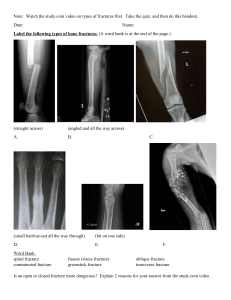

URTeC: 2677 Combining Pressure-Based Fracture Maps and Post-Stimulation LeakOff Analysis Lead to Informed Unconventional Development David Lerohl*1, Justin Mayorga1, Brent Vering1, Erica Coenen1, Sean Spicer1, 1. Reveal Energy Services. Copyright 2020, Unconventional Resources Technology Conference (URTeC) DOI 10.15530/urtec-2020-2677 This paper was prepared for presentation at the Unconventional Resources Technology Conference held in Austin, Texas, USA, 2022 July 2020. The URTeC Technical Program Committee accepted this presentation on the basis of information contained in an abstract submitted by the author(s). The contents of this paper have not been reviewed by URTeC and URTeC does not warrant the accuracy, reliability, or timeliness of any information herein. All information is the responsibility of, and, is subject to corrections by the author(s). Any person or entity that relies on any information obtained from this paper does so at their own risk. The information herein does not necessarily reflect any position of URTeC. Any reproduction, distribution, or storage of any part of this paper by anyone other than the author without the written consent of URTeC is prohibited. Abstract Fracture diagnostic technologies are an important aspect of unconventional stimulation where operators need the knowledge to improve completion performance and reduce capital expenditure. Diagnostic measurements provide information before production results and enable a larger number of samples to support statistical comparison. Pressure sensors provide cost-effective monitoring solutions which generate large volumes of data. Unfortunately, such data sets can be difficult to transform into actionable insight. Pressure monitoring can be done at many locations including the treatment well, offset parent well, nearby sealed wellbore, or an isolated stage from a nearby well. This paper focuses on combining the analysis of two pressure monitoring techniques: post-treatment pressure leak-off analysis and pressure-based fracture maps. Combining these two techniques provides near-field and far-field measurements. An estimated stimulated rock volume may be calculated by evaluating the fracture extent and connectivity along the wellbore. The average treatment parameters are compared for different combinations of fracture area and stimulation efficiency to highlight beneficial trends in completion designs. Each technology is briefly reviewed along with how these two methods compliment the other. A Wolfcamp A study was conducted using an anonymized data set. This larger study incorporated work from multiple operators and projects; thus providing sufficient sampling and conclusions. The study demonstrated that cost-effective monitoring can be used to update completion designs and to maximize the stimulated rock volume. Introduction Shale exploration has grown tremendously in the past decade. Many technological advances have been introduced, tested, and evaluated to help operators modify the completion pumping schedule and maximize the effective stimulated rock. More production should result from better stimulated rock, however, there is an economic tradeoff between the cost of the stimulation treatment plan and the recoverable hydrocarbons. A few challenges with waiting for production results to define better URTeC 2677 stimulation include: the time delay of production, cost of stimulating an entire well, and not having enough comparable data points to draw statistically significant conclusions. Fracture diagnostic tools have been created to provide insight into stimulation performance before getting production data. Diagnostics can measure information at the stage or cluster level. Pressure sensors have become an economical option to acquire large data sets for analytical applications. Several new analysis techniques can provide improved understanding of unconventional reservoir stimulation and production. Challenges arise as many operators acquire more pressure data without the proper knowledge of how to mine useful information to support completion and production decisions. There are two main hurdles: first, understanding how to get knowledge from a pressure data stream, and second, how to scale the results from a single well, or pad, and apply it to development acreage. This paper