SPEED's Electric Motors

An outline of some of the theory

in the SPEED software for electric machine design

with problems and solutions

© TJE Miller, University of Glasgow, 2002

SPEED's Electric Motors

Contents

Chapter 1 Sizing, gearing, cooling, materials and design

Chapter 2 Brushless permanent-magnet machines

Chapter 3 Induction machines

Chapter 4 Switched reluctance machines

Chapter 5 Commutator machines

SPEED's Electromagnetic Primer

Problems and solutions

1.

Sizing, gearing, cooling, materials and design

1.1

Motion control systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.2

Why adjustable speed? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3

Large versus small drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.4

Structure of drive systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.5

Drive system requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6

New technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.7

Which Motor ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8

1.8

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.14

1.9

Gearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.18

1.10

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.20

1.11

Intermittent operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.27

1.12

Permanent magnet materials and circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.30

1.13

Properties of electrical steels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.39

1.14

Machine and drive design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.42

1.15

Computer-aided design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.43

1.

SIZING, GEARING, COOLING, MATERIALS and DESIGN

1.1

MOTION CONTROL SYSTEMS

Technology is so saturated with developments in microelectronics that it is easy to forget the vital

interface between electrical and mechanical engineering. This interface is found wherever mechanical

motion is controlled by electronics, and pervades a vast range of products. A little consideration

reveals a large and important area of technology, in which motor drives are fundamental. In Japan the

term 'mechatronics' is applied to this technology, usually with the connotation of small drives. In the

west the term 'motion control system' is often used for small controlled drives such as position or

velocity servos. In the larger industrial range the term 'drive' usually suffices.

Many engineers have the impression that the technology of motors and drives is mature, even static.

But there is more development activity in drives today than at any time in the past, and it is not

confined to the control electronics. Two important reasons for the development activity and the

increasing technical variety are:

(1)

Increasing use of computers and electronics for motion control. Automation demands drives

with a wide variety of physical and control characteristics.

(2)

New technology in power semiconductors, sensors, integrated circuits, and microcontrollers,

facilitating the development of nonclassical motors such as brushless DC motors, steppers and

switched reluctance motors in a wide variety of designs.

1.2

WHY ADJUSTABLE SPEED?

Three common reasons for preferring an adjustable-speed drive over a fixed-speed motor are :

(a)

energy saving;

(b)

velocity or position control; and

(c)

amelioration of transients.

(a) Energy saving. In developed economies about one-third of all primary energy is converted into

electricity, and about two-thirds of that is re-converted in electric motors and drives, mostly

integral-kW induction motors running essentially at fixed speed. If a constant-speed motor is used to

drive a flow process (such as a fan or pump), the only ways to control the flow rate are by throttling or

by recirculation, Fig. 1. Since the motor runs at full speed regardless of the flow requirement, there

can be excessive energy losses in the recirculation valve. Similar considerations apply to the control

of airflow by adjustable baffles in air-moving plant.

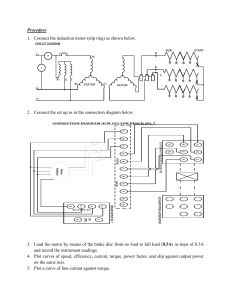

Fig. 1.1

Flow process controlled by recirculation can produce energy losses in the flow control valve.

1. Sizing, gearing, cooling, materials and design

Page 1.3

In such applications it is often possible to reduce average energy costs by 50 per cent or more by using

adjustable-speed drives, which eliminate the throttling or recirculation loss; see Fig. 1.2. The additional

losses in the adjustable-speed drive are generally much less than the throttling and recirculation losses,

since the drive efficiency is usually of the order of 90 per cent or more. The adjustable-speed drive may

be more expensive, but its capital cost can be offset against energy savings and the reduction of

maintenance requirements on mechanical components.

Recirculation in a flow-control process is analogous to the control of a DC motor by means of an

adjustable series resistance. The technique is inherently wasteful, and although it is cheap to

implement, it is increasingly hard to justify in the face of concerns about energy efficiency and

pollution, even at low power levels.

Fig. 1.2

Flow control efficiency is improved by adjustable-speed drive

(b) Velocity or position control. Obvious examples of speed control are the electric train, portable

hand tools, and domestic washing-machine drives. In buildings, elevators or lifts are interesting

examples in which not only position and velocity are controlled, but also acceleration and its derivative

(jerk). Countless processes in manufacturing industry require position and velocity control of varying

degrees of precision. Particularly with the trend towards automation, the technical and commercial

growth in drives below about 20 kW is very vigorous. Many system-level products incorporate an

adjustable-speed drive as a component. A robot, for example, may contain between 3 and 6 independent

drives, one for each axis of movement. Other familiar examples are found in office machinery:

positioning mechanisms for paper, printheads, magnetic tape, and read/write heads in disk drives.

(c) Amelioration of transients. The electrical and mechanical stresses caused by direct-on-line motor

starts can be eliminated by adjustable-speed drives with controlled acceleration.

A full

adjustable-speed drive is used in this situation only with very large motors or where the start-stop

cycles are so frequent that the motor is effectively operating as a variable speed drive. Most

soft-starting applications are less onerous than this, and usually it is sufficient (with AC motors) to

employ series SCR's (or triacs with smaller motors) which ‘throttle' the starting current to a controlled

value, and are bypassed by a mechanical switch when the motor reaches full speed.1 The soft-starter

is less expensive than a full adjustable-speed drive, which helps to make it economical for short-time

duty during starting.

1

Series control of induction motors is inefficient; produces excessive line harmonics; and is not very stable. These

factors can usually be tolerated for a few seconds during starting, but they render the soft-starter unsuitable for continuous

speed control.

Page 1.4

1.3

SPEED’s Electric Motors

LARGE VERSUS SMALL DRIVES

There are marked design differences between large and small drives. Large motors are almost always

chosen from one of the classical types: DC commutator (with wound field); AC induction; and

synchronous. The main reasons are the need for high efficiency and efficient utilization of materials;

and the need for smooth, ripple-free torque. In small drives there is greater variety because of the need

for a wider range of control characteristics. Efficiency and materials utilization are still important, but

so are control characteristics such as torque/inertia ratio, dynamic braking, speed range, acoustic

noise and torque ripple.

There are also several breakpoints in the technology of power semiconductors. At the highest power

levels (up to 20MW) SCRs (thyristors) and GTOs (gate turn-off thyristors) are the only devices with

sufficient voltage and current capability, but IGBTs (insulated-gate bipolar transistors) also now have

voltage ratings measured in kV and current ratings of hundreds of amps. Naturally-commutated or

load-commutated converters are preferred, because of the saving in commutation components and for

reliability and efficiency reasons. In the medium power range (up to a few hundred kW) forced

commutation and PWM are normal, and IGBT’s are very widely used. At low powers (below a few kW)

the power MOSFET is attractive because it is easy to switch at high chopping frequencies.

1.4

STRUCTURE OF DRIVE SYSTEMS

The general structure of a drive system is shown in Fig. 3. It comprises the load, the motor, the

electronic drive, and the control.

Fig. 1.3

Drive system structure

The range of modern motion-control applications is virtually unlimited. Any random list illustrates

the variety—aerospace actuators; washing machines; computer disk and tape drives; printer plattens

and printheads; inertial guidance systems; adjustable-speed pumps, blowers, fans and compressors;

locomotive and subway traction; automatic machine tools and machining centers; servo drives and

spindle drives; robots; automotive auxiliaries; refrigeration and air-conditioning drives; and many

others.

