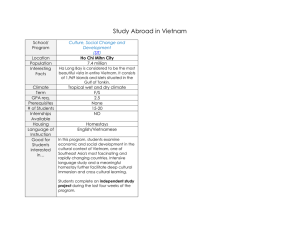

VIETNAM AUTOMOBILES AND AUTO PARTS INDUSTRY REPORT TABLE OF CONTENTS 03 54 Executive summary Entry landscape 07 55 Automobiles market overview Domestic auto parts manufacturers 14 69 Auto parts market overview Entry barriers 15 76 Business Environment Collaboration landscape 15 Government policy 27 Trade agreements 29 Market features 38 Hai Phong Industrial complex 43 Quang Ninh Industrial complex 48 Chu Lai Industrial complex VIETNAM AUTOMOBILES MARKET REPORT 82 Appendix: Financial statements 2 보고 요약 핵심 요약 – 1. 베트남 자동차 산업 현황 Automobile production in Vietnam, 2014 – 9M/2020 1 산업내 가치사슬 중 부가가치가 가장 낮은 Thousand units 300.0 120% 102.8% 100% 250.0 단계 영위 중 80% 200.0 2 완성차 조립의 마지막 부분에 집중 (OEM 일본 5, 미국 2, 베트남 합작사 3 등) 150.0 4 0% -14.2% 50.0 인근국가(태국, 인도네시아) 대비 약2.6배 작은 규모의 완성차 소비 시장 126.1 255.8 256.4 219.9 272.0 284.2 181.4 2014 2015 2016 2017 2018 2019 9T/2020 9M/2020 Production volume Thousand units 300.0 ‘20년 9개월간 완성차 18.1만대 조립생산 vs Growth 120% 100% 250.0 80% 60% 32.4% 3.3% 20% 0.8% 0% 254.8 209.5 277.3 279.5 174.9 -17.8% 246.7 50.0 40% 124.5 동기비 30.5% 감소 2014 2015 2016 2017 2018 2019 9T/2020 9M/2020 - -20% -40% Consumption volume 3 -40% Source: VIRAC, VAMA 98.1% 150.0 ‘20년 9개월간 수입차 소비 65,074대로 전년 -20% Vietnam automobile consumption, 2014 – 9M/2020 200.0 17.5만대 소비 VIETNAM AUTOMOBILES MARKET REPORT 20% 4.5% 0.3% 100.0 5 40% 23.7% 100.0 - 3 60% Growth Source: VIRAC, VAMA 보고 요약 핵심 요약 – 2. 베트남 자동차 부품시장 Completed auto parts production volume, 2014 - 9M/2020 1 Million units 12,000 Tier 1 : 83개사 (순정부품 제조업체 21개사 포함) Tier 2, 3 : 138개사, 기타 178개사 450.1% 500% 400% 10,000 300% 8,000 2 200% 일본 부품업체가 부품제조시장 주도(개사) : 6,000 100% 28.3% 일본(177), 베트남(136), 대만(57) 등 4,000 -10.1% -8.0% 0% -86.8% 2,000 3 다수의 기업이 오토바이 부품과 자동차 0 -100% 1378.1 7581.0 9729.0 1288.1 1158.2 1065.9 2014 2015 2016 2017 2018 2019 Production volume 부품의 혼합 생산 806.9 -200% 9T/2020 9M/2020 Growth Source: VIRAC, GSO Production of components and spare parts, 9M/2020 Other spare parts for motor vehicles 4 자동차 부품 소비량 : ‘20년 9개월간 부품 8억690만개 소비로 동년비 26.3% 감소 1.37% 1.50% 2.95% 0.86% 3.21% Ignition wire sets and other harnesses used in motor vehicles Other equipment used by motor vehicles 9.68% Other audio signal equipment Airbag 5 현재의 부품생산 현지화율은 10%대로 낮은 상황 80.42% Gear box Starter-generator Source: VIRAC, GSO VIETNAM AUTOMOBILES MARKET REPORT 4 보고 요약 핵심 요약 – 3. 산업 발전 가능성 Localization rate of key auto parts OEMs in Vietnam, 2019 1 2 현대타잉콩, 타코, 빈패스트 Company’s 등 베트남 가계소비지출 증가, 베트남 정부의 강력한 자동차 산업 육성 의지와 우대정책 전개 등록비 50% 인하 조치 단행 자동차 소유비율 상승여지 풍부 4 USD 200 Bus Target 15% - 18% 15 - 18% 35 45% 60% 60% ~12% 35% (Hyundai Accent) 40% ~25% 30% (Honda City) 15% (Honda CR-V) 40% ~20% 37% (Innova) 45% Less than 10% Less than 10% (Fadil) 60% Average income and spent per month, 2010 – 2019 180 : 166.9 160 (대/1천명) 베트남 16, 인도네시아 55, 태국 196, 113.5 120 100 80 60 베트남 정부와 현지 완성차 제조 및 조립업체들의 59.7 52.1 86.1 69.0 81.3 109.6 116.6 92.9 40 강력한 부품현지화율 제고 의지 20 0 2010 2012 2014 Average Income VIETNAM AUTOMOBILES MARKET REPORT 180.8 133.4 140 말레이시아 341 5 Truck 자동차 제조 및 조립 업체 성장 중 ‘20년7월부터 베트남내 제조 및 조립된 자동차의 3 Passenger cars average 5 2016 Spent per month 2018 2019 Source: VIRAC, GSO 보고 요약 핵심 요약 – 4. 우리기업 진출전략 포인트 10여개의 완성차 제조 및 조립공장 위치 감안 : 주로 1 Vinh Phuc 북부(하이퐁-빈패스트, 빈푹-토요타, 혼다, 닌빈& 꽝닌- Ninh Binh 현대 타잉콩)와 중부(꽝남-타코)에 집중 Hai Phong Da Nang 소규모 분산 제조, 부품 공급업체 부족, 숙련인력 2 Quang Nam 부족으로 인한 높은 제조 비용 감안 필요, 인근국가 대비 생산비용 약20% 고가 Binh Duong 3 Dong Nai 젊은 인력과 저렴한 인건비 활용 가능, 베트남 정부의 자동차 산업 육성 의지 강력 Can Tho Automotive designed capacity in Vietnam 4 5 OEMs Existing capacity 2019 Planned new capacity 2020 Expected total capacity 2025 Thaco 207 120 327 TC Motor 102 150 252 베트남내 소비시장 겨냥과 병행한 아세안 Honda 10 10 20 역내 생산거점 구축 전략 동시 구사 Toyota 50 20 70 VinFast 250 250 500 Total 619 550 1,169 현지업체와의 합작투자를 통한 점진적인 중기적 진출 전략 VIETNAM AUTOMOBILES MARKET REPORT 6 Source: VIRAC VIETNAM AUTOMOBILES MARKET OVERVIEW 7 1.1. Automobiles market overview Automobile production in Vietnam, 2014 – 9M/2020 Thousand units 300.0 120% 102.8% 100% 250.0 80% 200.0 60% 150.0 40% 23.7% 100.0 20% 4.5% 0.3% 0% -14.2% 50.0 - -20% 126.1 255.8 256.4 219.9 272.0 284.2 181.4 2014 2015 2016 2017 2018 2019 9T/2020 9M/2020 Production volume -40% Growth Source: VIRAC, GSO In the first 9 months of 2020, the number of cars produced and assembled nationwide reached 181.4 thousand units, a sharp decrease of 48.7% compared to the same period in 2019. There were many factors affecting volume of domestic car production: • In the first and second quarters, the effects of the epidemic on the entire production chain already took it toll on Vietnam's imports. Moreover, many large automobile manufacturers in Vietnam such as Ford, Toyota, Honda and TC Motor all had to stop production during March. Though some Thaco facilities are still operating, workers and production chain are still under social distancing. This is the main reason for the significant decline in car production • Since the end of June, with support from the government by reducing 50% of registration fee compared to previous amount and extending payment term for excise tax, a new door of opportunities has opened for domestic automobile production. According to the Ministry of Industry and Trade, car consumption in 2020 will decrease, but only by 3 - 5% compared to 2019. Therefore, many car manufacturers including FDI enterprises are considering maintaining operation, or even expanding production in the context of the government’s support. VIETNAM AUTOMOBILES MARKET REPORT 8 1.1. Automobiles market overview In the first 9 months of 2020, the total car consumption of the entire Vietnam domestic automobile consumption, 2014 – 9M/2020 Thousand units 300.0 120% 98.1% 100% 250.0 80% 200.0 60% 32.4% 150.0 3.3% 100.0 20% 0.8% 246.7 254.8 209.5 277.3 279.5 174.9 -17.8% 124.5 50.0 40% 2014 2015 2016 2017 2018 2019 9T/2020 9M/2020 - Consumption volume Growth domestic market reached 174.9 thousand units, a sharp decrease compared to the same period in 2019. After the surge from the second half of 2018 to the end of 2019, domestic demand for cars has been negatively affected by the epidemic. Luxury goods such as cars will suffer even more in the context of all goods stagnation; only a few essential items can maintain steady sales. All VAMA members recorded a plunge in sales; many businesses had to 0% stop production and close local car dealerships to avoid incurring losses. To -20% cope with decreasing demand, companies simultaneously reduced prices to -40% stimulate demand with preferential packages of up to thousands of USD. In addition, VAMA also proposed to the government to be exempt from Source: VIRAC, GSO registration tax to incentivize automobile businesses. Automobile consumption by type, 2019 – 9/2020 Units 40,000 35,000 30,000 333 8,917 25,000 580 20,000 15,000 10,000 5,000 377 863 5,781 511 584 7,345 6,649 319 460 6,812 176 3,300 22,528 19,624 14,362 7,228 7,203 7,959 20,287 19,394 226 291 5,964 6,079 27,396 6,532 365 331 20,916 21,355 22,314 15,228 24,823 223 2,757 12,807 8,958 333 4,812 372 262 5,711 5810 313 3,652 12,471 13,071 13,009 309 339 6,109 6,133 17,584 17,593 6,396 270 4,966 20,630 15,419 7,796 0 01/2019 02/2019 03/2019 04/2019 05/2019 06/2019 07/2019 08/2019 09/2019 10/2019 11/2019 12/2019 01/2020 02/2020 03/2020 04/2020 05/2020 06/2020 07/2020 08/2020 09/2020 Passenger cars VIETNAM AUTOMOBILES MARKET REPORT Commercial vehicles 9 Special-purpose vehicles Source: VIRAC, VAMA 1.1. Automobiles market overview FAVORITE VEHICLE TYPES CONSUMPTION BY REGION North Favorite vehicle type: • Sedan, Hatch back, Crossover • Pick-ups, Van, Truck Central Favorite vehicle types: • SUV • Pick-ups, Heavy truck South South Favorite vehicle types: Source: VIRAC • SUV, MPV (Multi Purpose Vehicle) • Light truck VIETNAM AUTOMOBILES MARKET REPORT 10 1.1. Automobiles market overview Automobile consumption by origin, 2019 – 9M/2020 Thousand units 40,000 35,000 30,000 25,000 14,711 13,459 12,539 12,211 20,000 11,358 10,773 11,391 6,947 12,542 13,251 9,426 8,155 8,889 15,000 5,919 7,276 7,977 7,786 7,986 6,188 10,000 5,000 18,799 4,749 19,769 14,047 15,269 16,162 15,275 16,994 12,594 16,406 16,595 19,700 4,361 9,599 7,685 11,697 11,878 7,400 15,874 16,088 11,095 17,826 12,869 0 01/2019 02/2019 03/2019 04/2019 05/2019 06/2019 07/2019 08/2019 09/2019 10/2019 11/2019 12/2019 01/2020 02/2020 03/2020 04/2020 05/2020 06/2020 07/2020 08/2020 09/2020 Domestic Import Source: VIRAC, VAMA • In 2019, the ATIGA agreement reduced the tax on imported CBU cars from ASEAN to 0%, causing a mass of imported CBU cars to flood into Vietnam. The proportion of car consumption has also shifted very unfavorably for locally assembled and manufactured vehicles. In 2018, the consumption of imported cars only reached 25% of the total volume of cars, but by 2019, this rate reached 41.2%. • Until early 2020, the car market is bleak; the volume of CBU imported cars, though cheap, still plummeted due to a decrease in demand. According to VAMA in the first 9 months of 2020, Vietnam consumed 65,074 CBU imported cars, a decrease of 30.5% compared to the same period in 2019. • In addition to the joining of VinFast, Toyota Vietnam has recently returned to the domestic assembly of the Fortuner model after 2 years of import. Accordingly, Toyota will buy more land to expand the factory as well as build a test track, aiming to increase capacity to 90,000 cars/year by 2023. VIETNAM AUTOMOBILES MARKET REPORT 11 1.1. Automobiles market overview VAMA’s automobiles consumption by region, 9M/2019 – 9M/2020 Units Units 60,000 VAMA’s automobile types consumption by region, 9M/2020 120,000 100,000 80,000 55,312 53,499 50,000 98,626 88,390 40,000 74,728 74,041 30,000 60,000 40,000 20,000 32,189 20,338 18,325 18,185 23,768 20,000 10,000 0 0 5,110 544 North Central 9M/2019 9M/2020 South North Source: VIRAC, VAMA Passenger cars 891 333 Central Commercial vehicles South Special-purpose vehicles Source: VIRAC, VAMA In the first 9 months of 2020, car sales decreased steadily in all 3 regions, North, Central and South. Total car sales of VAMA in all 3 regions only reached 172,537 cars, a decrease of 21.3% as compared to the same period in 2019. • The North recorded consumption of 74,041 vehicles, a decrease of 16.2% year-on-year. • Central Vietnam only achieved sales of 23,768 units, down by 26.2% compared to the same period in 2019, the sharpest decrease among the 3 regions. This is the region with the lowest car consumption in the country. • The Southern region reached 74,728 units, a decrease of 24.2% compared to the same period in 2019. • The consumption structure of vehicles has not changed much, with the highest consumption still being passenger cars due to high demand for individual vehicles; followed by commercial vehicles with trucks, pickups and buses, and finally specialized vehicles, which are mostly garbage trucks. VIETNAM AUTOMOBILES MARKET REPORT 12 1.1. Automobiles market overview Sales of top 10 best-seller automobiles in Vietnam, 9M/2020 Toyota Vios 19,120 2,912 Hyundai Accent 12,778 1,871 Hyundai Tuson 6,682 1,671 VinFast Fadil 6,461 1,515 Ford Ranger 8,101 1,500 Hyundai SantaFe 7,030 1,491 Mitsubishi Xpander 9,906 1,470 Hyndai Grand i10 10,101 1,313 VInFast Lux SA2.0 1,307 Mazda CX-5 6,380 1,267 0 5,000 10,000 9M/2020 VIETNAM AUTOMOBILES MARKET REPORT 13 15,000 20,000 25,000 9/2020 Source: VIRAC, VAMA 1.2. Auto parts market overview Completed auto parts production volume, 2014 - 9M/2020 • Million units tech spare parts such as wheel rims, exhaust pipes, brakes, 450.1% 12,000 and shock absorbers, so output has decreased significantly. 500% The aforementioned parts are in large quantity but bring 400% 10,000 little added value, so businesses turned to concentrated production of other types of components, both for 300% 8,000 domestic service and for export. 200% 6,000 100% 28.3% -10.1% 4,000 -8.0% -86.8% 2,000 0 Since 2017, Vietnam stopped producing a number of high- 1378.1 7581.0 9729.0 1288.1 1158.2 1065.9 806.9 2014 2015 2016 2017 2018 2019 9T/2020 9M/2020 Production volume • components and spare parts reached 806.9 million units, 0% a sharp decrease of 26.3% compared to the same period -100% in • 2.95% 0.86% during March, The average localization rate of Vietnam's auto industry in import price. Even the big business like THACO only achieved 15-18% of the localization rate. • Within the structure for complete auto parts, other motor vehicle parts account for the largest share with more than 80% of output. These are small components Airbag that do not have high expertise. Gear box • It is clear that the domestic production of auto parts is still limited in the variety of products; moreover, some high-tech Starter-generator spare parts have stopped production, leading to higher Source: VIRAC, GSO VIETNAM AUTOMOBILES MARKET REPORT pandemic so the domestic production cost of parts is higher than the Other spare parts for motor vehicles Other audio signal equipment 80.42% the production is still low, leading to a small scale of production, Other equipment used by motor vehicles 9.68% of ASEAN countries. This is because Vietnam's automobile Ignition wire sets and other harnesses used in motor vehicles 3.21% Because 2019 reached 10%, which is very low compared to other Growth Production of components and spare parts, 9M/2020 1.50% 2019. production stalled, and market demand also decreased. -200% Source: VIRAC, GSO 1.37% In the first 9 months of 2020, Vietnam's production of 14 import of auto spare parts every year to meet the demand of domestic automobile manufacturing and assembling industry. 1.3. Business Environment – Government policy Important regulatory environment in Vietnam automobile industry, 2003 – 2020 Time Event Content Cars with 7 or less seats (except passenger car business) and motorbikes of 2003 Change of registration fee organizations and individuals in provinces are charged the vehicle first registration fee of 5%. • 2004 Increase in special consumption tax • Approval for importing new • Increase special consumption tax from 5% to 24% • New CBU cars are allowed to be imported into Vietnam with 100% import tax rate CBU cars 2005 Increase in special consumption tax • in special consumption tax 2006 • 2007 Increase Reduction in import tax 3 times reduction in import tax Increase special consumption tax from 24% to 40% • Increase special consumption tax from 40% to 50% for cars with less than 5 seats • 7-seat car is only subject to 30% tax • Car import tax is reduced from 100% to 90% Impact Pushing the cost of buying a car by 5-8% Vehicle decreased by 26% Vehicle VIETNAM AUTOMOBILES MARKET REPORT 15 consumption decreased by 32% Cars with less than 5 seats will cost an extra 3,000 5,000 USD When Vietnam joins the WTO, all types of CBU cars are reduced import tax in 3 Domestic times from 90% to 80%, 70% and 60% consumption down car prices cool 1.3. Business Environment – Government policy Important regulatory environment in Vietnam automobile industry, 2003 – 2020 Time Event • 2008 Content • 2 times increase in import tax • Increase import tax for the first time from 60% to 70%, and the second to 83% • Increase in registration fees • Increase the registration fee from 10% - 15% • Amend special consumption • Car excise tax is charged by cylinder capacity, rather than seats tax law 2009 New registration fee • New excise tax goes into New registration fee is 12% effect 2011 car prices increased • The volume of imported cars increased sharply before the tax increase Domestic car prices increased Increase the registration fee bracket • Domestic decision took effect • • Impact Tighten the imported Increase the registration fee bracket from 10 - 15% to 10 - 20% Domestic car prices increased vehicle 2014 Import tax reduction Changing 2016 calculating the Import duties from ASEAN countries are reduced to 50% method excise tax of on imported vehicles. Import tax reduction. The calculation of excise tax changes from cost to wholesale price, i.e. cost of goods plus shipping costs, advertising, sales and profitability of the business. Reduce tax on cars imported from ASEAN to 40% VIETNAM AUTOMOBILES MARKET REPORT 16 The amount of imported cars surged Domestic car prices increased 1.3. Business Environment – Government policy Important regulatory environment in Vietnam automobile industry, 2003 – 2020 Time 2017 Event Content • Tighten the imported vehicle • Decree 116 tightens the business conditions of automobile importers • Support domestic car • In Decree 125, the import tax on automobile parts will be reduced to 0% if they assembly enterprises 2018 meet the conditions set out by the government Impact The number of imported cars fell sharply Import tax reduction Decree Reduce tax on cars imported from ASEAN to 0%. Passenger cars with 9 seats or less 116 Special with a cylinder capacity of 2.0 liters or less will receive a 5% discount on the special The number of imported consumption tax is based on consumption tax. Models with engines with a cylinder capacity of more than 2,500cc cars plummeted cylinder capacity - 3,000cc are subject to a 5% increase in special consumption tax takes effect. Promulgating the roadmap for the application of emission standards is issued for cars in traffic and imported used cars. 2019 Decree No.16/2019/QD-TTg • For cars produced before 1999: level I • For cars produced between 1999 – 2008: level II • For cars produced after 2008: level II • For imported used cars: level IV • 50% reduction in registration fees for domestically-produced or assembled • Sustainable growth in number of automobiles • Reduce pollution • vehicles 2020 • Decree 70/2020/ND-CP • Decree 109/2020/ND-CP • Decree 57/2020/ND-CP • consumption increased Extension of the deadline for the payment of special consumption tax on • domestically produced and assembled cars till the end of 2020 • domestically produced for the production, processing (assembly) of supporting products Imported cars had to cut profits to increase promotion to compete Import tax rate of 0% for raw materials, supplies and components that cannot be VIETNAM AUTOMOBILES MARKET REPORT Automobiles • Domestic auto industry was greatly supported 17 1.3. Business Environment – Government policy Conditions for manufacturing and assembling enterprises: Decree No. 116/2017/ND-CP dated October 17, 2017 providing for the conditions for