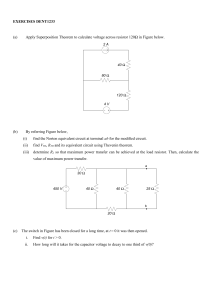

MAHENDRA ENGINEERING COLLEGE [AUTONOMOUS] Mahendhirapuri, Mallasamudram, Namakkal Dt. - 637 503. DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING YEAR: I SEMESTER: II 19EE23101 - ENGINEERING PRACTICES LABORATORY STUDENT NAME : REG NO : YEAR : BRANCH : SEMESTER : 1 Index S.No. 1. 2. NAME OF THE EXPERIMENTS Study of Multimeter Simple wiring connection 3. Fluorescent Lamp Wiring. 4. Stair Case Wiring 5. Measurement of Electrical quantities – voltage, current, power & Power factor in RLC Circuit. 6. Measurement of Energy using Single Phase Energy Meter 7. Measurement of Resistance to Earth of Electrical Equipment 8. 9. Study of Moving coil and Moving iron Study of Electronic Components and Equipments – Resistor Colour Coding 10. Measurement of AC Signal Parameter 11. Study of Logic Gates 12. Generation of Clock Signal. 13. Soldering & Desoldering Practice 14. Measurement of Ripple Factor of HWR and FWR 2 PAGE No. CIRCUIT SYMBOLS FOR ELECTRICAL & ELECTRONIC CIRCUITS S.NO SYMBOLS COMPONENTS Direct current 1. 2. Alternative current 3. Resistor 4. Variable Resistor 5. Inductor Capacitor 6. Variable Capacitor 7. 8. Fuse 3 9. Main Switch Light 10. Main Switch Power 11. Meter 12. One Way Switch 13. Two Way Switch 14. Lamp 15. Horn 4 16. Buzzer 17. Earth 18. Single phase alternating current 19. Neutral 20. Generator 21. Motor 22. Alternator 5 23. AC motor 24. Two pin socket 25. Three pin socket 26. Choke 27. Battery 28. DC voltmeter 29. DC ammeter 6 30. AC ammeter 31. Wattmeter 32. Ohm meter 33. Energy meter 34. Lamp 35. Wire 36. Wires joined 7 37. Wires not joined 38. DPSTS 39. Reversing Switch 40. Relay 41. Capacitor polarized 42. Diode 8 43. LED Light Emitting Diode 44. Zener Diode 45. Transistor NPN 46. Transistor PNP 47. Phototransistor 48. Oscilloscope 49. Ohmmeter 9 50. Microphone 51. Aerial (Antenna) 52. Amplifier (general symbol) 53. Loudspeaker 54. Thermistor 55. LDR 56. NOT 10 57. AND 58. OR 59. EXOR 60. NOR 61. NAND 62. EX-NOR 11 CIRCUIT DIAGRAM: 12 Ex No: Date : RESIDENTIAL HOUSE WIRING USING SWITCHES, FUSE, INDICATOR, LAMP 2 .a ) SINGLE LAMP CONTROLLED BY SINGLE SWITCH AIM: To construct a wiring for one lamp controlled by using one way switch. APPARATUS REQUIRED: S.NO 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. COMPONENTS One way switch Lamp holder Lamp Switch box Junction box (one way) T-bend Clamp 1/8 wire-3m Screw Insulating tape Connecting Wire RANGE 5A 60W 4”*4” - QUANTITY 1 1 1 1 1 1 1 1 1 1 As Required TOOLS REQUIRED: 1. Screw driver : 6” 2. Pocker : 1 3. Insulator cutting plier : 6” 4. Wooden hammer : 1 SAFETY PRECAUTIONS: Ensure that the power is switched off or not before connections are being made. Make sure that the fuse is connected in phase sheet select the correct current rating of wires. 13 LAYOUT DIAGRAM: 14 PROCEDURE: The wiring diagram of the one lamp controlled by one way switch was drawn one the wiring chalk and scale. The PVC pipe of required length and pipe fittings are taken and fixed in the wiring board.As per the wiring diagram using clamp and screw. The wires of required guage,colours are chosen and the wiring is being made through PVC. The lamp holder and switch are fixed in the corresponding location. Using red colour wire the phase line was given the lamp through one way switch. The other point of the lamp is being connected to neutral line using black wire. The terminal of the red and black wires are connected to main switch. The power supply was given to the circuit and the lamp was being made to glow by operating the switch. RESULT: The wiring of one lamp controlled by one lamp controlled by one way switch was constructed and operated successfully. 15 CIRCUIT DIAGRAM: 16 2 b)TWO LAMP CONTROLLED BY USING TWO ONE WAY SWITCH AIM: Construct a wiring for two lamp controlled by using two switch [one way]. APPARATUS REQUIRED: S.NO 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. COMPONENTS One way switch Lamp holder Lamp Switch box PVC pipe Junction box T-bend Clamp Screw Insulating tape Connecting Wire RANGE 5A 240V,6V 60W 4”11*4”11 -------One way ---------------------- QUANTITY 2 2 2 2 -------2 2 5 Required 1 As Required TOOLS REQUIRED: 1. Screw driver -6” : 1 2. Poker : 1 3. Insulating cutting plier 6” : 1 4. Wooden hammer : 1 SAFETY PRECAUTIONS: Ensure that the power is switched off or not before connections are being made. Make sure that the fuse is connected in phase sheet select the correct current rating of wires. 