Loads have widely differing requirements. The commonest requirement is for speed control, with

varying degrees of precision and accuracy. Position control is of increasing importance, particularly

in automated plants and processes, and in office machinery and computer peripherals. In some cases

it is the steady-state operation that is most important, for example in air-conditioning and pump drives.

1. Sizing, gearing, cooling, materials and design

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Page 1.5

Compliance with national, EC, USA and industry standards

Maximum continuous power or torque requirements

Forward/reverse operation

Motoring/braking operation

Dynamic or regenerative braking

Overload rating and duration

Supply voltage (AC or DC) and frequency

Type of control: speed, position, etc.

Precision required in controlled speed or position

Programmability: speed and/or position profiles, start/stop ramps etc.

Interface with plant control and communications

Dynamic requirements: torque/inertia ratio, acceleration/deceleration

Gearbox or direct drive; gear ratio

Reliability and redundancy of components

Protection arrangements, both mechanical and electrical

Maximum level of acoustic noise; noise spectrum

Compliance with EMC regulations

Limitation of harmonics in the supply system

Maintenance; spare parts; provision for expansion or reconfiguration

Environment: indoor/outdoor installation; enclosure; temperature; humidity; pollution; wind and seismic factors;

type of coolant.

TABLE 1.1

DRIVE SYSTEM REQUIREMENTS CHECKLIST

In other cases, such as in robots, tape drives, and actuators, dynamic performance is important because

of the need to minimize the time taken to perform operations or effect control changes. In these cases

the torque/inertia ratio of the motor is an important parameter. In automotive applications the prime

requirements are low cost and low noise. Efficiency is important in motors that run continuously, e.g.

heater blowers, but not in intermittent-duty motors such as window-winders. Torque ripple is

increasingly important in servo motors and applications such as automotive power steering, where less

than 1% ripple is typically required.

1.5

DRIVE SYSTEM REQUIREMENTS

Table 1.1 provides a checklist of application requirements. The speed/torque capability diagram is

especially important, Fig. 4. Typically at low speed the drive operates under current limit, and since

torque is generally proportional to current (or nearly so), the torque is controlled in this mode of

operation, such that any value can be obtained up to the value corresponding to maximum current. At

high speed, the back-EMF increases to a level at which the drive cannot maintain maximum current;

or even if it can maintain maximum current, it may not have sufficient voltage to maintain the correct

phase angle or waveform of the current. Base speed is the maximum speed at which rated torque can

be developed. Above this speed, drives are often evaluated according to the speed range over which

they can maintain constant power, the torque decreasing as the speed increases. Some drives (such as

triac-controlled AC universal motors) have almost no constant-torque region and their characteristics

are said to be “highly inverse”. On the other hand, brushless PM motors tend to have a predominantly

constant-torque characteristic with limited speed range above base speed.

1.6

NEW TECHNOLOGY

Several new technologies are contributing to the development of motion control systems.

Digital electronics. It would be hard to overstate the importance of microelectronics in motion

control. At the 'heavy' end of the spectrum are the multiple drives found in steel rolling mills, paper

mills, and other heavy process plants, where it is normal to coordinate the motion of all the shafts by

means of a computer or a network of computers, some of which may be quite large. At the light end

of the power range are the drives found in office machinery, small computers, and portable goods such

as cameras and compact-disk players, where custom integrated circuits and gate arrays are common.

Between these extremes there are many microprocessor-controlled systems of all levels of complexity.

Page 1.6

SPEED’s Electric Motors

Fig. 1.4

Speed/torque characteristic

The first functions implemented with microprocessors were low-speed functions such as monitoring

and diagnostics, but digital control has penetrated from outer position loops through the intermediate

velocity loop and is now routinely used even in high-bandwidth current regulators. The development

of field-oriented control for AC induction and synchronous motor drives would not have been practical

without the microprocessor. Field-oriented control is based on reference-frame transformation which

may require rapid computation of trigonometric functions of rotor position. It permits the outer

control loops of AC and DC drives to be the same, both in hardware and software, and improves the

dynamic performance of the AC drive. Its development since the mid 1970's was a key factor enabling

the AC induction motor to compete in precision speed control with the DC motor, which had been

preferred for speed control for at least 50 years before then.

Such is the sophistication and speed of modern microelectronics that the PWM schemes employed to

regulate the voltage and current can be optimized with respect to many attributes, such as efficiency,

acoustic noise, dynamic response, and harmonic content. There is increasing use of field-programmable

gate arrays for the high-speed functions, often combined with microcontrollers. Digital signal

processors (DSP) are also used in advanced drives, and many of these operate with “sensorless”

control, i.e., without shaft position sensing.

In motion control systems the ultimate objective is true instantaneous control of the torque, preferably

with a minimum of reliance on shaft position sensors and detailed knowledge of motor parameters.

In pursuit of this objective the processing power of modern microcomputers and DSPs has been

exploited together with new forms of control based on neural networks or fuzzy logic. At the other end

of the drive, communication with computers and other controllers is another area of continuous

development.

Power semiconductor devices. The IGBT is the most popular device in integral-kW drives, and the

power MOSFET in low-power drives, especially at low voltage. GTO thyristors are still used in large

drives especially above 1 MW.

New magnetic materials. The permanent-magnet industry has continued to improve the

characteristics of the main families of magnet used in electric machines: neodymium-iron boron, which

was pioneered by Sumitomo and General Motors; rare-earth/cobalt; and ferrite. At room temperature

NdFeB has the highest energy product of all the common magnet materials. In its early days the

performance was rather sensitive to temperature, but it is now widely used even in automotive and

industrial servo applications where high operating temperatures up to and exceeding 100EC are

common, even in the presence of strong demagnetizing fields.

CAD and numerical analysis in design. Motor design has been computerized since the early days

of computers, initially with the coding of well established design procedures. The last 20 years has seen

a steady development of commercially available finite-element software capable of analysing fields in

machines in two and three dimensions. The most advanced programs can determine eddy-currents and

transients, but the coupling of finite-element solvers to circuit-analysis and simulation algorithms is

1. Sizing, gearing, cooling, materials and design

Page 1.7

still in the research laboratory. In spite of the technical advances it remains the case that finiteelement analysis requires the application of highly skilled personnel, and although machine designers

use it fairly widely, they either follow well-established procedures or rely on specialists to practise

computations in support of more conventional design calculations.

The finite-element method is still far from being a complete design tool and is too slow for many of the

routine processes. It is fundamentally an analysis tool rather than a design tool: and it suffers from

certain limitations when applied to motor design. It requires detailed input data and the results need

skilled interpretation. It is accurate only in idealized situations where parasitic effects have been

removed. It is too slow to be cost-effective as part of a synthesizing CAD package, and is likely to remain

so for some time. It is most useful in helping to understand a theoretical problem that is too difficult

for conventional analysis, and in this role it has undoubtedly helped to refine many existing motor

designs and improve some new ones.

At the same time the development of special design software for electric machines has produced a

number of products which are much faster and are specificall intended for motor and generator

design. Such programs are widely used in the industry for initial design, for “what-if” analysis, and

(with suitable calibration against test data) for recording the characteristics of entire lines of motor

products. One example is the SPEED software from the University of Glasgow, which is used in places

to illustrate this book.2

The primary problems in motor and generator design are not simply electromagnetic, but require an

integrated approach to materials utilization and design-for-manufacture. The philosophy needs to be

a synthesizing one rather than an analytical one. This multidisciplinary problem includes heat

transfer and mechanical design as well as electromagnetics. The situation is more complicated in

adjustable-speed drives where the supply waveforms are 'switchmode' chopped waveforms rather than

pure sinewaves or DC. In these cases time-stepping simulation may be necessary to determine the

expected performance of a given design over a wide range of operating conditions.

