulations for prevention of accidents are to be followed. • Before opening the VM-3000 disconnect it from the mains supply. • Repairs and maintenance on the opened and powered instrument should only be carried out by trained personnel. • Operate the VM-3000 on a stable and dry surface. The interior of the VM3000 should never get moist or wet. In case it happens, consult an expert. • The VM-3000 is dedicated for the measurement of mercury concentration in gases. Do regard the related dangers especially while operating with toxic gases. Make sure that these parts of the instrument guiding the gas are not damaged and that the gas is guided back to the source or into an absorber. If explosive gases are measured or if measurements are made at places where explosion is possible, please follow the specific safety instructions. VM-3000_E-V-2.8.doc 13.06.2012 Page 2 of 42 VM-3000 CONTENT: 1. GENERAL DESCRIPTION ...................................................................................................................................5 1.1 FIELDS OF APPLICATION .....................................................................................................................................5 1.2 MEASURING PRINCIPLE ......................................................................................................................................7 2. PREPARATION FOR OPERATION ....................................................................................................................8 3. INSTALLATION ......................................................................................................................................................8 3.1 ELECTRICAL POWER SUPPLY..............................................................................................................................8 3.2 BATTERY OPERATION .........................................................................................................................................9 3.2.1 Battery charger ............................................................................................................................................9 3.3 FUSES .................................................................................................................................................................11 3.4 OPERATION AND DISPLAY COMPONENTS .........................................................................................................11 3.5 CONNECTION OF THE ELECTRICAL OUTPUTS ..................................................................................................11 3.5.1 Analogue signal 4-20 mA ..........................................................................................................................11 3.5.2 Serial data output (USB or 9-pin DSUB) ..................................................................................................11 3.5.3 Connection of a printer..............................................................................................................................13 3.5.4 Status and external alarm output ..............................................................................................................13 3.5.5 Sample gas connection ..............................................................................................................................13 4. OPERATING INSTRUCTIONS ..........................................................................................................................14 4.1 START-UP MEASURING ......................................................................................................................................14 4.1.1 Display of mean values ..............................................................................................................................15 4.2 MAIN MENU ......................................................................................................................................................15 4.3 MANUAL ZERO ADJUSTMENT ...........................................................................................................................16 4.4 SETTING OF PARAMETERS ................................................................................................................................16 4.4.1 Setting of duration and repeat-interval of the automatic zeropoint adjustment .....................................17 4.4.2 Selection of concentration units (µg/m³ / ppb) .........................................................................................18 4.4.3 Selection of measuring range ....................................................................................................................18 4.4.4 Setting of alarm thresholds........................................................................................................................18 4.4.5 Setting of averaging times for mean values calculation ...........................................................................19 4.4.6 Printer menue ............................................................................................................................................19 4.4.6.1 Printer Mode ........................................................................................................................................19 4.4.6.3 Auto-Print-Interval, Print on Alarm .....................................................................................................20 4.4.7 Setting of response time .............................................................................................................................21 4.5 SERVICE MENU ..................................................................................................................................................21 4.5.1 Display of calibration factors list ..............................................................................................................22 4.5.2 Entering a new calibration factor .............................................................................................................23 4.5.3 Setting date and time .................................................................................................................................23 4.5.4 Device data ................................................................................................................................................24 4.5.5 Set Status ...................................................................................................................................................24 4.5.6 Portable Operation.....................................................................................................................................25 4.5.7 Conversion of Readings to Standard Temperature and Pressure (STP) Conditions ...............................25 4.5.8 Manual Functional Check of Status Contacts and Zero Valve................................................................26 4.6 ERROR MESSAGES ............................................................................................................................................27 4.6.1 Lamp ! .....................................................................................................................................................27 4.6.2 p-Sensor ! ..............................................................................................................................................27 5. DATA LOGGER FUNCTION ..............................................................................................................................28 5.1 SETTING THE LOGGING RATE ...........................................................................................................................28 5.2 ACTIVATING THE DATA LOGGER ......................................................................................................................28 5.4 SENDING LOGGED DATA TO A PC WITH THE HG-TRANSFER SOFTWARE .......................................................29 5.5 DELETE LOGGED DATA .....................................................................................................................................31 VM-3000_E-V-2.8.doc 13.06.2012 Page 3 of 42 VM-3000 6. MAINTENANCE....................................................................................................................................................32 6.1 PARTICLE FILTER..............................................................................................................................................32 6.2 REPLACEMENT OF THE CARBON CARTRIDGE FOR ZERO AIR ..........................................................................32 6.3 CARE AND MAINTENANCE ................................................................................................................................33 6.4 CALIBRATION CHECK WITH REFERENCE SCREEN ...........................................................................................33 6.5 ZERO OFFSET ADJUSTMENT ..............................................................................................................................34 7. TECHNICAL INFORMATION .............................................................................................................................35 7.1 TECHNICAL SPECIFICATIONS............................................................................................................................35 7.2 INFLUENCING EFFECTS .....................................................................................................................................35 7.3 STORAGE AND TRANSPORT ...............................................................................................................................35 7.4 SPARE PARTS AND ACCESSORIES ......................................................................................................................36 7.5 BLOCK DIAGRAM OF ELECTRICAL PARTS ........................................................................................................37 7.6 DIAGRAM OF COMPONENTS ..............................................................................................................................38 INDEX ........................................................................................................................................................................40 APPENDIX .................................................................................................................................................................42 EC-DECLARATION OF CONFORMITY .............................................................................................................42 VM-3000_E-V-2.8.doc 13.06.2012 Page 4 of 42 VM-3000 1. General description 1.1 Fields of application The VM-3000 serves for continuous measurement of the mercury concentration in gases like air, nitrogen, argon, etc. Following applications are examples for the versatility of the VM-3000: Measurement of mercury in laboratory room air of high schools and universities. Mercury was used very often in the past for thermometers and barometers. Therefore such rooms where practical exercises have been performed by students often show increased mercury concentrations. Measurement of mercury at working places where mercury is (or was) used. Such working places may be dentists laboratories, thermometer manufacturers, fluorescence lamp manufacturers, chlorine-alkali production plants, battery manufacturers. Measurement of elemental mercury in flue or stack gas from combustion processes. Commonly a cooler has to be placed before the gas is entering the VM-3000 to remove moisture from the sample. Measurement of mercury in recycling plants for mercury containing material like lamps, batteries, filters and other components from natural gas industry. Monitoring of mercury in laboratories where mercury is used for example in porosimeters or diffusion pumps. Measurement of mercury in gases for quality control (hydrogen, nitrogen, calibration gases) Figure: VM-3000 in a field laboratory on top of the Teide volcano (Canary Islands) VM-3000_E-V-2.8.doc 13.06.2012 Page 5 of 42 VM-3000 Figure: Mercury Monitoring System (MMS) for emission control of cellrooms in chlorine-alkali