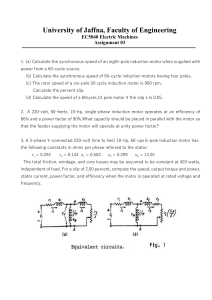

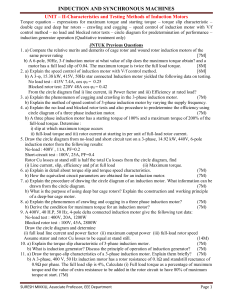

Procedure 1. Connect the induction motor (slip ring) as shown below. CIRCUIT DIAGRAM L1 I* A RUN D I START A1 E V F R S T B1 C1 STATOR ROTOR L2 L3 2. Connect the set up as in the connection diagram below. CONNECTION DIAGRAM ACM 101 FOR BENCH NO. 7 L1 L2 T1 D A T2 E B F C A B C AC WOUND ROTOR INDUCTION MOTOR L3 STATOR Power Analyser D E ROTOR F T2 AC SALIENT POLE ALTERNATOR T1 L DC 110V N BENCH SUPPLY NO. 7 L1 L2 L3 N AC 240V,3ø 3. Load the motor by means of the brake disc from no load to full load (8.5A) in steps of 0.5A and record the instrument readings. 4. Plot curves of speed, efficiency, current, torque, power factor, and slip against output power on the same axis. 5. Plot a curve of line current against torque. NB: Make sure that the motor is rotating clockwise looking from the disk brake. The reading on the force balance gives the force in newtons, but not the torque hence measures the distance from the center of the machine shaft and the center of the last hole on the balance. The product of the force indicated and the distance in meters will give the torque (Nm) Use tachometer for speed measurements At higher values of load current taking the reading very quickly. OBSERVATIONS 𝑽𝑳 Increasing load caused the speed to reduce. Current gradually increased as more load was added Table results are as follows: 𝑰𝑳 INPUT TORQUE (N-m) POWER FORCE DIST (kW) (N) (M) SPEED [RPM] OUTPUT EFFICIENCY P. F SLIP POWER (%) (kW) 234.9 5.35 1.257 0 0.225 1481 0.334 26.8 0.22 242.6 6.00 1.456 23 0.225 1475 0.880 60.4 0.52 243.7 6.55 1.596 31 0.225 1460 1.090 68.5 0.61 242.6 7.07 1.715 40 0.225 1457 1.300 75.8 0.67 242.5 7.49 1.816 46 0.225 1450 1.400 77.1 0.69 241.3 8.00 1.930 51 0.225 1445 1.610 83.4 0.73 241.0 8.43 2.031 54 0.225 1440 1.620 79.8 0.73 Analysis Input power 𝑷 = 𝑽𝑰 as shown in the table Efficiency of the motor = 𝒐𝒖𝒕𝒑𝒖𝒕 𝒑𝒐𝒘𝒆𝒓 𝒊𝒏𝒑𝒖𝒕 𝒑𝒐𝒘𝒆𝒓 i.e., the efficiency when the motor at 5.35A load = 𝟎.𝟑𝟑𝟒𝐤𝐰 𝟐𝟒𝟑.𝟗∗𝟓.𝟑𝟓 = 0.25 Current (IL) Torque (N-m) 14 12 10 8 6 4 2 0 -2 0 2 4 6 8 9 8 7 6 5 4 3 2 1 0 0 10 0,5 Line Current 1490 Effeciency (%) 1470 1460 1450 1440 1430 0,5 1 1,5 2 1,5 90 80 70 60 50 40 30 20 10 0 0 2 0,5 1 1,5 2 Output Power (kW) Output Power (kW) 14 12 Torque (N-m) Speed (rpm) 1480 0 1 Output Power (kW) 10 8 6 4 2 0 0 0,2 0,4 0,6 0,8 1 Output Power (kW) 1,2 1,4 1,6 1,8