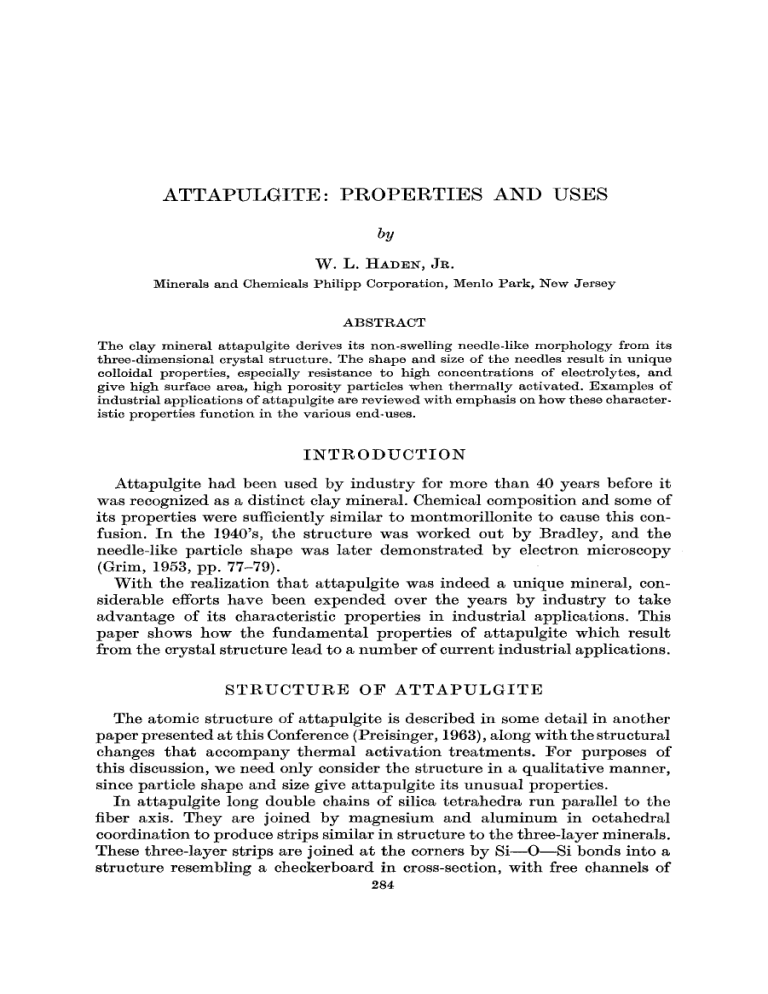

ATTAPULGITE: PROPERTIES AND USES by W. L. HADEN, JR. Minerals and Chemicals Philipp Corporation, Menlo ]?ark, New Jersey ABSTRACT The clay mineral attapulgite derives its non-swelling needle-like morphology from its three-dimensional crystal structure. The shape and size of the needles result in unique colloidal properties, especially resistance to high concentrations of electrolytes, and give high surface area, high porosity particles when thermally activated. Examples of industrial applications of attapulgite are reviewed with emphasis on how these characteristic properties function in the various end-uses. INTRODUCTION A t t a p u l g i t e h a d been used b y i n d u s t r y for m o r e t h a n 40 y e a r s before it was recognized as a d i s t i n c t clay mineral. Chemical composition a n d some of i t s p r o p e r t i e s were sufficiently s i m i l a r to m o n t m o r i l l o n i t e to cause this confusion. I n t h e 1940's, t h e s t r u c t u r e was w o r k e d o u t b y B r a d l e y , a n d t h e needle-like p a r t i c l e shape was l a t e r d e m o n s t r a t e d b y electron microscopy (Grim, 1953, p p . 77-79). W i t h t h e r e a l i z a t i o n t h a t a t t a p u l g i t e was i n d e e d a unique mineral, considerable efforts h a v e been e x p e n d e d over t h e y e a r s b y i n d u s t r y to t a k e a d v a n t a g e of its characteristic p r o p e r t i e s in i n d u s t r i a l applications. This p a p e r shows h o w t h e f u n d a m e n t a l p r o p e r t i e s of a t t a p u l g i t e which result from t h e c r y s t a l s t r u c t u r e l e a d to a n u m b e r of c u r r e n t i n d u s t r i a l applications. STRUCTURE OF ATTAPULGITE The a t o m i c s t r u c t u r e of a t t a p u l g i t e is described in some d e t a i l in a n o t h e r p a p e r p r e s e n t e d a t this Conference (Preisinger, 1963), along w i t h t h e s t r u c t u r a l changes t h a t a c c o m p a n y t h e r m a l a c t i v a t i o n t r e a t m e n t s . F o r purposes of t h i s discussion, we need o n l y consider t h e s t r u c t u r e in a q u a l i t a t i v e m a n n e r , since p a r t i c l e shape a n d size give a t t a p u l g i t e its u n u s u a l properties. I n a t t a p u l g i t e long double chains of silica t e t r a h e d r a r u n p a r a l l e l to t h e fiber axis. T h e y are j o i n e d b y m a g n e s i u m a n d a l u m i n u m in o c t a h e d r a l c o o r d i n a t i o n to p r o d u c e strips similar in s t r u c t u r e to t h e t h r e e - l a y e r minerals. These t h r e e - l a y e r strips are j o i n e d a t t h e corners b y S i - - O - - S i b o n d s i n t o a s t r u c t u r e resembling a c h e c k e r b o a r d in cross-section, w i t h free channels of 284 ATTAPULGITE: PROPERTIES AND USES 285 about 3.7 by 6.0 ~ in cross-section running the length of the needles. Preisinger (1963) has shown how these channels can collapse when attapulgite is dehydrated, for the open-channel structure is stabilized by the water of composition which completes the edges of the octahedral strips. Collapse of the channels on dehydration is the probable cause of the abrupt decrease in surface area from about 190 to 125 m2/g observed by Barrer and Mackenzie (1954), since nitrogen molecules are incapable of entering the collapsed channels. From the structure of attapulgite, it is fairly obvious t h a t two of the unusual characteristics of attapulgite should exist. First, since the structure is three-dimensional, no montmorillonite-type swelling can occur. Second, it is apparent t h a t cleavage will be easiest along the S i - - O - - S i bonds holding together the three-layer strips--hence the needle-like rather than plate-like particle shape. PROPERTIES Structure of a "Needle" The important industrially applied properties of attapulgite are a direct result of the structure just discussed. The attapulgite needle is typically about 1/z in length