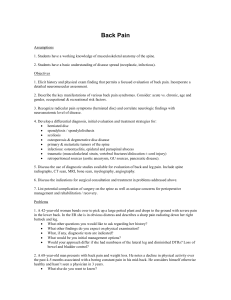

Health & Safety Training & Consultancy Risk management support services Manual Handling Training Your Name Manual Handling Instructor 1 Manual Handling Training It must cover • How to recognise risky manual handling • How to recognise potentially dangerous manual handling • The correct way of dealing with the problem • The use of mechanical aids • Good handling techniques 3 Did You Know ?` over 80% Of people In the western world are affected with back pain 4 Kinds of Accident Causing Injuries Other 12.6% Machinery 4.5% Handling 36.5% Falls 6.9% Handling Struck by Trips Falls Other Machinery Trips 19.1% Struck by 20.4% 5 Cumulative Manual Handling Injuries Back Pain Neck Shoulders Knees Feet Wrist/Elbows Hernia Overall Fatigue Many Others 6 Manual Handling Facts •Low back pain occurs with the same frequency in people with sedentary occupations as those in heavy labour •Musculo-skeletal disorders arising from work situations have an estimated annual cost in the region of 1.9 million lost work days each year costing small businesses €268 million(approx) •Smokers are more likely to suffer back pain than non-smokers •15% of Irish people are in chronic pain… Manual Handling Facts • Being overweight increases the likelihood of back pain • Age doesn’t necessarily make any difference, bad backs affect people of all ages • Poor handling techniques when you are young will contribute to problems in later life • Those who have suffered from a back injury are three times more likely to suffer injury again Back Pain Statistics Since 2000, manual handling has been the primary cause of all reportable workplace incidents to the Health & Safety Authority Four out of five adults will experience back pain at some stage 50% of people off work with back pain have a recurrence within one year 5% of back pain leads to prolonged disability Equally common among males & females Reasons for Manual Handling Training •Reduce lost working days through injury •The Law •Looking after one of the most important parts of the body •Companies Ethical & Moral responsibilities The Law & Manual Handling Whereas previous legislation set limits on the weight of loads that can be lifted, 2007 regulations require a number of relevant factors to be taken into consideration: RISK ASSESSMENT !!!!! It is a requirement of the Health & Safety Regulations that training courses have the following content: • • • • Legislation Anatomy Techniques Practicals 13 The Law Safety, Health and Welfare at Work Act 2005 and Safety, Health and Welfare at Work (General Application 2007) Regs. 14 • • • • • • • • • Employers Responsibilities A duty to manage Health & Safety Provide a safe place of work Safe plant and Equipment Safe system of work Safe competent staff Safe access and egress Information, Instruction and Training Emergency Planning Prevent risks to employees health from exposure to physical agents 16 Employees Responsibilities • To take reasonable care for the health and safety of self and others • To comply with :– The employer’s health and safety rules – Health and safety law • Not to intentionally or recklessly interfere with anything provided in the interest of health and safety 17 Duties of The Employees • Ensure that he/she is not under the influence of an intoxicant • If reasonably required by an employer to submit to testing • Report known defects in plant and /or equipment • Attend training • Not to engage in improper conduct / behaviour likely to endanger themselves or others 18 Manual Handling - Definition • Any transporting or supporting of a load by one or more employees and which may include; – – – – – LIFTING PUTTING DOWN PUSHING PULLING CARRYING OR MOVING A LOAD Which, by reason of its characteristics or of unfavourable ergonomics conditions involves risk particularly of Back Injury , to employees Regulation 68 19 What Is Manual Handling? • • • • • • • • Such as hauling on a rope Moving a trolley Pulling a lever Applying a force to manipulate a load supported on a pallet Spade / Fork in the garden Stacking a shelve or similar activity or item Picking something from the ground…. 20 Manual Handling Regulations 2007 Does not Specify maximum weights Highlights the need to avoid manual handling By taking appropriate organisational measures or by the use of mechanical equipment 21 (General Application) Regs.2007 • Regulation 69 – AVOID MANUAL HANDLING IF POSSIBLE – ID HAZARDS AND ASSESS THE RISKS • 3rd schedule – ERGONOMIC ASSESSMENT – PROVIDE INFORMATION 22 (General Application) Regs.2007 • Regulation 69 – PROVIDE ADEQUATE TRAINING – TAKE ACCOUNT OF INDIVIDUAL RISK FACTORS • 3rd Schedule – SENSITIVE RISK GROUPS PROTECTED – FOLLOW UP 23 Individual Risk Factors 3rd schedule THE EMPLOYEE MAY BE AT RISK IF HE OR SHE IS: WEARING UNSUITABLE CLOTHING WEARING UNSUITABLE FOOTWEAR NOT ADEQUATELY TRAINED NOT PHYSICALLY TRAINED GIVE EMPLOYEES INFORMATION ON WEIGHTS AND LOAD CENTRE 27 Relevant Factors Task: What is it about the way that we organise the task which might affect our health and safety? Individual Capabilities: What is it about the people who are doing the job that might affect their health and safety? Load: What is it about the load which might affect our health and safety? Environment: What is it about the place which might affect our health and safety? 