production, assembly, import and provision of warranty and maintenance services for all types of cars, effective from the date of signing. Automobile production and assembly conditions: Enterprises established in accordance with the law shall be granted certificates of eligibility for automobile production and assembly when they meet the following conditions: • Infrastructure: a) Enterprises must have legal rights to factories, assembly technology lines, welding lines, paint lines, product quality control lines and automobile test lines that meet minimum requirements in Appendix I enclosed herewith; b) Have an automobile warranty and maintenance facility owned by the enterprise, or leased by the enterprise, or under the authorized agent system of the enterprise that satisfies the provisions of this Decree. • Persons in charge of techniques of automobile production and assembly lines must have a university or higher degree in mechanics and automobiles, and have at least 5 years' experience in automobile manufacture and assembly. • Having sufficient human resources and plans to ensure occupational safety and sanitation in accordance with the law. • Satisfying the conditions of fire prevention and safety in accordance with the law on fire prevention. • Having documents on environmental protection for automobile production and assembly plants that have been approved by agencies in accordance with the law on environmental protection. Transition terms: • The operating automobile production and assembly enterprises may continue operating for 18 months from the effective date of this Decree. After this time, automobile production and assembly enterprises must fully satisfy the conditions specified in this Decree. VIETNAM AUTOMOBILES MARKET REPORT 18 1.3. Business Environment – Government policy General provisions on automobile import business: • Only enterprises can be considered for granting a business license to import cars. • Enterprises are entitled to import cars after satisfying the conditions and being granted automobile import business licenses are specified in this Decree. • Automobile importers must comply with the regulations on automobile import management in this Decree and other relevant legal documents. Conditions for car import business: Enterprises established in accordance with the law shall be granted the automobile import business license when meeting the following conditions: • Have car warranty and maintenance facilities owned by the enterprise, or leased by the enterprise, or under the authorized agent system of the enterprise that meet the provisions of this Decree. • There is a written certification or documents proving that the enterprise has the right to act on behalf of the foreign automobile manufacturer and assembly enterprise to recall imported cars in Vietnam. Transition terms: • The car import business will comply with current regulations until December 31, 2017; • From January 1, 2018, enterprises are only allowed to import cars after being granted a license to import cars according to the provisions of this Decree; • Regardless of the provisions specified at point a, Clause 2 of this Article, enterprises satisfy the conditions specified in this Decree and have the license for automobile import business granted by the Ministry of Industry and Trade before December 31, 2017 is entitled to import cars from the effective date of the License for import business. VIETNAM AUTOMOBILES MARKET REPORT 19 1.3. Business Environment – Government policy Do not test cars below Euro 4 emissions standards • From January 1, 2018, the Vietnam Registry Department stopped receiving the registration, granting technical safety certificates for cars manufactured, newly assembled, or imported, using diesel fuel with unsatisfactory emissions standard Euro 4 and below. The reason is to follow the instructions of the Prime Minister in Document No. 436 dated March 28, 2017, and of the Ministry of Transport on the implementation of the roadmap for applying emission standards for cars and motorcycles. • Accordingly, from January 1, 2018, all new manufactured, assembled and imported cars must meet level 4 emission standards by the provisions of Decision No. 49 to be inspected and issued circulation certificate. For vehicles using diesel fuel, automobile importers, manufacturers, and assemblers must have import and production plans to ensure the completion of customs procedures, registration before December 31, 2017. After this time if not completed, the vehicle must be reexported or exported. Reduce special consumption tax for cars below 2.0L • According to the roadmap for adjusting the special consumption tax passed by the National Assembly at the 11th session of the 13th National Assembly. From January 1, 2018, cars with 9 seats or less, equipped with engines below 1.5L will apply the special consumption tax of 35%. • Meanwhile, the special excise tax on cars equipped with engines that have a capacity of fewer than 2.0 liters will be 40%, a decrease of 5% compared to 2017. This will partly affect the car prices from 2018. VIETNAM AUTOMOBILES MARKET REPORT 20 1.3. Business Environment – Government policy Auto part manufacturers in Vietnam are entitled to enjoy incentive policies offered by the Government in accordance to Decree 111/2015/ND-CP dated on 3rd November 2015. Some key incentive policies: Corporate income tax Import tariff import tariff applied Surface water/land rent for Provincial Corporate income tax (CIT) is set 0% at 10% for 15 years (compared to machines/ equipment imported to shall provide further incentives for granted standard CIT rate of 20%) create fixed assets of the auto part large interest projects projects beside the Government’s auto People’s part Committees Preferential credit policy manufacturing rent exemption/reduction policy. VIETNAM AUTOMOBILES MARKET REPORT 21 Auto part manufacturers shall be loans rates at preferential from the Government’s funding resources 1.3. Business Environment – Government policy Changing the regulations on the price to calculate the special consumption tax on imported vehicles under 24 seats. ❖ Before January 1st, 2016: ➢ Producers: Price to calculate the special consumption tax = Factory price (including production and sales costs + profit) ➢ Exporters: Price to calculate the special consumption tax = CIF price + import tax ❖ Since January 1st, 2016: According to Decree No.108/2015/ND-CP, the price to calculate the special consumption tax on automobile is: ➢ Producers: Price to calculate the special consumption tax = Factory price (including production and sales costs + profit) *The factory price is not lower than 105% of the price of commercial retailers. ➢ Exporters: Price to calculate the special consumption tax (wholesale price) = Cost of goods sold + costs (shipping, advertising, sales) + profit *In which the wholesale price is not lower than 105% of the cost of goods sold. With the calculation of special consumption tax based on the wholesale price of importers will help curb the commercial fraud and the situation of transferring price through marketing, product promotion costs or declaring the business income tax to pay less (the special consumption tax for automobile is 45-60% while business income tax is only 22% of profits). At the same time, this provision would cause the price of imported automobiles to increase by at least 5% of the current price, which is advantageous for companies distributing locally assembled vehicles, also bringing long-term benefits due to the development of domestic production. Besides, in 2018, the tax rate on imported CBU automobiles will be 0%, while the import tariff on component still remain 20-25% (depending on components and the import market), keeping the current calculation of special consumption tax will cause the amount of taxes paid on CBU vehicles to fall sharply, making them be more advantages than domestically produced items. Therefore, the tax rate must be in line with the CKD parts for businesses to maintain local production, instead of collecting foreign currencies to import. VIETNAM AUTOMOBILES MARKET REPORT 22 1.3. Business Environment – Government policy Auto part manufacturers in Vietnam are entitled to enjoy incentive policies offered by the Government in accordance to Decree 111/2015/ND-CP dated on 3rd November 2015. Some key incentive policies: Corporate income tax Import tariff import tariff applied Surface water/land rent for Provincial Corporate income tax (CIT) is set 0% at 10% for 15 years (compared to machines/ equipment imported to shall provide further incentives for granted standard CIT rate of 20%) create fixed assets of the auto part large interest projects projects beside the Government’s auto People’s part Committees Preferential credit policy manufacturing rent exemption/reduction policy. VIETNAM AUTOMOBILES MARKET REPORT 23 Auto part manufacturers shall be loans rates at preferential from the Government’s funding resources 1.3. Business Environment – Government policy Roadmap of applying special consumption taxes (SCT) for automobiles • Changes in import tax on CBU in some countries: (1) According to the ASEAN Trade in Goods Agreement (ATIGA), which is effective from January 1, 2018, the tax on cars imported from other countries in the ASEAN region will decrease from 30% to 0%. (2) From December 20, No. Segment 1 Above 2.0L to ≤ 2.5L 20-24T dump trucks are subject to 20% and 30% tax respectively. Above 2.5L to ≤ 3.0L ASEAN-China trade commitment (ACFTA) in 2018: 4.0 ≤ 5.0L Cars of 30 or more specialized for airport use were subject to a tax of > 6.0L 50% tax in 2018. racing cars, sports cars were taxed 5% and in 2018 decreased to 0%. 2 4 50% 55% 130% 150% 10 seats to under 16 seats From 16 seats to under 24 seats Passenger cars 30% 15% 15% 10% 15% 15% 20% > 3.0L 5 60% 110% 60% 2.5 ≤ 3.0L and septic tanks are immediately subject to 0% tax. Other types are • 40% ≤ 2.5L Crane trucks, drilling cranes, firefighters, concrete mixers, road cleaning, subject to 50% tax in 2018. 35% 45% 90% 5.0L ≤ 6.0L 3 Cars and other motor vehicles designed mainly for golf players, small 50% 40% 3.0L ≤ 4.0L The import tax rate for cars from China is effective according to the 20% until 2018. Passenger cars designed from 6-18 tons are subject to • 45% From 1.5L to ≤ 2L trucks under 5T are subject to 70% tax, an increase of 2%; 10-20T and • Vehicles under 10 seats ≤ 1.5L 2015, the import tax on trucks will increase according to Circular 163: • July 1st, 2016 Since Current SCT – December January 1st, 31st, 2018 2018 25% Electric cars The tax reduction roadmap has been approved: Vietnam has signed a Under 9 seats 25% 15% free trade agreement (CPTPP), committing to gradually reduce the From 10 seats to 16 seats 15% 10% import tax on CBU cars to 0% after 7-9 years. Vietnam and the EU have From 16 seats to 24 seats Carrying both people and cargo 10% 5% 10% 10% also signed a free trade agreement (EVFTA) committing to gradually reduce the import tax on CBU cars to 0% after 9-10 years. The price of imported CBU cars will drop from 1.2 to 1.5 times, helping to stimulate 6 shopping demand. Vehicles powered by biofuels 7 Motorhome vehicles 8 Gasoline combined electrical energy powered vehicles (fuel not exceeding 70%) VIETNAM AUTOMOBILES MARKET REPORT 24 50% of the tax on same type vehicles 60% 70% 75% 70% of the tax on same type vehicles Source: VIRAC summarized from Ciircular No. 165/2014/TT-BTC 1.3. Business Environment – Government policy On November 16, 2017, Decree No.125/2017/ND-CP was issued amending and supplementing a number of articles of Decree No. 122/2016/ND-CP dated September 1, 2016 of the Government on the Export Tariff, Preferential Import Tariff, List of Goods and Absolute Tariff, Mixed Tax, and Non-Quota Import Tax. The Decree took effects from January 1, 2018. Car types 9-seat-or-less passenger cars Under-16-seat used passenger cars (cylinder capacity under 1,000cc) Taxes rate Cylinder capacity under 1,000cc Absolute tax at 10,000 USD/unit Cylinder capacity between 1,000 and 2,500cc Used car price multiply tax rate of a new car of the same type + 10,000 USD Cylinder capacity above 2,500cc Used car price multiply tax rate of a new car of the same type + 15,000 USD SUVs, sport cars excluding vans (cylinder capacity above 1,000cc) 10-to-15-seat cars Mixed tax of 200% or 150% + 10,000 USD per unit (based on the lowest rate) Cylinder capacity under 2,500cc Used car price multiply tax rate of a new car of the same type + 10,000 USD Cylinder capacity above 2,500cc Used car price multiply tax rate of a new car of the same type + 15,000 USD 16-seat-or-more passenger cars Remain unchanged On February 21, 2019, the Government issued Decree No.20/2019/D-CP amending and supplementing a number of articles of Decree No.140/2016/ND-CP dated October 10, 2016 of the Government on registration fee. In which, there are provisions relating to registration fee applicable to cars: From April 10, 2019, pick-ups and vans will have to pay the first registration fee equal to 60% of the initial fee of cars with less than 9 seats. Thus, with the current registration fee of 10% for cars of less than 9 seats, registration fee for pick-ups applied from April 10, 2019 will be 6%, increasing 3 times higher than the previous 2%. Particularly in Hanoi, the registration fee for pick-ups and vans will be higher than other localities, at 7.2% due to the current registration fee of passenger cars of less than 9 seats at 12%. The pick-ups truck is considered a multipurpose vehicle with tonnage of less than 1.5 tons, suitable for both city and rural use thanks to its ability to carry people and cargo at the same time, so businesses import complete built-up ones to Vietnam for distribution. In particular, this is a car with comfortable equipment and modern technology but has the advantage of low registration fee (only 2%) making this car the choice of many people. VIETNAM AUTOMOBILES MARKET REPORT 25 1.3. Business Environment – Government policy In 2020, due to Covid-19’s impacts, domestic automobile industry was benefiting from three recently government incentive policies: (1) 50% reduction in registration fees for domestically-produced or assembled vehicles in effect from June 28 to the end of 2020. (2) Allow automakers who met the requirements of outputs to enjoy zero import tariffs for automobile components which could not have been produced domestically, helps cutting production costs by 2-2.5%. (3) Extension of the deadline for the payment of Special Consumption Tax on domestically produced and assembled cars till the end of 2020. ➔ These policies would help lower production and service costs, making cars more affordable to more people. On February 5, 2020, the Government loosen conditions for importing cars by issuing Decree No.17/2020 – on adjustments and supplements to Government Decree No.116/2017 stipulating regulations on car manufacture, assembly, imports and warranty services. Automobile importers in Vietnam will no longer have to obtain a Vehicle Type Approval (VTA) certificate from authorities in exporting countries, making it easier for them to import cars into the country. Decree No.17/2020 has also relaxed its rules on clearance procedures for imported cars. Overall, Decree No.17/2020 helps reduce the amount of time needed for the clearance process and lower the costs for inspections, testing and storage for automobile importers. ➢ For imported cars: To annul regulations on type quality certificates specified in Clause 11, Article 3 of Decree 116. ➢ For automobile manufacturing and assembling enterprises: • To annul the regulation that there must be persons in charge of automobile production and assembly lines having university or higher degree in the mechanics and automobile disciplines and have experience in automobile manufacture and assembly. at least 5 years as prescribed in Clause 2, Article 7 of Decree 116; • To annul the regulations on having sufficient manpower and plans to ensure occupational safety and sanitation in accordance with the law on occupational safety and sanitation in Clause 3, Article 7 of Decree 116; • To annul the regulations on the satisfaction of fire prevention and fighting safety conditions and fire-fighting plans in accordance with the law on fire prevention and fighting in Clause 4, Article 7 of Decree 116. VIETNAM AUTOMOBILES MARKET REPORT 26 1.3. Business Environment – Trade Agreement ASEAN free trade area (AFTA) – Import taxes procedure: 2013 – 60% 2014 – 50% 2015 – 50% 2016 – 40% 2017 – 30% 2018 – 0% Non-tariff barriers were set up to protect the domestic auto industry. Facing fierce competition from imported cars, especially when the tax rate for cars imported from ASEAN is reduced to 0%, the Government has issued a number of policies aimed at protecting the domestic automobile manufacturing and assembly industry. For example, Decree No.116/2017 tightens business conditions for automobile importers; circular 03/2018 providing for technical safety quality inspection and environmental protection for imported cars; Decree No.125/2017 on the reduction of import tax on car components with terms of annual output is expected to support domestic car manufacturers. EU-Vietnam free trade agreement (EVFTA) In June 2019, the EU-Vietnam Free Trade Agreement (EVFTA) was signed after 9 years of negotiation. According to the roadmap, EVFTA can be ratified by the EU in the first half of 2020. According to the regulations, the agreement takes effect 2 months later or at a time agreed by the two sides. EU Goods Vietnam Base tax rate Route Base tax rate Route Tractor (8701) • 0% with agricultural tractors • 16% for tractors A 5-30% B10 Bus (8702) 10-16% B7 70% 5% for vehicles weighted 6-18 tons B10 Car (8703) 10% B7 78% for vehicles under 3,000 cc 74% for vehicles over 3,000 cc 15% for specialized vehicles B10 B9 B9/B10 Truck (8704) 10-22% 3.5% for dedicated trucks B7 A 15% for vehicles under 3,000 cc 65% for vehicles weighted under 5 tons 0% for vehicles weighted over 45 tons B10 B10 A Auto spare parts (8708) 3-4% A 5-25% B7 VIETNAM AUTOMOBILES MARKET REPORT 27 1.3. Business Environment – Trade Agreement Meaning of symbols: • A: The base tax will be eliminated as soon as the agreement comes into force • B7: The base tax is eliminated after 8 regular reductions, once