17 LAYOUT DIAGRAM: 18 PROCEDURE: The wiring diagram of two lamp controlled by two way switches was drawn on the wiring board using clamps. The PVC pipe of required length and pipe fitting were taken and tired on the board as per the diagram using screws. The lamp holder and switches were fixed in the corresponding location. Using red color wire the phase line was given to the two lamps using one way switches. The other points of the bulbs were being connected to the neutral line using black wire. The terminals of the red and black wires are connected to main switch. The power supply was given to the circuit and it glow bright. RESULT: The wiring of the two lamps in parallel controlled by single switch was constructed and operated successfully. 19 CIRCUIT DIAGRAM: 20 Ex No: Date : FLUORESCENT LAMP WIRING AIM: To construct a flourescent lamp wiring using the given components. APPARATUS REQUIRED: S.NO 1 2 3 4 5 6 7 COMPONENTS Tube light frame Tube light holder Choke Starter Tube light Wires Insulating tape QTY 1 2 1 1 1 Req 1 TOOLS REQUIRED: 1. Screw driver :1 2. lnsulated cutting plier 6” : 1. 3. Wooden hammer : 1 SAFETY PRECAUTIONS: Ensure that the power is switched off or not before connections are being made. Make sure that the fuse is connected in phase sheet select the correct current rating of wires 21 22 PROCEDURE: The wire diagram of the fluroscent lamp controlled by one way switches drawn on the wiring board. The pvc pipe of the required length and pipe fittings were taken and fixed in the wiring board as per the wiring diagram using clamp and screw. The wire of required gauge and the wiring is being made through the pvc contact. The bulb holder and switch were fixed in corresponding location. The bulb holder consists of two points on either side. The sound point of the bulb holder located on either side is being short circuited through starter. The first point of one side of the bulb holder was connected to the phase line through one way switch and choke. The first point of other end of the bulb holder was connected with neutral line. The phase and neutral wires were connected to main switch. The power supply was given to the circuit and the bulb was made to glow by operating switch. RESULT: The wiring of fluorescent lamp was constructed and operated successfully. 23 CIRCUIT DIAGRAM: 24 Ex No: Date : STAIR- CASE WIRING AIM: To construct the wiring for one lamp controlled by using two switches (two way) APPARATUS REQUIRED: S.NO 1 2 3 4 5 6 7 8 9 10 COMPONENTS Two way switch Lamp holder Lamp Switch box PVC pipe Junction box T-bend L-bend Screw Wires RANGE 5A 240,6A 60W 4”*4” One way 1/18 QUANTITY 2 1 1 2 Required no’s 1 2 1 Required no’s Required no’s TOOLS REQUIRED: 1. Screw driver -6” : 1 2. Pocker : 1 3. Insulation cutting plier-6” : 1 4. Wooden hammer : 1 SAFETY PRECAUTIONS: Ensure that the power is switched off or not before connections are being made. Make sure that the fuse is connected in phase sheet select the correct current rating of wires 25 LAYOUT DIAGRAM: INDIRECT CONNECTION 26 PROCEDURE: The wire diagram of one of the controlled by two one-way switches was drawn on the wiring board using chalk and the scale. The wires of required length and pipe fittings were taken and time in the wiring board as per the wiring diagram using clamp and the screw. The wire of required guage and colour was choosen wiring is being made through the pvc contact. The bulb holder and switches was fixed in a corresponding location. The two way switch have three terminals the middle point of I switch was connected to one end of the bulb. The other point of the bulb being connected to the neutral like using black wire. The terminal of the red,black wires was connected to main switch. The power supply was given to the circuit and the bulb was being made close by operation switch. 