plants Applications for the VM-3000 (cont.) As a highly sensitive mercury detector for research work Survey of mercury in contaminated areas like abandoned plants which used mercury in production processes. Tracing of mercury spillage in rooms. Control of sanitation/ decontamination work Geochemical applications (see picture below) Employment in the Mercury Monitoring Systems (MMS) for monitoring of mercury concentrations at 2-48 measuring points. Figure: tracing mercury spillage with the VM-3000 VM-3000_E-V-2.8.doc 13.06.2012 Page 6 of 42 VM-3000 1.2 Measuring principle Basis for determination of the mercury concentration is the resonance absorption of the Hgatoms at a wavelength of 253.7 nm. The sample gas is drawn through a 1 micron PTFE filter into the optical cell by a membrane pump. The optical cell is entirely made of synthetic quartz glass. Radiation of a mercury lamp passes through the cell and is measured by a solid state detector. The attenuation of the UV light reaching the detector depends on the number of mercury atoms in the optical cell. The internal computer performs the quantitative evaluation of the mercury concentration in the sample in real-time. In order to get an extremely stable baseline, the UV-light source is controlled by a reference beam and reference detector device. In addition to this, the UV detectors of the VM-3000 are thermostatically controlled. Heating of the optical cell (45 °C +/- 0.3 °C) makes the VM-3000 insensitive to water vapor. Figure: Schematic diagram of the VM-3000 VM-3000_E-V-2.8.doc 13.06.2012 Page 7 of 42 VM-3000 2. Preparation for operation The VM-3000 is unpacked and placed on a flat surface (e.g. table). The handle can be adjusted in several steps in order to be used for carrying the VM-3000 or as a base to position it on a bench. 3. Installation 3.1 Electrical power supply The voltage of the power source has to be the same as the operation voltage indicated on the rating plate of the VM-3000. One end of the included power cord has to be connected to the power cord receptacle on the back of the VM-3000. The opposite end has to be plugged into an appropriate power outlet. For operation turn on the VM-3000 by pushing the power switch on the back plate to position I. Figure: Rear panel of VM-3000 VM-3000_E-V-2.8.doc 13.06.2012 Page 8 of 42 VM-3000 3.2 Battery operation The 12 Volt-version of the VM-3000 can be operated with mains as well as with 12V rechargeable batteries. If „LOW BATTERY“ is indicated on the display the VM-3000 can still operate a few minutes in order to give the operator some time to finish measuring and recharge the batteries. 3.2.1 Battery charger The charger ACS 410 is designed to quick charge the nickel-cadmium battery pack of the VM3000. Charging time of empty battery packs lasts approximately 10 hours. Note that new battery packs or packs that have not been used for a longer period, in the beginning only use part of their capacity. Charging operation : (a) Switch off the Mercury Vapor Monitor. (b) Disconnect Mercury Vapor Monitor from mains power supply by pulling the power plug. (c) Put primary plug of battery charger into wall socket. (d) Connect the Mercury Vapor Monitor by means of the included cable observing correct polarity; in case of wrong connection the red LED will be continuously lit. (e) Charging of the NiCd power packs will start automatically once being properly connected. (f) Red LED will flash for about 10 seconds, battery contact detection - test phase. Note: If the red LED keeps flashing after the test phase, check the polarity of the battery pack (+/- switched). If polarity is right and the red LED keeps flashing after the test phase, the battery pack is broken. The test phase is followed by the charging procedure (red LED on). After termination of the charging time the device will automatically switch over to impulse-trickle-charge. This is indicated by a flashing green LED, red LED off. Features of the battery charger: for NiCd and NiMH battery packs capacity: 500 mAh to 5000 mAh micro-controller controlled charging battery test phase at the start of each charging cycle to detect broken battery packs broken battery pack detection and charging current cut off short circuit detection electronic protection against reversed battery battery charging at the start of the charging cycle is of no importance automatic switching over to trickle charge button for discharging automatically followed by charging VM-3000_E-V-2.8.doc 13.06.2012 Page 9 of 42 VM-3000 To avoid memory effect (loss of capacity due to frequent partly discharging), you have to discharge the battery pack every now and then. After the test phase, press the „PRESS” button approximately 2 seconds (red LED flashing). After discharging and after a power interruption the charger automatically switches over to charging. LEDs: Red LED flashing: battery contact detection (test phase) Red LED on: Green LED on: battery pack reversed battery pack broken or unsuitable amount of cells discharging after pressing the PRESS button Charging Battery fully charged, trickle charge Charging times: Number of cells: 4-10 Capacity: Charging time: 5000 mAh approx. 10h Safety: Do not charge dry batteries. Danger of explosion! Only charge rechargeable NiCd / NiMH battery packs. Do not open the charger. Repairs may only be done by the manufacturer. For indoor use only. Environment: Batteries are small chemical waste. Throw away broken or used up batteries in a special container or hand them in at a recycling centre. Technical specifications: Operation on mains: 230 V~ (+-10%), 50Hz (Euro version) Charging tension: Charging current: Discharge current: VM-3000_E-V-2.8.doc 120 V~ (+-10%), 60Hz (US-version) approx. 30V dc at no load, 4-18 Vdc at charge-/discharge function 700 mA +-10% 200 - 500 mA 13.06.2012 Page 10 of 42 VM-3000 3.3 Fuses The fuse compartment is located on the rear of the VM-3000 between the power cord receptacle and the power switch. It can be opened with a small screw driver and contains two fuses. CAUTION: Disconnect instrument from electrical mains supply before opening the fuse compartment ! Fuse type: The rating of the fuses to be used as spares depends on the operation voltage indicated on the rating plate of the VM-3000: 230V operation voltage: fuse type T 400mA (time lag) 115V operation voltage: fuse type T 1.25 A (time lag) 3.4 Operation and display components The VM-3000 features a waterproof IP 65 keypad and a graphic LCD with background illumination for comfortable communication with the operator. 