focuses on integrating two pressure analysis techniques and applying the results on a regional scale to identify connections between completion parameters and the effects on reservoir stimulation. The first method is Pressure-Based Fracture Maps, which uses isolated pressure signals during stimulation to resolve fracture geometries (Spicer & Coenen, 2018). The second method is Post-Stimulation Leak-Off (Sullivan, et al., 2019). A benefit from combining these techniques is that they focus on two different aspects of rock stimulation. The pressure-based fracture maps resolve the geometry for the largest dominant fracture and thus showing the extent to which fluid, and potentially proppant, is pumped into the formation. The post-stimulation leak-off is a proxy for well-to-reservoir connectivity and theoretical fluid distribution. The combination of these techniques is applied to multiple wells and stages in the Wolfcamp A formation in the Delaware Basin. The highlighted trends demonstrate correlations to reservoir stimulation quality. Methods Pressure-Based Fracture Maps Technology Overview Pressure-Based Fracture Maps (PBFMs) transform pressure signals originating from stages isolated with a solid bridge plug into quantitative fracture geometries for the dominant fracture in a stage. This process has been thoroughly documented through previous publications (Coenen & Spicer, 2019) (Kampfer & Dawson, 2016). This paper provides more information regarding the relationship of the dominant fracture and the created stress field. PBFMs are a cost-effective method for evaluating the dominant fracture extent into the reservoir, both vertically and horizontally. The results may be used to compare stimulations across various completion designs. During a multi-well pad completion, a single stage must be in contact with the reservoir and pressure isolation set to prevent communication from other stages. This is typically done by placing a solid bridge plug before completing a stage on a well. A surface pressure gauge is installed on this well to monitor the pressure response from this stage. Stimulation continues on the other nearby wells while the pressure is monitored from the isolated stage. The differential stress field induced by fracture growth during offset well treatment stages causes a poro-elastic response through the reservoir. In the compressional regions, the pore pressure increases due to the stress. Figure 1 visualizes the treatment stage with the stress field in shadows and the isolated monitoring stage in the lower right. The net pressure on the fracture, fracture propagation location, monitoring location, and observed pressure response are incorporated into a physics-based digital twin model. The geometries are resolved by comparing pressures observed in the field to those predicted by the digital twin. URTeC 2677 Figure 1. Graphic of the stress field from a treatment stage and a monitoring stage. The grey zone is compressional stress with the darker color having a larger magnitude. The pink zone is the tensile region extending from the fracture tip. The graphs contain sample pressure monitoring versus time plots. Multiple stages are monitored and resolved together to constrain the solution space. The output of this process yields a fracture half-length, fracture height, and azimuth. The application and validation of this method for quantitative decision support has been discussed in numerous publications (Kahn, et al., 2018) (Kopp, et al., 2019) (Das, et al., 2019). While many other fracture diagnostic technologies are qualitative in nature, the quantitative results provide engineers the ability to quantify the distribution of actual fracture geometries for a given completion design. Therefore, the engineer can distinguish outcomes that are driven by completion decisions independent of the underlying variations in the formation. Historically, the petroleum industry has not acquired sufficient data in completions optimization contexts that support statistically significant results with well controlled testing environments. This “anecdote-as-data” approach to optimization leads to a lack of confidence in decision making and to decisions being made on scientifically inconclusive data and poor testing. Fracturing rock is a stochastic problem which requires appropriate sampling to statistically define