27 DIRECT CONNECTION 28 RESULT: The stair-case wiring was constructed and operated successfully 29 CIRCUIT DIAGRAM: 30 Ex No: Date : MEASUREMENT OF ELECTRICAL QUANTITIESVoltage, Current, Power & Power factor in RLC circuit. AIM: To measure the Voltage, Current ,Power & Power factor consumed by the resisitive load using Voltmeter,Ammeter & Wattmeter respectively. APPARATUS REQUIRED: S.NO COMPONENTS RANGE QUANTITY 1. Wattmeter 300V,10A,UPF 1 2. Voltmeter (0-300)V 1 3. Ammeter (0-10)A 1 4. Variac (0-270V / 10A) 1 5. Resistive load 230V,2.7KW 1 6. Connecting Wire - As Required FORMULA USED: POWER = V* I Watts Where, V is voltmeter reading in volts I is ammeter reading in amperes SAFETY PRECAUTIONS: Before switch on the supply i) Load rheostat should be kept at off condition ii) The wattmeter readings should be checked for power value 31 TABULATION: Multiplication Factor: S.No Voltmeter reading (Volts) Ammeter reading (Amps) Wattmeter reading (Watts) Actual Observed value Value (W) (W) 32 Apparent Power (V * I) P.F = (W/VI) PROCEDURE: Connections are given as per the circuit diagram. Switch on the single phase AC supply. Load is varied gradually in each step. The ammeter, voltmeter and wattmeter readings are tabulated and power factor is calculated. RESULT: Thus the Voltage, Current ,Power & Powerfactor consumed by the resistive load was measured and calculated. 33 CIRCUIT DIAGRAM: 34 Ex No: Date : MEASUREMENT OF ENERGY USING SINGLE PHASE ENERGY METER. AIM: To measure the energy using single phase energy meter at UPF load condition. APPARATUS REQUIRED: S.NO 1. 2. 3. 4. 5. 6. COMPONENTS Voltmeter Ammeter Stop clock Energy meter Watt meter Lamp load TYPE/RANGE MI/(0-300)V MI/(0-10)A 300V,10A,UPF - QTY 1 1 1 1 1 1 FORMULA: Energy meter specification = 3200 imp/kwhr 3200 imp 1 imp = 1 kwhr = ( 1 kwhr ) / 3200 = (3600*1000) / 3200 = 1125 watt sec For UPF conditions Power calculated from energy meter reading = 1125 / Time for 3 imp % Error = [( Power calculated from energy meter reading - Wattmeter reading) ] * 100 Wattmeter reading SAFETY PRECAUTIONS: 1. There should be no load at the time of starting. 2. The connections must be made proper for UPF. 35 TABULATION: Multiplication Factor: Wattmeter Reading Voltmeter Ammeter S.No Reading Reading (Volts) (Amps) (Watts) Observed Actual Value Value Power Time for from 3 energy impulse meter (Watts) Energy meter constant: s 36 % Error PROCEDURE: The connections are given as per the circuit diagram. The DPST switch is closed and the supply is effected and the load is adjusted to full load value. The time taken for 10revolutions of the aluminium disc in the energy meter is noted. The error is calculated if it is more than +- 3% the brake magnet is adjusted such that the error is within +- 3%. The load is reduced in steps and for each step the step3 is repeated and the % error is calculated. RESULT: Thus the given single phase energy meter was used to measure the energy consumed at UPF load conditions and the error curve was drawn successfully. 37 Ex No: Date : MEASUREMENT OF RESISTANCE TO EARTH OF ELECTRICAL EQUIPMENT AIM: To measure the resistance to earth / insulation resistance of the order of mega ohms. THEORY: Megger is the equipment used in this experiment. It is an instrument for testing the insulation resistance of the order of mega ohms. PRINCIPLE: A megger consists of an EMF source and a Voltmeter. The voltmeter scale is calibrated in ohms. In measurement, the EMF of the self contained source should be equal that of the source used in calibration. The deflection of the moving system depends on the ratio of the currents in the coils and is independent of the applied voltage. The value of unknown resistance can be found directly from the scale of the instrument. Figure shows the detailed diagram of a megger. It consists of hand driven dc generator and ohmmeter, a small permanent magnet. Hand driven dc generator generates a EMF about 500V. The permanent dc meter has two moving coils. First one is deflecting coil and another one controlling coil. The deflecting coil is connected to the generator through a resistor R. The torque due to the two coils opposes each other. It consists of three terminals E, L and G. OPERATION: When the terminals are open circuited, no current flows through the deflecting coil. The torque due to the controlling coil moves the