3.5 Connection of the electrical outputs 3.5.1 Analogue signal 4-20 mA The socket for the analogue output signal is located on the rear panel of the VM-3000. To transmit the signal the included cable is connected with BNC-plug to the socket marked with "SIGNAL". Maximum load is 400 Ohm. GND + 4 ... 20 mA socket for signal output (BNC) Figure: BNC socket for measurement signal 3.5.2 Serial data output (USB or 9-pin DSUB) To connect the VM-3000 with a PC there are two possibilities provided: a USB-socket and a 9pin DSUB-socket on the rear panel of the instrument. The serial port of the PC has to be connected to one of them with an appropriate cable (part No. 202-07 pins 2-3-5 are 1:1/ 20207a). The two ports are not activated simultaneously and there is a dip-switch inside the back panel of the instrument (see fig. below) which allows to select either USB or RS232. Factory setting is: USB activated. For being able to use this port you have to install the USB-driver (CDM Driver) which you will find on the Hg-Transfer CD-ROM. VM-3000_E-V-2.8.doc 13.06.2012 Page 11 of 42 VM-3000 All data are transferred as ASCII characters. They can be read by the PC with a terminal program like Hyper Terminal or the HG-Transfer software which has been included with the delivery of the instrument. Using the HG-Transfer software is explained in chapter 5.5. Figure: Dip switch for selecting USB or RS 232 RS 232 5 9 Pin Nr. 1 6 5 3 2 GND RxD TxD Figure: wiring of the RS 232 socket The parameters used for serial data transfer are: 9600 baud / 8 data bit /stop bit 1 / no parity / flow control: none The measurement actualises every second, and every 30 seconds status information is transferred. Data format: XXXX.X; Example: 1.0; 1.5; 3.4; 12.3; 11.5; 100.0; 1901.5; Status is output as following characters: N= NORMAL; M= ERROR; A= ALARM Example: 1.0; 1.5; 3.4;N; 12.3; 11.5; 100.0; 1901.5; VM-3000_E-V-2.8.doc 13.06.2012 Page 12 of 42 VM-3000 3.5.3 Connection of a printer To connect a printer (DOS-compatible) a 25-pin DSUB-socket is installed on the rear panel. If the printer mode is activated, a periodical printout of mercury concentration and according data like date and time is performed. The time intervals between two printouts can be set in the printer menu. Printer 13 1 25 Pin Nr. 14 1 2 3 4 5 6 7 8 9 PSTROBE D0 D1 D2 D3 D4 D5 D6 D7 11 18 BUSY DGND Figure: parallel output socket for printer connection 3.5.4 Status and external alarm output Operational status and alarm messages are available through potential free relay contacts. The maximum load of the contacts is 80 V / 0.4 A. Factory setting is: The contacts are open when active. It is possible to change this setting in the software, see chapter 4.5, page 22, F4 – Set status. STATUS 13 25 1 14 Pin Nr. Status 2+ 14 Error 3+ 15 Zeroing 4+ 16 Alarm 3.5.5 Sample gas connection The sample inlet is located in the centre of the particle filter at the front panel of the VM-3000. It is possible to analyse ambient air by directly taking it into the sample inlet. The sample gas can also be drawn from distance to the VM 3000 through a tubing. The VM-3000 has a standard hose connector for tubing with 8 ... 10 mm inner diameter. A fitting for 4 mm (ID) / 6 mm (OD) tubing can be ordered (part No. 203-10). This is recommended for using tubing with a length of more than one meter. Recommended materials are TYGON R 3603 (part No. 201-03) or PFA (part No. 301-01) because of low permeability and minimum surface effects. VM-3000_E-V-2.8.doc 13.06.2012 Page 13 of 42 VM-3000 4. Operating instructions 4.1 Start-up measuring After turning the VM-3000 on the mercury lamp is ignited and warmed up to operation temperature. Following indications appear on the display first: After the lamp has ignited and the instrument has stabilized, which typically takes 3-15 minutes (depending on the ambient temperature), an AutoZero is performed. After the auto zero is finished, the VM 3000 automatically starts measuring. Now on the display are shown: actual absorption, concentration in µg/Nm³ or in ppb (whatever has been selected), time left until the next zero point adjustment, a bar graph visualising concentration of mercury. The measuring mode will stay active until it is interrupted by double pressing the ESC-key. VM-3000_E-V-2.8.doc 13.06.2012 Page 14 of 42 VM-3000 4.1.1 Display of mean values If the F1 key is pressed while measuring, the mean values over pre-set time intervals are shown. By pressing the ESC key the VM-3000 returns to the measuring mode whereas after pressing the F1 key the averaging times can be edited. After editing you can return to the measuring mode by pressing the ESC key. 4.2 Main Menu If the ESC key is double pressed during measurement, the main menu will be displayed. From this menu following operating functions like measurement or zero adjustment can be chosen, or the sub menus for parameter setting or service can be selected. VM-3000_E-V-2.8.doc 13.06.2012 Page 15 of 42 VM-3000 4.3 Manual zero adjustment If F2 is pressed in the main menu (see chapter 4.1) the zero point adjustment is started. During zero point adjustment an internal pinch valve cuts off the sample flow and filtered air is drawn through the optical cell. CAUTION: Performing zero adjustment, the mean of measurements during the last second will be set as new baseline. If the zero adjustment procedure is interrupted (double press of ESC) but there is still sample gas in the optical cell the zero adjustment may be incorrect. 