Because of the fact that finite-element analysis usually requires foreknowledge of the current

waveform, it could be argued that preoccupation with this class of software tool could hinder the

development of drive systems which escape from the classical DC and sinusoidal waveforms in order

to explore the possibilities of a wider class of drive current waveforms, coupled with new concepts in

motor geometry. The key lies in using the finite-element tool in the correct way to determine

parameters that can be used in time-stepping simulations that will be executed by other software.

It is perhaps surprising that design software for electric machines is rarely capable of synthesis in the

true sense. It is much more common to find “optimization” techniques which rely on the automatic

generation of large numbers of “feasible” designs, and then rank them according to a more or less

complex criterion which includes constraints on particular dimensions and other parameters. The

imaginative element in the design process remains in the human mind, and the computer appears to

be far from taking it over.

For simulation of complete systems, such as an automotive power steering system or an aircraft flight

control surface actuation system, there are several software packages, such as Simulink™, Saber™,

Simplorer™, Easy5™ and many others. Suitably modified and extended, some of these packages permit

the simulation of detailed motor models and their drives and controls. They may be used for the

development of control algorithms that are subsequently programmed in a microprocessor or gate

array.

Other contributing technologies. Plastics and composite materials find many applications in motors.

Fans, slot liners and wedges, end-bells and covers, and winding supports are the commonest, but

moulded slot insulation and encapsulation of rotors are also widely used. In brushless motors designed

for high peripheral speeds, the magnets are often restrained against centrifugal force by banding or

tubes made of Kevlar™, glass-reinforced plastics, or carbon fiber.

Motor drives generally require transducers for control and protection, and there has been progress

in current-sensor and shaft position sensor technology. In particular the linearity and

2

Others include design programs from Trimerics in Stuttgart, Germany and Yeadon Engineering Services, Wisconsin.

Page 1.8

SPEED’s Electric Motors

temperature-independence of Hall-effect current sensors has improved greatly, and it is common to

mount these devices in the same package, or on the same printed-circuit card, as the driver stage of the

power electronics in small drives. For larger drives flux-nulling current sensors can be used with

bandwidths of up to several kHz and isolation at least as good as that of a C.T.

In brushless drives the commutation signals are often derived from Hall sensors, activated either by

the rotor magnet or by a separate magnet ring. Alternatively, optical interrupters may be used with

a shaft-mounted slotted disk. At high speeds the commutation sensor can be used to generate a speed

signal via a frequency-to-voltage conversion. For motion control systems and servo-quality drives

separate velocity and position transducers usually have to be used. For such systems the resolver is

attractive because of its ruggedness, resolution, and its ability to provide accurate absolute position

and velocity signals from one sensor.

1.7

WHICH MOTOR ?

The proliferation of new ideas, materials and components obviously generates many opportunities but

also complicates the question, what is the best drive for a particular job? We can perhaps address this

by attempting to trace the evolution of the different motor types in such a way as to bring out their

most important advantages and disadvantages. It is the motor that determines the basic characteristics

of the drive system, and it alsodetermines the requirements on the power semiconductors, the

converter circuit, and the control.

Evolution of motors. The evolution of brushless motors is shown in Fig. 5. Row 1 contains the three

'classical' motors : DC commutator (with wound field); AC synchronous; and AC induction. The term

'classical' emphasizes the fact that these motors satisfy three important criteria:

(1)

they all produce essentially constant instantaneous torque (i.e., very little torque ripple);

(2)

they operate from pure DC, or AC sinewave supplies, from which

(3)

they can start and run without electronic controllers.

The classical motors of row 1 are readily coupled to electronic controllers to provide adjustable speed;

indeed it is with them that most of the technical and commercial development of power electronic

control has taken place. Together with the PM DC commutator motor in row 2 and the series-wound

AC commutator motor or 'universal' motor, the row 1 motors account for the lion's share of all motor

markets, both fixed-speed and adjustable-speed, even though they represent only a minority of the

many different principles of electromechanical energy conversion on which motor designs may be

based. By contrast, the nonclassical motors are essentially confined to specialist markets and until

recently, few of them except the brushless DC motor have been manufactured in large numbers. Table

1.2 is a classification of some common types of motor according to these criteria.

The motors in row 2 are derived from those in row 1 by replacing field windings with permanent

magnets. The synchronous motor immediately becomes brushless, but the DC motor must go through

an additional transformation, from row 2 to row 3 with the inversion of the stator and rotor, before the

brushless version is achieved. The induction motor in row 1 is, of course, already brushless in its 'cage'

version, but not in its wound-rotor or slip-ring version. The brushless motors are all those with three

terminals, together with the switched reluctance motor, which cannot be derived from any of the other

motors. Its awkward placement in Fig. 5 reflects the fact that it has various properties in common with

all the brushless motors. Obviously the emphasis in this book is on the brushless motors, with only

a relatively superficial treatment of the DC motor and the induction motor. Stepper motors are also

excluded.

The DC commutator motor. The traditional DC commutator motor with electronically adjustable

voltage has always been prominent in motion control. It is easy to control, stable, and requires

relatively few semiconductor devices in the drive. For many years the wound-field DC motor held its

own against the challenge of AC drives—arguably for at least fifty years from the mid-1930's until the

mid-1980's—but AC field oriented control, manufacturing cost structures, the development of the IGBT,

and huge R&D investments finally forced it into a declining role.

1. Sizing, gearing, cooling, materials and design

DC wound field (brush)

AC/DC universal (brush)

AC synchronous

wound-field

DC PM (brush)

[Brushless PM Exterior Rotor]

Brushless PM AC

Page 1.9

AC induction

Switched

reluctance

Brushless PM

Squarewave or sinewave

Fig. 1.5

Synchronous

reluctance

Evolution of brushless motors from classical AC and DC motors

Page 1.10

SPEED’s Electric Motors

The main objections to the commutator motor are brush and commutator wear, and the fact that the

losses arise mostly on the rotor, making cooling more difficult than in AC motors where the losses arise

mostly on the stator. It is not that brushgear is unreliable—on the contrary, it is reliable, well-proven,

and 'forgiving', as is proven by the widespread use of DC motors in railway systems throughout the

world, and in automotive auxiliaries where the life of the brushes is not a serious limitation.

The PM DC commutator motor. In small DC commutator motors, replacing the field winding and

pole structure with permanent magnets usually permits a considerable reduction in stator diameter,

because of the efficient use of radial space by the magnet and the elimination of field losses. Armature

reaction is reduced and commutation is improved, owing to the low permeability of the magnet. The

loss of field control is not as important as it would be in a larger drive, because it can be overcome by

the controller. In small drives the need for field weakening is less common anyway. The PM DC motor

is usually fed from an adjustable voltage supply, either linear or pulse-width modulated.

In automotive applications the PM DC motor is well entrenched because of its low cost and because of

the low-voltage DC supply. Here it is usually operated at fixed speed or with series-resistance control.

For safety-critical and demanding applications such as electric power steering and braking, brushless

motor drives are more suitable. The development of higher-voltage automotive power supply systems

(above 40V) will help to make brushless motors more acceptable by reducing the current levels and

therefore the size and cost of MOSFETs required in the drive.

AC induction motor drives. AC induction or synchronous motors are often preferred because of the

limitations of commutation and rotor speed in DC motors. Slip is essential for torque production in

the induction motor, and it is impossible, even in theory, to achieve zero rotor losses. This is one of the

limitations of the induction motor, since rotor losses are more difficult to remove than stator losses,

and it is one main reason to use permanent-magnet and/or reluctance-type synchronous motors.