the results. Dominant Fracture Geometry The geometries reported from the PBFMs are for the dominant fracture of each monitored treatment stage. The poro-elastic pressure response in the reservoir is propagated through the stress field. The stress is not cumulative or multiplicative with additional clusters being stimulated. Figure 2 illustrates the stress response with different perforation cluster configurations. As shown, the stress field is similar for each and every configuration: one cluster, multiple clusters of the same size, or one large cluster and other small clusters. The stress response of the rock compression is driven by the dominant fracture area and is unaffected by the number of treatment and/or monitoring parallel fractures in a stage. URTeC 2677 Figure 2. Hydrostatic pressure plots shows the influence of multiple parallel fractures: (a) single treatment - single monitor, (b) four equisized treatment fractures - single monitor, (c) four non-equisized fractures - single monitor, (d) single treatment – four equisized monitors Figure 3. Graphic showing the dominant fracture in the black outline compared to potential cluster fractures shown in pink. On the left is the gun barrel view with the overlapping fractures shown with the darker pink. On the right is the cross-section view showing a theoretical distribution of fractures in the given treatment stage. Figure 3 shows the resolved fracture geometry on a given stage with multiple parallel fractures. The dominant fracture captures the extent to which the fluid reaches, horizontally and vertically. This provides the edge condition for which all other hydraulic fractures must be equal to or smaller than the dominant fracture. This understanding is critical when interpreting PBFMs in conjunction with pressure leak-off analysis. Pressure Leak-Off Analysis Diagnostic Fracture Injection Test Post fracturing pressure leak-off data have been widely gathered and the analysis remains a cost-effective method to analyze formation properties. A standardized method widely applied to unconventional development is a Diagnostic Fracture Injection Test (DFIT), also referred to as a Minifrac. This traditional analysis of pressure leak-off was established and defined by Nolte (Nolte, 1979). It is the gold standard of diagnosing and estimating hydraulic fracture parameters. In this process, a small volume of non-proppant-laden fracturing fluid is injected into the formation to establish a stable fracture geometry and to observe the shut-in period immediately after. Parameters measured include: formation breakdown pressure, estimation of formation closure and pore pressure, estimated permeability, and leak-off coefficients. URTeC 2677 Flow regimes are identified during the shut-in period. The fluid flow within the fracture transitions from wellbore storage to linear flow, bi-linear flow, pseudolinear flow, and then pseudo-radial flow (Cinco-Ley & Samaniego, 1981). In unconventional reservoirs, the permeability is low (< 0.1 millidarcies); accordingly, some flow behaviors may take hours, if not days, to observe. However, wellbore storage and linear flow are the early onset flow regimes that can be rapidly identified. Wellbore storage occurs when a well is shut-in at surface. However, there is still flow within the wellbore driven by the compressibility of the fluid pumped. Linear flow occurs when the fracture remains open after the formation breakdown. Since no proppant is present within the fluid, the conductivity within the fracture is defined as infinite. Fluid pressure within the fracture is larger than reservoir pressure; thus the fluid will leak off through the fracture face into the reservoir. Post-Treatment Leak-Off Analysis The main difference between post treatment leak-off and traditional DFITs are: 1. Fluid volume within DFITs are small compared to full stimulation treatments. DFITs can range from 50-100bbls of clean fluid. In contrast, a full stimulation can yield tens of thousands of barrels. 2. Clean rates are a few barrels per minute (bpm) for DFITs, while slurry rates during a stimulation can range from 80-120bpm. 3. DFITs are typically pumped through a toe sleeve (single-point entry) vs. a stimulation stage with a full perforation cluster set. 4. DFITs are pumped in unperturbed reservoirs, while a stimulation stage in a multi-well completion can have several recently stimulated stages in its vicinity. 