4.4 Setting of parameters To get to the "Set Parameters" menu, F2 has to be pressed in the main menu (see chapter 4.1). By pressing the arrow-symbol you can turn to page two of the parameter menu: VM-3000_E-V-2.8.doc 13.06.2012 Page 16 of 42 VM-3000 4.4.1 Setting of duration and repeat-interval of the automatic zeropoint adjustment Press F1 Zero Duration/Interval on page 1 of the parameter menu: F1 is for setting the duration F2 is for setting the time interval between two automatic zero point adjustments. A typical setting for portable use at low measuring range is shown in above figure. If Zero Interval is set to "0" the automatic zero adjustment is not active. VM-3000_E-V-2.8.doc 13.06.2012 Page 17 of 42 VM-3000 4.4.2 Selection of concentration units (µg/m³ / ppb) Press F2- Select conc. Unit on page 1 of the parameter menu: F1: selection of µg/Nm³ F2: selection of ppb 4.4.3 Selection of measuring range Press F3 -Select Range on page 1 of the parameter menu. One of three measuring ranges can be selected by pressing F1. 4.4.4 Setting of alarm thresholds Press F4 Set Alarm Thresholds on page 1 of the parameter menu: By pressing F1/ F2/ F3 up to three alarm thresholds can be set. VM-3000_E-V-2.8.doc 13.06.2012 Page 18 of 42 VM-3000 4.4.5 Setting of averaging times for mean values calculation Press F1 Mean Values on page 2 of the "Set parameters" menu. While measuring the VM-3000 files the mean values for the pre-set time intervals. These can be retrieved during measuring and also printed out by a connected printer. By pressing F1/F2/F3 up to three time intervals can be entered for determination of the mean values. 4.4.6 Printer menue The printer menu will appear, if F2 Enter on page 2 of the parameter menu is pressed. If you have connected a PC and uses the software Hg-Transfer you can record all measured values immediately. You can change interval-parameters in the software ( see chapter 5.4, page 29, HgTransfer). 4.4.6.1 Printer Mode When you connect a printer, you have to change the interface setting from serial (default setting from factory) to parallel first by pressing F4 Printer Mode. 4.4.6.2 Print actual settings The actual parameters will be printed by pressing the F1 key. When you connect a PC and use our software Hg-Transfer (see pages 29ff) you can also transfer the actual settings by pressing the F1 key. Be sure that the printer mode is set to serial! VM-3000_E-V-2.8.doc 13.06.2012 Page 19 of 42 VM-3000 4.4.6.3 Auto-Print-Interval, Print on Alarm The following printer settings will only be completed if a printer is on-line: Setting of auto-print interval: Press F2 Auto-Print Interval. The automatic printout of the measurements will be completed periodically in the set time interval. If zero is entered , no print will succeed (printer = OFF). Print only in case of alarm: Press F3 Print on Alarm. If „ON“ is displayed printing of the measurements will succeed in one-minute-intervals as long as the alarm threshold is exceeded. Figure: Printout showing date, time, mercury concentration, 2-minutes mean, 10-minutes mean, 20-minutes mean VM-3000_E-V-2.8.doc 13.06.2012 Page 20 of 42 VM-3000 4.4.7 Setting of response time Press F3- Response Time on page 2 of the parameter menu. By pressing F1- Response Time a time constant between 0 and 9 seconds can be entered. The measuring signal will be smoothened by this time factor. 4.5 Service menu Press F4- Service in the main menu (see chapter 4.2) to get into the Service mode. After entering the code 321 [ENT], you have access to the service mode: F1 Calibration F2 Set Date / Time F3 Device Data F4 Set Status ESC <<< Back VM-3000_E-V-2.8.doc Page2 13.06.2012 Page 21 of 42 VM-3000 4.5.1 Display of calibration factors list The actual calibration factor and all previously entered calibration factors can be recalled in form of a list on the display. After pressing F1- Calibration in the service mode, following page will appear. The actual calibration factor is marked by an arrow. VM-3000_E-V-2.8.doc 13.06.2012 Page 22 of 42 VM-3000 4.5.2 Entering a new calibration factor CAUTION: Every alteration of the calibration factor influences the measurements. Therefore the calibration factor should only be changed after previous determination with a suitable calibration gas source (e.g. Mercury Calibrator MC-3000 by Mercury Instruments). Each VM-3000 has been calibrated before delivery. Every two years a professional calibration check is recommended. According to regulations applied on a special application more frequent re-calibration may be necessary. ATTENTION: If parts of the VM-3000 in contact with sample gas are contaminated with active substances like sulphur, an immediate calibration check is recommended. After pressing F1- Calibration and pressing F1 again, a new calibration factor can be entered. 4.5.3 Setting date and time Press F2- Set Date/Time in the service menu. Press F1 to edit date Press F2 to edit time VM-3000_E-V-2.8.doc 13.06.2012 Page 23 of 42 VM-3000 4.5.4 Device data By pressing F3-Device data you get information about the operational hours, the actual voltage of the lamp and the stored software version. The standard operation range of lamp voltage is 3.0 – 9.0 V Operational Hours: Lamp Voltage: Software-Version: 425 h 4.3 V 3.02 Copyright: Mercury Instruments GmbH IMT Innovative Messtechnik GmbH ESC <<< Back 4.5.5 Set Status If you press F4-Set Status, you can change the setting of the relay contacts for the output status signals. F1 Alarm Status active opened F2 Malfunc Status active opened F3 Zero Status active opened F4 External Zero off ESC <<< Back It is also possible to give an external signal for doing a zero adjustment by setting F4-External Zero to ON. Default setting is Off. If the setting is ON, you can give a signal for performing a zero adjustment from any device outside the VM-3000 by closing contact pins 7 and 19 of the 25-pol. DSUB-Plug on the backside of the VM-3000. A suitable connection cable with a ready-for-use DSUB-plug on one side and 2-pole cable on the other side is available as spare (part-no. 202-10) VM-3000_E-V-2.8.doc 13.06.2012 Page 24 of 42 VM-3000 4.5.6 Portable Operation For some applications like indoor screening of mercury contamination it is useful to select Portable Mode. Select Service Mode (see chapter 4.4) Enter Service Code 3 2 1 Go to page 2 Press F2 - Portable Mode Press ESC to leave the Service Mode If Portable Mode has been activated, the last measurement is frozen during Auto Zero. The performance of an Auto Zero is indicated on the screen. Recommendation: If the instrument is used in Portable Mode, the Auto Zero Interval should be set to ca. 0.5 minutes. Thus zero drift which may be caused by temperature changes is compensated. 