and approximately 0.01/z across. A model of the needle at a scale-up of one million times would look very much like a meter stick in size and shape. The channels running the length of the model would, on this scale, be only about 0.5 m m in cross-section. Only in rare instances are the tiny channels of importance in determining the properties of attapulgite. The external surface of the needles and the arrangement of the needles in gross particles are of p r i m a r y importance. I t is convenient to divide the applications of attapulgite into two broad categories, colloidal and non-colloidal. Colloidal properties result when the particles are dispersed in a liquid medium to the extent that the individual needles are capable of more or less independent motion relative to one another. In the non-colloidal case, the needles are attached to each other to give rigid particles, each of which is made up of m a n y discrete needles. Structure of a "Particle" Since attapulgite is always supplied to users in the form of powder or granules, regardless of whether the application is to be colloidal or not, the structure and properties of the aggregates should be considered first. The aggregates m a y be considered to have a haystack or brush-heap structure, in which the needles are packed loosely in a more or less random fashion. Using the meter stick model again, if meter sticks are thrown into a pile about 10 ft high, we then have a rough model of a typical 3/z particle of fluid-energy milled attapulgite, the finest grind available commercially. I t is evident that, even in the most finely-ground condition, a particle consists of an aggregate of very m a n y individual intermeshed crystallites. 286 TENTH NATIONAL CONFERENCE ON CLAYS AND CLAY MINERALS Non-colloidal Characteristics The packing of the needles in this highly porous fashion results in the properties characteristic of the non-colloidal grades of attapulgite. Although the true density of the crystal is about 2.5, the particle density is close to 1.0, and the pore volume will approximate 0.6 ml/g (McCarter, Krieger and Heinemann, 1950). The average pore diameter is of the same order of magnitude as the needle diameter, about 2004. The surface area of the particles, which is in reality the external surface area of the component needles, is about 125 m2/g. Several applications of attapulgite depend on this internal structure of the aggregate and its stability. I t is remarkable that there is little change in these properties over an enormous range of temperature up to about 1300~ although there are marked changes in the crystal structure as bound water and hydroxyls are removed (McCarter, Kricger and Heinemann, 1950). Colloidal Characteristics The colloidal nature of attapulgite does not usually become apparent until the particles are separated into individual needles. This separation becomes progressively more difficult as the heat treatment of the raw clay is made more vigorous, and when most of the bound water has been removed, the possibility of obtaining a colloidal dispersion is almost nil. Processing the colloidal grades of attapulgite therefore includes a drying step mild enough to insure t h a t little or no bound water is lost. In contrast to the swelling bentonites, which partially disperse themselves spontaneously in water owing to the swelling caused by penetration of water between the unit layers, the three-dimensional structure of attapulgite prohibits any such internal swelling action. The attractive forces between the needles in a particle are appreciable, and mechanical action is necessary to tear apart these needles (Gabrysh et al., 1961). In the laboratory, a high-speed mixer like the Waring Blendor or Osterizer, or a milk-shake mixer, is highly effective. I n commercial applications colloid mills, homogenizers, and other high-shear mixers are commonly used. Effective dispersion results when individual needles, or at least small bundles, are capable of moving relative to