5. Clean fluid is pumped during a DFIT and proppant-laden fluid is pumped during stimulation. 6. Time allowed for leak-off during DFITs may be a few days while leak-off post-stimulation, depending on the data acquisition, could range from a few minutes to an hour. Despite the differences between DFITs and Post Treatment leak-off analysis, they share similarities in early time flow regimes. As pumping ceases, the fracture will remain open and unsupported by proppant. Because of this, two leak-off regimes must exist before the fracture closes; the wellbore storage and formation linear flow have multiple methods used for identification. Early flow regime detection can provide insight on stage-to-stage level performance through the multiple accepted methods in analyzing leak off regimes and types including: • Square root vs. Time • G-Function • Log-Log. All methods share a linear relationship of shut-in pressure and time given their respective semi-log derivatives in early elapsed shut-in time (Liu, et al., 2020): 𝐺 𝑑𝑝 𝑑𝑝 𝑑𝑝 ≅ ∆𝑡 ≅ √∆𝑡 𝑤ℎ𝑒𝑛 𝛥𝑡 ≪ ∆𝑡𝑝 𝑑𝐺 𝑑∆𝑡 𝑑√∆𝑡 (1) Where G is dimensionless time, p is pressure, t is time, and d represents a derivative. This relationship provides early detection of linear flow which is typically observed in the allotted time for data gathering between stages (Sullivan, et al., 2019). Linear flow observes a pressure drop proportional to the square root of time, that can be described by the following equation (Barree, et al., 2007). This relationship can be seen in Figure 4, where calculated values are plotted with assumed formation properties and varying time and fracture half length. URTeC 2677 1 𝑃𝐷 ≈ (𝜋𝑡𝐷 )2 𝑡𝐷 = 0.000264𝑘𝑡 ∅𝜇𝑐𝑡 𝑥𝑓 2 (2) (3) Figure 4. Calculated linear relation shown between dimensionless pressure drop and square root of time. This linear relation established the initial flow regime of linear flow. With varying the fracture half length, it can be seen that the closer the fracture is to the wellbore, a larger pressure drop will be expected. Where PD is dimensionless pressure, tD is dimensionless time, k is permeability, t is time, µ is viscosity, x f is fracture half-length, ϕ is porosity, ct is compressibility, and the coefficient in front is for field units. This linear relation can also be observed in log-log plot given the following principles of linear flow and at slope of 0.50. 1 (4) 𝐿𝑜𝑔(∆𝑃𝑤 ) = 𝐿𝑜𝑔(𝑡) + Log(Pi ) 2 This represents a one-dimensional flow pattern into the (unbounded) formation, perpendicular to the fracture surface. The formation (permeability) governs the speed of this process. This linear relation can also be achieved by the utilization of the G-Function, described by Valko’s equation: 𝑃 = (𝑃𝑐 + 𝑆𝑓 𝑉𝑖 − 2𝑆𝑓 𝑆𝑝 ) − (2𝑆𝑓 𝐶𝐿 √𝑡𝑒 ) ∗ 𝑔(𝛥𝑡𝑑 , ∝) 𝐴𝑒 (5) Simplified in Eq. 6 to: 𝑃𝑤 = 𝑏 + 𝑚 ∗ 𝑔(𝛥𝑡𝑑 , ∝) Field-measured data of post treatment leak-off are illustrated in Fig. 5. Duration of the leak-off was approximately 60 minutes post shutdown during zippering operations and measured through a high- (6) URTeC 2677 quality, temperature-compensated surface pressure gauge. In all three diagnostic plots, the relation of linear flow can be observed (Fig. 5). Figure 5. Field measured data utilizing three different diagnostic plots for pressure leak-off analysis. (a) Top-Left, Pressure vs √time, (b) TopRight, Log-Log, (c) Bottom, G Function. As described by their underlying equations, a linear trend can be readily identified thus suggesting linear flow By identifying the linear portion, a value can be assigned to assess relative total surface area based on the relation between surface area and rate of leak-off. Total surface area is described by the total hydraulic contact established during the stimulation, which could be parallel fractures and or secondary growth through natural fissures. Figure 6. Field measured data plotted applying Pressure vs √time with the slope of linear flow. The slope is used as a relative measurement of total surface area provides insight on stage to stage differences. In theory, the faster leak-off relates to larger fracture surface area. URTeC 2677 The rate (slope) of leak-off is determined by total surface area. Fig. 6 is an example of this slope. Ultimately, the rate of leak-off is primarily driven by the fracture geometry and the quantity of fractures present