28 Benefits Of Well Applied Ergonomic Principles • Less days lost through illness / injury • Safer workplace • More efficient workplace 33 Lifting and Lowering Limits Guidance for tasks performed less than 30 per hour 34 Musculo - Skeletal System MAIN POINTS • Structure • The lumbar spine • Muscles / Soft Tissue Repair • Bony Injuries • M.S.D.’s 36 ANATOMY Musculo Skeletal System •WHY ?? Matching the task to the person nAnatomy nMuscularnSkeletalnJoints nI.V. Power / Soft Tissue Structure / Hard Tissue – Hinge / Fluid – Flexibility Discs – Cushion / mobility / Nerve access Definitions Ligament Cartilage A fibrous structure which joins bone to bone A protective tough fibrous tissue covering the body of the vertebrae Joint Tendon The joining together of two or more bones for movement purposes. The bone ends are covered with cartilage Joins muscle to bone Muscle Produces Movement 39 Hard Tissue injuries… nFractures nOsteoarthritis (Inflammatory) Soft Tissue Injuries…. • Upper limb disorder • Lower limb injuries • Abdominal injuries • Lower back injuries Soft Tissue Injuries….. Upper limb nTendonitus nTenosynovitis nRotar nUpper cuff Cross Syndrome nEpicondylitis nCarpal Tunnel Syndrome Soft Tissue Injuries….. Lumber disorders Sciatica Nerve Irritation Lumber radiculopathy Spondytis Soft Tissue – IV disc Soft Tissue Injuries….. Abdominal / lower limb Hernia / Tears & strains Menscsal tears Heal spurs / Planter Fasciitis / Dropped Arch nAC n / Collateral ligament Hernia / tear / strain Soft Tissue Injury • Muscles, tendons, ligaments, joint capsules. • Can be strained or sprained, especially if not sufficiently flexible. • When a particular incident causes damage, soft tissue must suffer damage first Spinal Column 7 Cervical Neck 12 Thoracic Ribcage 5 Lumbar 5 Sacrum (fused) Lower back 4 coccyx (fused) 47 The Spine Spine - 3 main functions. To protect the spinal cord To allow movement. To support the upper body. 48 The Structure & Function of the Spine Provides a flexible connection between the upper and lower half of the body Encloses and protects the spinal cord Is involved in most movements of the trunk and limbs by providing key attachment points for muscles Has a very significant function in weight bearing but only with correct posture Is very prone to injury if used incorrectly 49 The Nerves 52 Lumbar Segment Vertebrae (Bone) Facet Joint Disc 53 The Spine • Each vertebrae is separated by a gel like substance, the disc. These discs bend and stretch as we move 54 Functions of the Disc • These functions are to: – CUSHION SHOCK – ALLOW SPINAL MOVEMENT – SEPARATE THE BONES – ALLOW NERVES TO EXIT 55 Structural Features Annulus fibrosus Nucleus pulposus 58 Slipped Disc • A slipped disc is also called a “herniated or prolapsed” disc • It is a bulge in the wall of one of the discs between the vertebrae pressing onto the nerve 59 Forward Bending and to One Side 60 Disc Damage Normal Disc Prolapsed Disc 61 Herniated Disc "Superior View" Leaking pulposus puts pressure on nerves exiting from spinal cord 62 63 Disc Prolapse • Spine loaded in bent forward position • Disc is wedged at front • Jelly-like substance is forced backward or back/ laterally. • This substance forces through fibrous rim resulting in disc prolapse • This process can happen gradually when a poor posture is habitually adopted during lifting. 67 NERVOUS SYSTEM • Sciatic 68 Soft Tissue Injuries • These include injuries to: – MUSCLES – TENDONS – LIGAMENTS 70 Mechanical Back Injury • Causes of mechanical back injury when handling or lifting – POOR POSTURE – POOR TECHNIQUE – CARELESS ACTIONS – FAILURE TO ASSESS 71 • Ligaments 72 Soft Tissue Injury • Muscles, tendons, ligaments, joint capsules. • Can be strained or sprained, especially if not sufficiently flexible. • When a particular incident causes damage, soft tissue must suffer damage first 73 Major Back Muscle Groups 74 Skeletal Muscle Posture Muscle • Short Fibres • Contract Slowly • Use Ready oxygen, red in colour • Slow Chemical Turnover • High Endurance Action Muscle • Long Fibres • Contract Quickly • Use stored Chemical Energy. White in colour • Fast Chemical Turnover • Tire Easily 75 Postural Muscles Maintain position / posture Trunk muscles 76 Causes of Back Pain Not just caused by heavy work and heavy weights Can