one another under shear. Such a dispersion in water at say 3 percent solids is highly thixotropic, having high apparent viscosity at low shear but becoming nearly water-thin under high shear. Recovery of high viscosity upon removal of high shear is almost instantaneous in pure water, and at rest a definite yield point is observed. These phenomena are indicative of a high degree of interaction between needles, so that a three-dimensional network is built up within the fluid. However, the interaction is not so strong that it resists high shear. Addition of a deflocculating agent to the suspension results in a decrease in apparent viscosity. A considerable range of flow behavior m a y result, depending on solids content and quantity of deflocculant. I t is possible to prepare a non- ATTABULGITE: PRO]?ERTIES AI~D USES 287 pourable gel which becomes almost water-thin on shaking, but which sets up again to a gel in a few minutes. A characteristic of attapulgitc t h a t makes it suitable for m a n y applications where clays such as bentonite are unsuitable is its dispersibility in the presence of high electrolyte concentrations, giving dispersions little different from those in pure water. Since electrolytes prevent the swelling of bentonite, satisfactory dispersions cannot be made under these conditions. Attapulgite is also dispersible in m a n y organic liquids, especially if a surface active agent is added to reduce the oleophobic nature of the surface. Such dispersions resemble those made in water, ranging from thin thixotropic liquids to stiff gels. APPLICATIONS A number of representative applications of attapulgite are listed in Table l, classified as to the primary function of the attapulgite. It is not possible in a short article to give details of all the many uses of attapulgite, so only a few typical applications can be discussed here. A more extensive survey is given by Grim (1962) and some applications are described in detail in technical bulletins published by the processors of attapulgite. Colloidal Applications Oil well drillingfluids.--The drilling mud circulated through a well serves the primary function of removing bit cuttings from the hole. I n addition, it lubricates the bit, prevents hole sloughing, and forms an impervious filter cake on the walls of the hole, thus preventing loss of the fluid to porous formations. Of utmost importance among the characteristics of a clay for a drilling mud is the ability of the clay to build up a suitable viscosity at a relatively low solids level, and to maintain the desired viscosity throughout the drilling of the well. Bentonite has been widely used for this purpose, but it can be used only with the help of expensive chemical treatments in areas where contaminants such as salt, calcium suffate, or magnesium sulfate are encountered. Since these contaminants prevent the swelling of bentonite, bentonite is quite ineffective in yielding or maintaining viscosity in their presence. Attapulgite, on the other hand, does not depend on swelling in order to yield viscosity and is quite stable in the presence of these contaminants; it also shows excellent stability under the high temperature conditions encountered in deep drilling in certain areas. Adhesives.--In the production of corrugated board the starch adhesives employed lose viscosity under shear, making it difficult to apply a constant amount of adhesive during a production run. As mentioned earlier, attapulgite develops viscosity under shear, so the incorporation of attapulgite has been an effective method of counteracting the loss of viscosity of the starch. Liquid suspension fertilizers.--Liquid fertilizers are furnishing an increasing proportion of the plant food consumed in the United States. Within the 288 T E N T H NATIONAL CONFERENCE ON CLAYS A N D CLAY MINERALS TABLE 1.