within a given stage. The greater number of fractures present in each stimulation; the larger the hydraulic surface area will exist; thus resulting in a faster leak-off. This can be expressed by Carter’s leak-off equation (Eq. 7): 𝑉𝐿 = 𝐴𝐿 (2𝑐𝐿 √𝑡 + 𝑆𝑝 ) (7) Calculated values are shown below in Figure 7, where it can be seen mathematically with an increase of surface area, the rate of leak off (Volume Loss per Time) also increases. Figure 7. Calculated volume of fluid loss vs time for varying surface areas. Expressed by Carter’s leak-off equation, the larger surface area will always result in a faster leak-off. Stage to stage workflow can now be established with the assumptions that stages are completed with similar fluid volume, rate, and geology throughout the lateral. 1. Determine time interval for formation linear flow by preferred method of measurement (√t, Gfunction, or log-log) (Figure 5) 2. For this interval, linear slope approximation is performed in Pressure vs √Time (Figure 6) 3. Linear slope is assumed proportional to fracture area and therefore enables relative comparison of stages. Field Example Instead of a mini fracture being created with 50-100bbls through a single point entry, a full stimulation will not only have a larger geometry, but also have multiple fracture initiation points through the designed cluster sets. In a perfect scenario, every cluster will take equal amounts of fluid, creating similar fracture half-lengths, heights, and apertures. However, this is unlikely in a real stimulation. A dominant fracture will consume most of the pumped fluid and cause some clusters to be ineffective. Using PBFMs, the surface area of the largest dominant fracture can be measured. An aperture, or width, input is needed to calculate total volume of the fracture and injection fluid. This can be calculated with the PKN 2D method and estimations of Poisson’s ratio and Young’s modulus: 𝑤𝑚𝑎𝑥 = 2𝑃𝑛𝑒𝑡 ℎ𝑓 𝐸′ (8) URTeC 2677 𝐸′ = 𝐸 (1 − 𝑣 2 ) (9) Coupling these measurements and calculations with the rate of leak-off during the linear flow regime, a qualitative assessment of volumetric fluid distribution can be achieved. Figure 8a shows a field measured half-length and total height of the largest dominant fracture in a cluster set. For simplicity, a single bi-winged fracture is assumed with secondary fractures ignored. Figure 8. Field data example utilized to show the effects of cluster distribution and total surface area. (a) Top-Left. PKN dominant fracture model created to perform volumetric balance for remaining stimulation fluid. (b) Top-Right. Dominant fracture size versus cluster efficiency. PBFMs provides the dominant fracture within a cluster set, this provides a max limit of the non-dominant fracture xf. Plot shows theoretically, a minimum of 60% of clusters must be open for remaining fracture to be smaller than or equal to the largest dominant. (c) Bottom. Total surface area versus cluster efficiency. As previously stated, if all clusters are open, resulting in high cluster efficiency, a higher total surface area is expected, thus fast leak-off. Fracture dimensions from measurements and calculations: • PBFMs Fracture Half Length (Xf) ≈ 1,100 ft. • PBFMs Fracture Total Height (Hf) ≈ 290 ft. • Calculated Max Fracture Width (w) ≈ 0.25 in. (Value obtained from PKN 2D Model with assumed E and υ) • Number of Clusters = 15 • Assumed Fluid Efficiency ≈ 90% Assuming that fluid outside of the dominant fracture is equally distributed into the remaining clusters sets, and the non-dominant fractures share the same height of the dominant fracture, a volumetric balance can be achieved to calculate the volume of each fracture and ultimately the total fracture surface area. Since the dominant fracture is known, provided by pressure-based fracture maps, a non-dominant threshold can be achieved, thus providing a qualitative assessment of fluid distribution into the remaining cluster sets (Figure 8b). URTeC 2677 As previously proposed, a stimulation stage with a larger distribution through its clusters will result in a larger surface area (Figure 8c), therefore resulting in a larger pressure drop or rate of leak-off during the linear flow regime. Utilizing the rate of leak-off in conjunction with pressure-based fracture maps, mass data aggregation can be used to observe differences not only on a pad to pad