4.5.7 Conversion of Readings to Standard Temperature and Pressure (STP) Conditions In some cases the user wants to read the mercury concentrations based on mass per standard cubic meter. A pressure sensor is installed close to the outlet of the optical cell and a separate temperature sensor on the backside of the photometer, to allow conversion of the readings to standard temperature and pressure (STP) conditions. The actual pressure and temperature readings are displayed in the service mode window (see chapter 4.5.8). After selecting F3 – pT-correction you can activate (ON) or deactivate (OFF) the pT-correction function. If for some reasons the PT-correction factors have been deleted (for example after an EPROM has been replaced or after the buffer battery of the microprocessor has been replaced), it may be necessary to restore them. Enter Service Code 3 2 1 + ENTER Go to page 2 Select F4- Set Pressure Cal. Data After pressing F1- Set gradient you can enter the gradient (practically you use the same value as noted in the instruments calibration certificate) VM-3000_E-V-2.8.doc 13.06.2012 Page 25 of 42 VM-3000 After pressing F2- Set constant you can enter the offset (practically you use the same value as noted in the instruments calibration certificate) Press ESC to leave the Service Mode. 4.5.8 Manual Functional Check of Status Contacts and Zero Valve The status contacts and the operation of the zero valve can be checked manually. Select Service Mode (see chapter 4.4) Enter Service Code 9 8 7 + Enter Select the wanted function by pressing the 1 – 5 keys Press ESC to leave the Service Mode Status Valve 1 Off 4 Zero Off 5 Reserve Off 2 Alarm Off 3 Malfunction Off Pressure: TSample: 958 mbar 21 °C ESC <<< Back Read sample pressure and temperature: In this window also the values for pressure and temperature of the sample are displayed (see also chapter 4.5.7). VM-3000_E-V-2.8.doc 13.06.2012 Page 26 of 42 VM-3000 4.6 Error Messages 4.6.1 Lamp ! The installed electrodeless mercury lamp is monitored permanently. If its performance drops under a certain limit (lamp voltage >8.5 V) the warning „LAMP!” indicates that the lamp should be replaced within the next days. 4.6.2 p-Sensor ! This error message can only be displayed if the pT-correction is ON (see chapter 4.5.5). This error message is displayed if the pressure measured by the pressure sensor is either <500 mbar or if the pressure is > 1200 mbar. There can be following causes for this: (a) the calibration of the pressure sensor has been lost, check calibration parameters of the pressure sensor in the service mode (see chapter 4.5.5). (b) the pressure of the sample at the location where it is measured (at outlet of the optical cell) is out of the allowed range. Check sample path upstream the pump for plugging and check, if there is flow restriction in the sample feed which may lead to low pressure; check also if there is overpressure at sample feed. (c) the pressure sensor is not working correctly and has to be replaced. This may be the case if (a) and (b) have been checked and are OK. VM-3000_E-V-2.8.doc 13.06.2012 Page 27 of 42 VM-3000 5. Data Logger Function The VM-3000 is available with a data logger function (as an option). Up to 15000 measurements can be stored in the RAM of the VM-3000. This enables the user to register up to 4 hours of measuring time if a logging rate of 1 second is set (respectively 40 hours of measuring if a logging rate of 10 seconds is set). The logging function has to be activated after the instrument has been switched on (see 5.2). 5.1 Setting the logging rate Jump to the Set Parameters menu (cf. 4.3 of manual). Go to page 2 of Set Parameters menu by pressing the▼-key Press F4- Logger Mode. The Logger Menu appears. Press F2- Logging Rate (1-999 sec) Enter the desired logging rate. Values from 1 sec to 999 seconds are allowed. All previously stored data are cleared if the logging rate is changed ! 5.2 Activating the data logger After the VM-3000 has been turned on the instrument automatically performs an Auto Zero and jumps into the measuring mode. For logging of data the data logger has to be activated. • Go to the Logger Mode menu as described under 5.1. • Press F1- Logger on/off to activate/deactivate the logger. The data logger is automatically deactivated after power has been turned off. It is also deactivated if 15000 measurements are stored in the RAM. VM-3000_E-V-2.8.doc 13.06.2012 Page 28 of 42 VM-3000 5.3 Start logging of measurement data After the data logger has been activated the measurement data are automatically logged whenever the measurement mode is active. The status of the logger is indicated on the display (ON/OFF). 5.4 Sending logged data to a PC with the Hg-Transfer Software Calibration and analysis data are sent via serial output of the VM-3000 to a connected computer using the Hg-Transfer software (comes with the instrument). The Hg-Transfer software has to be installed on the connected computer before data are transferred. Data can be displayed, stored (as .txt file or EXCEL® file) and printed. Two sockets are available on the instrument back panel (see also chapter 3.5.2): a 9-pin D-Sub socket for connecting the VM-3000 to a COM-port of the PC and a USB socket for connecting the VM-3000 to a USB port of the PC. If USB connection is used you have to install a USB driver (CDM Driver which comes with the Hg-Transfer software) on your PC first. The USB-driver is on the CD-ROM with the HgTransfer software. Figure: Hg-Transfer software main screen. Under „Port Settings“ you can select the port of your computer used for connection with the VM-3000 and the communication parameters. VM-3000_E-V-2.8.doc 13.06.2012 Page 29 of 42 VM-3000 By choosing „Configuration“ you can choose the type of analyzer: VM = VM-3000. You can enter a number to determine how many values will be discarded before a value is shown and saved. Transferring of the data from the VM-3000 