a year, starting from the year the agreement comes into force. • B9: The base tax is eliminated after 10 regular reductions, once a year, starting from the year the agreement comes into force. • B10: The base tax is eliminated after 11 regular reductions, once a year, starting from the year the agreement comes into force. The Government maintains a policy of protecting the auto industry when joining EFTA. Looking at the roadmap of tax cuts on both sides of possible auto goods, Vietnam is implementing a policy of protecting the automobile manufacturing and assembly industry, with a high base tax rate, and an extended protection period. VIETNAM AUTOMOBILES MARKET REPORT 28 1.3. Business Environment – Automobiles market features Number of automobiles manufacturing and assembling enterprises, 2014 – 2019 Number of labors in automobiles industry, 2014 – 2019 35,000 100 32,564 30% 26.92% 90 25% 80 70 17.02% 60 25,000 17.11% 15% 20,000 12.12% 50 10% 40 0% 20 10 - -5.45% 55 52 2014 2015 -5% 66 74 76 89 2016 2017 2018 2019 Number of enterprises Growth 50% 20,302 15,000 14,503 17,937 16,284 30% 20% -10% 10,000 5,000 12.28% 5.75% 15.1% 10% 10.15% 0% -1.67% - -10% 2014 Source: VIRAC, GSO 40% 17,638 5% 2.70% 30 60.4% 60% 30,000 20% 70% 2015 2016 Number of labors 2017 2018 Growth 2019 Source: VIRAC, GSO The number of enterprises operating in the field of manufacturing and assembling domestic cars in 2019 increased by 17.11% compared to 2018, reaching 89 enterprises. • The number of automobile manufacturing and assembling enterprises in the past year has increased significantly, due to the fact that the Government has had policies and decrees to develop the domestic automobile industry. However, production technology is still basic, the localization rate (refer to page No.34 and 35) is still quite low compared to other countries in the region. • In addition, domestically produced cars also have to compete with imported cars from other countries in the ASEAN region (Thailand, Indonesia, ...) as prices for imported cars are relatively lower than that of domestic ones. The domestic automobile industry is on the rise, the number of automobile manufacturing and assembling factories has continuously increased each year, leading to the great attraction of the industry to the workforce. In 2019, there were more than 32 thousand employees in the field of automobile production and assembly, up to 60.4% compared to 2018. The highly trained workforce has gradually met the needs of the domestic market. VIETNAM AUTOMOBILES MARKET REPORT 29 1.3. Business Environment – Automobiles market features USD million Revenue of automobile manufacturing and assembling industry, 2014 – 2019 USD million 16,000 120% 14,000 109.3% 100% 12,000 60% 8,000 60% 52.7% 40% 8.5% 2,000 2,490.6 3,811.2 5,599.6 6,622.4 2013 2014 2015 2016 Revenue 40% 35.5% 15,000 30% 27.6% 10,000 10% 20% 18.3% 4,000 50% 20,000 20% 46.9% 6,000 -7.6% 6,121.1 6,638.8 2017 2018 0% 13,892.4 -20% -0.5% 0% 5,000 0 2019 8,095.4 12,365.6 16,755.3 2014 2015 2016 Revenue Tăng trưởng Growth *Exchange rate: USD/VND = 23,230 • 25,000 80% 10,000 0 Revenue of automobile wholesaling and retailing, 2014 – 2019 Source: VIRAC, GSO *Exchange rate: USD/VND = 23,230 -10.9% 14,932.2 19,053.4 2017 2018 -10% 18,954.2 -20% 2019 Tăng trưởng Growth Source: VIRAC, GSO Revenue from car manufacturing and assembly activities recorded strong growth in 2019. This is an impressive growth in the period of 2014 - 2019 thanks to the support and promotion of domestic automobile production along with that is the rise of major car manufacturers with domestic production and assembly lines such as THACO, Toyota, VinFast, etc. • However, the car wholesale and retail industry saw a slight decrease in revenue of 0.5% compared to last year, reaching USD 18,954.2 million. The reason is that the volume of cars consumed is not increased significantly in addition to the decrease in car prices due to the impact of the reduction of import tax on CBU from some regions, causing the car price to drop overall. VIETNAM AUTOMOBILES MARKET REPORT 30 AUTOMOBILES SUPPLY CHAINS Tier-3 suppliers Nhà cung cấp cấp 3 Tier-2 suppliers Nhà cung cấp cấp 2 • 138 suppliers • 5 spare parts manufacturers • 178 other parts manufacturers • 61 motorbike spare parts suppliers • 50 motorbike and automobile spare parts suppliers • 18 automobile spare parts suppliers • 277 other parts suppliers • Tier-1 suppliers Nhà cung cấp cấp 1 • 21 assembling OEMs • 5 Japanese OEMs • 2 USA OEMs (GM, Ford) 177 Japanese suppliers • 1 German OEM (MBV) • 136 Vietnamese suppliers • Vietnamese and other country • 57 Taiwanese suppliers • 14 Korean suppliers • The rests from USA, Germany, Malaysia, etc. • Simple mechanical automobile parts can be supplied by local SMEs • Complicated and high-tech automobile parts are manufactured by FDI • 83 suppliers OEMs OEM lắp ráp OEMs • enterprises for export Simple spare parts and assemblies • CKD automobiles assembling such as chairs, batteries, bulky plastic • Production procedure: welding, details, etc. painting, assembling, checking Source: MOIT, ASEANSC VIETNAM AUTOMOBILES MARKET REPORT 31 1.3. Business Environment – Automobiles market features Vietnam level of participation in global automobiles 4.0 value chain Value added Vietnam participation 3.0 value chain Research Design Auto parts manufacturing Assembling Marketing Others Source: VIRAC, ASEANSC According to World Bank, Vietnam's participation in the global value chain is mostly the last stage of assembly, and this stage always has the lowest share of value-added in the value chain. Moreover, when the global value chain moves to the 4.0 value chain, the value added in assembly will be narrower. However, with the Government's support for domestic auto assemblers, Hyundai Thanh Cong, Truong Hai and VinFast are expected to create a triangle for the development of Vietnam's auto manufacturing industry. VIETNAM AUTOMOBILES MARKET REPORT 32 1.3. Business Environment – Automobiles market features • Due to the Price Appraisal Center – Ministry of Finance, until 2020, the cost of producing cars in Vietnam is about 20% higher than that of Thailand and Indonesia: After 25 years of development, Vietnam's automobile industry is still extremely small and weak, not only in comparison with major manufacturing centers in the world but also with other regional countries. • There are about 20 large domestic and foreign assemblers. Domestic production only meets about 60-70% of domestic demand, and this number is on the downward trend in recent years due to increasing competition from imported vehicles. • The weakness of the auxiliary component manufacturing industry and the lack of uniformity in the transport infrastructure is the reason for the slow development of the automobile industry in Vietnam: ➢ Vietnam's automobile industry still depends on imported spare parts, so it is only involved in assembly and distribution of cars in the domestic market. ➢ As a result, domestic manufacturers have to bear the cost of packaging, logistics and import duties on components. This leads to a 20% higher cost of automobile production in Vietnam than Thailand and Indonesia. ➢ The number of Vietnam's automobile manufacturers in 2019 is only about 89, much less than other ASEAN countries. ➢ One of the reasons that make the automobile industry in Vietnam weak is the fact that domestic firms have not yet cooperated, associated and specialized between automobile assembly and production with production of spare parts and components. ➢ Locally-produced products contain very low technology content including tubes, automobile tires, seats, mirrors, glasses, wires, batteries, plastic products. • Tier-1,2,3 suppliers has not been able to cooperate with the car manufacturers: Many domestic supporting companies cannot become partners with car manufacturers because the prices are not competitive compared to imported sources since Vietnam's car output is still low, making suppliers unable to invest in machinery, equipment, technology, and people with such a small market size. Besides, products requiring high technical requirements, the quality of the domestic supplier cannot meet the requirements, and lack of supplier network. • Opportunities for the Vietnamese auto parts production market: ➢ Vietnam is facing the greatest opportunity to become a new manufacturing hub in the world. Manufacturing enterprises continue to move out of China due to rising costs; trade conflicts with the United States, and manufacturers' strategies to minimize dependence on a single market, especially after Covid-19. ➢ The CBRE Vietnam report shows that tier-1 suppliers are expanding rapidly in the Vietnam automobile market, such as Bosche, Schaeffler, and Mitsubishi Motors. Industrial complexes located near ports and car manufacturers will attract new investors. Northern provinces such as Vinh Phuc, Hung Yen, Hai Phong, and Hai Duong are expected to become the focus of investment in the future. VIETNAM AUTOMOBILES MARKET REPORT 33 1.3. Business Environment – Automobiles market features Localization rate of countries in Asia, 2019 Localization rate in Vietnam’s car industry remains low compared to Asean 55% Malaysia regional peers for 4 main reasons: 45% 65% Indonesia 70% Thailand 0% importing from neighboring countries. Car sales in Vietnam reached 385,600 units last year (2019), but the size of the Indonesia and Thailand market was 2.6 times bigger and that of 20% 10% Malaysia, 1.6 times. For October 2020, the total sales volume of the members of the Vietnam Automobile Manufacturers’ 90% 10% 20% 30% 40% Domestic 50% Small car sale volume: Due to low vehicle demand, investment in technology for localization is much more expensive than 30% 80% Vietnam • 35% Association (VAMA) was 204,144 units, a decrease of 17% in 60% 70% 80% 90% 100% comparison to October 2019. Import Source: VIRAC, VAMA • Heavy reliance on imported raw materials: about 80-90 percent of the main raw materials used to manufacture components are still imported. As a result, companies are required to import approximately USD 2 to 3.5 billion in components and parts for vehicle manufacturing, assembly, and repair each year. • Under-developed local supporting industries: the local automobile industry has not been able to invest in core and high technology products such as engine production and transmission systems. Localized parts are mostly of low technology products such as tires, seats, mirrors, glasses, cable harnesses, batteries, and plastic products. • A latecomer in the automobile industry: Vietnam’s automobile industry only got its proper start in the 2000s, 20 or 30 years after Thailand or Indonesia. This is one of the reasons attributable to the lack of an ecosystem to support the automobile industry in Vietnam. VIETNAM AUTOMOBILES MARKET REPORT 34 1.3. Business Environment – Automobiles market features Localization rate of major vehicle types, 2020 Plan to increase the ratio of domestic manufacturing value to automobile Production due to Decree No.1211/QD-TTg Under-9 passengers vehicle 2020 2025 2035 9-passenger vehicles 30% - 40% 40% - 45% 55% - 60% 10-or-more passenger vehicles 35% - 45% 50% - 60% 75% - 80% Trucks 30% - 40% 45% - 55% 70% - 75% Special purpose vehicles 25% - 35% 40% - 45% 60% - 70% 53% 10-or-more passengers vehicle Under-7 tons truck 0% 10% 20% 30% 40% 50% Source: VIRAC, ASEANSC VIETNAM AUTOMOBILES MARKET REPORT Source: VIRAC, Ministry of Industry and Trade 35 1.3. Business Environment – Automobiles market features Development of automobile industry in some ASEAN countries Vietnam Philippines MAINTENANCE The size of the market is small, low Description competitiveness of the production cost compared to imported vehicles • High production costs • Low localization rate Problems • Low production rate Indonesia Thailand DEVELOPMENT MATURE Thanks to the expansion of the market, the competitiveness is on the same level as that of imported cars from other countries Accelerate technical know-how, compete with vehicles of other countries in foreign markets. • Low tech • High labor cost • Low capacity • Manpower shortage Promote expansion of market size Investment promotion (increase production capacity - localizationrate) Essential support from the government Commercial promotion Domestic car protection/ narrowing gap of Promoting investment production costs in products with high added value VIETNAM AUTOMOBILES MARKET REPORT 36 1.3. Business Environment Ninh Binh Vinh Phuc Hai Phong Hanoi Vietnam Da Nang autombile industry consists of less than 10 key players that already Quang Nam had their own factories in Vietnam. These factories located at some big industrial parks in the North and Central of Vietnam with brands: TC Motor, THACO and a new Binh Duong Dong Nai Can Tho VIETNAM AUTOMOBILES MARKET REPORT 37 Vietnamese brand VinFast. 1.3. Business Environment – Hai Phong Industrial complex Hai Phong VIETNAM AUTOMOBILES MARKET REPORT 38 VINFAST’S AUTOMOBILE FACTORY 1.3. Business Environment – Hai Phong Industrial complex Hai Phong transport & logistics infrastructure Personal income tax •50% reduction to the normal rate for lifetime of the project for locals and expats. •(Other industrial zones: 0% reduction). Hai Phong – Hanoi highway The 105.5km highway shortened traffic time between the two cities from 4 hours to 1.5 hours. Passage of 18-ton truck and 40-feet container becomes accessible Cat Bi international airport The 105.5km highway shortened traffic time between the two cities from 4 hours to 1.5 hours. Passage of 18-ton truck and 40-feet container becomes accessible Tan Vu – Lach Huyen Ocean bridge Connecting Hai Phong city with Lach Huyen Int‘l Deep Water Port. Constructed as the Import – export tariff •Goods exempted duty are: •Goods from free trade zones exported. •Goods imported into free trade zones and only used in free trade zones longest bridge with 15km in-length in Vietnam Lach Huyen international deep water port Constructed with 14m in water depth, 2 berth to host cargo vessels with loading capacity of 100,000 tons. Traffic time to USA and EU is shortened by about 1 week Dinh Vu – Cat Hai economic zone indices VAT tax •Goods traded between foreigners using in free trade zones has been exempted VAT tax; •Goods & services sold in free trade zones has been applied 0% VAT tax. VIETNAM AUTOMOBILES MARKET REPORT 39 Area Population 22,540 ha 310,000 Tariff zones Port system 12,932 ha 1,046 ha 39 1.3. Business Environment – Hai Phong Industrial complex VinFast industrial complex: The project located on Dinh Vu – Cat Hai industrial zones, with an area of 335 ha. Designed capacity of VinFast industrial complex 1st stage: 250,000 units per year 250,000 units per annum; 2nd stage: 500,000 units per annum An automobile manufacturing zone Electrical motorbike VinFast industrial complex An electrical motorbike manufacturing zone 3,000 units per Electrical bus Automobile An operation zone 1st stage: annum; 2nd stage: 500,000 units per annum; Expansion plan: 1 million units per annum. An electrical bus manufacturing zone Source: VIRAC, VinFast Automobile manufacturing zone contains a body shell workshop, an An auxiliary industrial zone automobile paint workshop, an engine workshop, an assembly workshop and an auxiliary workshop. Key components such as engines and chassis will be purchased from leading European and US designers. A trainning center The project is invested by big corporations such as Bumper, Aapico, Lear, ZF to invest in large-scale factories to manufacture and assemble engines, front and rear axle assemblies, to manufacture, assembling car A research and development institute. seats, manufacturing car front bumper, rear bumper, stamping and welding frame details, assembling batteries for electric cars and Source: VIRAC, VinFast VIETNAM AUTOMOBILES MARKET REPORT motorcycles. 40 40 1.3. Business Environment – Hai Phong Industrial complex Stamping workshop Area (m2) Capacity VinFast industrial complex Manufacturing growth rate Body welding workshop Painting workshop 50,000 100,000 25,000 16 units per min 38 units per hours More than 800 units per day 21.88% 14.4% With the process monitoring by technology of SCHULER Company (Germany), the data are collected online by equipment acompanying with assemble lines. By continuously checking actual parameters, production status and technical issues are quickly identified and required measures equipment is promptly set up and implemented to ensure the quantity and quality of products. In addition, smart diagnostics at workshop works like black boxes on an airplane: Specific data are selfdirected continuous storage. In case of a breakdown or failure, a retrospective analysis can be performed to confirm identifying the cause, for example software bugs or machine parts or lines. VinFast body welding workshop. designed and supplied by leading partners such as FFT, EBZ, HIROTEC, is equipped with about 1200 ABBmade robots. This is modern and fully automatic body welding machine in Vietnam and Southeast Asia.. VIETNAM AUTOMOBILES MARKET REPORT 41 The EcoSmart VEC intelligent air management system by Dürr comes from the Germany, fully automatic, delivering power on demand through realtime recording in production. This technology significantly reduces the amount of air and electricity consumed when drying new vehicles paint. Engine workshop Assembly workshop Auxiliary workshop 50,000 200,000 20,000 The workshop is designed and supplied by leading partners such as GROB, Thyssenkrupp, AVL, MAG, using the latest in precision mechanical technology to machine the Engine heads, Engine body and Shaft engine crankshaft. The line is designed and supplied by a leading supplier Eisenmann, with highly automated conveyors and self-controlled vehicles that are interlocked together. In addition, the assembly stages are equipped with modern Atlas Copco torque clamps linked production lines ensure that the tightening force of each assembly is controlled and retrievable at all times. Auxiliary workshop includes paint area of plastic details (front bumper, rear bumper) with friendly paint technology environment provided by supplier Dürr. In addition the workshop also has tire finishing area and capacity to expand for future molding of plastic parts. 