Fig. 1.6

Integrated motor/inverter and hand-held controller

(courtesy of Grundfos A/S, Denmark)

The efficiency and power factor of induction motors falls off in small sizes because of the natural laws

of scaling, particularly at part load. As a motor of given geometry is scaled down, if all dimensions are

scaled at the same rate the MMF required to produce a given flux-density decreases in proportion to the

linear dimension. But the cross-section available for conductors decreases with the square of the linear

dimension, as does the area available for heat transfer. This continues down to the size at which the

mechanical airgap reaches a lower limit determined by manufacturing tolerances. Further

scaling-down results in a more-or-less constant MMF requirement while the areas continue to decrease

with the square of the linear dimension. There is thus an “excitation penalty” or “magnetization

penalty” which becomes rapidly more severe as the scale is reduced. It is for this reason that

permanent magnets are so necessary in small motors. By providing flux without copper losses, they

directly alleviate the excitation penalty.

1. Sizing, gearing, cooling, materials and design

Page 1.11

The induction motor is “brushless” and can operate with simple controls without a shaft position

transducer. The simplest type of inverter is the six-step inverter. With no shaft position feedback, the

motor remains stable only as long as the load torque does not exceed the breakdown torque, and this

must be maintained at an adequate level by adjusting the voltage in proportion to the frequency as the

speed changes. At low speeds, oscillatory instabilities may appear. To overcome these limitations

there have been several improvements including slip control and, ultimately, full field-oriented or

“vector” control in which the phase of the stator currents is regulated to control the angle between

stator MMF and rotor flux. Field orientation usually requires a shaft position encoder and may include

an in-built control model whose parameters are specific to the motor, and which must be compensated

for changes caused by changing load and temperature. Such controls are complex and generally cannot

be justified in small drives, but excellent results have been achieved in larger sizes (above a few kW).

In the fractional and low integral-horsepower range the complexity of the AC drive is a drawback,

especially when dynamic performance, high efficiency, and a wide speed range are among the design

requirements. These requirements cannot be met adequately with series- or triac-controlled induction

motors, which are therefore restricted to applications where low cost is the only criterion. Together

these factors favour the use of brushless PM motor drives in the low power range.

The brushless DC PM motor. The smaller the motor, the more sense it makes to use permanent

magnets for excitation. There is no single 'breakpoint' below which PM brushless motors outperform

induction motors, but it is usually in the1!10 kW range. Above this size the induction motor improves

rapidly, while the cost of magnets works against the PM motor. Below it, the PM motor has better

efficiency, torque per ampere, and effective power factor. Moreover, the power winding is on the

stator where its heat can be removed more easily, while the rotor losses are extremely small. These

factors combine to keep the torque/inertia ratio high in small motors. The brushless DC motor is also

easier to control, especially in its ‘squarewave' configuration (Chapter 4). Although the inverter is

similar to that required for induction motors, usually with six transistors for a 3-phase system, the

control algorithms are simpler and readily implemented in 'smartpower' or special-purpose ICs.

Fig. 1.7

The Minas brushless PM motor produced by Matsushita with its stator fabricated from segments. Courtesy of

Matsushita Ltd., Japan

The brushless PM AC synchronous motor. In Row 2 of Fig. 5 the brushless synchronous machine

has permanent magnets instead of a field winding. Field control is again sacrificed for the elimination

of brushes, sliprings, and field copper losses. This motor is a classical salient-pole synchronous AC

motor with approximately sine-distributed windings, and it can therefore run from a sinewave supply

without electronic commutation. If a cage winding is included, it can self-start 'across-the-line'.

The magnets can be mounted on the rotor surface (Chapter 5) or they can be internal to the rotor. The

interior construction simplifies the assembly and relieves the problem of retaining the magnets against

centrifugal force. It also permits the use of rectangular instead of arc-shaped magnets, and usually

there is an appreciable reluctance torque which leads to a wide speed range at constant power.

Page 1.12

SPEED’s Electric Motors

The PM synchronous motor operates as a synchronous reluctance motor if the magnets are left out or

demagnetized. This provides a measure of fault-tolerance in the event of partial or total

demagnetization through abnormal operating conditions. It may indeed be built as a magnet-free

reluctance motor, with or without a cage winding for starting 'across-the-line'. Although the power

factor and efficiency are not as good as in the PM motor, synchronous reluctance motors can be

designed with wide speed range and substantial short-term overload capacity..

In larger sizes the brushless synchronous machine is sometimes built with a brushless exciter on the

same shaft, feeding a rotating rectifier which passes DC to a field winding on the main rotor. This

motor has full field control. It is capable of a high specific torque and high speeds. As a generator, this

configuration is popular in high-speed aircraft generators (at 24,000 and 12,000 rpm, 400 Hz) and in a

wide variety of small industrial applications.

All the motors on the diagonal of Fig. 5 operate with inverters that share the same power circuit

topology (three 'totem-pole' phaselegs with the motor windings connected in star or delta to the

midpoints). This gives rise to the concept of a family of motor drives providing a choice of motors and

motor characteristics, but with a high degree of commonality in the control and power electronics and

all the associated transducers. The trend towards integrated phaselegs, or indeed complete three-phase

bridges, with in-built control and protection circuitry makes this concept more attractive. This family

of drives covers a wide range of requirements, the main types being the conventional brushless DC

(efficient in small sizes with good dynamics); the interior-magnet synchronous motor (wide speed

range); the synchronous reluctance motor (free from magnets and capable of high speeds or

high-temperature operation); and the induction motor. It should be noted that all these drives are

essentially “smooth-torque” systems with low torque ripple.

Stepper motors represent a major class of motors not included in Fig. 5. Steppers are always

brushless and usually operate without shaft position sensing. Although they have many properties in

common with synchronous and brushless DC motors, they cannot naturally be evolved from the motors

in Fig. 5. By definition they are pulsed-torque machines incapable of achieving ripple-free torque by

normal means. Variable-reluctance (VR) and hybrid steppers can achieve an internal torque

multiplication through the use of multiple teeth per stator pole and through the ‘vernier' effect of

having different numbers of rotor and stator poles. Both these effects work by increasing the number

of torque impulses per revolution, and the price paid is an increase in commutation frequency and iron

losses. Steppers therefore have high torque-to-weight and high torque-to-inertia ratios, but are limited

in top speed and power-to-weight ratio. The fine tooth structure requires a small airgap, which adds

to the manufacturing cost. Beyond a certain number of teeth per pole the torque gain is “washed out”

by scale effects that diminish the inductance variation on which the torque depends. Because of the

high magnetic frequency and the effect of MMF drop in the iron, such motors require expensive

lamination steels to get the best out of them.

Switched reluctance motors are derived from the single-stack VR stepper, in which the current

pulses are phased relative to the rotor position to optimize operation in the 'slewing' (continuous

rotation) mode. This usually requires a shaft position transducer similar to that which is required for

the brushless DC motor, and indeed the resulting drive is like a brushless DC drive without magnets.

With this form of control the switched reluctance motor is not a stepper motor because it can produce

continuous torque at any rotor position and any speed. There is still an inherent torque ripple,

however, which can be compensated only by current waveform profiling and accurate phase control

of the current waveform relative to the shaft position. The switched reluctance motor suffers the same

'excitation penalty' as the induction motor and cannot equal the efficiency or power density of the PM

motor in small sizes.

When the classical motors are interfaced to switchmode converters (such as rectifiers, choppers, and

inverters) they continue to respond to the average voltage (in the case of DC motors) or the

fundamental voltage (in the case of AC motors). The harmonics associated with the switching operation

of the converter cause parasitic losses, torque ripple, and other undesirable effects in the motors, so

that de-rating may be necessary. The nonclassical motors are completely dependent on the switchmode

operation of power electronic converters. In steppers it is acceptable for the torque to be pulsed, but

most brushless drives are designed for smooth torque even though the power is switched.