pointer to one end of the scale. When the terminals are short circuited, the torque due to the controlling coil and the pointer is deflected to the other end of the scale, i.e.zero mark. In between the two extreme positions the scale is calibrated to indicate the value of unknown resistance directly. The unknown insulation resistance is connected across E and L terminals. The effective insulation resistance is the combination of insulation volume resistance and surface leakage resistance. The guard wire terminal makes the surface leakage current to bypass the instrument hence only insulation resistance is measured. RESULT: Thus the resistance to earth / insulation resistance of the order of mega ohms can be measured 38 ENGINEERING PRACTICES LABORATORY MANUAL Ex. No: STUDY OF ELECTRONIC COMPONENTS AND EQUIPMENTS. Date: 1. Resistor. It is a Electronic passive component. It’s used to control the flow of current and to get required voltage drops in required places. The symbol of the resistor is “R” the unit is “ohm”. The schematic representation of a resistor is shown in the diagram. Ohm: Ohm is defined as the amount of resistance that allows one ampere of current to flow when one volt potential is applied. (i) (ii) Resistors are classified into two types. Fixed Resistors. Variable Resistors. FIG .1 FIXED RESISTANCE FIG 2 VARIABLE RESISTANCE Colour Coding of Resistor. Colour coding is a system of colour used to indicate the electrical resistance value of a component. In this colour bands are printed on the resistance body. The signification of each colour is shown in the diagram. These are four colour bands 1,2,3 and 4.The first two bands 1 and 2 denotes the first and second digits of the resistance value and third 3 indicates how many zeroes follow the first two digits. The fourth band 4 denotes the tolerance. 39 ENGINEERING PRACTICES LABORATORY MANUAL Fig. 3 colour coding values 2. Capacitors. Capacitor is an Electronic passive component. The materials those permit the flow of electric current are known as capacitor (or) conductors. It consists of two conducting plates separated by an insulator. The conducting surfaces are called electrodes and insulating medium a=is called dielectric. The capacitor unit is ‘Farad” and its symbol is denoted by ‘C’. Most of the capacitors have their values printed on their bodies. The schematic representation of a capacitor is shown in the diagram. FIG .4 DISC CAPACITOR FIG .5 ELECTROLYTIC CAPACITORS Inductors. The material those blocks the flow of electric current are called inductors or insulators. The self inductance is the property of a coil by which it opposes any change of current. The inductance unit is ‘Henry” and its denoted by ‘L’.The schematic 40 ENGINEERING PRACTICES LABORATORY MANUAL representation of an inductor is shown in the diagram. FIG .6 TOROIDAL INDUCTOR INDUCTOR FIG .7 CORE 3. Transistors. Transistor is an active component. It is a three terminal device. The three terminals are (i) Emitter. (ii) Base (iii) Collector. (iv) Semiconductor device consisting of two PN junctions is formed by sand witching a thin layer of n-type conductor s between two layers of p-type semiconductors. Transistors are classified into two types. (i) PNP Transistor. (ii) NPN Transistor. FIG .8 PNP TRANSISTOR Diodes. FIG .8 NPN TRANSISTOR A Semiconductor diode is a two layer. one junction device, which is formed by joining one p-type and one n-type semiconductor material. Schematic representation of diode is shown in the diagram. The p-region of a diode is called anode and n-region is called cathode. 41 ENGINEERING PRACTICES LABORATORY MANUAL FIG .9.VARIOUS TYPES OF DIODES 4. Light emitting Diode (LED). This Diode converts electrical energy into light energy (green or infrared energy).They are used in electronic instrument.LED is a diode made up of semiconductor. Gallium arsenium diphosphide. This material glows when current passes through it. FIG .10 LED 5. Rectifiers. It is a Electronic device used for converting AC voltage into unidirectional voltage. Rectifiers are classified into two types (i) Half Wave Rectifiers. (ii) Full Wave Rectifiers. (iii) Bridge Rectifiers 42 ENGINEERING PRACTICES LABORATORY MANUAL RESULT: Thus the study of Electronic components have been studied and verified. 