be due to: Poor static posture Sitting too long in one position Sudden movement Vibration during handling Psychological stress 77 INJURIES CAUSED BY MANUAL HANDLING ARE RARELY FATAL, BUT…. Can cause permanent disability 78 Mechanism of Injury MECHANISM OF INJURY • Three types of mechanical back injury which may be caused by poor manual handling practice – SOFT TISSUE INJURY – BONY INJURY – DISC INJURY 79 Flexibility MAIN POINTS • Fitness • Flexibility / Tightness • Posture • Stretching 82 Most Susceptible to Injury n Early in the shift u NOT WARMED UP n Lunch-time u LOW GLUCOSE n End of day u TIRED 84 Elements of Stretching Stretch EASY DEVELOPMENTAL DRASTIC A sudden drastic stretch can be painful and can damage tissue NEVER DO A DRASTIC STRETCH! 85 Reasons why we should be Flexible • To prevent injury • To increase the range of joint movement • To help improve co-ordination 88 89 THE EIGHT PRINCIPLES OF MOVEMENT AND HANDLING 90 Principles of Lifting • • • • • Assess the task - area / load Broad stable base (Feet Flat on the Floor) Bend the knees Back straight - Not necessarily vertical Firm grip with palm of hand – Palmar grip • Arms in line with trunk • Weight close to centre of gravity • Turn feet in direction of movement 91 1.Stop and Think 92 Assessment • The Area: – CLEAR OF OBSTACLES – SURFACE- SMOOTH OR SLIPPY – ADEQUATE WORKING SPACE – GIVE SELF STRAIGHT ON APPROACH – LIGHTING 93 Assessment • The Load – THE WEIGHT – SIZE – SHARP CORNERS – CAN YOU LIFT IT ON YOUR OWN OR DO YOU NEED HELP – IS A MECHANICAL AID NEEDED – STABILITY 94 2.Place the feet 95 Broad Stable Base • Feet hip distance apart • Feet firmly on floor • Provides stability 96 3.Get a Firm Grip 97 4.Don’t Jerk 98 Bending the Knees • Puts quadriceps muscles in mid range • Reduces distance between body to load thus putting the load within reach • Reduces compressive forces on the spine • Focuses the lift with the legs 99 Back Straight • • • • • • Not necessarily erect Neutral spine Curves reduced Opposing muscles in mid range Structural benefits Lift with legs/knees bent 100 Firm palmar Grip • • • • • • Power via palm of hand Fingers are not for weight bearing Firm contact Arms guide Hands grip Lifting with the legs 101 Arms in line with trunk • • • • • Avoids lifting with outstretched arms Minimises weight of load Closer to centre of gravity Provides greater stability Encourages the legs to do the work 102 Weight close to the centre of gravity • Avoids outstretching • Minimises the weight of the load • Reduces forces on the spine 103 5.Move the Feet, Keep Close to the Load 104 Feet in the direction of movement • • • • • Straight on approach Avoids bending and twisting movements Lift in smooth and controlled manner Maximises base of support Minimises weight transfer 105 6.Put down, Then adjust 106 Manual Handling Principles • Stay balanced • Keeping your centre of gravity close to the load’s centre of gravity • Bending from the knees • Keeping the back straight, and head up • Staying compact when pushing • Moving the feet to turn, not the body • Moving smoothly, particularly when setting loads down 107 Important • Knowledge and training alone will not guarantee safe handling • A risk assessment needs to be undertaken • Avoid if possible • Know your own limits • Put training into action at work as well as home 109 REMEMBER PREVENTION IS BETTER THAN CURE 110 Hurt at Work • You've carefully thought out all the angles. • You've done it a thousand times. • It comes naturally to you. • You know what you're doing, its what you've been trained to do your whole life. • Nothing could possibly go wrong, right ? 111 Think Again! 112 113 WRONG CORRECT 114 MANUAL HANDLING TECHNIQUE 115 The Command for Lifting Prepare to Lift Get yourself and equipment ready and positioned and Take the Strain LIFT... Move 117 PUSHING 118 PUSHING WRONG CORRECT 119 MANUAL HANDLING GOOD HANDLING RULE 1: If you think that you cannot manage to move the Load GET HELP ! 120 MANUAL HANDLING GOOD HANDLING RULE 2: You must always be in charge of the Load, never the load in charge of you. 121 Principles of Lifting • • • • • Assess the task - area / load Broad stable base (Feet Flat on the Floor) Bend the knees Back straight - Not necessarily vertical Firm grip with palm of hand – Palmar grip • Arms in line with trunk • Weight close to centre of gravity • Turn feet in direction of movement 122 MANUAL HANDLING PRACTICAL TRAINING Lifting: Floor to Floor Floor to Bench Bench to Floor Bench to Height Pushing Pulling 124 Principles of Lifting • • • • • Assess the task - area / load Broad stable base (Feet Flat on the Floor) Bend the knees Back straight - Not necessarily vertical Firm grip with palm of hand – Palmar grip • Arms in line with trunk • Weight close to centre of gravity • Turn feet in direction of movement 125