1. Sizing, gearing, cooling, materials and design

Motor

Page 1.13

Drive or supply

Typical application

Constant DC or variable DC from DC

generator, phase-controlled rectifier,

or chopper

Integral-kW industrial drives; railway

traction

DC commutator motors

(a) Wound-field

(b) Permanent-magnet

DC homopolar motors with slip-rings

or segmented slip-rings

Automotive and aircraft auxiliaries;

small servo and variable-speed drives

Ship-propulsion specials

Brushless PM motors

(a) Squarewave

Electronically commutated rectangular Disk drives, automotive auxiliaries,

current waveform from inverter

small portable goods, servo motors,

spindles

(b) Sinewave

Sinewave current waveform from

inverter

Servo motors, spindles

Universal AC/DC series commutator

motors

Fixed AC; triac-controlled AC; also

variable or constant DC

Domestic appliances (washing

machines, food processors); power

tools

(a) Cage-type, 3-phase

Constant voltage AC or inverter-fed

Pumps, fans, compressors, industrial

machinery of all types

(b) Cage-type, 1-phase

Constant-voltage AC

Low-power pumps, fans, machinery

(c) Wound-rotor, 3-phase

Constant voltage AC or inverter-fed

High-power drives with difficult starting

conditions; sometimes used with sliprecovery energy systems

Constant voltage AC or inverter-fed

Very large drives

Induction motors

Synchronous motors

(a) Wound rotor with DC winding and

slip-rings

(b) Wound-rotor with brushless exciter Constant voltage AC or inverter-fed

(motoring)

(c) Permanent magnet

Most often used as a generator

Same as Sinewave brushless PM motor

Reluctance motors

(a) Synchronous reluctance (line-start, Inverter-fed AC

with rotor cage)

Multi-machine variable-speed drives

with several motors fed from one

inverter

(b) Synchronous reluctance (cageless) Inverter-fed AC

Servo/spindle motors

(c) Switched reluctance

Electronically regulated and

commutated DC

Washing machine drives, mining

machinery, door openers, automotive

auxiliaries, aircraft actuators, highspeed compressors

(d) Single-phase reluctance

Switched DC or AC

Small actuators, clocks

Switched DC, usually current-limited

Motion-contol applications dependent

on open-loop stepping for position

control (indexing); office equipment,

industrial machinery

(a) Cylindrical rotor

Inverter-fed or constant AC voltage

Simple synchronous motor with good

starting characteristics

(b) Can-type rotor

Constant-voltage AC

Motorized valves and actuators

Stepper motors

(a) VR, single-stack

(b) VR, multiple-stack

(c) Permanent-magnet

(d) Hybrid

Hysteresis motors

TABLE 1.2

A SELECTION OF MOTORS WITH TYPICAL APPLICATIONS

Page 1.14

1.8

SPEED’s Electric Motors

SIZING

When a new electric machine is to be designed from scratch, the requirements usually includes a set

of performance specifications and a set of constraints or limitations such as the maximum physical size,

the maximum temperature rise, and the supply voltage. This section explains how the basic size of a

machine can be determined, starting from the performance specifications and working within the

limits of material properties and temperature rise.

In many cases, new machine designs are evolved from existing ones, by modifying existing laminations

and components to minimize the cost of changes in tooling and components. Even so, the same

principles determine how much power and performance can be achieved from a machine of given size

and temperature rise.

The output equation. The classical output equation applies to (and unifies) all electrical machines

from the tiniest micromotors (a few µW) up to the largest AC motors used in process plants or ship

propulsion (up to 20MW). Intuitively it comes from the fundamental law of electromagnetic force which

is often loosely stated as “force = flux × current”, according to the left-hand rule. For engineering

purposes we need to derive a more precise statement of this law. Except in linear motors, we are more

interested in torque than force. It is convenient to work with flux-density and current-density, because

these parameters have values which do not change greatly from one machine to another. Further, the

flux and current densities are closely related to the power loss density which determines the cooling

requirements and temperature distribution throughout the machine.

Specifically, the output equation relates the torque per rotor volume (TRV) to the electric loading A and

the magnetic loading B. We will define A and B first before deriving a precise form of the output

equation. The definitions are written in a form suitable for AC synchronous and induction machines.

For other types of machine the definitions are similar, but with slight variations of multiplying

constants and interpretation.

The electric loading A is defined as the linear current density around the airgap circumference, that

is, the number of ampere-conductors per metre around the stator surface that faces the airgap.

A '

Total ampere&conductors

'

Airgap circumference

2 m Nph I

BD

A/m

(1.1)

where I is the RMS phase current, m is the number of phases, Nph is the number of turns in series per

phase, and D is the diameter of the airgap. The airgap is assumed to be small compared to the rotor

diameter, so that no distinction is made between the rotor diameter and the stator diameter. The RMS

2

current is used because it determines the I R heating, which is what limits the electric loading.

The magnetic loading B is defined as the average flux-density over the rotor surface. In AC motors the

flux-density is distributed sinusoidally so that the fundamental flux/pole is

M1 ' B ×

B D L stk

2p

Wb

(1.2)

where p is the number of pole-pairs and Lstk is the stack length, i.e., the axial length of the active part

of the machine. In slotted stators and rotors, the peak

flux density in the teeth Bt(pk) must be limited to

about 1.6T, otherwise the magnetizing current and/or

the iron losses may become excessive. The peak fluxdensity Bg(pk) in the airgap is therefore Bg(pk) . JBt(pk),

where J is the ratio of tooth width to slot-pitch,

measured at a diameter where the tooth flux-density

is maximum; see Fig. 1.8. Typically J is of the order of

0.5. Thus B = 2Bg(pk)/B = 2JBt(pk)/B, so B is normally

limited to around 2 × 0.5 × 1.6/B . 0.5T.

Fig. 1.8

Definition of tooth pitch and J

1. Sizing, gearing, cooling, materials and design

Page 1.15

The generated EMF per phase is given by the standard equation3

2B

E '

2

kw1N ph M1 f '

B2 kw1N ph B D Lstk f

p

2

V.

(1.3)

where f is the fundamental frequency, kw1 is the fundamental harmonic winding factor, and the product

kw1Nph is the effective number of turns in series per phase. The maximum available electromagnetic

power at the airgap is mEI. We consider this as being converted into mechanical power TT/p, where

T/p = 2B f is the speed in rad/sec. (Note also that T = 2B/60 × rpm). We can obtain the TRV as

2

T/(BD Lstk/4), and substituting from equations. 1.1, 1.2 and 1.3 we get

TRV

'

T

'

Vr

B

2

kw1 AB

Nm/m 3 .

(1.4)

This equation reflects the “flux-current product” in the form AB. The

multiplying factor is simply a constant multiplied by the winding

factor kw1, which incidentally casts kw1 in the role of a utilization

factor—the higher the winding factor, the greater is the utilization of

flux and current in producing torque. Since kw1 is usually about

0.85!0.95, TRV . 2AB.

The TRV is also related to the airgap shear stess F, which is the

tangential (torque-producing) force per unit of swept rotor surface

area; see Figs. 1.9 and 1.10. For every unit of rotor surface area, the

electromagnetic torque is r F = D F/2, so the total torque is T = BD ×

2

D F/2 = BD F/2, from which it follows that

'

TRV

T

' 2 F.

