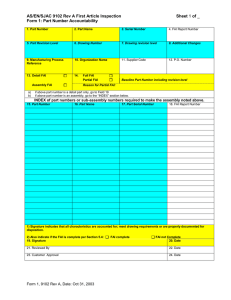

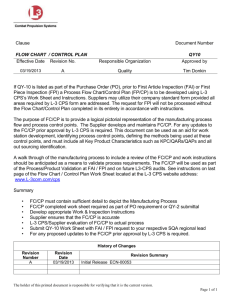

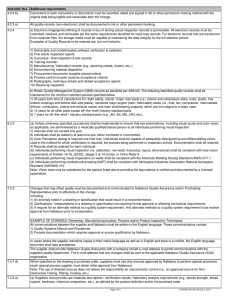

AS9102 First Article Inspection (FAI) Request Data Package submittal requirements Completed Inspection Request Form, including SQMR/SPCR numbers. Make sure you are using the latest revision of the form at the Quality webpage: http://www2.l-3com.com/cps/quality.html Copy of L-3 CPS Purchase Order, (verify B/P revision on P.O. matches the B/P revision that you are manufacturing and inspecting the parts to) Ballooned Drawing (all characteristics, including notes must be accounted for) Ballooned QAP/QAR/SQAP etc.(all characteristics, including notes must be accounted for) All Ordering Data sheets and Deviation/Waivers. (all characteristics must be accounted for) Product to be evaluated applicable for “New Part Number” FPI Review only (Reference CQ10) All original Certifications for materials and processes, including specification cancellation documents and the new Specifications 100% dimensional verification. The Ballooned Characteristic number (#) shall match the Inspection Report (#) i.e. Characteristic #1 on the Inspection Report shall be listed as Balloon #1, etc. Actual dimensional results required, “accept or OK” are not acceptable QAP / QAR / SQAP validation form (as applicable). The Ballooned Characteristic number (#) shall match the Inspection Report number (#) i.e. Characteristic number #1 on the Inspection Report shall be listed as Balloon #1, etc. Actual dimensional results are required, “accept or OK” are not acceptable. The Inspection Report must include the Inspection Method.etc. An SPCR must be submitted for any method that is different, even if it is considered to be a better method. Test Reports/ATP (as applicable) If software is utilized, provide a copy of the L-3 C.P.S. Software Approval letter A copy of Shipper/Packing Slip (not applicable for “New Part Number” Review) The shipping container and the Shipper/Pack List shall be identified per SLP2 if applicable. Copy of the Control Plan/Flow Chart (QY-10 appears on Purchase Order) L-3 Approval Letter for weld/braze (applies to casting suppliers also) Picture of Parts Marking Scan and email the entire package in one PDF document to your SQA Commodity Lead, commodity buyer agent and DLCPS-SQA@L-3com.com This material is derived from SAE AS9102A, which is copyrighted intellectual property of SAE international. SAE is not responsible for outcomes resulting from use of this material. Form 1: Part Number Accountability Sheet 1 of ___ 1. Part Number 2. Part Name 3. Serial Number 4. FAI Report Number 5. Part Revision Level 6. Drawing Number 7. Drawing revision level 8. Additional Changes 9. Manufacturing Process Reference 10. Organization Name 11. Supplier Code 12. P.O. Number 13. Detail FAI 14. Assembly FAI Full FAI Baseline Part Number including revision level Partial FAI Reason for Partial FAI: a) b) if above part number is a detail part only, go to Field 19 if above part number is an assembly, go to the “INDEX” section below. INDEX of part numbers or sub-assembly numbers required to make the assembly noted above. 15. Part Number 16. Part Name 17. Part Serial Number 18. FAI Report Number 1) Signature indicates that all characteristics are accounted for; meet drawing requirements or are properly documented for disposition. 2) Also indicate if the FAI is complete per Section 5.4: 19. Signature FAI complete FAI not Complete 20. Date 21. Reviewed By 22. Date 23. Customer Approval 24. Date Form 2: Product Accountability - Raw Material, Specifications and Special Process(es), Functional Testing Sheet 1 of ___ 2 Part Name 5. Material or Process Name 6. Specification Number 11. Functional Test Procedure Number 12. Acceptance report number, if applicable 7. Code 8. Special Process Supplier Code 13. Comments 14. Prepared By 4. FAI Report Number 3. Serial Number 1. Part Number 15. Date 9. Customer Approval Verification (Yes/No/NA) 10. Certificate of Conformance number