level, but a multi-stage level. This powerful implementation of statistics can provide proper methods for A-B testing and enable confident completion decisions to be made. Combined Pressure Analysis Combining two complementary pressure monitoring techniques enables a new holistic framework to evaluate fracturing treatment results. The PBFMs provide the geometry for the dominant fracture. It acts as the edge condition which all other fractures in the given stage must be equal to or smaller than. The post-stimulation leak-off analysis uses pressure observations on the treatment well and can be used as a proxy for reservoir connectivity. Using the assumption of linear flow, the faster leak off values indicate larger surface area contact with the reservoir. The theoretical stimulated rock volume (SRV) from a given treatment stage is the combination of dominant fracture area multiplied by the stage length and scaled by the rate of leak-off. There may be a tradeoff between the size of the dominant fracture and the measured leak-off connectivity. The goal of this combined analysis is to highlight completion designs that prove optimal in balancing this tradeoff. # 𝑠𝑡𝑎𝑔𝑒𝑠 𝑇𝑜𝑡𝑎𝑙 𝑆𝑅𝑉𝑇ℎ𝑒𝑜𝑟𝑒𝑡𝑖𝑐𝑎𝑙 = ∑ 𝐴𝑟𝑒𝑎𝑖 ∗ 𝐿𝑒𝑛𝑔𝑡ℎ𝑖 ∗ 𝜂𝑖 (10) 𝑖 Where Area is calculated using the dominant fracture result per stage from PBFMs, the length is the difference in measured depth from the top to the bottom of the stage, and η is a scalar efficiency factor from the leak-off exponential coefficient. The transformation from leak-off exponential coefficient to the efficiency η factor is not yet defined. By grouping results into different bins based on geometry and leak-off coefficient, distinct treatment parameters highlight the most beneficial results. The larger the dominant fracture area and the high the leak-off coefficient, the greater estimated stimulated rock volume was created from the treatment. For comparisons used in a stage level SRV, the categories of leak-off and fracture area are given a value of 13 for Low-High, respectively. The SRV calculation is a multiplication of the rating for both the leak-off and fracture area class. The results with the largest estimated SRV are the stages with the largest dominant fracture area along with the highest leak-off coefficient. Figure 9 through Figure 12 group data points into low, mid, and high for both dominant fracture area and exponential leak-off coefficient. The bounds are the same on grouping data points so these graphs may work on the same grouped values. The colors correspond to the leak-off coefficient and the shape of the data point identifies the dominant fracture area group. URTeC 2677 Figure 9. Results from a single project showing the exponential leak-off coefficient versus dominant fracture area. Each stage is represented by a symbol which is colored relative to the leak-off class and the shape is associated with the fracture size. A total of 38 stages from 2 wells were collected on this single-pad project. Figure 9 illustrates the results from a single pad which contained two wells and 38 total stages. Sampling data at the stage level is the quickest and most cost-effect method of acquiring statistically significant data. However, one project may not contain enough data to perform more than a single A/B test. To fully realize the power of combining these two techniques, this method is applied to a data set of several pads, as shown in Figure 10. Fracturing rock is a stochastic process. Characterizing the results requires adequate sampling to define the probability distributions and average results within desired confidence intervals. Individual (single pad) projects work well when testing a limited number of treatment parameters. Scaling these results to extract formation level trends, data from multiple pads, consisting of 18 wells, were combined. It also illustrates how this process improves understanding of the correlation between treatment parameters and the desired result. The presented results are aggregated from many different projects and operators. The data points are anonymized and filtered to the Wolfcamp A formation in the Delaware Basin. It is critical the compared points share similar geologic characteristics. URTeC 2677 Results Wolfcamp A (Delaware Basin) Figure 10. Results from multiple projects in the Wolfcamp A formation plotting the exponential leak-off