Vr

Fig. 1.9

Airgap shear stress

(1.5)

The airgap shear stress F is measured in kN/m2. Typical values are

given in Table 1.3.4 The winding factor kw1 is generally between 0.8

and 0.95, so that TRV . 2 BA and F . BA. For example, if the electric

loading A = 20 A/mm and the magnetic loading B = 0.5 T, F . 0.5 × 20

× 103 = 10 kN/m2. For totally-enclosed motors the lower values of F

and TRV would apply with natural convection, while the higher values

would apply with forced-air cooling supplied by an external or shaft- Fig. 1.10 Airgap shear stress

mounted fan.5

Class of machine

kNm/m3

TRV

lbf/in

F

Small totally-enclosed motors (Ferrite magnets)

7 ! 14

0.5 ! 1

Totally-enclosed motors (sintered Rare Earth or NdFeB magnets)

14 ! 42

1!3

20

1.5

Integral-hp industrial motors

7 ! 30

0.5 ! 2

High-performance servomotors

15 ! 50

2!4

Aerospace machines

30 ! 75

2!5

100 ! 250

7 ! 18

Totally-enclosed motors (Bonded NdFeB magnets)

Large liquid-cooled machines (e.g. turbine-generators)

TABLE 1.3

TYPICAL VALUES FOR TRV AND F (CONTINUOUS OPERATION)

3

See chapter 2.

4

In Imperial units, if D and Lstk are in inches, then T is in lbf-in. If F = 1 lbf/in2, TRV = 13.8 kNm/m3.

5

In some references the output coefficient K is defined as T/(D L), so K = TRV × B/4.

2

2

Page 1.16

SPEED’s Electric Motors

The coefficient Bkw1//2 in eqn. (1.11) is peculiar to AC machines where the ampere-conductor

distribution and the flux-density are sinusoidally distributed in space around the airgap; this can be

written

A(2) ' A(pk) sin 2

and

B(2) ' B(pk) sin 2.

(1.6)

2

The product A(2)B(2) is the force per unit of rotor surface in N/m , and therefore the torque can be

2

obtained by integrating rA(2)B(2)d2 = rA(pk)B(pk) sin 2 over the entire rotor surface, where r = D/2,

2

and dividing by the rotor volume BD Lstk/4. This gives TRV = A(pk)B(pk). But the RMS value of A is

A(pk)//2, while the average value of B is BB(pk)/2, giving TRV = BAB//2. The winding factor appears

because only the fundamental space-harmonic component of the current distribution produces torque,

in conjunction with the fundamental component of flux-density, and the effectiveness of the winding

in producing the fundamental component is represented by kw1.

2

In DC machines the integral rA(2)B(2)d2 has no sin 2 term, and the result is TRV = 2AB, where B is the

average value of flux-density over the whole rotor periphery. The RMS value of A is equal to the peak

value, since the current is uniformly distributed around the rotor, and

A '

Z I a /a

(1.7)

BD

where Z is the number of rotor conductors, a is the number of parallel paths, Ia is the armature current,

and D is the armature (rotor) diameter.

The electric loading A is limited by the slot fill factor, the depth of slot, and the cooling. It is also

related to the current density J in the conductors. Suppose the area of one slot is Aslot. Let d = slotdepth, t = tooth width, w = slot width, and 8 = slot pitch = BD/Ns, where Ns is the number of slots. Also

let J = t/8. Then t + w = 8 and Aslot = wd = (1 ! t)8d. Now if the slot-fill factor Fslot is defined as the ratio

of actual copper cross-section area to the total area of each slot, we can write

J '

A8

'

Fslot Aslot

A

.

Fslot d( 1 ! J )

(1.8)

For example, if the slot depth is d = 15mm, the slot-fill factor is Fslot = 0.4, the tooth-width/slot-pitch

ratio is J = 0.5, and the electric loading is A = 20 A/mm, the current density is

J '

20

0.4 × 15 × ( 1 ! 0.5 )

' 6.7 A/mm 2 .

(1.9)

Typical values of current density for use in AC or brushless machines for different applications are

given in Table 1.4. Note that in machines operated from electronic drives there are usually timeharmonics in the current which increase the current-density without increasing the torque-producing

value of A, and it may be necessary to allow for this by multiplying J by a form factor kf. In AC

machines this will be the ratio of the true RMS current to the RMS value of its fundamental component.

In DC machines it will be the ratio of the RMS current to the average current.

Condition

A/mm2

A/in2

Totally enclosed

1.5—5

1000—3000

Air-over, fan-cooled

5—10

3000—6000

Liquid cooled

10—30

6000—20000

TABLE 1.4

TYPICAL CURRENT DENSITIES (CONTINUOUS OPERATION)

1. Sizing, gearing, cooling, materials and design

Page 1.17

These current-density values assume that the windings are varnished for good heat transfer. In aircooled machines, the fan is mounted on the rear of the motor outside the frame with a shroud which

focuses the air over the outside of the motor. Liquid cooled motors may have a passageway around the

outside of the stator with a cooling fluid circulating to remove the heat. The highest values are obtained

with hollow conductors with coolant flowing through them (“direct conductor cooling”).

It might seem strange to evaluate the magnetic loading as the average flux-density in the airgap rather

than the peak or RMS value, but the idea behind this is to indicate how well the entire cylinder of steel

is being utilized.6 Its value is limited by the available MMF of the excitation source, and by core losses

which increase rapidly at high flux-density.

It is interesting to see why it is the rotor volume and not its surface area that primarily determines the

torque capability or 'specific output'. As the diameter is increased, both the current and the flux

increase if the electric and magnetic loadings are kept the same. Hence the diameter (or radius) appears

squared in any expression for specific output. On the other hand, if the length is increased, only the flux

increases, not the current. Therefore the length appears linearly in the specific output. Thus the

specific output is proportional to D2Lstk, or rotor volume. In practice as the diameter is increased, the

electric loading can be increased also, because more intense fan-cooling or liquid cooling can be used

without reducing the efficiency. Consequently the specific output (TRV) increases faster than the rotor

volume.

Although it is theoretically possible to write one general equation from which the torque of any electric

motor can be calculated, in practice a different torque equation is used for every different type of

motor. Only in certain cases is it possible to discern in this equation an explicit product of flux and

current, or even of quantities directly related to them. For example, in the DC commutator motor the

electromagnetic torque is given by

T ' k N Ia

(1.10)

where N is the flux and k is a constant. Here the flux-current product is obvious. In rotating-field AC

machines the classical torque equations do not contain this product explicitly. However, the recent

development of 'field-oriented' or 'vector' controls has necessitated the transformation of the classical

equations into forms in which the flux and current may appear explicity in a scalar or vector product.

In eqn. (1.6) it is tacitly assumed that the flux and current are oriented at such angles as to maximize

the torque, but this is not automatically the case except in field-oriented drives. By contrast, in DC

machines the commutator automatically maintains the optimum relative angle of orientation between

the flux and the ampere-conductor distribution. In the case of doubly-salient motors such as the

switched reluctance motor and stepper motors, the torque cannot be expressed as the explicit product

of a flux and a current. However, the TRV can still be used for initial sizing provided that A and B can

be meaningfully defined (Miller, [1993]).

So far we have restricted attention to the torque per unit rotor volume, a natural consequence of the

fact that the torque appears at the rotor surface. For a very rough estimation of overall size including

the stator, we can use a typical value of 'split ratio' S (i.e., rotor/stator diameter ratio): thus

Stator volume '

Rotor volume

S2

(1.11)

A typical value of split ratio for an AC motor is in the range 0.55!0.65. For switched reluctance motors

rather smaller values are found. For DC commutator motors the value is usually somewhat higher.