41 6.11.3. Business Environment – Hai Phong Industrial complex • Tax policy is not stable and synchronous; • Favorable geographical location: Hai Phong has the largest seaport in the North, an important trading hub • Transport and supply costs for auto manufacturers are between the North and regional countries. In addition, still high due to limited localization and low Hai Phong Industrial Park has a full range of traffic types, maximum support for Logistics for competitiveness of foreign manufacturers. the • Lack of high-skilled labor in automobile industry; automotive industry. • Enjoy the policy of promoting transport infrastructure and economy. Dinh Vu - Cat Hai Industrial Park is one of the 16 economic zones that enjoy the most incentives. Hai Phong's integration capacity is S W enhanced with a series of technical infrastructure works. • Hai Phong is actively implementing policies to support businesses to expand investment, prioritizing the development of the automobile and supporting industries to attract major car manufacturers, typically • Domestic car production is still low, and the high rolling O T VinFast. • Program costs make cars a luxury item, and demand is not high. • The quantity of domestically produced components and accessories is small, less diversified and of poor quality, and difficult to compete with ASEAN countries such as to support investment in technical Thailand and Indonesia. infrastructure of industrial clusters, guaranteed by the • Difficulties in mobilizing resources, especially capital, budget of Hai Phong city for the period 2019 - 2025 human resources and technology to establish a concentrated automobile manufacturing and assembly industrial park VIETNAM AUTOMOBILES MARKET REPORT 42 42 1.3. Business Environment – Quang Ninh Industrial complex Major Industrial Parks in Quang Ninh Name Dong Mai Industrial park Total area (ha) 160 Quang Ninh Major industry Building materials manufacturing, Textile, etc Hai Yen Industrial park 182.4 Home furniture manufacturing, etc. Cai Lan Industrial park 242.8 Wooden furniture manufacturing, Shipbuilding, etc Viet Hung Industrial park 301 Auto parts manufacturing, Mechanical engineering, etc Hoanh Bo Industrial park 681 Electronic manufacturing, Consumer goods industry, etc Phuong Nam Industrial park 709.1 High-tech industry Hai Ha Industrial park and sea port 4,988 Seafood processing industry Dam Nha Mac Industrial and service park 3,710 Shipbuilding, Logistics service, etc Source: VIRAC, Kland Quang Ninh is located in the North-east of Vietnam. To the north, it is adjacent to China with 118.8 km border and Gulf of Tonkin to the east. Quang Ninh has a geostrategic position in terms of politics, economics, military and foreign affairs. It is located in the Vietnam-China economic cooperation area with ”Two Corridors and One Belt”, inter-regional cooperation of extended Gulf of Tonkin, ASEAN-China connection point and Nam Ninh-Singapore economic corridor. VIETNAM AUTOMOBILES MARKET REPORT 43 1.3. Business Environment – Quang Ninh Industrial complex Viet Hung Industrial Park is invested in Ha Long City with the scale of 300 hectares. The Besides, Vietnam’s conglomerate Vingroup also complex plays an important role in implementing the policy of attracting projects of announced a plan to invest in an industrial processing industry, manufacturing, using modern technology. It’s the result of cooperation production complex south of Luc Lam River at between Quang Ninh province and Thanh Cong Group to build an environmentally friendly car Mong Cai border with a capital scale of more than factory. The complex is built on a total area of 340 hectares, with a strategic location, located right on $147.8 million in order to manufacture spare parts the banks of Cua Luc Bay, convenient for both domestic and international trade. It’s expected to and accessories for cars and other motor vehicles. attract many businesses in the automotive supporting industry, manufacturing components and spare parts. • The project is divided into two investment phases. Phase 1 (2020 - 2022) will focus on investing in building production lines for auto components, accessories and spare parts with an expected capacity of 500,000 sets/year. Phase 2 (2022- 2025) expands auto parts factories, and increases the capacity to 1,000,000 sets/year. • DEEP C invested in two industrial zones in Quang Yen town – Bac Tien Phong and Nam Tien Phong IZs, also known as DEEP C Quang Ninh – on a total area of 1,680 ha. In DEEP C’s investment plan, a 150,000 m2 ready-built factory space at DEEP C Quang Ninh is scheduled to be built and put into operation next year. THANH CONG – VIET HUNG AUTOMOTIVE SUPPORTING INDUSTRIAL COMPLEX MAP VIETNAM AUTOMOBILES MARKET REPORT 44 1.3. Business Environment – Quang Ninh industrial complex Viet Hung Industrial Park Infrastructure investors Cienco 5 Location Viet hung commune, Ha Long city, Quang Ninh province Scale Total area base on Master plan: 301 ha • Decision No.519/TTg by the Prime Minister on 06/8/1996 to approve the establishment of Viet Hung industrial park. • Document No.727/TTg-CN by the Prime Minister on 15/5/2006 to set up Viet Hung industrial park. • Decision No.2416/QD-UBND of Quang Ninh Provincial People's Committee on 17/8/2006 to approve constructing and servicing infrastructure Viet Hung Industrial park in Ha Long City. Documents • Document No.1154/BXD-KTQH by the Ministry of Construction on 28/07/2004 to approve plans of Viet Hung industrial park. • Decision No.330/QD-UBND of Quang Ninh Provincial People's Committee on 26/01/2007 to approve detailed construction planning ratio 1/20000 of Viet Hung industrial park. Land lease period Contents of land use according to Master plan approval documents Land lease method 50 years • Industry assembly • Manufacturing engineering, interior vessel; • Construction material production, • Processing agricultural products, aquatic products, consumer goods production; • Investors are allowed to propose of adjusting industrial sectors plan to match practical Land lease VIETNAM AUTOMOBILES MARKET REPORT 45 1.3. Business Environment – Quang Ninh industrial complex Dong Mai Industrial Park Viglacera Infrastructure Investment Development Company – The Vietnam Glass and Ceramic for Construction Infrastructure investors Corporation Location Planned total area and current status Quang Yen town, Quang Ninh province • Planned total area: 160 ha • Current status of Ip: Technical infrastructure works outside the fences of the industrial zone such as the power supply system, water supply and drainage system, traffic system, communication system... have been invested for construction. Currently, investors have been implementing construction site clearance and infrastructure investment. Approved document • The industrial zone belongs to the Planning for developing Industrial Zones in the whole country until 2020 approved by the Prime Minister in Decision No 1107/QD-TTg of August 21st, 2006. Legal documents • Established under the Decision No 2276/QD-UBND of July 14th, 2008 of Quang Ninh Provincial People’s Committee. Decision on planning approval Detailed construction planning at 1:2,000 scale for Dong Mai Industrial Zone was approved by Quang Ninh Provincial People’s Committee in Decision No 1153/QD-UBND April 17th, 2008. Land lease period 50 years • Dong Mai Industrial Zone is oriented to become the industrial zone that would not make the environment polluted with the encouraged investment sectors: Mechanical engineering, Transport equipment assembly, Construction material manufacturing, Interior architecture, Precision machining and mechanical assembly, Agricultural products and Contents of land use according to Master plan approval documents food processing, Medical devices manufacturing, Electronic and electrical devices assembly and manufacturing, Consumer goods production, Textile, garments and some other industries. • Land lease method Investors are allowed to propose adjustments to the planning of industries in the industrial zone to meet the practice. Land lease or factory hiring VIETNAM AUTOMOBILES MARKET REPORT 46 6.11.3. Business Environment – Quang Ninh industrial complex • Quang Ninh Industrial Park is adjacent to a high-speed • The connectivity of inter-regional traffic has not been system with a route across the border with China, fully optimized and some bottlenecks in important traffic converging types of transport: Van Don international routes have not been resolved airport, Lach Huyen seaport suitable to form a biological Manufacturing industrial zones associated with Logistics • Policies and incentives to promote businesses in the field of automobile production and assembly S W • Quang Ninh is in the process of completing projects on the road connecting Cai Lan Industrial Park to Ha Long - Van Don Expressway and Van Don - Mong Cai Expressway to create a basis for supporting • The progress of production and assembly projects is O T transportation for businesses site clearance • Challenges in administrative procedure reform and developing high-quality human resources • Policy of economic development towards restructuring industries, improving technology map and expanding connection with other industrial zones in the region VIETNAM AUTOMOBILES MARKET REPORT still slow, unsatisfactory due to the impact of ineffective 47 1.3. Business Environment – Chu Lai industrial complex CHU LAI INDUSTRIAL PARK Quang Nam VIETNAM AUTOMOBILES MARKET REPORT THACO AUTOMOBILE COMPLEX 48 48 1.3. Business Environment – Chu Lai industrial complex Since 2003, THACO has invested in Chu Lai Industrial Park to form THACO CHU LAI open economic zone with the total acreage of 1,200 ha. THACO CHU LAI consists of 4 major industries that the company has already had strengths and opportunities: • Mechanical engineering & automotive industry (325 ha) • Agricultural & Forestry (451 ha) • Sea port & Logistics (140 ha) • Chu Lai Real estate (320 ha) THACO CHU LAI industrial park Location Hamlet 4, Tam Hiep Commune, Nui Thanh District, Quang Nam Province Total investment Over USD 3.4 billion • Road: THACO CHU LAI located on the main national traffic junctions, including 1A National Highway, north-south railway and Da Nang – Quang Ngai expressway Transportation Infrastructure • Seaways: THACO CHU LAI is 2.5 km away from Chu Lai port (port number 1 - Tam Hiep port). Chu Lai port belongs to the national seaport system, with the advantage of being a wind-tight port, convenient for cargo ships to enter and dock • Airways: THACO CHU LAI is 15 km away from Chu Lai airport. This is the largest airport in Vietnam, currently has routes Chu Lai Hanoi and Chu Lai - Ho Chi Minh City • Electricity: Power is supplied from the national grid via 110KV Ky Hoa transformer station with 2 transformers with capacity of 40 MVA each, providing stable power to the industrial park Technical infrastructure • Water supply: provided by Tam Hiep Water Plant with a total capacity of 20,000 m3/day and night to ensure sufficient water supply, connected to the fence of businesses • Wastewater treatment system: wastewater is treated locally from each factory and sent to a general treatment area. Waste water collection and treatment system for North Chu Lai Industrial Park - phase 1 with capacity of 1,900 m3/day and night has been put into operation VIETNAM AUTOMOBILES MARKET REPORT 49 Source: VIRAC, THACO 1.3. Business Environment – Chu Lai industrial complex Organizational structure of automotive department at THACO Chu Lai General manager of automotive and mechanics Vice manager of automotive manufacturing Trucks and buses manufacturing and assembling factories Passenger vehicles manufacturing and assembling factories Vice manager of automotive supporting industry Automotive supporting factories Vice manager of mechanics Mechanical manufacturing and processing complexes Design and commercial companies Source: VIRAC, THACO VIETNAM AUTOMOBILES MARKET REPORT 50 1.3. Business Environment – Chu Lai industrial complex Factories of THACO Chu Lai industrial complex THACO passenger vehicles THACO Bus THACO Truck THACO Kia THACO Mazda THACO Semitrailer and trailer Operational time May 2019 December 2017 March 2020 September 2019 March 2018 February 2016 Total invesment USD 190 million n/a USD 190 million USD 20 million n/a USD 6.5 million Total acreage 7.5 ha 17 ha 11 ha 31 ha 30.3 ha 4 ha Capacity 20,000 units per year 20,000 units per year: • 8,000 buses • 12,000 minibuses 50,000 units per year 50,000 units per year 100,000 units per year 5,000 units per year Types of products Peugeot 3008, Peugeot 5008, Peugeot Traveller Premium and Peugeot Traveller Luxury 12, 47, 60-seat buses in 3 segments: Deluxe – Luxury - Premium Trucks, Dump trucks and Specialized trucks branded Foton, Forland, Kia, Mitsubishi Fuso Kia Morning, Kia Soluto, Kia Cerato, Kia Optima, Kia Rondo, Kia Sorento, Kia Seltos Mazda 3, Mazda 6, Mazda CX-5, Mazda CX-8 Hooded trailers, Special-purpose trailers, concrete mixing tanks, etc. Source: VIRAC, THACO VIETNAM AUTOMOBILES MARKET REPORT 51 1.3. Business Environment – Chu Lai industrial complex 6.1 • Chu Lai industrial park has a convenient transportation • Transportation infrastructure among Chu Lai industrial infrastructure that includes highway, airways and park is unequal, esspecially outside THACO Chu Lai. seaways with the distance of under 10 km Lack of investment and incentive policies make it hard for synchronzing • THACO Chu Lai is the biggest automotive industrial complex of Vietnam due to its parties of automobile assembling industry and supporting • Lack of connectivity with other economic centers such industry altogether • THACO Chu Lai has a long period of development and as Hanoi and Ho Chi Minh City S W has fulfilled the manufacturing process in order to raise the localization rate • Quang Nam province has been improving the standard of living, resulted from economic growth. Main factors that enable rapid growth is THACO Chu Lai industrial complex, Nam Anh industrial park and North Chu Lai • The progress of production and assembly projects is O industrial park. These industrial parks will be the site clearance • Challenges in administrative procedure reform and developing high-quality human resources flagship of Quang Nam economy, attract more • Automobiles consumption in Vietnam central remains investors in relative industries low, this create a high transportation cost to bring • Localization rate has chance to increase due to products to customers in big cities in the North and mechanical supporting industries among Chu Lai VIETNAM AUTOMOBILES MARKET REPORT T still slow, unsatisfactory due to the impact of ineffective South 52 ENTRY LANDSCAPE 2.1. Domestic auto parts manufacturers Automotive designed capacity in Vietnam Unit: thousand units p.a. OEMs Existing capacity 2019 Planned new capacity 2020 Expected total capacity 2025 Thaco 207 120 327 TC Motor 102 150 252 Honda 10 10 20 Toyota 50 20 70 VinFast 250 250 500 Total 619 550 1,169 Source: VIRAC Total designed capacity stays at 619,000 units p.a. with the commercial launching of VinFast and Thaco Luxury car plant in May 2019. The industry is expected to witness a surge by 550,000 units p.a. in designed capacity by 2025. VIETNAM AUTOMOBILES MARKET REPORT 54 2.1. Domestic auto parts manufacturers Projected capacity of some automobile assembly plants, 2018 – 2020 Plants Truong Hai JSC Capacity Investment units Localization rate USD 500 million (phase 1) Industrial Zone Plans • Completion of phase 1: 4/2018 Chu Lai 50,000 Mazda plant Location 18% (Quang Nam) • Production of tires and other components will increase the localization rate of 40% • Export to Myanmar, Cambodia, Philippines • Completed in mid-2019 Thanh Cong Group Hyundai Thanh 12,000 Cong plant units/year USD 500 million Gia Vien (Ninh Binh) • Total production of tires and other components will increase 19% the localization rate to 40% • To become a Hyundai Motor Manufacturing Center in South East Asia • USD 3.5 billion Vingroup VinFast plant 500,000 units/year • Completed in 2025 Dinh Vu-Cat • To launch electric vehicles after 12 months, and launch cars • Phase 1: USD1-1.5 billion Hai • Credit Suisse AG sponsors USD 800 million Economic 60% Zone (Hai after 24 months • To contribute to Hai Phong budget: USD 860 million Phong) • To become the leading car manufacturer in Southeast Asia • The project is divided into two phases: phase 1 is expected to Huyndai Thanh Huyndai Thanh 100,000 Cong and Cong 2 units/year Huyndai (HTMV2) be completed in June 2022, phase 2 will be completed in June Gian Khau USD 138 million Motor VIETNAM AUTOMOBILES MARKET REPORT Industrial Zone (Ninh Binh) 40% 2025 • Production and assembly on modern lines were transferred from Hyundai Motor and leading partners in the field of hightech mechanical engineering 55 2.1. Domestic auto parts manufacturers THACO Truck Some typical models of Thaco Auto Truong Hai Auto Corporation (Thaco) was founded on April 29, 1997 by Tran Ba Duong, and has a total of about 20,000 staff members. As one of the leading and largest automakers in Vietnam, THACO has an A-to-Z value chain ranging from product R&D, auto parts THACO Bus manufacturing to auto assembly, logistics, distribution and retail. The company is now offering a wide range of products: trucks, buses, passenger cars, and special-purpose vehicles from mid-range to luxury segments which have successively earned high sales and automotive manufacturing and supporting industries in Vietnam. It is home to 32 100,000 and mechanical complexes, Chu Lai port and logistics units, road transport and shipping companies, construction & investment companies, THACO College and other support 96,127 91,700 80,421 80,000 40.3% 59,709 60,000 companies and units, including automotive assembly plants, automotive parts factories 89,602 42,339 7.3% 40,000 -4.6% 20,000 -20.6% 0 2014 units. 2015 2016 2017 Sales 2018 100% Units 80% 30,000 60% 25,000 40% 20,000 20% 15,000 0% 10,000 -20% 5,000 -40% 0 9M/2020 2019 9T/2020 Growth Source: VIRAC, VAMA VIETNAM AUTOMOBILES MARKET REPORT 56 Thaco Kia Thaco Mazda 9M/2020 Peugeot Thaco Truck 9M/2019 540 1,613 Quang Nam is considered the largest hub of 112,847 89.9% 120,000 Sales volume of Thaco by brands, 9M/2019 – 9M/2020 17,043 17,150 Industrial Park in the central province of Sales volume of Thaco, 2014 – 9M/2020 2,277 2,755 Thaco Chu Lai Mechanical and Automotive Units 19,444 24,569 years. 