Liquid Handling Robots!

For Middle or High School BioTech

The Power of STEAM Across Grades and Disciplines

Mark L. Miller, Ph.D. (Learningtech.org)

Ingmar Riedel-Kruse, Ph.D. (Stanford)

California STEAM Symposium

October 29, 2018

The LHR Team

Principal Investigators

• Paulo Blikstein, Ph.D. (Stanford/Columbia)

• Mark L. Miller, Ph.D. (Learningtech.org)

• Ingmar Riedel-Kruse, Ph.D. (Stanford)

Other Key Contributors

• Len Erickson, Ph.D. (Learningtech.org)

• Tamar Fuhrmann, Ph.D. (Stanford)

• Ethan Li (Stanford)

• Chris Miller (Learningtech.org)

• Mike Wirth, Ph.D. (Learningtech.org)

The support of the National Science Foundation is gratefully acknowledged.

What It Is

• A prototype, inexpensive robot that pipettes liquids,

capable of being programmed by students using a

block-based coding environment

• Cuvettes and Pipettes

• 96 Well Plate

• Motors and Sensors

• Arduino (Mega)

• Software Layers

• Laser Cut Plastic

• Downloadable Designs

void loop() {

LHR_updateMessaging(transport, messager);

LHR_updateBasics(core, board);

LHR_updateAxes(pipettorAxis, zAxis, yAxis, xAxis);

}

Why Do It?

• Enable hands-on, NGSS-aligned experiments with

liquids in a project-based, inquiry-driven, costeffective manner

• Empower students to explore the power of coding

and robotics, in authentic context beyond simple

game development or autonomous vehicles

• Let students directly experience how

technological advances can

accelerate scientific research

• College/Career Readiness – BioTech

workers do not do much manual

pipetting anymore

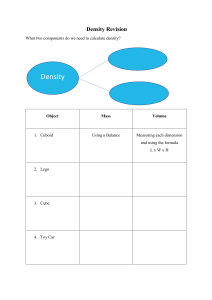

Middle School Examples

Middle School

• Integrate coding, computational thinking with

authentic science topics

–

–

–

–

Measurement and Precision

Repetition with Variations

Relationship Between Density and Layering of Liquids

Color Theory

• See relationships between art and engineering

High School Examples

High School

• Study Impact of Increased Ocean Salinity on Krill or

other organisms, relationship to other life forms such

as whales (Gr9)

• Learn Advanced Laboratory Procedures (Gr10+)

– Serial Dilutions

– Enzyme-Linked ImmunoSorbent Assay [ELISA]

• Horseradish Peroxidase (Grade 10)

• Maker Space / Fab Lab Projects

– Improved Designs (such as snap together parts)

– Variations (such as undersea data collector)

Project Evolution

Early Versions Used Lego Mindstorms

• 3-axis version provided cuvettes only

• Constructed with 1 Lego set plus specialized parts

• 4-axis version added 96 well plate

• Required >1 Lego set

Project Evolution

Other Approaches We Explored

• Lego Mindstorms

– Brick Pi instead of Lego Brick

• Laser Cut Plastic

– Arduino Microprocessor

– BBC micro:bit User Control

– MakeCode for Student

Programming Environment

• Each had pros and cons

• What we needed was a “bigger”

Arduino

Project Evolution

Latest Versions

• Laser cut plastic

• Arduino Mega handles both back end and user interface

• 1 motor per axis (3-axis and 4-axis versions in use)

• Low level code combines C, Javascript, and Python

• Student code is written in Snap! (similar to Scratch)

• 3-axis supports 8 cuvettes and a 96 well plate, with

prompts to manually move tray on non-automated X axis

• 4-axis supports 16 cuvettes and a 96 well plate, with full

automation

4-Axis Serial Dilution Demo

• Snap! front end not yet available

on 4-axis model

• Launches via Python temporarily

$python3.6 -m lhrhost.tests.robot.serial_dilution ascii

3-Axis Hands On!

• Code with Snap! Blocks

• Move Tray Front to Back (X

axis) as Prompted

• Try it out (10 mins)!

Questions for User Studies

• At which grade levels would the technology be most

beneficial? Middle School versus High School?

• Is it more effective to include this type of technology in

an authentic, integrated science context, or to offer

unrelated exposure to coding and robotics?

• Do gender, ethnicity, or socioeconomic status impact the

appeal or effectiveness of this technology?

• How close is it to being sufficiently robust and reliable

for classroom use?

• Will teachers want to try it?

User Studies – Middle Grades

Pilot Studies to Date

• McKinley Institute of Technology (RWC)

– Students built Lego pipetter mechanism

– Fascinated by Layering and Density

• Ralston Middle School (Belmont)

– Similar to McKinley

• Christa McAuliffe School (Saratoga)

– Girls coded well plate designs in Snap!

– All girls chose LHR

– All boys chose Lego vehicles

– Small sample size

User Studies – High Schools

Pilot Studies to Date

• Design Tech High School (Redwood Shores)

– Two Fab Lab Intersessions weeks (15 hrs)

– First time, some created non-LHR robots

– Second time, most worked on LHR

• Some built variations (micro:bit)

• Some designed improvements

• Carlmont High School BioTech Institute

– We began study with micro:bit version

– We taught students MakeCode

– Aborted due to equipment unreliability

– Will reprise in Feb 2019 with latest

3 Minute Discussion at Table

• What grade levels do you teach?

• What grade levels do you see this as

most useful for?

• Could this technology be useful with

your students?

• Can you think of a sample lesson/topic

where it would be especially helpful?

• Are you OK with spending a bit of

science time to introduce coding?

• What sorts of professional development

would you want before trying it?

For the Future

•

•

•

•

•

•

•

•

Controlled user studies

Adapt Snap! front end for 4-axes

Support Chromebook usage

Improve ruggedness and robustness

(better cable harnesses, easier calibration)

Incorporate color sensors

Explore CTE potential for community colleges to

fabricate units for local high schools

Improve the documentation for the CAD materials and

software build

Prepare and Deliver Professional Development

How You Can Help

• Sign up to stay informed of our progress

• Participate in a user study at your school

• Help us identify incremental funding opportunities

Resources

• https://journals.plos.org/plosbiology/article?id=10.1371/

journal.pbio.2001413

• https://github.com/ethanjli/liquid-handling-robotics

• http://snap4arduino.rocks/

• https://cad.onshape.com/documents/

6f3ff9e60612f07463807b51/w/

7c9831bb106114d48918156b/e/

4506227faff13d408760d512

• https://learningtech.org/casteam2018

• mailto:mlmiller@learningtech.org