43 ENGINEERING PRACTICES LABORATORY MANUAL Ex.No: MEASUREMENT OF AC SIGNAL PARAMETER Date: (PEAK-PEAK,RMS PERIOD,FREQUENCY) USING CRO AIM: To study the functions of different knobs of CRO and to measure i) Amplitude ii) Time period and Frequency Apparatus Required: S.No 1 2 3 Item CRO Signal Generator BreadBoard Specification (0-20)MHZ (0-1) MHZ - Quantity 1 1 1 THEORY: An oscilloscope is a type of electronic test instrument that allows signal voltages to be viewed, usually as a two dimensional graph of one are more electrical potential differences( vertical axis) plotted as a function of time or of some other voltage(horizontal axis). An oscilloscope is a measuring device used commonly for measurement of voltage, current, frequency,phase difference and time intervals. The heart of oscilloscope is the cathode ray tube, which generates the electron beam, accelerates the beam to create the image and contains the phosphor screen where the electron beam eventually becomes visible. To accomplish these tasks, various electrical signals and voltages are required. The power suppy block provides the voltage is required by the cathode ray tube to generate and accelerate the electron beam,as well as to supply the required operating voltages for the other circuits of the oscilloscope.Relatively high voltages are required by the cathode tubes,on the order of few thousand volts,for acceleration as well as a low voltage for the heater of electron gun, which emits electrion. Supply voltages for the other circuits are of various values usually not more than few hundered volts. The oscilloscope has a time base, which generates the correct voltage to supply the CRT to deflect this part at a constanttime dependent rate.The signal to be view is fed to vertical amplifier which increases the potential of input signal to a level that will provide a useful deflection of electron beam.To synchronise the horizontal deflection the vertical input, such that the horizontal deflection starts at the same point of the vertical signal each time it sweeps,a synchronizing or triggering circuit is used,.This circuit is the link between the vertical input and the horizontal time base. 44 ENGINEERING PRACTICES LABORATORY MANUAL FIG .11 CATHODE RAY OSCILLOSCOPE Procedure: Voltage and Time Peroid Measurement:: 1.Select the sine output of the signal generator,set as 1KHZ. 2. Feed the signal to the vertical input of CRO. 3. Adjust level and time base to get one or two cycles of the sine signal on the oscilloscope ,and calculate the vertical scale. 4.Count the number of vertical divisions NV on the scope and find peak-peak level. Vpp=NV (volts/Division) where NV = number of vertical divisions 5 calculate the Vrms values Vrms = Vpp/ 2 √2 5. Measure the signal with an AC milli voltmeter as well.It gives the rms value of the signal. 6. Measure the time period “T” of the signal by counting the number of horizontal divisions. NH covering the spam of one cycle. T=NH *(Time/Division) where NH = No of Horizontal Divisions 7. Calculate the frequency as f=1/T 45 ENGINEERING PRACTICES LABORATORY MANUAL 8. Apply the DC voltage from the regulated power supply and measure the DC level on the scope.(CRO) Tabulation: AC Voltage and Frequency Measurement: S.No Number of divisions along Y-axis S.No Number of divisions along X-axis Volt/div Time/div Peak to peak voltage(volt/div) Time Period Frequency time/div F=1/T RESULT: Thus the study of electronic components has been studied and verified. And also the operation and applications of Cathode Ray Oscilloscope have been studied. 