The best way to acquire typical practical values of F or TRV is by experience. An engineer who is

familiar with a particular design of motor will have built and tested several, and the test data provides

values of TRV correlated with temperature rise, electric and magnetic loadings etc. The values quoted

in Table 1.3 relate to the continuous rating. Peak ratings may exceed these values by 2!3 times,

depending on the duration and other factors.

6

Switched reluctance machines have very high local flux-densities but a comparatively low magnetic loading, because

the high flux-density is limited to a small fraction of the stator periphery.

Page 1.18

SPEED’s Electric Motors

The TRV determines the volume of the rotor but not its shape. To estimate the rotor diameter and length

separately, a length/diameter ratio should be specified. A value around 1 is common; however, it is also

common to design motors of different ratings using the same laminations but with different stack

lengths. The length/diameter ratio may then vary over a range of 3:1 or more. Very large

length/diameter ratios are undesirable because of inadequate lateral stiffness, but may be used where

a high torque/inertia ratio is desired, or in special cases where the motor has to fit into a narrow space.

The foregoing discussion concerns the electromagnetic torque, that is, the raw torque produced by the

electromechanical energy conversion process at the airgap. The actual torque available at the shaft

coupling is less than this in motors, or greater in generators, by the amount of the mechanical losses

which include friction, windage, and certain electromagnetic losses appearing on the rotor. Allowance

should be made for these losses, which typically amount to less than 5% of the electromagnetic torque,

and in larger machines or high-efficiency machines, less than 1%.

1.9

GEARING

Compared to the torque density in mechanical and hydraulic devices, the torque density (TRV) in

electric motors is miserably low in comparison with what engineers would really like to achieve.7 It

always has been low, and it always will be low until someone discovers or invents a material that can

carry ten times as much flux as steel for the same magnetizing force; or a material that has a fraction

of the resistivity of copper. Such inventions would not by themselves be enough to increase the fleapower of the electric motor by an order of magnitude, unless they were manufacturable in reasonable

quantity at reasonable cost—a test which has been repeatedly failed by laboratory prototypes and

“wonder motors” for many decades.

For this reason motors are often used with gearboxes to drive the load. A gearbox is the obvious way

to step up the torque. If the gear ratio is n, and Tm is the motor torque, the torque applied to the load

is nTm. The motor speed Tm is increased over the load speed TL by the same ratio. Thus

TL ' n Tm

and

Tm ' n TL .

(1.12)

In most cases the increased motor speed falls in a standard speed range for 'high-speed' motors, which

may be typically anywhere from a few hundred rev/min to 30,000 rev/min or more.

If the gearbox efficiency is 100%, the output power of the motor is equal to the power applied to the

load. The choice of gear ratio depends on how the drive operates. If the speed is constant it is usually

a simple matter of matching the load torque TL to the rated continuous motor torque Tmc :

n '

TL

(1.13)

T mc

If, however, the load has a 'dynamic' requirement which specifies a profile of speed or position as a

function of time, the choice of the gear ratio and the motor parameters is more complicated.

Simple acceleration of pure inertia load. Referring to Fig. 1.11, if the motor torque is its peak rated

torque Tmp, the acceleration of the load is given by

" '

T mp

n Jm %

7

JL

(1.14)

n2

This assertion is valid only in the normal range of sizes. In large intensively-cooled machines such as power-station

generators, the electric machine clearly outperforms the steam turbine — it is typical for the generator to be dwarfed by the

turbines.

1. Sizing, gearing, cooling, materials and design

Page 1.19

Fig. 1.11 Gear ratio

where the term in brackets is the inertia of the motor combined with the load inertia, referred to the

motor shaft. If n is large the gearing makes the load inertia insignificant, but it reduces the load speed

and acceleration relative to those of the motor. If n is small the referred load inertia is large, and this

limits the acceleration. Between the extremes of large and small n, there is a value that gives maximum

acceleration for fixed values of Tmp and the separate inertias. This 'optimum' value can be determined

by equating the differential coefficient d"/dn to zero, giving

JL

n '

(1.15)

JM

which is a well-known result. This value of n makes the referred load inertia equal to the motor inertia.

The maximum acceleration of the load is therefore

"max '

1

2

T mp

Jm

1

n

(1.16)

The corresponding acceleration of the motor is n times this value. In this analysis, the inertias of the

pinions (gearwheels) have been ignored. For a very precise evaluation, in the case of a single-stage

gearbox, the pinion inertias can be combined with (added to) the respective motor and load inertias.

Acceleration of inertia with fixed load torque. A slightly more complicated example is where the

load has a fixed torque TL in addition to its inertia.

" '

T mp & T L /n

n Jm % JL /n 2

.

Again there is one value of gear ratio n that produces maximum acceleration, and by the same

differentiation process it is found to be

n '

TL

T mp

1 %

1 %

JL T mp2

.

.

JM T 2

L

If the inertias are unchanged from the previous case, the gear ratio is increased. The expression for the

optimum ratio can be substituted back in the formula for acceleration to find the maximum load

acceleration. The result is the same as eqn. (1.16); the difference is that with a larger ratio n the load

acceleration will be smaller. It is interesting to note that the maximum acceleration of the motor is

unchanged, and is equal to one-half the torque/inertia ratio of the motor.

Page 1.20

SPEED’s Electric Motors

Peak/continuous torque ratio of motor. In the constant-speed case, the choice of n maximizes the

utilization of the continuous torque rating of the motor, Tmc. In the acceleration case, the choice of n

maximizes the utilization of the motor's peak acceleration capability as expressed by its peak

torque/inertia ratio Tmp /Jm. Consider a load that requires both short periods of acceleration and long

periods at constant speed. Then there is a question, can the two values of n be the same? If so, the

utilization of both aspects of motor capability will be maximized at the same time.

This problem can be solved analytically in a few special cases, and one solution is given here as an

example of the kind of analysis that is needed to get a highly optimized system design. Assume that the

load torque is constant at all times, but that short bursts of acceleration (or deceleration) are required

from time to time. The peak rated torque of the motor will be used for acceleration, and the continuous

rated torque for constant speed. If we equate the two separate values of n from the appropriate

formulas given above, and if we write

T mp ' kT mc

(1.19)

where k is the ratio of peak motor torque to continuous motor torque, then the following relationship

can be derived:

n 2J m

JL

'

k2

(k & 1)2 & 1

.

(1.20)

The left-hand expression is the ratio of the referred motor inertia to the load inertia, and we can refer

to it as the 'referred inertia ratio' or just 'inertia ratio'. For a range of values of the inertia ratio, the

equation can be solved to find the values of k that simultaneously optimize n for both the

constant-speed and acceleration periods. The most interesting result of this is that a large range of

inertia ratio is encompassed by only a small range of values of k : as the inertia ratio changes from

infinity down to 2, k changes only from 2 to 4. But values of k in this range are extremely common: so

common, in fact, as to appear to be a natural characteristic of electric motors. This implies that for

most inertia ratios where the referred motor inertia is more than twice the load inertia, the gear ratio

can be chosen to make good utilization of both the continuous torque and the peak acceleration of the

motor, provided k $ 2. If k < 2, the gear ratio must be chosen for constant speed or for acceleration, and

cannot be optimal for both. The property of electric motors to provide short bursts of peak torque for

acceleration is one of the most important aspects of their use in motion control systems.

General speed and position profiles. The cases considered are all idealised by rather restrictive

assumptions that may be too simple in a complex motion-control system. For detailed work it is

desirable to simulate the performance of the whole system using system-simulation software

1.10

COOLING

The need for cooling

There are two major aspects to the thermal problem in electrical machines:

1.

2.

heat removal; and

temperature distribution within the motor.

The main reasons for limiting the temperature rise of the windings and frame of a motor are:

1.