--SOME USES OF A'2TAI'ULGITE* COLLOIDAL Actions: Viscosity building, gelling, thickening, protective colloid, suspending agent, adsorbent, bonding agent. t. Oil-base and water-base foundry sand binders 2. Adhesive viscosity control 3. Oil well drilling muds 4. Latex paint thickener and gelling agent 5. Pharmaceutical thickener and adsorbent 6. Liquid suspension fertilizers 7. Polishes--suspending agent for abrasives 8. Wax emulsion stabilizer 9. Metal drawing lubricants--suspendingagent 10. Laundry washing powders 11. Bonding agen~ for granulation of powders I~OIW-COLLOIDAL Actions : Adsorption, absorption, catalyst, mild abrasive, parting agent. 1. Petroleum refining, decolorizing, neutralizing, brightening, desulfurization, deodorizing 2. Anti-caking agent for ammonium nitrate, etc. 3. Carrier for granular and powdered agricultural chemicals (insecticides, herbicides, etc.) 4. Flatting agent in paints 5. Pharmaceutical intestinal absorbent 6. Floor absorbents 7. Animal bedding (cats, laboratory animals) 8. Polish ingredient for mild abrasive action 9. Flowability additive to dry fire extinguisher powders 10. Catalyst in NCR paper 11. Catalyst carrier 12. Olefin polymerization catalyst 13. Chromatographic adsorbent 14. Drying of oils * Technical bulletins and additional information on many of these applications are available from Minerals and Chemicals Philipp Corp., Menlo Park, N.J. last two years, liquid suspension fertilizers have b e g u n to come into prom i n e n c e because of several l i m i t a t i o n s on the t r u e l i q u i d fertilizers, which require complete solution of t h e components i n order to be useful. The r e q u i r e m e n t of complete solubility is a n obvious l i m i t a t i o n on the a m o u n t of p l a n t food available a n d further limits the producer to r a t h e r h i g h - p u r i t y c o m p o n e n t s c o n t a i n i n g no insoluble constituents. Secondary p l a n t foods a n d trace elements m ~ y also cause solubility problems. The suspension fertilizers c i r c u m v e n t these l i m i t a t i o n s of the liquids b y the simple expedient of using t y p i c a l l y 1 or 2 percent a t t a p u l g i t e to stabilize the suspension a n d p r e v e n t settling of insoluble components. A t t a p u l g i t e is the obvious choice for this application because of its highly stable colloidalproperties i n high concentrations of salts. ATTAI~ULGITE: I)ROI)EI~TIES AND USES 289 Emulsion paints.---Although there are many other colloidal applications, as indicated in Table 1, only one other application is mentioned here to illustrate additional characteristics of colloidal attapulgite. Attapulgite has been used to replace organic thickeners in emulsion paints, resulting in a much more water-insensitive film, having improved color retention on washing because of the insolubility of the attapulgite thickener. Other advantages of attapulgite are its suspending characteristics for pigments, and its thixotropic properties which reduce sag and provide easy brushing. Attapulgite also acts as an emulsion stabilizer, serving as a protective colloid. Non-Colloidal Applications Percolation adsorptive processes.--The mechanical and thermal stability and high surface area resulting from the brush-heap structure of granular attapulgite lead to its wide use as a percolation adsorbent. The relatively large pores adapt it to the removal of high molecular weight compounds, for example, the sulfonatcs, resins, and asphaltines in petroleum oils. In the decolorization and neutralizing of a petroleum oil, granular clay (30/60 mesh, for example) is first heat-activated at 500-800~ and charged to the filter shell. The oil is percolated through the bed of clay until the adsorptive capacity is reduced to the point where the efffluent oil reaches a predetermined quality level. After draining the bed, washing with naphtha, and steaming, the clay is sent to a regenerating kiln. The adsorbed organic matter is burnt off at 1000-1100~ and the clay is re-used. Most refiners use attapulgite for 10-20 cycles before discarding it. Floor absorbents.