20,405 21,081 market shares in the domestic market over the Bus Thaco Financial statement INCOME STATEMENT TRUONG HAI AUTO CORP. (THACO) Unit: USD BALANCE SHEET Unit: USD 2018 2018 Net sales 1,964,570,948 1,917,285,460 Cost of goods sold 1,879,665,003 1,829,660,351 84,905,945 87,625,108 271,729,344 192,659,293 21,703,512 63,470,320 Interest expenses 8,832,025 28,673,725 Selling expenses 31,276,332 45,374,361 Administration expenses 31,727,402 35,397,166 Gross margin 2019 2019 Income from financial activities 795,451,535 656,360,001 4,082,367 4,000,222 II, Short-term investment 110,328,634 8,214,879 III, Short-term receivables 522,122,362 549,386,339 74,765,140 68,822,592 Profit from operation 271,928,044 136,042,554 142,840,630 77,098,036 Profit before tax 276,125,550 136,642,624 1,199,195,849 1,870,788,632 3,844,064 80,355 1,646,935 352,235,593 -312 -3,904,613 221,044,175 251,131,840 272,281,798 140,466,882 1,994,647,384 2,527,148,632 2018 2019 A, LIABILITIES 828,086,816 1,137,166,342 I, Short-term liabilities 827,908,243 966,854,777 Cash flows from operating activities 436,884,151 554,681,879 II, Cash flows from investment activities 1,296,425 2,290,061 178,574 170,311,565 - 170,131,111 145,944 171,650 B, EQUITY 1,166,560,568 1,389,982,290 TOTAL LIABILITIES AND OWNER'S EQUITY 1,994,647,384 2,527,148,632 A, CURRENT ASSETS I, Cash and cash equivalents 1, Accounts receivable from customers IV, Inventories B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets TOTAL ASSETS Expenses from financial activities Current income tax expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD 1, Short-term loans and debts 2, Taxes payable to State Treasury II, Long-term liabilities 1, Long-term loans and debts 2, Science and technology development fund I, Cash flows from operating activities Cash flows from investment activities 57 49,518,987 -231,448,103 -397,120,149 1,698,419 -82,017 4,082,367 4,000,222 III, Cash flows from financial activities Cash flows from financial activities Effects from exchange rate difference Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 121,631,303 2.1. Domestic auto parts manufacturers TYPICAL MODELS TC Motor is formerly known as Thanh Cong Mechanical Co., Ltd and was established in 1999, with a vision to Huyndai Kona Huyndai i10 become the leading corporation in the region. From the early beginning, TC MOTOR has relied on internal resources to expand and grow strongly, and to become a typical contributions business to with the Huyndai Elantra Huyndai Accent important Vietnamese automotive industry. Huyndai Santafe Huyndai Tucson In 2009, Thanh Cong Group became an official partner with Hyundai Group in the field of distributing Hyundai passenger cars in Vietnam. After 10 years of cooperation, expansion and joint ventures, Thanh Cong Group has made Hyundai become one of the leading automotive brands in Vietnam. In the first 9 months of 2020, Hyundai car Sales volume of TC Motor, 2015 – 9M/2020 Units 106.3% 90,000 120% 80,000 100% 70,000 80% 60,000 sales reached 49,200. With the distribution 50,000 channel of 81 dealers, all car models 40,000 produced and distributed by TC MOTOR 30,000 dominate their segments. Especially, Thanh 20,000 Cong Group has shifted its structure from 10,000 importing the whole cars to nearly 100% 0 assembly production. 60% 34.8% 20% 0% -15.4% -20% 27,000 36,400 30,800 63,526 79,568 49,200 2015 2016 2017 2018 2019 9M/2020 Sales VIETNAM AUTOMOBILES MARKET REPORT 40% 25.3% 58 -40% Growth Source: VIRAC Financial statement INCOME STATEMENT HYUNDAI THANH CONG VIETNAM JSC. Unit: USD BALANCE SHEET Unit: USD 2018 2018 Net sales 1,258,784,915 1,859,108,233 Cost of goods sold 1,214,952,882 1,642,321,232 43,832,033 216,787,002 Income from financial activities 5,010,537 9,004,550 Expenses from financial activities 3,629,608 4,630,809 Interest expenses 2,777,508 4,043,473 Selling expenses 15,333,652 22,001,535 541,074 831,699 Gross margin 2019 2019 198,657,445 357,399,695 I, Cash and cash equivalents 30,889,200 34,198,129 II, Short-term investment 58,619,037 98,527,295 III, Short-term receivables 70,489,155 192,777,285 1, Accounts receivable from customers 42,035,411 73,247,463 Profit from operation 29,338,236 198,327,508 IV, Inventories 33,754,871 31,896,985 Profit before tax 28,786,710 198,142,322 B, LONG-TERM ASSETS 81,447,252 83,037,150 Current income tax expenses 2,531,908 17,213,814 - - - - 68,988,182 71,389,491 26,254,802 180,928,508 TOTAL ASSETS 280,104,697 440,436,845 A, LIABILITIES 127,329,920 115,289,307 I, Cash flows from operating activities I, Short-term liabilities 127,329,920 115,289,307 Cash flows from operating activities A, CURRENT ASSETS 1, Long-term receivable 2, Fixed assets Administration expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD 13,331,183 45,630,650 II, Cash flows from investment activities 2,977,773 14,316,906 Cash flows from investment activities II, Long-term liabilities - - 1, Long-term loans and debts - - 2, Science and technology development fund - - B, EQUITY 152,774,776 325,147,537 TOTAL LIABILITIES AND OWNER'S EQUITY 280,104,697 440,436,845 1, Short-term loans and debts 2, Taxes payable to State Treasury 59 2019 -26,939,586 62,890,094 -42,903,957 -43,225,479 60,787,405 -16,351,129 - - -9,056,138 3,313,486 III, Cash flows from financial activities Cash flows from financial activities Effects from exchange rate difference Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2018 2.1. Domestic auto parts manufacturers TYPICAL MODELS Honda was established in 1948 in Japan and is one of the most valuable brand in the world (Forbes' annual ranking of the world's most valuable brands). The company's global strategy is to supply products of the highest quality yet at a reasonable price for worldwide customer Honda City satisfaction. Honda Civic Honda CR-V Honda City Honda Vietnam was established in 1996 as a joint venture between 3 partners, Japan Honda Motor Company (42%), Thailand Asian Honda Motor Company (28%), and Vietnam Engine and Agricultural Machinery Corporation (30%) to manufactures two main products: motorcycles and automobiles. In March 1998, Honda Vietnam inaugurated the first factory Honda Vietnam's strategy Units Sales volume of Honda Vietnam, 2014 – 9M/2020 35,000 140% 33,102 Honda Motor Vietnam is to provide 123.3% 27,099 30,000 120% 25,000 100% 20,000 80% manufacturing motorcycles, and in March 2005, Honda Vietnam officially received the license from the Ministry of Planning and Investment to allow the production and assembly of automobiles in Vietnam with a modern factory and assembly line in Vinh Phuc with the capacity of about 10,000 vehicles/year. Honda 16,520 15,000 10,000 6,492 5,000 8,312 38.4% 22.2% Accord and Honda Civic lines to fully meet the 2014 needs of Vietnamese customers. VIETNAM AUTOMOBILES MARKET REPORT 2015 2016 2017 Sales 60 fuel-saving technology in order to optimize the value for customers. In Vietnam, most Honda models use new I- VTEC technology engines combined with continuously variable transmission (CVT) 20% operate smoothly, save fuel and be environmentally friendly. Every year, Honda Vietnam organizes 5.5% 0 products with advanced, durable and gearboxes, which give the ability to 40% 28.0% Vietnam currently offers passenger cars such as Honda City, Honda CR-V, and import Honda 60% 12,134 11,501 One of the business strategies of 0% 2018 Growth 2019 9M/2020 9T/2020 Source: VIRAC, VAMA safe driving programs and experiences new models to help consumers to appreciate the most authentic Honda products in Vietnam. Financial statement INCOME STATEMENT HONDA VIETNAM CO., LTD Unit: USD BALANCE SHEET Unit: USD A, CURRENT ASSETS 2018 2019 1,480,795,400 1,502,461,375 1,069,730,078 1,149,107,065 II, Short-term investment - - III, Short-term receivables 65,153,628 1, Accounts receivable from customers I, Cash and cash equivalents 2018 2019 Net sales 4,590,351,458 4,666,103,683 Cost of goods sold 3,204,162,355 3,247,936,527 Gross margin 1,386,189,103 1,418,167,156 Income from financial activities 53,618,656 56,512,532 Expenses from financial activities 23,072,644 18,618,679 - - Selling expenses 187,367,122 186,306,205 65,022,110 Administration expenses 217,805,692 227,646,541 61,413,411 60,864,709 Profit from operation 1,011,562,302 1,042,108,262 IV, Inventories 296,972,041 252,436,271 Profit before tax 1,009,396,961 1,041,379,212 B, LONG-TERM ASSETS 279,678,616 307,060,506 Current income tax expenses 177,475,581 167,545,921 95,576 250,568 -3,801,255 1,782,098 207,077,119 211,757,301 835,722,635 872,051,193 1,760,474,016 1,809,521,881 A, LIABILITIES 871,614,551 884,333,858 I, Cash flows from operating activities I, Short-term liabilities 810,812,771 807,912,098 Cash flows from operating activities 1, Long-term receivable 2, Fixed assets TOTAL ASSETS Interest expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD - - 2, Taxes payable to State Treasury 45,683,476 47,987,847 II, Long-term liabilities 60,801,780 76,421,760 - - 52,555,520 63,697,617 888,859,465 925,188,023 1,760,474,016 1,809,521,881 1, Short-term loans and debts 1, Long-term loans and debts 2, Science and technology development fund B, EQUITY TOTAL LIABILITIES AND OWNER'S EQUITY 61 2019 791,264,600 923,607,416 -42,510,918 -69,176,631 -842,351,926 -788,025,313 -93,598,244 66,405,472 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities Effects from exchange rate difference Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2018 2.1. Domestic auto parts manufacturers TYPICAL MODELS Toyota Co., Motor Ltd Vietnam (TMV) automobile Joint is an Camry Ventures Vios Corrolla Fortuner founded in September, 1995. The total investment capital was 89.6 million USD based on the capital contributions from Toyota Motor Innova Corporation (70%), Vietnam Engine and Machinery Agricultural Corporation - KUO Units 90,000 (10%). 80,000 Since establishment, TMV has 70,000 VEAM (20%) Singapore incessantly and Pte.Ltd developed not only in sales but also in production scale. By now, TMV is holding the leading 30,000 automobile market with the 20,000 capacity of more than 30,000 10,000 units/year (two working shifts 0 a day) and the accumulated 20.5% 65,856 57,036 20% 15% 13.4% 40,820 4.1% 2016 2017 Sales apply higher prices than competitors in every segment. Marketing and branding policy: product exhibition, discount, sponsorship, customer club, annual participation in Vietnam Motorshow. In addition, activities, from year-end thank you party, golf 5% driving... to bring company brand closer to consumers. tournament, car maintenance instruction courses, safe Labour training policy: Toyota Vietnam applies a 2018 2019 9M/2020 9T/2020 Source: VIRAC, VAMA 62 strategy of professional training and regular qualification testing, especially the company is very interested in and prioritizes the recruitment of local Growth * Sales does not include Lexus VIETNAM AUTOMOBILES MARKET REPORT Toyota 10% 0% 2015 policy: the company also organizes a lot of customer care 41,109 11.0% 2014 Price promotion, 59,355 50,285 sales of TMV reaching more than 305,799 units. 25% 79,328 23.2% 40,000 position in the Vietnamese Honda Vietnam's strategy Sales volume of Toyota Vietnam, 2014 – 9M/2020 60,000 50,000 Hiace human resources. Financial statement INCOME STATEMENT TOYOTA MOTOR VIETNAM CO., LTD Unit: USD BALANCE SHEET Unit: USD A, CURRENT ASSETS 2018 403,441,300 I, Cash and cash equivalents 91,283,047 86,493,221 II, Short-term investment 23,676,281 60,266,896 III, Short-term receivables 22,101,661 1, Accounts receivable from customers 2019 Net sales 1,644,776,950 1,762,104,176 Cost of goods sold 1,369,759,730 1,473,539,017 275,017,220 288,565,159 12,887,352 11,797,905 5,228,974 7,997,893 Gross margin 2019 430,984,885 2018 Income from financial activities Expenses from financial activities - - Selling expenses 31,835,132 29,605,613 24,471,038 Administration expenses 22,450,869 24,094,457 11,042,491 14,412,112 Profit from operation 228,389,597 238,665,100 289,078,538 226,244,198 Profit before tax 226,448,156 238,567,690 56,607,642 65,142,735 46,051,548 48,836,896 275,339 216,289 -644,923 1,136,456 50,878,785 56,007,224 181,041,532 188,594,338 TOTAL ASSETS 487,592,527 468,584,034 A, LIABILITIES 242,424,532 215,863,234 I, Cash flows from operating activities I, Short-term liabilities 236,844,898 203,766,088 Cash flows from operating activities IV, Inventories B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets Interest expenses Current income tax expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD - - 50,130,924 38,685,113 5,579,634 12,097,146 - - 5,579,634 12,097,146 B, EQUITY 245,167,995 252,720,800 TOTAL LIABILITIES AND OWNER'S EQUITY 487,592,527 468,584,034 1, Short-term loans and debts 2, Taxes payable to State Treasury II, Long-term liabilities 1, Long-term loans and debts 2, Science and technology development fund 63 2019 25,988,893 224,113,575 -33,935,716 -47,868,903 -133,822,876 -181,041,532 -141,769,699 -4,796,860 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities Effects from exchange rate difference Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2018 2.1. Domestic auto parts manufacturers TYPICAL MODELS VinFast was founded in 2017, and is part of VinFast President VinFast Fadil Vingroup which is Vietnam’s biggest private enterprise. The company aims to become the leading automobile and motorcycle manufacturer in Southeast Asia. It plays a key role in Vingroup’s vision to become an VinFast Lux A 2.0 international standard technology-industry- VinFast Lux SA 2.0 service conglomerate by 2028 with a focus and VinFast’s strategy application. set up a manufacturing, research, supplier park, and development complex at a greenfield factory in the Dinh Vu Economic Zone located in Cat Hai District, Haiphong. The manufacturing plant complex comprises 335 hectares and includes a Centre for Product Research & Development, Automobile Manufacturing Plant, Training Centre and Localization Area. From now to 2025 – 2030, most R&D is expected to be channeled towards electric cars. VinFast diversified its product scope in an attempt to compete with both mid-high-level prices such as MercedesBenz, BMW, Audi, Lexus and electric models for lower segments. VinFast has bought in German technologies from BMW, Italian design from Pininfarina, and auto parts from Bosch and 3,500 Siemens. When previous original equipment manufacturers took about 60 months from design to 3,000 production, VinFast reduces lead time to a mere 24 months by replacing the time-consuming clay remodification 2,500 process with digital modelling. The designs have been 2,000 selected by an online survey in which 60,000 people participated. By proactively involving the general public, the 1,500 company hopes to capitalize on national pride which should 1,000 500 0 give the domestic consumer base the decisive push to 3,626 1,515 804 1,307 will Sales volume of VinFast, 5 – 9/2020 1,494 849 337 308 VinFast Units 4,000 2,214 1,577 355 282 development 2,170 1,364 467 339 technology 2,161 1,156 682 323 on 5/2020 6/2020 7/2020 8/2020 9/2020 Total sales VIETNAM AUTOMOBILES MARKET REPORT Fadil Lux A2.0 Lux SA2.0 Source: VIRAC 64 purchase VinFast’s vehicles. With an aggressive recruitment strategy, VinFast is attracting top talents for CEO, managers and staffs. Some key positions are taken by high-level managers from GM, Bosch, Hoden. Notably, attractive packages are introduced to hire a pool of skilled staff from Samsung. Financial statement INCOME STATEMENT VinFast TRADING AND PRODUCTION CO., LTD Unit: USD BALANCE SHEET Unit: USD A, CURRENT ASSETS 2018 2019 783,073,994 793,233,982 2018 Net sales 12,032,396 263,754,378 Cost of goods sold 13,932,562 450,197,482 Gross margin -1,900,165 -186,443,104 Income from financial activities 42,536,324 169,192,563 3,037,513 114,072,126 Expenses from financial activities 100,712,355 41,546,981 II, Short-term investment - - III, Short-term receivables 619,156,097 237,409,679 1, Accounts receivable from customers 27,728,862 40,610,830 IV, Inventories 10,245,593 419,893,867 1,562,131,994 3,101,466,849 1, Long-term receivable 139,475,248 348,175 2, Fixed assets 162,849,177 2,738,351,205 TOTAL ASSETS 2,345,205,988 3,894,700,831 A, LIABILITIES 1,264,204,405 3,060,911,552 543,035,639 756,981,323 Cash flows from operating activities 195,586,485 218,604,784 II, Cash flows from investment activities 10,558,744 17,963,512 II, Long-term liabilities 721,168,766 2,303,930,228 1, Long-term loans and debts 721,168,766 2,303,930,228 - - B, EQUITY 1,081,001,583 833,789,279 TOTAL LIABILITIES AND OWNER'S EQUITY 2,345,205,988 3,894,700,831 I, Cash and cash equivalents B, LONG-TERM ASSETS - 100,436,713 1,955,640 56,023,852 25,706,908 61,850,015 Profit from operation 9,936,097 -249,196,534 Profit before tax 7,455,569 -248,030,464 Current income tax expenses 1,273,716 - - - 6,181,852 -248,030,464 Interest expenses Selling expenses Administration expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD I, Short-term liabilities 1, Short-term loans and debts 2, Taxes payable to State Treasury 2, Science and technology development fund 65 2018 2019 I, Cash flows from operating activities Cash flows from investment activities -98,431,703 -362,756,453 -1,566,860,805 -1,281,626,556 1,760,841,675 1,584,876,726 95,549,167 -59,506,283 III, Cash flows from financial activities Cash flows from financial activities Effects from exchange rate difference Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2019 2.1. Domestic auto parts manufacturers Localization rate of key auto parts OEMs in Vietnam, 2019 Company’s average Passenger cars Truck Bus Target 15% - 18% 15 - 18% 35 - 45% 60% 60% ~12% 35% (Hyundai Accent) 40% ~25% 30% (Honda City) 40% 15% (Honda CR-V) ~20% 37% (Innova) 45% Less than 10% Less than 10% (Fadil) 60% Source: VIRAC VIETNAM AUTOMOBILES MARKET REPORT 66 Analysis of domestic tier-1 and tier-2 auto parts production Breaking down the existing auto part suppliers by tier type, among 404 suppliers identified by JETRO and JICA experts, there are 83 first tier suppliers, 138 second and third tier suppliers, 5 aftermarket producers, and 178 are not classifiable. By supplier specialization, 61 firms supply motorcycle parts, 50 firms supply both motorcycle and automobile parts, 18 firms supply