46 ENGINEERING PRACTICES LABORATORY MANUAL OR GATE: AND GATE: SYMBOL: PIN DIAGRAM 47 ENGINEERING PRACTICES LABORATORY MANUAL STUDY OF LOGIC GATES EX NO: DATE : Aim: To study about logic gates and verify their truth tables. Apparatus required: SL No. COMPONENT SPECIFICATION QTY 1. AND GATE IC 7408 1 2. OR GATE IC 7432 1 3. NOT GATE IC 7404 1 4. NAND GATE 2 I/P IC 7400 1 5. NOR GATE IC 7402 1 6. X-OR GATE IC 7486 1 7. NAND GATE 3 I/P IC 7410 1 8. IC TRAINER KIT - 1 9. PATCH CORD - 14 48 ENGINEERING PRACTICES LABORATORY MANUAL NOT GATE: SYMBOL: PIN DIAGRAM: X-OR GATE : SYMBOL : PIN 49 DIAGRAM : ENGINEERING PRACTICES LABORATORY MANUAL THEORY: Circuit takes that logical decision and the process are called logic gates. Each gate has one or more input and only one output. Basic Gates - OR, AND & NOT Universal Gates - NOR, NAND & XOR OR GATE: (Addition) The OR gate performs a logical addition commonly known as OR function. The output is high when any one of the inputs is high. The output is low level when both the inputs are low. AND GATE: (Multiplication) The AND gate performs a logical multiplication commonly known as AND function. The output is high when both the inputs are high. The output is low level when any one of the inputs is low. NOT GATE: ( Inverter ) The NOT gate is called an inverter. The output is high when the input is low. The output is low when the input is high. NAND GATE: The NAND gate is a contraction of AND-NOT. The output is high when both inputs are low and any one of the input is low .The output is low level when both inputs are high. NOR GATE: 50 ENGINEERING PRACTICES LABORATORY MANUAL 2-INPUT NAND GATE: SYMBOL: PIN DIAGRAM: NOR GATE: The NOR gate is a contraction of OR-NOT. The output is high when both inputs are low. The output is low when one or both inputs are high. X-OR GATE: The output is high when any one of the inputs is high. The output is low when both the 51 ENGINEERING PRACTICES LABORATORY MANUAL inputs are low and both the inputs are high. Procedure: (i) Connections are given as per circuit diagram. (ii) Logical inputs are given as per circuit diagram. (iii) Observe the output and verify the truth table RESULT: Thus the basic logic gates are studied and the truth tables verified. 52 ENGINEERING PRACTICES LABORATORY MANUAL Circuit Diagram: FIG.12 CIRCUIT DIAGRAM OF GENERATION OF CLOCK SIGNAL : Tabulation: S.No Amplitude(V) Model Graph: 53 Time Period(ms) ENGINEERING PRACTICES LABORATORY MANUAL GENERATION OF CLOCK SIGNAL Ex No: Date: Aim: To generate the clock signal using IC555 Apparatus required: S.NO NAME OF THE APPARATUS RANGE QUANTITY 1 2 3 4 5 6 7 NE555 Resistor Capacitors RPS CRO Bread Board Connecting Wires 10k 0.1f (0-30) Mhz - 1 2 2 1 1 few Theory: INTRODUCTION ABOUT IC555: One of the most versatile linear integrated circuit is the 555 timer. It was first introduced by signetics corporation in early 1970. It is a monolithic timing circuit that can produce accurate and highly stable time delays or oscillation. The timer basically operates in one of the two modes: A).Either as a monostable or B).As a astable multivibrator The important features of the 555 timer are: 1. It can operate +5V to +18V supply, 2. It has an adjustable duty cycle, 3. Timing is from microseconds to hours, 4. It has high current output, 5. It has a temperature stability of 50 parts per million per degree Celsius change in temperature and, 6. Like a general purpose IC, it is reliable, easy to use, and low cost and its output can be made compatible. INTERNAL CIRCUITARY AND FUNCTIONS: The function block diagram and the pin out details of 555 timers are shown in the left hand side fig.1.The pin functions are detailed as follows: PIN 1: GROUND: All voltages are measured with respect to this terminal 54 ENGINEERING PRACTICES LABORATORY MANUAL PIN 2: TRIGGER: The output of the timer depends on the amplitude of the external trigger pulse applied to this pin. The output is low if the voltage at this pins greater than 2/3 Vcc. However , when a negative going pulse of amplitude larger than 1/3Vcc is applied to this pin, the comparator output goes low, which in turn switches the outout of the timer high. The output remains high as long as the trigger terminal is held at a low voltage. PIN 3: OUTPUT: There are two ways a load can be connected to the output terminal: either between pin 3 and ground (pin 1) or between pin 3 and supply voltage +Vcc. PIN 4: RESET: The 555 timer can be reset by applying a negative pulse to this pin. When the reset function is not in use, this terminal should be connected to +Vcc to avoid any possibility of false triggering. PIN 5: CONTROL VOLTAGE: An external voltage applied to this terminal changes the threshold as well as the trigger voltage. The pulse width of the output waveform can be varied by imposing a voltage on this