coefficient versus dominant fracture area. Each stage is represented by a symbol which is colored relative to the leak-off class and the shape is associated with the fracture size. A total of 296 stages from 72 wells were collected. The most obvious result is there are no monitored stages which resulted with a large fracture area and a high exponential coefficient for the leak-off. This validates the tradeoff between the area of the dominant fracture and the effective stage connectivity. The largest group of stages has a low-sized fracture area and a mid-rating for exponential leak-off. The next largest group of points is the mid-sized fracture area and mid-rating exponential leak-off. As operators continue to improve completions, it is critical to match the design with the geology and well spacing to maximize the return on investment (ROI). Larger fracture geometries with higher values of leak-off coefficients would enable operators to reduce well count per section while keeping the SRV similar. Figure 11. (a) Left. Average fracture area versus the number of perforation clusters per foot. (b) Right. SRV calculation versus the average rate per foot. The SRV calculation is a combination of the area and the leak-off coefficient. Figure 11 details the average treatment parameter for each classification group—fracture area and leakoff coefficient. From Figure 11a, the cluster density, or average number of clusters per foot, is negatively correlated with the fracture area. This trend shows the lower cluster density stages had a larger fracture area. The limited number of contact points to the reservoir directs completion fluids to fewer potential fractures. This result supports other publications where an increase in perforation clusters resulted with an increase in Fracture Initiation Points (Natareno, et al., 2019). Figure 11b shows the average rate per foot is negatively correlated with the SRV calculation. This result may be counter-intuitive with many operators moving toward limited entry or other high-rate applications. The specific perforation designs were not included in this analysis. The results of this URTeC 2677 publication indicate limiting the rate had the combined effect of fracture area and efficiency to result in the larger SRV values. Figure 12. Stage results are grouped by the fracture area class and the leak-off class as shown by the shape and color, respectively. The y-axis is the proppant per foot used in a given stage. The blue dashed line represents the average for the group of stages and the blue shaded region represents the confidence interval for the true mean. The box and whisker overlay highlight the distribution characteristics of the sample points. The proppant per foot values were plotted by the fracture area class and the leak-off class. Confidence bands of 80% confidence were added around the group. The confidence bands can be used for statistical comparison where if the bands do not overlap, the two groups are statistically different. For the highfracture area group (Fig. 12), the mid-level leak-off group has statistically less proppant per foot than the low-level leak-off. For the mid-fracture area group, the high-level leak-off group had less proppant per foot than the low-level group. The results indicate only a minimum amount of proppant is required to make the fracture conductive enough to be a conduit. Also, the lighter proppant loading may enable the fluids to carry the proppant further before settling Discussion and Conclusion The Wolfcamp A study combining Post-Stimulation Leak-Off Analysis and Pressure-Based Fracture Maps showed unique insight into completion design parameters that influenced the dominant fracture growth and connectivity to the reservoir. As operators continue to improve completion designs to maximize ROI, cost-effective monitoring is vital. Identifying key parameters to optimize designs will save capital, improve production, and provide data to support design changes. The data presented in this publication was aggregated from multiple multi-well projects from multiple operators who agreed to the use of anonymized data. The broad scope provides a unique and statistically significant data set previously unable to be acquired and aggregated. As more data points are added to this anonymized data set, additional informative trends and insights can be