automobile parts, and 275 firms are not classifiable. By nationality, there are 177 Japanese, 136 Vietnamese, 57 Taiwanese, 14 South Korean, and the remains belong to Germany, Malaysia, USA, etc. Suppliers by tier type Suppliers by nationality Suppliers by specialization Motorcycle parts 15% 1st tier 21% Automobile parts 5% Unknown 44% South Korea 3% Others 7% Taiwanese 14% Japanese 43% Both, 12% Unknown 68% 2nd tier 34% Vietnamese 33% AMP 1% 1st tier 2nd tier AMP Unknown Motorcycle parts Automobile parts Both Unknown AMP: Aftermarket producers Japanese Vietnamese Taiwanese South Korea Others Source: VIRAC, Synthesizing from JETRO’s and JICA’s list of local firms • To meet the growing demand, an automotive assembly company needs at least 20 suppliers of various components. However, even big joint ventures like Toyota is not able to produce CBU vehicles in Vietnam because the number of enterprises engaged in manufacturing spare parts is too small. • Automobile supporting industry only produces a number of components including components of chassis, car body, cabin cover, car door, tires, radiators, brakes, electric motors, shafts, wheel rims, etc. Therefore, the components and spare parts of automobiles are small in size, types and quantities. • The majority of domestic firms in the automobile supporting industries only provide products to the domestic automobile assembly companies, while the FDI enterprises in the supporting industries only supply products to FDI automobile assembly companies. VIETNAM AUTOMOBILES MARKET REPORT 67 Analysis of domestic tier-1 and tier-2 auto parts production Technical skill is not a major problem of local tier-1 suppliers, but the key barriers for them to engage in the automotive supply chain are high cost, low management skills (production, quality, warehouse, human...), and their perception of safety, environment. What car manufacturers expect from their potential suppliers include an updated and attractive business profile; cost and quality competitiveness; samples following to drawings; entrepreneur’s enthusiasm and perseverance; stable product quality, accurate tolerance; and ability to provide with different scales to different customers. ➔ Recommendations to potential suppliers: To become auto part suppliers and participate in automobile global supply chain, local businesses should: • Take part in auto part supplier databases and business matching programs. • Create attractive business profile. • Improve productivity, cut costs, compete on price and quality. • Improve management capability, and comply to the international norms of doing business. • Obtain international certification for quality, environment. VIETNAM AUTOMOBILES MARKET REPORT 68 10 Key tier-1 auto parts manufacturers No. Company name Tax code Location Net sales 2019 (USD) 1 DENSO MANUFACTURING VIETNAM CO., LTD. 0101210878 Lot E1, Thang Long Industrial Park, Kim Chung Commune, Dong Anh District, Hanoi City 480,710,500 2 YAZAKI HAI PHONG VIETNAM CO., LTD 0200438947 Lot L, Nomura Industrial Park, Hai Phong, An Hung Commune, An Duong District, Hai Phong 428,302,997 3 SUMI-HANEL WIRING SYSTEMS CO., LTD 0100113945 Industrial Road 4, Sai Dong B Industrial Park, Thach Ban Ward, Long Bien District, Hanoi 356,189,388 4 VIETNAM PRECISION INDUSTRIAL NO.1 CO, LTD 2500213190 Khai Quang Industrial Park, Khai Quang Ward, Vinh Yen City, Vinh Phuc Province 168,585,158 5 TOYOTA BOSHOKU HANOI CO., LTD 2500152396 No. 144, Tran Phu Street, Phuc Thang Ward, Phuc Yen Town, Vinh Phuc Province 118,796,461 6 GS BATTERY VIET NAM CO., LTD 3700255457 No. 18, Street 3, Vietnam - Singapore Industrial Park, Binh Hoa Ward, Thuan An Town, Binh Duong Province 103,601,922 7 HARADA INDUSTRIES VIETNAM CO., LTD 3600243024 Lot A1, Long Binh EPZ, Bien Hoa City, Dong Nai 84,305,847 8 HANOI PLASTICS JOINT STOCK COMAPY 0100100858 Group 12, Phuc Loi Ward, Long Bien District, Hanoi 51,837,654 9 INOAC VIETNAM CO., LTD 2500236896 Lot 36, Quang Minh Industrial Park, Quang Minh Town, Me Linh District, Hanoi 50,719,875 10 SUMMIT AUTO SEATS INDUSTRY CO., LTD 0101841425 Noi Bai Industrial Park, Soc Son District, Hanoi 2,391,905 *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 69 10 Key tier-1 auto parts manufacturers Tier-1 suppliers Denso Manufacturing Vietnam Co., Ltd. Overview Products Location Denso Manufacturing Vietnam Co., Ltd was established on October 4, 2001 (the System control Hanoi official time of receiving the investment license) in Thang Long Industrial Park, Dong component Anh, Hanoi, Vietnam. Since establishment, DENSO Vietnam has always focused on (Pedal, Valve environmental protection in all business activities and working towards sustainable switching) development. The company has received ISO 14001 certificate in 2004. Yazaki Hai Phong Vietnam Co., Ltd Yazaki Hai Phong Vietnam is a subsidiary of the Yazaki Group, Japan. Yazaki Electric Wire Group is a global business with 596 factories and branches in 46 countries around the System Hai Phong world. In Vietnam, Yazaki Hai Phong provides the electric wire system for cars. The company is also one of the leading factories in terms of quality, product prices, and on-time delivery to customers in Vietnam. Sumi-Hanel Wiring Systems Co., Ltd Sumi- Hanel Wiring System Co., LTd is a joint venture between Hanel and Electric Wire Sumitomo Corporation (Japan), specializing in manufacturing electric wires for System Hanoi automotive, motorbike and electronic industries. The Company was established under the Investment License No. 1588/GP dated 11 June 1996 issued by the Ministry of Planning and Investment. Currently, Sumi- Hanel is operating with 5,000 employees in Sai Dong B Industrial Zone, Hanoi. The company's products are highly valued for quality and technical safety. With the advantage from the brand of Hanel MTV Co., Ltd., Sumi-Hanel Wiring System Co., Ltd has received the trust of many partners in the electronics and automobile industry both in and outside the country. Established in 2001, Vietnam Precision Industrial No.1 Co., Ltd. manufactures and Stamping part, Vietnam Precision Industrial No.1 Co, supplies metal fabrication parts to various reputable companies including Honda, Chassis frame Ltd Ducati and Ford. VPIC1 has obtained multiple ISO certificates and grown to a assy, Side step, company with approximately 3,500 employees. VPIC1 is part of Eurocharm Hunger seat assy Group which primary operates in Taiwan. Since 1974, the Group has been focusing on delivering the best metalworking result with the most reliable quality. VIETNAM AUTOMOBILES MARKET REPORT 70 Vinh Phuc 10 Key tier-1 auto parts manufacturers Tier-1 suppliers Overview Products Location Toyota Boshoku Hanoi Co., Ltd Toyota Boshoku group is one of the world's premium interior systems suppliers and Seats and Vinh Phuc filter manufacturers, develops and produces interior components, unit components with the interior main office in Japan. Toyota Boshoku Asia (TBAS) employ over 11,000 team members in about components, 20 locations throughout Thailand, Malaysia, Philippines, Taiwan, Vietnam. TBAS group is a Carrier sub- premier manufacturer of automotive interior systems, which include seats, door trims, assays /Spare headliners, substrate, and carpet in addition to air and oil filters for a variety of customers. wheels, Floor Toyota Boshoku Hanoi Co., Ltd is established on 06/26/2008, with head office located in Carpets Phuc Yen City, Vinh Phuc Province, Vietnam. GS Battery Viet Nam Co., Ltd. GS Battery VietNam Co., Ltd is a company 100% foreign-owned capital, a joint venture between GS-Yuasa Corporation which is the No. 1 biggest lead-acid batteries manufactures in Battery Binh Duong Asia and Mitsubishi Corporation which is the biggest trading conglomerate in Japan. The company was established on May 12th,1997, and began its operation and business activities in 1999. Market share: - No 1 position in Vietnam for the original equipment market for famous manufacturers such as Toyota, Honda, Mercedes- Benz, Yamaha, Mitsubishi, Piaggio. - No 1 position in Vietnam for the replacement market of motorcycle and automotive batteries. Harada Industries Vietnam Co., Ltd. HARADA has been delivering automotive antennas since 1957 with the Lock Antenna, a radio receiving automotive antenna. Since then, they have advanced into a world-class supplier occupying a high share of OEM supplies for global automakers. The company provides customers a clear solution on antenna and surrounding technologies meeting the customer and market needs in response to the fast moving world of the automotive industry. VIETNAM AUTOMOBILES MARKET REPORT 71 Attenna Dong Nai 10 Key tier-1 auto parts manufacturers Tier-1 suppliers Overview Products Location Hanoi Plastics Joint Stock Comapy Hanoi Plastics Joint Stock Company (HPC) was established in 1972, headquartered in Long Plastics part Hanoi INOAC group were founded in 1926, and starts their business by producing tires and tubes for Rubber part, Hanoi bicycles. Since then, they have created new materials and products one after another, Dam/ Assays Bien, Hanoi and became a member company of An Phat Holdings - Plastic Plastic Group Art from the end of 2018. HPC is equipped with modern production lines and equipment systems imported from the US, Western European countries, Japan and some new industrial countries with mechanized qualifications and relatively high automation. Inoac Vietnam Co., Ltd including launching Japan’s first polyurethane production operation. INOAC Vietnam is one of the overseas subsidiaries of INOAC group, which focuses on manufacturing rubber, polyurethane and developing their applications such as automotive, electric products, office automation equipment, industrial machine, garment, furniture. Summit Auto Seats Industry Co., Ltd Summit Auto Body Industry Co., Ltd. or "SUMMIT" was established in 1986 and is one of the largest suppliers in Thailand's automotive industry. The ability to produce its own tooling and R&D combined with a constant production enhancement has led SUMMIT to the leading position. All SUMMIT's factories have passed IATF 16949:2016 , which is the latest standard in the industry. VIETNAM AUTOMOBILES MARKET REPORT 72 Sunviso, Headlining Hanoi 2.2. Entry barriers - Challenges for manufacturers • The small domestic vehicle market does not encourage the development of auto parts industry: Among the existing suppliers, more than 90% are FDI enterprises, only a few local suppliers can participate in the supply chains of auto manufacturers in Vietnam. Compared to Thailand, the number of suppliers in the Vietnam’s automobile industry is too little. Regarding the tier-1 suppliers in 2019, Thailand has nearly 700 enterprises, but Vietnam has only 83 suppliers. • The condition of more number of assemblers sharing smaller and more scatter size makes Vietnam harder to develop supplier networks: The local parts available for auto assemblers are normally labor intensive, simply produced, bulky and heavy parts, such as auto chairs, glasses, tires, wheels, etc. • Vietnam is seeing a major shortage of skilled labor: Only 12% of Vietnam’s 57.5 million-strong workforce are highly skilled, according to recruitment firm ManpowerGroup. A number of Vietnam human capital index rankings is quite low, including know-how and development and education. These limitations can certainly offset any savings in labor costs to make Vietnam a less attractive for many manufacturers since it will be hard for them to find quality labor force to support the automotive industry. • Price: ➢ Low orders quantity due to small car sale volume ➢ Reliance on imported raw materials (must purchase raw materials from suppliers appointed by car manufacturers) ➔ High product selling price • Capability: ➢ Quality management system requirement ➢ Low technical skill ➢ Lack of experience in producing high end products ➢ Weak R&D capacity ➢ Lack of funding sources to purchase modern facilities ➢ Management capacity (late delivery, etc.) ➔ Difficulties to meet high technical requirements from car manufacturers. VIETNAM AUTOMOBILES MARKET REPORT 73 2.2. Entry barriers - Key attractive points of Vietnamese automobiles industry • High potential automobile consumption market ➢ Vietnam’s automobile market has unique characteristics, which differentiates from those of other ASEAN countries: Vietnam has two major markets, Hanoi and Ho Chi Minh City, but others have only one big market in capital city (Indonesia may have two, Jakarta and Surabaya). In Vietnam, potential market seems to have a wider distribution, not only in Hanoi and Ho Chi Minh City, but also in other big cities like Hai Phong, Da Nang. These market characteristics combining with other factors, i.e. demographic dividend, infrastructure, GDP per capital growth will make Vietnam to become a high potential for automobile market in coming years. ➢ High saving rate among family: Average income of a typical family has been increasing year on year, in contrast spent per month has the same trend but at a much lower speed. Therefore, savings has been increased for large spent on houses and expensive stuff like autos. ➢ Loan outstanding balance for individual’s consuming has steady growth speed, reached USD 63.9 billion in 2019. Average income and spent per month, 2010 – 2019 USD 200 180 166.9 160 113.5 120 100 60 86.1 59.7 69.0 81.3 109.6 Vietnam loan outstanding balance, 2012-2018 70 180.8 80% 67.03% 60 133.4 140 80 USD billion 116.6 92.9 65.35% 60% 50 43.86% 40 50% 40% 30 52.1 70% 25% 40 9.53% 10 20 0 0 2010 30% 20 2012 2014 Average Income 2016 2018 2019 Spent per month *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 11.75 19.63 28.24 46.69 58.37 63.93 2014 2015 2016 2017 2018 2019 Loan outstanding balance Source: VIRAC, GSO 74 *Exchange rate: USD/VND = 23,230 20% 10% 0% Growth Source: VIRAC, NFSC 2.2. Entry barriers - Key attractive points of Vietnamese automobiles industry • Auto companies are increasing investments in supporting industries: ➢ On September 22, 2020, TC Motor began construction of the 340 ha Thanh Cong Viet Hung Complex for Automotive Supporting Industries in northern Quang Ninh Province. A spokesperson for the Ninh Binh-based auto firm believed that the complex would attract many companies in the auto ecosystem. ➢ Next to Quang Ninh is the VinFast plant that makes cars, motorbikes and electric bikes in the Dinh Vu-Cat Hai industrial zone in Hai Phong City. A third of the 335-ha plant is used to produce auto and motorbike parts. ➢ Truong Hai (Thaco) making large investments in supporting industries. It currently has 12 plants in the 1,200 ha Chu Lai-Quang Nam industrial zone making both internal and exterior parts for buses, trucks and cars; composite parts; automotive glass; air conditioners for trucks, buses and passenger cars; car body parts and more. • Vietnam young and cheap labor forces: ➢ Vietnam have low labor costs. The country monthly minimum wages in 2019 vary by region from $125 to $180, with the highest rates in urban areas like Ho Chi Minh City and Hanoi. Besides, Vietnam’s minimum wage growth is showing signs of stability. Minimum wages increased by an average of 5.3% in 2019, a lower increase than in 2018 (6.5%) and 2017 (7.3%). The abundant low-wage labor force is one of the key attractive point in the initial stage of the Vietnamese automotive industry’s development. • Taxes on automobiles and auto parts ➢ The Ministry of Finance has worked on a special consumption tax policy to submit it to the government, proposing to reduce or waive the tax on domestically made car components to help local automobile manufacturers cut costs. ➢ The Ministry of Industry and Trade (MoIT) has also proposed other support policies such as lower corporate income tax for the auto industry and its supporting industries. ➢ The Vietnamese central bank have also been considering policies to increase demand for cars, such as lower loan interest rates for buying domestically produced cars. VIETNAM AUTOMOBILES MARKET REPORT 75 2.2. Entry barriers - Proposals of entry strategy for Korean auto parts manufacturers Reason that urges South Korean investors to pour money into projects on making car parts in Vietnam: • Vietnam’s new regulations, including Decree 116 that tightens control over imported automobiles, “positively influence” South Korean auto firms’ investment decisions. • The saturation of the world market which has led to a drop in exports, domestic sales and manufacturing in South Korea. According to a report by the Korea Automobile Manufacturers Association (KAMA), the country made 2,162,000 vehicles in the first six months of 2017, a 1.5 % year-on-year decline against 2016, marking the lower production since 2010. • The auto industry of South Korea owns an effective supply chain which its leading firms can take of advantage to reach out to international markets. • Vietnam’s strategic geographic location: many Korean auto part manufacturers' major goal is selling automobile parts to Southeast Asia, which may include Vietnam’s VinFast - the automotive arm of conglomerate Vingroup. So the factories, one in place, would help Korean investors reduce the cost and raise the convenience for supplying their products in the Southeast Asian market. General strengths of Korean auto parts manufacturers: • The auto industry of South Korea owns an effective supply chain which its leading firms can take of advantage to reach out to international markets. • Investment from South Korea in Vietnam remains strong. The Northeast Asian country is the second-largest source of foreign direct investment (FDI) for Vietnam in the first six months of this year, second only to Japan. During the reviewed period, South Korean firms invested US$5.06 billion, or 24.9% of total investment to the country. • Korean is increasing investment in Vietnam to boost supporting industry: VITASK - a cooperation project between the South Korean Ministry of Trade, Industry, and Energy and the Vietnamese Ministry of Industry and Trade, was officially launched on December 11, 2020, in Hanoi, to help Vietnamese businesses in the automotive and electrical-electronic industries improve their capacity and deeply participate in the global supply chain. • Korea has experience in developing a successful auto industry and makes it a vehicle for economic growth. Korean