--The high porosity of attapulgite lcads to its wide use in granular form for the removal of oil, grease, and water from garage and factory floors. The pores in attapulgite are large enough to permit rapid saturation and, at the same time, are small enough to hold the liquid tenaciously by capillary action. The lack of inflammability is an obvious reason for selecting attapulgite in this application. Carrier for agricultural chemicals. The absorbent properties which make attapulgite useful as a floor absorbent also find extensive use in converting pesticides and herbicides to free-flowing granules or dusts. Many of these chemicals are liquids or sticky pastes which would be difficult or impossible to use as produced. Impregnated and absorbed within particles of attapulgite, the chemicals may be readily applied in the field. Pharmaceuticals.--Lack of toxicity and high adsorptive power have resulted in the incorporation of attapulgite in pharmaceutical preparations, including intestinal adsorbent preparations. Kaolin had previously been used almost exclusively in such preparations. It has been shown (Barr, 1957) that attapulgite is far superior to kaolin in the adsorption of alkaloids, diphtheria toxin, and bacteria. The superior characteristics were maintained following gastric juice washing. Also of interest in the pharmaceutical field is the capacity to neutralize considerable amounts of strong acid. Catalysts.--The catalytic properties of attapulgite have not been exploited 19 290 TE~TI~ NATIONAL COI~FERE~NCE ON CLAYS AND CLAY MII~ERALS t o t h e e x t e n t t h a t other p r o p e r t i e s have, a n d a d v a n c e s m a y be e x p e c t e d in t h i s field. A recent d e v e l o p m e n t has been the use of a specially-processed a t t a p u l g i t e as a coating on t h e p a p e r used in N C R ( " n o carbon r e q u i r e d " ) m u l t i c o p y business forms. I n this case, t h e a t t a p u l g i t e acts as a c a t a l y s t to c o n v e r t t h e d y e i n t e r m e d i a t e s t o t h e colored d y e s w h e n t h e e n c a p s u l a t e d i n t e r m e d i a t e s are released b y pressure (Green a n d S a n d b e r g , 1951). SUMMARY AND CONCLUSION The colloidal, a d s o r p t i v e , a b s o r p t i v e , a n d c a t a l y t i c p r o p e r t i e s of a t t a p u l gite h a v e m a d e i t widely used b y m a n y industries. T h e r e has been a s t e a d y d e v e l o p m e n t in knowledge of t h e f u n d a m e n t a l p r o p e r t i e s of a t t a p u l g i t e a n d a c o r r e s p o n d i n g l y s t e a d y g r o w t h i n its i n d u s t r i a l applications. A t t h e same t i m e , t h e p r o d u c e r s of a t t a p u l g i t e h a v e been d e v i s i n g b e t t e r processing m e t h o d s , a n d i m p r o v e m e n t s in q u a l i t y h a v e been e x p e r i e n c e d w i t h respect t o each of t h e p r o p e r t i e s described. I f t h e p a s t is a n y indication, current research will result in f u r t h e r i m p r o v e m e n t s in p r o p e r t i e s , a n d t h e n u m b e r of i n d u s t r i e s e m p l o y i n g this u n u s u a l clay m i n e r a l will continue to increase. REFERENCES Barr, Martin (1957) Adsorption studies on clays: J. Amer. Phc~rm. Assoc., v. 46, pp. 486497. Barter, R. M. and Mackenzie, N. (1954) Sorption by attapulgite: J. Phys. Chem., v. 58, pp. 560-568. Gabrysh, A. F., Ree, T:, Eyring, H., MeKee, N. and Cutler, I. (1961) Flow properties of attapulgite suspension in water: Trans. Soc. Rheol., v. 5, pp. 67-84. Green, B. K. and Sandberg, R. W. (1951) Pressure sensitive record material : U.S. Patent 2,550,471. Grim, R. E. (1953) Clay Mineralogy: McGraw-Hill, New York, 384 pp. Grim, 1%. E. (1962) Applied Clay Mineralogy : McGraw-Hill, New York, 422 pp. McCarter, W. S. W., Krieger, K. A. and Heinemann, H. (1950) Thermal activation of attapulgus clay: 1rid. Eng. Chem., 42, v. pp. 529-533. Preisinger, A. (1963) Sepiolite and related compounds: its stability and application: in Clays and Clay Minerals, this volume.