gained. The study results support a negative correlation between dominant fracture area and exponential leak-off coefficient. Clearly, tradeoffs develop between the extent of the dominant fracture and the complexity of the given stimulation. The increase in proppant per lateral foot of stage length may cause more barriers and pressure blocks instead of providing additional permeability. Lower proppant loading can support sufficient fracture permeability while enabling the fluid to carry proppant further into the formation and away from the wellbore. URTeC 2677 A future extension of this study involving these two pressure analysis methods should include production. Specific interest remains in an investigation involving summing the scaled reservoir contact along an entire well to determine correlation with well production. This test would require numerous wells to meet sufficient data sampling requirements. The results would identify better connections the treatment parameters and the production results. Cost-effective pressure monitoring methods help petroleum engineers make improved decisions while reducing capital expenditure. URTeC 2677 Nomenclature ct = total compressibility, Lt2/m, psi-1 cL = leakoff coefficient, Dimensionless k = permeability, L2, millidarcies P = pressure, m/Lt2, psia G = G-Function, Dimensionless g = loss-volume function, Dimensionless hf = fracture total height, L, ft E = Young’s modulus, m/Lt2, psia E’ = plain-strain modulus, m/Lt2, psia η = efficiency factor, Dimensionless Φ = Porosity, Dimensionless Sp = spurt loss coefficient, Dimensionless Sf = fracture Stiffness, m/L2t2, psi/ft t = time, hr μ = fluid viscosity, cp v = Poisson’s ratio, Dimensionless wf = fracture total width, L, ft xf = fracture half length, L, ft α = area exponent, Dimensionless Subscripts D = Dimensionless e = end of pumping i = initial p = Time Pumped, hours L = Leakoff w = wellhead URTeC 2677 References Barree, R. D., Barree, V. L. & Craig, D., 2007. Holistic Fracture Diagnostics. s.l., Society of Petroleum Engineers. Cinco-Ley, H. & Samaniego, V., 1981. Transient Pressure Analysis for Fractured Wells. s.l., Society of Petroleum Engineers. Coenen, E. & Spicer, S., 2019. Development Specific Modeling of Hydraulic Fracture Induced Poromechanical Pressure Responses in Offset Wells. New York City, American Rock Mechanics Association. Das, P. et al., 2019. Child Well Analysis from Poroelastic Pressure Responses on Parent Wells in the Eagle Ford. The Woodlands, Society of Petroleum Engineers. Dawson, M. & Kampfer, G., 2016. Breakthrough in Hydraulic Fracture & Proppant Mapping: Achieving Increased Precision with Lower Cost. s.l., Society of Petroleum Engineers. Kahn, C. et al., 2018. Rapic Evaluation of Diverter Effectiveness From Poroelastic Pressure Response in Offset Wells. s.l., Society of Petroleum Engineers. Kampfer, G. & Dawson, M., 2016. A Novel Approah to Mapping Hydraulic Fractures Using Poromechanic Principles. s.l., American Rock Mechanics Association. Kopp, J. et al., 2019. Determining the Most Effective Diversion Strategy Using Pressure Based Fracture Maps: A Meramec STACK Case Study. The Woodlands, Society of Petroleum Engineers. Liu, G. et al., 2020. Fracture Surface Area Estimation from Hydraulic-Fracture Treatment Pressure Falloff Data. s.l., Society of Petroleum Engineers. Natareno, N. et al., 2019. Continuous Use of Fiber Optics-Enabled Coiled Tubing Used to Accelerate the Optimization of Completions Aimed at Improved Recovery and Reduced Cost of Development. The Woodlands, Society of Petroleum Engineers. Nolte, K., 1979. Determination of Fracture Parameters fromFracturing Pressure Decline. Las Vegas, Society of Petroleum Engineers. Notle, K. G., 1982. Fracture Design Considerations Based on Pressure Analysis. s.l., Society of Petroleum Engineers. Roussel, N. & Agrawal, S., 2017. Introduction to Poroelastic Response Monitoring - Quantifying Hydraulic Fracture Geometry and SRV Permeability from Offset-Well Pressure Data. s.l., Society of Petroleum Engineers. Spicer, S. & Coenen, E., 2018. Estimation of Fracture Geometries From Poroelastic Pressure Responses in Offset Wells. s.l., Society of Petroleum Engineers. Sullivan, M., Zanganeh, B., Springer, A. & Clarkson, C., 2019. Post-Fracture Pressure Decay: A Novel (an Free) Stage-Lvel Assessment Method. s.l., Society of Petroleum Engineers.