to the PC is commenced by clicking onto the start icon. During measuring there is a continuous transfer of readings with a frequency depending on the set value in the configuration menu (select number of measuring values to show and to save). The following datas are shown: Measured Value; measured value….. and every 30 sec there is a signal indicating the status: Z = zero adjustment, N= normal operation When there are already logged data stored in the VM-3000, the whole log-file can be sent to the PC using the Hg-Transfer-Software. The following data are transferred and shown: Date; Time; Logging rate; Measured value VM-3000_E-V-2.8.doc 13.06.2012 Page 30 of 42 VM-3000 The values displayed in the Hg-Transfer window can be stored with the Save Logfile command (EXCEL® format). With the Save Continuously command results of a running measurement are continuously stored (EXCEL® format). With pressing About (i) you can check which version of hg-TransferSoftware you are using. With choosing Exit you are leaving the Hg-Transfer software. 5.5 Delete logged data Select the Logger Mode as described under 5.1. Press F4- clear logdata. Now all measurement data stored in the RAM are deleted. VM-3000_E-V-2.8.doc 13.06.2012 Page 31 of 42 VM-3000 6. Maintenance 6.1 Particle filter Under normal operation conditions, the sample gas particle filter has to be inspected regularly. If a deposit of particulate matter is visible, the filter membrane has to be replaced. Expected time interval for a filter replacement is 1 ... 6 months when normal room air is measured. For filter replacement carefully screw out the front part of the filter holder. Remove sealing ring and filter membrane. Insert spare filter membrane that the slick side faces towards the user and away from the instrument. Insert sealing ring and screw in front part of the filter holder. Make sure everything is gas tight. Figure: particle filter replacement 6.2 Replacement of the carbon cartridge for zero air The internal carbon cartridge of the VM-3000 should be replaced annually. Replacement of carbon cartridge: Place the instrument on a flat surface with its rear panel facing to you. Then loosen the two screws on the back of the VM-3000 and remove the top of the case by pulling it towards you. The carbon cartridge is now visible and can be removed from its holding clamps. To replace the carbon cartridge the hose has to be pulled off. Figure: replacement of activated carbon cartridge pull out cartridge and remove tubing 3 photometer unit top view unscrew with 3mm Allen key 1 remove top 2 VM-3000_E-V-2.8.doc 13.06.2012 Page 32 of 42 VM-3000 6.3 Care and maintenance • The VM-3000 should be maintained regularly once a year. Following service work has to be done: Replacement of the pinch valve tubing (part No. 203-12), check of the optical cell and of the internal tubing for visible deposits. • If the VM-3000 is in permanent operation the membrane pump should be replaced every two years. 6.4 Calibration check with reference screen This test is for check of the calibration stability of the instrument. Instead of using calibration gas a simple reference screen with known absorbance is brought into the light path. CAUTION: for this test the instruments top cover has to be opened during the instrument is powered. There is danger of electric shock and physical damage if parts under high voltage are touched. This test may be performed by personnel only who is trained and qualified for work at opened electric equipment. Following steps have to be followed: a) bring instrument into a dry room and place it on a dry and stable surface (table). a) switch on instrument and allow to warm up for min. 30 minutes. c) perform zero adjustment. d) open top cover (see chapter 6.2) of the instrument and place test screen (available as an accessory, part no. # 202-15) into the gap between lamp and optical cell or between UV detector and optical cell. Touch screen only on the labelled side, take care that the screen surface does not get dirty. e) put the top cover onto the instrument to prevent light from entering into the instruments interior. f) take reading of the absorbance value on the instruments display on the front panel. g) switch off power and disconnect from mains. h) remove test screen and mount top cover again. The reading of the Absorbance value during the screen is positioned in the light path of the photometer should be 0,4075 +/- 0,050. If the reading is out of this range, contact the service for check. VM-3000_E-V-2.8.doc 13.06.2012 Page 33 of 42 VM-3000 Test Screen Test Sc reen Figure: positioning of screen into the gap between optical cell and detector 6.5 Zero offset adjustment In some cases it may be observed that the reading of zero air is not zero even after a zero adjustment has been performed. In this case the zero offset may be re-adjusted. For this the service menu is selected and as service code 4 5 6 ENT is entered (see chapter 4.5). Now the Device Adjustment menu is displayed. Note: for the following steps the analyzer has to be free of mercury, this can be done by measuring mercury free air or by installing a zero cartridge at Sample IN and allow to measure for 15-30 minutes. After this the Device Adjustment procedure can be started by pressing F1- Start Adjustment. VM-3000_E-V-2.8.doc 13.06.2012 Page 34 of 42 VM-3000 7. Technical information 7.1 Technical specifications Instrument type Manufacturer Measuring component Measurement principle Wavelength UV-source Method of stabilising Optical cell Cell temperature Measuring ranges Sensitivity Sample gas flow Analogue output Binary outputs Digital outputs Electrical power consumption Power supply Dimensions Weight 19" rack mount version Mercury Vapor Monitor VM-3000 Mercury Instruments Mercury vapor Hg° Atom absorption 253,7 nm electrodeless mercury discharge lamp optically with reference beam; thermally entirely of fused silica Suprasil, l= 230 mm 45 °C (+/- 0.3 °C) thermostatically controlled 0.1 - 100; 0.1 - 1000; 0.1 - 2000 [µg/m³] 0 - 10; 0 - 100; 0 - 200 ppb ca. 0.1 [µg/m³] ca. 70 - 90 l/h Hg concentration in real time; 4 - 20 mA Malfunction; zeroing; alarm Serial (RS 232) for PC connection, parallel (Centronics) for printer connection max. ca. 40 W 230 VAC / 50 Hz ; 115 VAC / 60 Hz (option) ; 12 V DC (option) 45 x 15 x 35 cm (WxHxD) photometer unit 24 x 48 x 27 cm (WxHxD) reaction unit ca. 7 kg option, for installation in 19" racks 7.2 Influencing effects Operating temperature Sample temperature max. Operating humidity Sample gas humidity, max. CE approval 0 °C ... 