auto parts manufacturers can draw lessons for the development of auto industries in latecomer countries like Vietnam, and offer measures that can use, drawing on the successes and failures of the Korean auto industry’s development experience. VIETNAM AUTOMOBILES MARKET REPORT 76 2.2. Entry barriers - Proposals of entry strategy for Korean auto parts manufacturers For the market entry strategy, Korean auto part makers may start with “pass through” first to test the market demand and then set up factories later on. Key requirements for such pass through collaboration are as follows: • Be an existing auto part suppliers for OEMs’ overseas plants • Have a local partners with an existing manufacturers plant in Vietnam • Providing key input materials or parts for further processing in Vietnam and supplying to OEMs to test the market demand. Suitable options of market penetration: Collaboration with FDI auto parts markers ➢ Collaboration opportunity: low ➢ Collaboration type: Become their potential suppliers (preferred for Korean auto part makers have manufacturing plants in Vietnam already) ➢ Most of tier-1 auto part companies in Vietnam are FDIs who produce auto parts upon the orders from their parent companies or foreign customers. Majority of their output products are exported while small portions are supplied to local car manufacturers. Collaboration with local auto part makers ➢ Collaboration opportunity: high ➢ Collaboration type: R&D co-operation or become their clients or suppliers ➢ Local companies are open for cooperation with new partners and clients. However, most of them are small-scale businesses and able to provide small and simple auto parts only. They would be good candidates for Korean auto parts makers in pass through collaboration since they have existing manufacturing plants in Vietnam and are open to cooperate. VIETNAM AUTOMOBILES MARKET REPORT 77 2.2. Entry barriers - Proposals of entry strategy for Korean auto parts manufacturers Step 1 Information exchange between car manufacturers and auto part makers Site visit by car manufacturers to assess Step 2 auto part supplier’s production capability Car manufacturer provides standard technical General procedure Step 3 of entry strategy Step 4 drawings and technical requirements Auto part company provides sample & quotation Sample product verification & contract Step 5 Step 6 VIETNAM AUTOMOBILES MARKET REPORT 78 negotiation Archive licenses and sign the contract 2.2. Entry barriers - Proposals of entry strategy for Korean auto parts manufacturers Searching for suppliers • Searching for potential suppliers: • First visit: The purpose of the Regularly, the car manufacturer first visit is to confirm the usually looks for new auto part information suppliers gathered databases profile screening, preliminarily developed by consulting assess companies or government the ability requirements on to introduction assurance, etc. the existing Profile screening: • When a Second visit: If the samples meet the requirements, the car potential supplier is identified, the manufacturer car manufacturer will look at its second visit. The purpose of this profile necessary visit is mainly to confirm the information about main products, progress of improvements per size of their recommendations in the customers, first time, the readiness of equipment and technology in use, potential suppliers to become financial status, etc. If they find all their suppliers, as well as the conditions are satisfied, they will enthusiasm and passion of the contact to make an appointment firms’ leaders. of to the collect business, establishment, main year will require a Request for quotation: if a visible, the car manufacturer will contact to request for quotation for the products they offer. After receiving the quotation, if it is safety, management systems, quality reasonable, they will send a request for sample production. • Request for sample production: There can be several ways to request for sample production. The car manufacturer can send detailed blueprints, on which potential suppliers will produce molds base on and to make samples. The car manufacturer can also send a sample product, and the potential suppliers should measure the sample to draw blueprints, making the for a factory visit. mold, and copied one. VIETNAM AUTOMOBILES MARKET REPORT Order possibility of collaboration is meet organizations, trade fairs, or the of • from through suppliers or employees. • Request for quotation and sample Visit 79 then produce a • Order for mass production: If the second positive visit results, manufacturer achieved the will car consider making the first order for mass production. It normally takes about 1.5 to 2 years from this date until the launching date of the first vehicle assembled with their products. Throughout this period time, the car manufacturer suppliers still frequently collaborate, have and to work together to ensure the quality and progress of work. 2.3. Collaboration landscape Key factors enable collaboration in Vietnamese automobiles industry • Increasing demand for higher localization rate: ➢ The Ministry of Finance proposed a draft regulation on new special tax calculation for domestically-produced cars to encourage automotive makers to increase localization rate. Taxable price for domestically-produced automobiles with 9 seats or less will be exclusive of the value od the auto parts produced domestically, encouraging automotive makers to increase the localization rate and enhance price competitiveness of domestic assembled car. ➢ To enjoy the tax incentives from the regulation, car manufacturers are expected to increase their localization rate via the cooperation with domestic auto part suppliers. • Local OEMs aims to increase their localization rate: ➢ Car manufacturers are aims to increase their localization rate to over 40% via further development of local supplier base. For example, Toyota Vietnam’s key focuses for localization in Vietnam include Seats, Body parts and Plastics auto parts. ➢ OEMs are leveraging existing motorcycle supplier base to find new auto part suppliers. ➢ Many OEMs in Vietnam are open for collaboration with Korean auto part suppliers such as Thaco Auto, Toyota Vietnam, Honda Vietnam, Ford Vietnam, etc. VIETNAM AUTOMOBILES MARKET REPORT 80 2.3. Collaboration landscape SWOT analysis for Vietnamese automobiles industry S W • In the short term, vehicles assembled in Vietnam are cheaper than imported vehicles. However, in the long run, with the current import tax reduction schedule for cars, it is likely that imported cars will be priced close to domestically assembled ones • The advantages from geographic location will help reduce costs and facilitate the supply of products to T • Vietnam is in a period of deep international integration with a series of FTAs signed which will be a good opportunity for the country to join the global supply chain and develop the supporting industry. • Living standard and income of the people are gradually increasing. Opportunities to develop for • The size of Vietnam's automobile market is fragmented as car assemblers are disconnected. • The automobile supporting industry is small which cannot stimulate the development of parts • Consumers in Vietnam tend to wait for lowpriced imported cars when the car import tax from ASEAN is reduced to 0%. • There are many contradictions in the development policies of the automobile industry • Countries in the region have more competitive the auto industry are still abundant. VIETNAM AUTOMOBILES MARKET REPORT manufacturing and supporting industries is weak. manufacturers. the markets in Southeast Asia. O • The connection between automobile price and higher localization rates than Vietnam. 81 SWOT analysis OEMs in Vietnam suitable for collaboration – VinFast ❖ Strengths: ❖ Weaknesses: • The sound business and financial performance of Vingroup over the • The most serious challenge for VinFast is to compete with international years is a strong foundation for the company to confidently take up the new giants in both domestic and foreign markets. As a young brand with no challenge. proven track record, it will need to focus on the domestic market first, at • The company’s business ecosystem in different sectors and its large least in the coming five to ten years, then looks to export its products. customer base of about 5 million middle-class people provide the • VinFast will have to invest heavily in R&D capabilities and human company with a unique advantage in marketing its automotive products in resource development to internalize the imported technologies and the domestic market. The company can provide promotion packages with know-hows. VinFast’s technical teams are reportedly rather inexperienced additional benefits from its other businesses, such as health care or holiday and still unable to master these technologies, leading to their reliance on vouchers, or even discounts for housing products to lure new car buyers. consultants, especially AVL. S W • Vingroup in general, and VinFast in particular, enjoy strong political • VinFast need to work with partners to establish facilities for backing from Vietnamese government authorities. It is an open secret manufacturing car components and spare parts to achieve the expected that Vingroup’s success in the real estate business is significantly indebted to localization ratio of 60 per cent. its political connections. These connections facilitated the group’s acquisition of large, well-located land lots in major cities, mostly from state-owned enterprises, to develop its real estate projects, which gave Vingroup a considerable advantage over its competitors. have led the Vietnamese government to provide VinFast with various • Nationalist sentiments is VinFast’s strength in the domestic market. Right from the beginning, VinFast wanted to mobilize nationalist sentiments as a means to connect with Vietnamese customers and to win government support, and capitalize on Vietnamese customers’ pride in driving a modern and quality national car. VIETNAM AUTOMOBILES MARKET REPORT of their technologies, know-hows, parts and components, but in the long run, failing to internalize these resources will cause the company to produce just another type of “Made in Vietnam” cars, and not the type of • Strong political support and VinFast’s importance to the local economy preferential incentives. • In the initial stage, VinFast had to take a short cut by importing most 82 “Made by Vietnam” cars that the company wishes to develop. SWOT analysis OEMs in Vietnam suitable for collaboration – VinFast ❖ Threats: ❖ Opportunities: • The potential for the Vietnamese automotive market remains ample. The car ownership ratio in Vietnam is 16 cars/1,000 residents, significant lower than that of Malaysia (341/1,000), Thailand (196/1,000), and Indonesia • In the domestic market, Vingroup will have to work hard to sell its cars to customers who typically prefer Japanese brands and imported cars to domestic ones. (55/1,000). As a country of 94 million people with young demographics and a • In order to make its production more efficient, and to reduce car prices, fast expanding middle class, Vietnam is a promising market with significant Vingroup will need to increase its manufacturing scale. In this regard, the sale opportunities for VinFast and other automakers if they can cater to the small size of the domestic market is a major impediment. O varied demands of local customers. T • To change the country’s traffic culture, reduce air pollution and grow • As a new player in the industry, VinFast is no doubt facing many the automotive market, the Vietnamese government is likely to consider difficulties, but also enjoys certain benefits from being a latecomer: the gradually phasing out motorbikes in certain big cities, especially Hanoi and company can adopt new, advanced technological platforms or a forward- Ho Chi Minh City. However, this measure is not going to be feasible unless looking business strategy right from the beginning without having to deal local governments provide alternative public transport options for those who with legacy issues, decision to develop e-scooters and electric cars are cases cannot afford cars. in point. • The lack of infrastructure for cars is yet another challenge that not only • Appealing for investments from financial institutions and win the trust VinFast but also other automakers will have to face. Frequent traffic jams of its partners and suppliers: Vingroup has a good track record, esspecially and the lack of parking spaces have long discouraged car buyers in major asset management not only in automobile industry but also other sectors. cities. Vietnam will need to build more highways within and between cities • To the end of 2020, domestically manufactured or assembled automobiles will receive a 50% reduction in registation fee, which is a huge opportunity for VinFast. and reserve more urban spaces for parking facilities if it wants to give a boost to the automotive industry. • The large investment needed and the lack of a relevant technological base and of qualified human resources in Vietnam is another significant challenge. VIETNAM AUTOMOBILES MARKET REPORT 83 SWOT analysis OEMs in Vietnam suitable for collaboration – Thaco ❖ Weaknesses ❖ Strengths • Thaco is currently the leading company in the Vietnamese auto industry • Thaco is a domestic private manufacturing enterprise and a pioneer in terms of investment scale, capital resources, technology, number of brands in the automobile manufacturing and assembling industry - a young held, automobile segment and product consumption, etc. industry in Vietnam; therefore, its financial resources are inferior to those • Thaco owns the largest complex of modern automobile manufacturing and assembling factories in Vietnam. This complex is built in Chu Lai Open of competitors whose parent company is national corporations such as Toyota, Mercedes-Benz, GM, and Ford. Economic Zone, it is also considered as the largest mechanical manufacturing • Experience in management, production, access to modern production center in Vietnam with the main products being automobiles and all kinds of technologies, advanced management models, as well as the strength of auto parts. the brand are also inferior to that of big and long-standing companies S • Thaco has diversified products, serving quite a full range of segments on the market. In addition, the possession of modern technology and large production scale helps Thaco create quality products with low prices (the cheapest on the market among other prestigious car brands). • The distribution system is strong and nationwide, so customer service is wellmanaged and prioritized. • Cost of goods sold is cheap, due to tax incentives from the government. The government supporting operation activities within the industry and advantage from a centralized chain model help Thaco outperform other competitors. W such as Toyota and Ford. • The technical level of the production team is not high, still requiring a lot of training time. • The ability to understand the needs of consumers and topography of regions across the country helps Thaco quickly improve car models in accordance with consumer preferences, terrain, and transportation systems. VIETNAM AUTOMOBILES MARKET REPORT 84 84 SWOT analysis OEMs in Vietnam suitable for collaboration – Thaco ❖ Opportunities ❖ Threats • The favorable geographical location of the factory complex, together • Intense competition in the automobile manufacturing industry: with the government’s preferential policies and political environment economic development and increase in consumer demand for cars will give Thaco the opportunity to expand production scale and complete the inevitably bring about stronger competition. self-contained production system, from the production of components and spare parts to assembly, distribution and repair services, customer service. O Southeast Asia, compared to the general level of the world automobile T manufacturing industry, THACO's technology is still much inferior. • Improvement of people’s living standard and the rise of Vietnamese middle class help Thaco expand its business. • It is necessary to prioritize upgrading and improving technology, improving • Government guidelines and policies on domestic consumption such as the movement and slogan "Vietnamese people use Vietnamese goods" together with prehension of Vietnamese culture create a better image of Thaco in Vietnamese people’s mind. VIETNAM AUTOMOBILES MARKET REPORT • Although the technology is considered to be the most modern in efficiency and production scale to ensure stable development and steady growth. • Thaco faces challenges of training highly skilled workers who will be directly in charge of the new advanced production technologies. • Increasing gasoline prices, requirements for clean technology and environmentally friendly products are also a challenge for Thaco. • Vietnam's automobile manufacturing industry has gradually become stable; opening Vietnam for integration with the world, tariff barriers and techniques for protection will also change. This will cause Thaco to lose tax incentives. 