pin or by connecting a pot between this pin and ground. When not used, the control pin should be by passed to ground with a 0.01Чf capacitor to prevent any noise problems PIN 6: THRESHOLD: This is the non inverting input terminal of the upper comparator [UC] which monitors the voltage across the external capacitor C connected across it. When the output is low, Q1 is saturated and act as a short circuit, shorting out the external capacitor C to ground. PIN 7: DISCHARGE: This pin is connected internally to the collector of transistor Q1. when the output is high, Q1 is ”OFF” and act as an open circuit to the external capacitor C connected across it. When the output is low, Q1 is saturated and act as a short circuit, shorting out the external capacitor C to ground. PIN 8: +Vcc: The supply voltage voltage of +5V to +18Vis applied to this pin with respect to ground. ASTABLE MULTIVIBRATOR USING 555: The left hand side fig(2) shows the 555 timer connected as an astable multivibrator. Capacitor C starts charging towards Vcc through RA and RB. As soon as capacitor voltage equals 2/3 VCC upper comparator [UC] triggers the flip flop and the output switches low. Now capacitor C starts discharging through RB and transistor Q1. When the voltage across C equals 1/3 Vcc lower comparator(LC), output triggers the flip flop and the output goes high. Then the cycle repeats. The capacitor is periodically charged and discharged between 2/3 Vcc and 1/3 Vcc is equal to the time the output is high and is given by 55 ENGINEERING PRACTICES LABORATORY MANUAL Tc=0.69(RA+RB)C Where RA,RB are in ohms and C in farads. Similarly the time during which the capacitor discharges from 2/3 Vcc to1/3 Vcc is equal to the time the output is low and is given by Td= 0.69RBC The total period of the output wave form is T= tc +td=0.69(RA+2RB) The frequency of oscillation Fc = 1/T = 1.45/(RA+2RB)C The above Eqn shows that f0 is independent of supply voltage Vcc. DUTY CYCLE: Duty cycle is the ratio of the time td, during which the output is low to the total time period (t). This definition is applicable to 555 astable multivibrator only; conventionally the duty cycle, ratio is defined as the ratio as the time during which the output is high to the total time period. %duty cycle= td/T *100 = RB/(RA+2RB) *100 To obtain 50% duty cycle, a diode should be connected R and RA must be a combination of a fixed resistor potentiometer; so that the potentiometer can be adjusted for the exact square value 56 ENGINEERING PRACTICES LABORATORY MANUAL PROCEDURE: 1. Rig-up the circuit of 555 astable multivibrator as shown in fig(2) With the designed value of the components. 2. Connect the CRO probes to pin 3 and pin2 displays the output signal and the voltage across the timing capacitor. Set suitable voltage sensitivity and time-base on the CRO. 3. Switch on the power supply to CRO and the circuit. 4. Observe the waveforms on the CRO and draw to scale on a graph sheet. Measure the voltage levels at which the capacitor starts discharging, output high and low timings and frequency, and compare the measured values with theoretical or designed values. 5. Switch off the power supply. Connect a diode across RB as shown in dashed lines in fig(2), to make the astable with 50% duty cycle ratio. Switch on the power supply. Observe the output waveform. If necessary change RA to get 50% duty cycle. 6. Take the output from pin no: 3 and measure the amplitude & time period. 7. Also measure the charging and discharging of the capacitor across pin no:2 &6 using CRO RESULT: Thus the clock signal was generated using IC555 and wave forms were verified. 57 ENGINEERING PRACTICES LABORATORY MANUAL FIG .13 SOLDERING CIRCUIT FRONTSIDE FIG .14 SOLDERING CIRCUIT BACKSIDE 58 ENGINEERING PRACTICES LABORATORY MANUAL Ex No: Date: Aim: SOLDERING AND DE-SOLDERING PRACTICE To practice soldering and de soldering for the given electronic circuit by assembling and de-assembling the resistor R1 and R2 and capacitor C1 in the given printed circuit board (PCB). Components Required: S. No 1. 2. 3. 4. 5. 6. 7. 8. Component PCB Board for the given Circuit Soldering Iron Solder Flux Electrician’s knife Noise Plier Resistors Capacitors Range Quantity 2 10W (or0 35W 60/40 Grade 1 1 1 1 2 1 10kΩ 0.01µf Procedure: Soldering. 