40 °C 65 °C ca. 90 % max. R.H. dew point < 65 °C according to 89/336/EEC and 73/23/EEC 7.3 Storage and transport The interior of the VM- 3000 should be kept save from moisture and hard shocks. Vibrations caused by transport in a car or an airplane do not harm the VM-3000. VM-3000_E-V-2.8.doc 13.06.2012 Page 35 of 42 VM-3000 7.4 Spare parts and accessories ID Item Description 201-03m Tygon tubing, 4/7, internal tubing for photometer or sample tubing 201-04 Activated Carbon Filter filled with sulphurized activated carbon 201-11 Y-piece, glass, for the connection tubes between pinch valve and optical cell 201-12 Tubing-reduction (PTFE), pinch valve 202-05 Membrane Filter PTFE, 47 mm diameter, 1µ, pack of 25 pcs. 202-06 Signal cable with BNC plug, l= 180 cm 202-07 PC connection cable to transfer Data to a PC via RS 232 port 202-10 Gold Filter Cartridge for testing of nonspecific readings 202-15 Reference Screen for Calibration test 203-01 Membrane pump complete pump 203-02 Optical cell l= 230 mm, completely made of synthetic fused silica (Suprasil) 203-03 Pinch valve complete unit, 2 valves unit 203-05 LC-Display 203-12 Tubing for the pinch valve 203-60 Filter holder, clear plastic holds 47 mm diameter filters 203-61 UV Lamp, electrodeless spare lamp bulb 301-02 Sample tubing FEP 4 x 6 mm, low memory effect, recommended for lengths > 10 m 301-10 Buffer battery for RAM, Li-battery 301-11 4-20 mA-IC with cooler 301-12 Battery charger ASC 410 203-10 Fitting, for connection of a 4 mm (ID) x 6 mm OD) sample tubing to the sample inlet filter 202-07 PC connection cable 202-08 Printer connection cable 350-01a Rechargeable battery pack, 12 V, for ca. 4-5 h operation, complete with ICcontrolled charger, charge / discharge function 300-04 Data logger function 300-05 Sampling probe (wand) for field testing, stainless steel, complete with 3 m tubing 401-00 MC-3000 Mercury Calibrator. Calibration gas generator for elemental mercury vapor VM-3000_E-V-2.8.doc 13.06.2012 Page 36 of 42 13.06.2012 G F E D C 1 2 Valve Pump 2 1 2 PT100 3 3 9 UV-Det. ST B 2 ST12 ST13 ST SV1 Printer Status ST 3 Interface STPT 4 6 9pol. ST ST12 5 6 Mercury instruments GmbH, Fax: +49-8131-505722 Tag bearb. 28.09.11 gepr. Name Norm Keypad Display Microcontroller MT25 P-Sensor 2 Name Keck UV Lamp I: 4-20mA U: 0-4096mV battery-version Backplane ST4 ST5 40 5 ST15 4 Ausg. Änder. Tag STC3 ST2 ST9 ST1 USB RS232 Optical cell heating 4 ST7 VM-3000_E-V-2.8.doc ST6 A 1 pri VM - 3000 Blockschaltbilder Diagramm Trafo for heating of optical cell ST 2 7 8 8 3pol. 40 Trafo Power Supply File: electrical diagram v3.cdr sec 9 7 230Vac ST 2pol. ST 2 230Vac / 110Vac 1 3 12V Batterypack 9 Battery-version 2 Batt.- plug: 1 Charger 2 GND 3 ext. Battery 9 G F E D C B A VM-3000 7.5 Block diagram of electrical parts Page 37 of 42 VM-3000 7.6 Diagram of components Fig: interior view of the photometer VM-3000_E-V-2.8.doc 13.06.2012 Page 38 of 42 VM-3000 fig: part numbers VM-3000_E-V-2.8.doc 13.06.2012 Page 39 of 42 VM-3000 Index F A accessories alarm thresholds application Auto Zero parameters Auto-Print Interval 38 18 5 17 20 9 9 39 35 23 22 34 18 13 11 13 24 D data logger activating Data Logger delete data send data to PC (Hg-Transfer) Data Logger Function date and time setting Declaration of Conformity Diagram of components duration of auto zero VM-3000_E-V-2.8.doc General description Installation interval of auto zero logged data send to PC logging start of logging rate seting of 5 8 17 Main Menu Maintenance mean values display of measuring start up Measuring principle measuring range O 30 31 27 of averaging times adjustment output 4-20 mA signal RS232 23 44 40 28 28 27 M 27 15 34 15 14 7 18 19 11 11 P 17 E EC-Declaration electrical parts Error Messages G L C Calibration check calibration factor enter new calibration factors list carbon cartridge replacement concentration units connection sample gas Connection electrical output printer Conversion of Readings to Standard Temperature and Pressure (STP) Conditions 11 I B Battery charger Battery operation Block diagram Fuses 44 39 26 parameters setting Particle filter replacement Portable Operation power supply Preparation for operation 13.06.2012 16 34 24, 25 8 8 Page 40 of 42 VM-3000 Print on Alarm printer connection printer settings 20 13 20 R reference screen response time setting read Service menu Spare parts specifications Standard Temperature and Pressure Start-up Status output 25 22 38 37 24 14 13 35 T 21 Technical specifications 37 S Z Safety information Sample gas sample pressure and temperature VM-3000_E-V-2.8.doc 2 13 zero adjustment manually 13.06.2012 16 Page 41 of 42 VM-3000 APPENDIX EC-Declaration of Conformity The Company: Declares that the product: Intended purpose: Mercury Instruments GmbH Liebigstrasse 5 D-85757 Karlsfeld Germany VM-3000 Mercury Analyzer Automatic measurement of mercury at trace concentration levels in air and other gases conforms with the basic requirements of the relevant EC directives. A conformity assessment method as provided in the directives has been executed. The following harmonized standards were applied: CENELENC EN 50 081-1 : 1992 CENELENC EN 50 081-2 : 1993 CENELENC EN 50 082-2 : 1995 CENELENC EN 55 011 : 1991 CENELENC EN 55 011 : 1991 CENELENC EN 61000-3-2 : 1998 CENELENC EN 61000-3-3 : 1996 CENELENC EN 61 000-4-2 : 1995 CENELENC EN 61 000-4-4 : 1995 CENELENC EN 61 000-4-3 : 1996 CENELENC EN 61 000-4-6 : 1996 CENELENC ENV 50 204 : 1995 The tests regarding above standards have been conducted by Intertek Deutschland GmbH, Kaufbeuren/Germany (Test Reports Nr. 97KFE163/98-01-14 and 00KFE1188/00-11-21). The test documents are available for inspection. This declaration is submitted by: Karlsfeld, 22nd June, 2007 VM-3000_E-V-2.8.doc Dr. Alfred Sauerer (CEO) 13.06.2012 Page 42 of 42