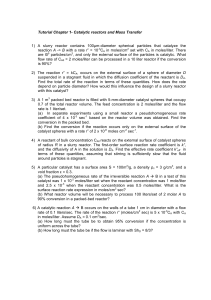

School of Chemical and Metallurgical Engineering. CHMT3043A: Chemical Reaction Engineering B 26 August 2021 Tutorial 2: Catalysts, Catalytic Reactors and Catalysis Engineering QUESTION ONE The kinetics of ethanol dehydrogenation over Cu-Co catalyst is depicted with the following kinetic models: 1. 2. 3. 4. 𝐴 + 𝑆 ↔ 𝐴. 𝑆 𝐴. 𝑆 + 𝑆 ↔ 𝑅. 𝑆 + 𝑆. 𝑆 𝑅. 𝑆 ↔ 𝑅 + 𝑆 𝑆. 𝑆 ↔ 𝑆 + 𝑆 Note S is the active site and as product formed during the reaction as well. If step 2 is the rate determining step in the mechanism, show that the rate expression for the dehydrogenation is given as: 𝑘 𝐶 𝐾 𝑟= 𝑃 − 𝑃 𝑃 𝐾 (1 + 𝐾 𝑃 + 𝐾 𝑃 + 𝐾 𝑃 ) QUESTION TWO A fixed-bed reactor that behaves as a PFR with negligible pressure drop was used to conduct catalytic isomerization of meta-xylene (MX) to para-xylene (PX) and orthoxylene over a supported Pt catalyst. During the catalytic reaction, the catalyst was found to be 99.9% selective to PX and no other product was obtained. The mechanism for the elementary reactions as studied in a differential reactor could be depicted with three steps as shown below: 1. 𝑀𝑋 + 𝑆 ↔ 𝑀𝑋. 𝑆 2. 𝑀𝑋. 𝑆 ↔ 𝑃𝑋. 𝑆 3. 𝑃𝑋. 𝑆 ↔ 𝑃𝑋 + 𝑆 School of Chemical and Metallurgical Engineering. i. List steps involved in the catalytic reaction from bulk phase to production of PX in sequential order ii. If step 1 is the rate determining step during the reaction, determine the rate expression for the reaction and describe how the parameters of the rate expression could be determined. QUESTION THREE During the kinetic study of the reaction depicted in equation (1) using a batch reactor in a laboratory, the pressure-time data shown in Table 1 was obtained. If at the initial stage, only A is present in the reaction vessel, use the data provided to determine the kinetic parameters of the reaction (.i.e. order of the reaction and the rate of reaction constant, k) 𝐴 → 𝐵 + 2𝐶 … … … … … … … … … … … … . .1 Time (minutes) 0.0 2.5 5.0 10 15 20 Total Pressure (mm Hg) 7.5 10.5 12.5 15.8 17.9 19.4