2.

3.

to preserve the life of the insulation and bearings;

to prevent excessive heating of the surroundings; and

to prevent injury caused by touching hot surfaces.

Insulation life. The "life" of electrical insulation is inversely related to the temperature. A sustained

10EC increase in temperature reduces the insulation life by approximately 50%. The extent to which

excessive temperatures can be tolerated depends on the duration and the actual temperatures reached.

An interesting example of a motor designed for exceptionally high temperatures is the FUMEX motor

manufactured by Invensys Brook Hansen, used to extract fumes via the ventilation systems of public

1. Sizing, gearing, cooling, materials and design

Page 1.21

buildings in the event of fire; these motors can operate in an ambient temperature of 300EC for a limited

period of 30 minutes. Similar considerations apply to bearings. Grease-lubricated bearings may be filled

with high-temperature grease for hot-running applications, but in aerospace machines the bearings

are usually lubricated by separately-cooled oil or oil mist.

Heating of the surroundings is obviously undesirable especially if the motor is heating the equipment

it is driving. For this reason it is important to minimize rotor losses conducted along the shaft. PM

motors have cooler rotors than DC or induction motors. In some applications such as hermetic

compressors used in air-conditioning, refrigeration, etc., the motor losses are removed by the working

fluid, reducing the thermodynamic efficiency of the system.

To prevent injury or harm from touching, exposed surfaces must be kept below 50EC. In certain

applications (e.g., under car bonnets), this requirement is impossible to meet because the "ambient"

temperature under the bonnet may reach 100EC. In industrial applications the ambient temperature

is generally less than 50EC, and NEMA ratings for electrical insulation assume an ambient temperature

of 40EC. In aerospace applications motors and generators may be directly cooled by oil or fuel and

coolant temperatures can be as high as 100EC.

The increase in winding temperature increases the resistivity of the windings: a 50EC rise by 20%, and

a 135EC rise by 53%, increasing the I 2R losses by the same amount if the current remains the same. The

resistance increase is used in test procedures to determine the actual temperature rise of the winding,

but this is obviously an average temperature; hot-spot temperatures can be 10!20E higher. At any

temperature T EC the resistivity of copper can be calculated as

D ' D20 [1 % " ( T ! 20 ) ]

ohm&m

(1.21)

where " = 0.00393 /EC , is the temperature coefficient of resistivity and D20 is the resistivity at 20EC, that

!8

is, 1.728 ×10 ohm-m.

Heat Removal

In most industrial and commercial motors, heat is removed by a combination of

1.

2.

3.

conduction to the frame mountings;

air convection, which may be natural or forced; and

radiation.

In highly-rated machines direct cooling methods are used:

1.

2.

3.

oil mist, especially in aerospace machines;

immersion in refrigerant, in "hermetic" motors used in refrigerator compressors;

direct conductor cooling, with hydrogen, oil, or water forced through hollow conductors,

especially in turbine-generators.

Conduction. The conduction equation for a block of thickness t and area A is

Q ' k A

dT

dx

. k A

)T

t

W

(1.22)

where )T is the temperature difference through the thickness t. The coefficient k is the thermal

conductivity, with units (W/m2) per (EC/m), i.e. W/EC-m. The thermal conductivity is a material

property, and usually it is a function of temperature. Most metals have high thermal conductivities,

especially those which are also good electrical conductors. On the other hand, electrical insulating

materials and most fluids have low thermal conductivities.

Page 1.22

SPEED’s Electric Motors

As an example, consider the flow of heat along a conductor whose cross-section area is A = 64 mm2 and

length 50 mm, when the RMS current-density is 7 A/mm2. The electrical resistivity of copper is 1.7 ×

3

10!8 ohm-m, so heat is produced at the rate of J 2D = (7 × 106)2 × 1.7 × 10!8 = 833,000 W/m3 or 83.3 W/cm .

In one conductor the I 2R loss is therefore 833,000 × 64 × 10!6 × 50 × 10!3 = 2.7 W. To take the most

pessimistic estimate, assume that all of this heat is generated at the mid-point of the coil-side, half-way

along the motor. The thermal conductivity of copper is 387 (W/m2) per (EC/m). So the temperature

gradient along the coil-side is given by eqn. (1.22) as

dT

'

dx

Q

'

kA

2.7

' 108 EC/m.

387 × 64 × 10!6

(1.23)

Since the heat can flow in both directions, the temperature-gradient is only half this value, and the

temperature rise between the ends of the stack and the centre is therefore 110/2 × 50 × 10!3/2 = 1.4 EC,

which is negligible. A more thorough analysis would have to consider the full diffusion equation along

the length of the coil-side, but this quick calculation reveals that such sophistication is not needed in

the example considered.

Thermal resistance and contact resistance. Eqn. (1.24) can be used to define thermal resistance as

the ratio of temperature difference )T to heat flow rate Q : the symbol used for thermal resistance is

R, with units EC/W. Thus

R '

)T

Q

'

t

kA

EC/W.

(1.24)

The thermal resistance is a "lumped parameter" that can be used to model the conduction through a

region or interface where the individual values of k, A, and t may be difficult to determine. The contact

resistance between two surfaces is usually treated in this way, as, for example, between the frame and

the stator core. The temperature drop across a thermal resistance is given by eqn. (1.24) as )T = QR.

For example, if the contact resistance between the motor flange and the mounting plate is 1EC/W, then

with 40W flowing though it the temperature difference across the interface would be 40EC.

Radiation. Radiation is described by the Stefan-Boltzmann equation

Q

' e F ( T14 ! T24)

A

W/m 2

(1.25)

where F is the Stefan-Boltzmann constant, 5.67 × 10!8 W/m2/K4 for a black body, T1 is the absolute

surface temperature of the radiating body in degrees Kelvin, and T2 is the absolute temperature of the

surroundings.8 A black body is a perfect radiator, that is, one which reflects no radiated heat but

absorbs all the heat radiated towards it. Real surfaces are imperfect radiators, and their radiative

effectiveness relative to that of a black body is called the emissivity e. A black lacquered surface can

achieve an emissivity as high as 0.98, but a more practical rule of thumb is to take 0.9 for black-painted

or lacquered surfaces. For example, a surface with an emissivity of 0.9 that is 50EC above the

surroundings at 50EC, has a net heat transfer rate of

0.9 × 5.67 × 10!8 × ( (50%50%273)4 & (50%273)4 )

(1.26)

2

which is 432 W/m2 or 0.28 W/in . A surface 30EC above the surroundings at 20EC has a rate of 186 W/m2

— quite a useful component of the heat-removal capability of the frame.

Convection. Heat removal by convection is governed by Newton's Law:

Q

' h )T

A

W/m 2

(1.27)

where )T is the temperature difference between the cooling medium and the surface being cooled, and

h is the heat-transfer coefficient. The units of h are W/m2/EC. The value of h depends on the viscosity,

8

The absolute temperature in degrees Kelvin (K) is the temperature in EC plus 273.

1. Sizing, gearing, cooling, materials and design

Page 1.23

thermal conductivity, specific heat, and other properties of the coolant, and also on its velocity. In

natural convection the flow of coolant is not assisted by fans, blowers, pumps etc. In forced convection

the flow is assisted by one of these external means.

The heat transfer coefficient for natural convection around a horizontally-mounted unfinned

cylindrical motor can be roughly estimated as

h . 7.5

)T

D

1/4

W/m 2/EC

(1.28)

where D is in mm. For example, for an unfinned cylinder of diameter D = 100 mm and a temperature

rise of 50EC, the natural-convection heat-transfer coefficient is calculated as 6.3 W/m2/EC. For a )T of