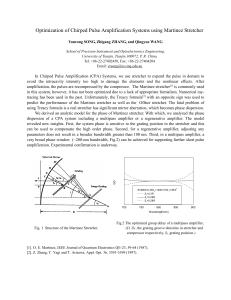

Hill-Rom Stretcher Service Manual: P8000, P8005, P8010, P8020, P8040, P8050

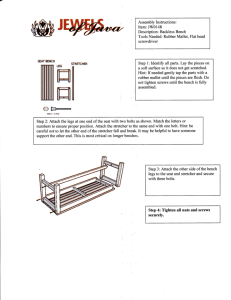

advertisement