85 85 Appendix: Financial Statement Financial statement DENSO MANUFACTURING VIETNAM CO., LTD. INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 144,412,013 138,760,285 68,073,111 61,162,208 II, Short-term investment - - III, Short-term receivables 47,549,491 48,727,322 1, Accounts receivable from customers 44,574,645 44,984,709 IV, Inventories 27,472,692 27,477,098 54,989,332 59,097,658 76,065 64,694 52,730,865 42,502,181 199,401,345 197,857,943 A, LIABILITIES 52,698,226 51,423,647 I, Short-term liabilities 49,843,542 50,265,922 A, CURRENT ASSETS I, Cash and cash equivalents B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets TOTAL ASSETS 2018 Net sales 483,650,166 480,710,500 Cost of goods sold 348,664,646 309,341,494 84,002,294 79,850,984 Income from financial activities 3,172,811 2,018,414 Expenses from financial activities 1,037,697 1,097,532 Gross margin - - 20,107,139 16,744,983 9,432,226 9,024,107 Profit from operation 56,598,043 55,002,774 Profit before tax 56,241,713 53,461,599 8,740,199 8,766,780 -124,973 -219,012 47,626,488 44,913,832 Interest expenses Selling expenses Administration expenses Current income tax expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD - 2, Taxes payable to State Treasury 2,427,544 1,624,972 II, Long-term liabilities 2,854,684 1,157,725 - - 2,854,684 1,157,725 B, EQUITY 146,703,119 146,434,296 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 199,401,345 197,857,943 Net cash flows during the fiscal year 1, Long-term loans and debts 2, Science and technology development fund Cash flows from operating activities II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 87 2018 2019 I, Cash flows from operating activities - 1, Short-term loans and debts 2019 87,475,190 59,283,295 0 0 -8,698,526 -19,221,626 0 0 -60,083,319 -45,747,530 0 0 18,693,345 -5,685,861 Financial statement YAZAKI HAI PHONG VIETNAM CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 140,020,777 136,458,693 21,434,766 18,834,953 II, Short-term investment - - III, Short-term receivables 63,379,448 58,668,325 1, Accounts receivable from customers 63,184,402 58,603,711 IV, Inventories 54,186,174 58,338,305 93,791,404 85,028,803 70,933 69,603 80,985,694 74,263,413 TOTAL ASSETS 233,812,181 221,487,496 A, LIABILITIES 184,820,115 162,149,004 172,319,632 151,731,594 A, CURRENT ASSETS I, Cash and cash equivalents B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets I, Short-term liabilities 89,569,492 76,346,767 185,553 576,216 II, Long-term liabilities 12,500,483 10,417,410 1, Long-term loans and debts 10,257,905 8,396,358 2,242,578 2,021,052 48,992,066 59,338,492 233,812,181 221,487,496 1, Short-term loans and debts 2, Taxes payable to State Treasury 2, Science and technology development fund B, EQUITY TOTAL LIABILITIES AND OWNER'S EQUITY 88 2019 Net sales 427,257,471 428,302,997 Cost of goods sold 416,771,796 406,171,834 10,485,675 22,131,163 400,185 93,904 Expenses from financial activities 3,262,916 3,702,528 Interest expenses 2,925,341 2,694,248 Selling expenses 1,593,849 1,506,336 Administration expenses 6,030,891 5,457,956 -1,796 11,558,247 Profit before tax 206,130 11,221,152 Current income tax expenses 138,658 1,973,873 - - 67,472 9,247,279 Gross margin Income from financial activities Profit from operation Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD 2018 2019 I, Cash flows from operating activities Cash flows from operating activities 3,771,828 19,116,401 -6,754,611 -5,321,297 6,468,509 -16,711,724 3,485,726 -2,916,620 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities Effects from exchange rate difference Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2018 Financial statement SUMI-HANEL WIRING SYSTEMS CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 2018 Net sales 356,189,388 399,114,540 Cost of goods sold 338,289,795 378,095,867 17,899,593 21,018,672 1,079,956 1,275,609 952,707 563,150 57,295,975 63,690,575 1,462,995 2,397,541 II, Short-term investment - - III, Short-term receivables 38,667,233 38,676,233 1, Accounts receivable from customers 38,402,886 38,483,448 IV, Inventories 16,173,203 20,031,816 32,076,132 28,669,569 323,774 330,033 24,659,575 24,240,073 TOTAL ASSETS 89,372,107 92,360,144 A, LIABILITIES 66,092,481 65,426,204 62,334,491 62,993,556 Unit: USD 14,984,143 10,945,435 I, Cash flows from operating activities 697,551 1,945,768 3,757,990 2,432,648 1,881,331 2,207,974 B, EQUITY 23,279,626 26,933,940 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 89,372,107 92,360,144 Net cash flows during the fiscal year A, CURRENT ASSETS I, Cash and cash equivalents B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets I, Short-term liabilities 1, Short-term loans and debts 2, Taxes payable to State Treasury II, Long-term liabilities 1, Long-term loans and debts 2, Science and technology development fund Gross margin Income from financial activities Expenses from financial activities 558,245 350,651 Selling expenses 4,425,900 5,397,762 Administration expenses 5,339,240 6,121,430 Profit from operation 8,261,701 10,211,939 Profit before tax 8,239,068 10,314,951 Current income tax expenses 1,224,382 1,470,209 -2,020 77,796 7,016,707 8,766,946 Interest expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Cash flows from operating activities 89 2018 2019 8,685,756 16,623,934 -9,776,638 -4,219,005 -9,626 -11,525,076 -1,100,507 879,853 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2019 Financial statement VIETNAM PRECISION INDUSTRIAL NO.1 CO, LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 146,365,632 168,585,158 Cost of goods sold 122,360,886 140,633,670 24,004,747 27,951,488 3,402,945 2,477,866 253,291 552,040 80,180,818 I, Cash and cash equivalents 13,262,424 21,584,174 Income from financial activities II, Short-term investment 10,288,420 11,622,901 Expenses from financial activities III, Short-term receivables 25,996,151 23,388,358 1, Accounts receivable from customers 22,608,053 22,291,480 IV, Inventories 20,580,361 20,110,634 49,223,552 56,957,782 B, LONG-TERM ASSETS Gross margin 106,309 306,575 Selling expenses 1,507,196 1,626,910 Administration expenses 3,294,514 3,994,512 Profit from operation 22,352,690 24,255,893 Profit before tax 22,518,475 24,867,980 4,550,664 4,033,424 17,967,811 20,834,556 Interest expenses Current income tax expenses 1, Long-term receivable Income tax expenses is deferred 34,887,550 43,295,698 TOTAL ASSETS 122,148,756 137,138,600 A, LIABILITIES 38,558,511 32,713,799 38,558,511 32,713,799 Unit: USD I, Cash flows from operating activities 2, Fixed assets I, Short-term liabilities 1, Short-term loans and debts 6,924,338 12,902,753 2, Taxes payable to State Treasury 1,345,661 357,644 CASHFLOW STATEMENT Cash flows from operating activities Cash flows from investment activities 1, Long-term loans and debts 2018 2019 13,250,178 20,259,739 -9,927,255 -17,919,957 -4,369,724 5,978,415 -1,046,801 8,318,197 III, Cash flows from financial activities 2, Science and technology development fund TOTAL LIABILITIES AND OWNER'S EQUITY Net profit after tax II, Cash flows from investment activities II, Long-term liabilities B, EQUITY 2019 Net sales 72,925,204 A, CURRENT ASSETS 2018 Cash flows from financial activities 83,590,245 104,424,801 Effects from exchange rate difference 122,148,756 137,138,600 Net cash flows during the fiscal year *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 90 Financial statement TOYOTA BOSHOKU HANOI CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2019 31,787,754 10,779,665 15,111,246 II, Short-term investment - - III, Short-term receivables 11,621,152 10,621,589 1, Accounts receivable from customers 11,440,257 9,306,911 7,395,506 6,038,447 8,295,553 8,277,835 I, Cash and cash equivalents IV, Inventories B, LONG-TERM ASSETS 7,867,569 7,453,607 TOTAL ASSETS 38,091,876 40,065,589 A, LIABILITIES 11,204,039 11,139,307 10,859,975 10,705,462 2, Fixed assets I, Short-term liabilities 118,796,461 Cost of goods sold 94,193,316 99,959,623 Gross margin 16,815,406 18,836,838 432,251 507,841 - 26,335 Selling expenses 3,744,468 4,041,641 Administration expenses 2,323,939 2,664,453 Profit from operation 11,179,250 12,612,250 Profit before tax 11,186,964 12,617,160 2,323,261 2,614,875 8,863,703 10,002,285 Income from financial activities Expenses from financial activities Interest expenses Current income tax expenses 1, Long-term receivable Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD Cash flows from operating activities 1,027,446 555,528 344,065 433,846 344,065 433,846 B, EQUITY 26,887,836 28,926,282 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 38,091,876 40,065,589 Net cash flows during the fiscal year II, Long-term liabilities 1, Long-term loans and debts 2, Science and technology development fund 2018 2019 I, Cash flows from operating activities 1, Short-term loans and debts 2, Taxes payable to State Treasury 2019 111,008,721 Net sales 2018 29,796,323 A, CURRENT ASSETS 2018 91 13,756,349 -1,680,687 -1,488,957 -5,208,782 -7,963,840 1,137,041 4,303,552 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 8,026,509 Financial statement GS BATTERY VIET NAM CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 87,805,220 103,601,922 Cost of goods sold 66,099,646 80,190,400 Gross margin 21,705,575 23,411,522 1,254,790 1,588,084 612,167 405,958 Selling expenses 6,910,214 8,209,385 Administration expenses 2,309,346 2,303,069 Profit from operation 13,128,638 14,081,194 Profit before tax 13,140,399 14,096,093 2,404,167 2,703,312 10,736,232 11,392,781 47,536,017 3,977,950 11,225,016 Income from financial activities II, Short-term investment 25,942,316 19,328,455 Expenses from financial activities III, Short-term receivables 3,964,381 5,465,096 1, Accounts receivable from customers 3,143,910 3,695,192 13,302,886 10,941,517 18,821,346 21,014,294 I, Cash and cash equivalents IV, Inventories B, LONG-TERM ASSETS 15,747,991 15,311,808 TOTAL ASSETS 66,444,986 68,550,311 A, LIABILITIES 8,195,609 9,644,385 7,901,194 9,352,899 2, Fixed assets I, Short-term liabilities Interest expenses Current income tax expenses 1, Long-term receivable Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD Cash flows from operating activities 1,879,833 1,039,936 294,415 291,486 294,415 291,486 B, EQUITY 58,249,377 58,905,926 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 66,444,986 68,550,311 Net cash flows during the fiscal year II, Long-term liabilities 1, Long-term loans and debts 2, Science and technology development fund 2018 2019 I, Cash flows from operating activities 1, Short-term loans and debts 2, Taxes payable to State Treasury 2019 Net sales 47,623,640 A, CURRENT ASSETS 2018 92 15,238,647 -1,082,480 2,718,514 -8,753,788 -10,736,232 1,316,410 7,220,929 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 11,152,678 Financial statement HARADA INDUSTRIES VIETNAM CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD A, CURRENT ASSETS I, Cash and cash equivalents 2018 2019 22,457,996 22,874,404 658,730 1,837,485 2018 Net sales 75,267,257 84,305,847 Cost of goods sold 68,541,674 79,406,308 6,725,583 4,899,539 29,568 18,418 122,595 309,398 Gross margin Income from financial activities Expenses from financial activities II, Short-term investment 103,467 249,264 1,740,389 1,774,903 814,279 952,843 Profit from operation 4,077,887 1,880,814 Profit before tax 4,148,210 1,489,205 Current income tax expenses 834,336 1,352,268 Income tax expenses is deferred -77,911 35,017 3,391,785 101,920 Interest expenses 10,010,488 10,522,806 9,812,072 10,483,168 IV, Inventories 11,657,762 10,176,242 B, LONG-TERM ASSETS 5,384,113 7,496,388 529,788 529,629 3,775,815 6,326,457 TOTAL ASSETS 27,842,109 30,370,792 A, LIABILITIES 16,236,374 19,675,820 16,101,652 19,532,536 Unit: USD 4,494,189 10,971,588 I, Cash flows from operating activities 2, Taxes payable to State Treasury 531,366 243,758 II, Long-term liabilities 134,722 143,284 134,722 143,284 B, EQUITY 11,605,736 10,694,972 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 27,842,109 30,370,792 Net cash flows during the fiscal year III, Short-term receivables 1, Accounts receivable from customers 1, Long-term receivable 2, Fixed assets I, Short-term liabilities 1, Short-term loans and debts 1, Long-term loans and debts 2, Science and technology development fund Selling expenses Administration expenses Net profit after tax CASHFLOW STATEMENT Cash flows from operating activities 93 2018 2019 1,574,719 -314,781 -2,259,090 -4,039,167 991,132 5,499,720 306,761 1,145,772 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2019 Financial statement HANOI PLASTICS JOINT STOCK COMAPY INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 2018 Net sales 46,739,376 51,837,654 Cost of goods sold 41,514,229 46,772,165 5,225,147 5,065,489 466,568 1,212,776 40,325 1,301,756 17,497,413 18,823,491 I, Cash and cash equivalents 855,484 600,161 II, Short-term investment 860,956 2,001,722 III, Short-term receivables 12,466,348 12,381,803 1, Accounts receivable from customers 6,324,178 7,736,070 IV, Inventories 3,059,658 3,481,020 5,274,157 23,042,191 - 5,469,806 Current income tax expenses 3,288,407 6,450,045 Income tax expenses is deferred TOTAL ASSETS 22,771,570 41,865,683 A, LIABILITIES 8,262,806 21,787,216 8,262,806 16,885,442 Unit: USD 2,000,785 10,543,892 I, Cash flows from operating activities 203,197 195,440 II, Long-term liabilities - 4,901,774 1, Long-term loans and debts - 4,901,774 B, EQUITY 14,508,765 20,078,466 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 22,771,570 41,865,683 Net cash flows during the fiscal year A, CURRENT ASSETS B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets I, Short-term liabilities 1, Short-term loans and debts 2, Taxes payable to State Treasury 2, Science and technology development fund Gross margin Income from financial activities Expenses from financial activities 30,959 591,350 Selling expenses 1,810,593 1,492,420 Administration expenses 1,259,282 1,471,661 Profit from operation 2,581,515 2,012,427 Profit before tax 2,986,765 2,022,669 553,978 496,212 - - 2,432,787 1,526,457 Interest expenses Net profit after tax CASHFLOW STATEMENT Cash flows from operating activities Cash flows from investment activities 2019 2,503,726 -1,471,220 -6,742,985 -16,406,894 14,110 17,622,824 -4,225,149 -255,290 III, Cash flows from financial activities *Exchange rate: USD/VND = 23,230 94 2018 II, Cash flows from investment activities Cash flows from financial activities VIETNAM AUTOMOBILES MARKET REPORT 2019 Financial statement INOAC VIETNAM CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 19,592,712 22,352,550 2,758,865 3,464,847 II, Short-term investment - - III, Short-term receivables 11,043,691 12,318,105 1, Accounts receivable from customers 10,771,166 11,984,291 5,463,492 6,175,172 26,148,916 26,223,976 533,780 534,512 20,469,569 20,797,923 TOTAL ASSETS 45,741,627 48,576,525 A, LIABILITIES 24,004,221 22,388,148 16,933,075 17,377,544 A, CURRENT ASSETS I, Cash and cash equivalents IV, Inventories B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets I, Short-term liabilities 2018 Net sales 46,046,995 50,719,875 Cost of goods sold 37,634,019 38,734,944 8,412,975 11,984,931 Income from financial activities 137,807 502,422 Expenses from financial activities 633,363 672,603 Gross margin 335,610 343,565 Selling expenses 3,206,288 3,399,296 Administration expenses 2,990,116 2,904,016 Profit from operation 1,721,016 5,511,438 Profit before tax 1,752,784 5,662,563 225,291 1,172,850 - - 1,527,493 4,489,713 Interest expenses Current income tax expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD 3,786,277 130,784 468,618 II, Long-term liabilities 7,071,146 5,010,604 1, Long-term loans and debts 7,044,972 4,985,091 26,174 25,513 B, EQUITY 21,737,406 26,188,378 Effects from exchange rate difference TOTAL LIABILITIES AND OWNER'S EQUITY 45,741,627 48,576,525 Net cash flows during the fiscal year 2, Taxes payable to State Treasury 2, Science and technology development fund Cash flows from operating activities 95 2019 3,396,239 6,142,388 -3,239,141 -2,274,582 -2,352,453 -3,151,501 -2,195,355 716,306 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2018 I, Cash flows from operating activities 4,885,861 1, Short-term loans and debts 2019 Financial statement SUMMIT AUTO SEATS INDUSTRY CO., LTD INCOME STATEMENT Unit: USD BALANCE SHEET Unit: USD 2018 2019 3,983,961 4,028,620 168,714 210,937 II, Short-term investment 3,240,529 3,231,644 III, Short-term receivables 307,990 242,965 1, Accounts receivable from customers 154,819 150,931 IV, Inventories 251,739 312,545 368,926 609,575 - - 149,008 360,172 4,352,888 4,638,195 A, LIABILITIES 267,953 1,015,073 I, Short-term liabilities 266,434 1,013,019 A, CURRENT ASSETS I, Cash and cash equivalents B, LONG-TERM ASSETS 1, Long-term receivable 2, Fixed assets TOTAL ASSETS - - 12,437 5,578 1,518 2,054 - - 1,518 2,054 B, EQUITY 4,084,935 3,623,122 TOTAL LIABILITIES AND OWNER'S EQUITY 4,352,888 4,638,195 1, Short-term loans and debts 2, Taxes payable to State Treasury II, Long-term liabilities 1, Long-term loans and debts 2, Science and technology development fund 96 2019 Net sales 2,961,680 2,391,905 Cost of goods sold 1,713,422 1,296,127 Gross margin 163,645 189,079 Income from financial activities 224,024 226,290 39,741 64,622 Expenses from financial activities - - 20,476 14,013 Administration expenses 129,798 147,504 Profit from operation 197,654 189,230 Profit before tax 198,334 190,137 20,660 23,013 - - 177,674 167,124 Interest expenses Selling expenses Current income tax expenses Income tax expenses is deferred Net profit after tax CASHFLOW STATEMENT Unit: USD 2018 2019 I, Cash flows from operating activities Cash flows from operating activities 70,434 543,234 -8,812 127,937 II, Cash flows from investment activities Cash flows from investment activities III, Cash flows from financial activities - -628,937 Effects from exchange rate difference 61,622 42,234 Net cash flows during the fiscal year 61,622 42,234 Cash flows from financial activities *Exchange rate: USD/VND = 23,230 VIETNAM AUTOMOBILES MARKET REPORT 2018 Report Disclaimer This document has been prepared in good faith on the basis of SHOULD YOU NEED ANY ASSISTANCE, PLEASE CONTACT US: information available at the date of publication without any VIETNAM INDUSTRY RESEARCH AND CONSUTANCY (VIRAC JSC.,) independent verification. VIRAC has produced this report for private circulation to professional clients only. All information and statistical data herein have been obtained from sources we believe to be reliable 5th Floor, Anh Minh Building, 36 Hoang Cau, O Cho Dua, Dong and made to ensure the accuracy of the contents of the pages of the Da, Hanoi, Vietnam report at the time of preparation. Such information has not been Website: http://virac.com.vn/ independently verified and VIRAC makes no representation or warranty, whether express or implied, of any kind with respect to the document Email: viracresearch@virac.com.vn | Tel: +84 463289520 and its contents, information and materials. The content found in this report is proprietary to VIRAC and is provided solely for your personal and non-commercial use. You agree that you will not use this report for any purpose that is unlawful and that you will not reproduce the report or redistribute it outside your organisation, or place it on a website for public access without the express written permission of VIRAC. VIETNAM AUTOMOBILES MARKET REPORT 97 Thank you!