1. Study the given Electronic circuit. 2. Clean the given PCB board. 3. Clean the tip of the soldering iron before heating and also clean the resistors, capacitors which are to be soldered. 4. Heat the soldering iron and apply solder to the tip as soon as it is hot to melt on it. 5. Bend the Resistor (R1) leads to fit into the holes on the board. Insert the Resistor R1 as per the circuit in the figure and bend the leads. 6. Apply the hot tip to the joints and apply solder. 7. Remove ht soldering tip and hold the resistor until the solder has cooled and set. 8. Trim excess component lead with side cutter. 9. Repeat the above steps to fix other Resistor R2 and capacitor C1 as shown in the circuit. De-Soldering. 1. Hold the resistor R1 to be unsoldered by a hose plier. 2. Place the tip of the soldering iron on the joint until the solder is melt. 3. When the solder is melted, remove the resistor R1 with the Tweezer and brush away the molten solder. 4. Repeat the above steps to remove resistor R2 and capacitor C1. 5. Clean the resistor and capacitors so that they can be used to make other circuits 59 ENGINEERING PRACTICES LABORATORY MANUAL RESULT: Thus the soldering and de-soldering practice is done for the given Electronic circuit. 60 ENGINEERING PRACTICES LABORATORY MANUAL Half Wave Rectifier: Circuit Diagram HALF WAVE RECTIFIER WITHOUT FILTER: HALF WAVE RECTIFIER WITH FILTER 61 ENGINEERING PRACTICES LABORATORY MANUAL MEASUREMENT OF RIPPLE FACTOR FOR HALF WAVE RECTIFIER. Ex No: Date: Aim: To Study the ripple factor and regulation characteristics of a half wave rectifier with and without filter. Components Required: S.No Components Type/range Quantity 1. Diode IN 4007 1 2. Capacitor 220µc,100µf,470µf Each 1 3. Transformer 230v/6A 1 4. Resistor 1KΩ 1 5 Bread board - 1 6 CRO (0-30)MHz 1 Formula : Ripple factor, γ = Vrms /Vdc & (Vrms / Vdc)2 – 1]1/2 Where, Vrms =The rms value of a.c. component of the output voltage. Vdc = the average or d.c. value of the output voltage. 62 ENGINEERING PRACTICES LABORATORY MANUAL TABULATION: HALF WAVE RECTIFIER: (WITHOUT FILLTER): S.No Time Period(ms) Amplitude Vm(V) Ripple Factor Vrms = Vm/2 Vdc = Vm/ π r = Vrms/Vdc HALF WAVE RECTIFIER: (WITH FILTER): S.No Time Period(ms) Amplitude Vm(V) Ripple Voltage Vr(v) Ripple Factor Vrms = Vm/2 Vd = Vm/ π r = Vrms/Vdc Procedure : (i) Connections are given as per the circuit diagram. (ii) The AC supply is switched “ON” directly to filter circuit. (iii) On moving the rheostat, get the voltage form AC voltage which gives V L such that the rheostat is in minimum position. 63 ENGINEERING PRACTICES LABORATORY MANUAL RESULT: Thus the ripple factor and regulation characteristics of half wave rectifier with and without filter are studied and verified. 64 ENGINEERING PRACTICES LABORATORY MANUAL FULLWAVE RECTIFIER WITHOUT FILTER: FULLWAVE RECTIFIER WITH FILTER: 65 ENGINEERING PRACTICES LABORATORY MANUAL MEASUREMENT OF RIPPLE FACTOR FOR FULL-WAVE Ex No: RECTIFIER. Date: Aim: To study the ripple factor and regulation characteristics of full wave rectifier with and without filter. Components Required: S.No 1. 2. 3. 4. 5. 6 Components Diode Step-down transformer Resistor Capacitor Braed Board CRO Type/range In 4007 (0-6v) 10Ω 100µF,220µF (0-30)MHz Quantity 2 1 1 1 1 1 Formula : Ripple factor γ= (Vrms/Vdc) & (Vrms / Vdc)2 – 1]1/2 Where, Vrms=The rms value of the a.c. component of the output voltage. Vdc= The average or d.c. value of the output voltage. TABULATION: FULL WAVE RECTIFIER: WITHOUT FILLTER: Time S.NO Period(ms) Amplitude(V) Ripple Factor Vrms=Vm/2 Vd = Vm/ π r = Vrms/Vdc WITH FILLTER: S.NO Time Period(ms) Amplitude(V) Ripple Voltage Vr(v) 66 Vrms=Vm/2 Vd = Vm/ π Ripple Factor r = Vrms/Vdc ENGINEERING PRACTICES LABORATORY MANUAL Model Graph: Procedure: Without filter (i) Connections are made as per the circuit diagram. (ii) Switch on the AC supply and note down the no-load voltage, full load voltage. (iii)Then vary the rheostat and note down the corresponding Vrms, Vdc and Idc in steps. (iv) Calculate the ripple factor and regulation using the formula. With filter. (i) (ii) (iii) Connections are made as per the circuit diagram. Switch on the Ac supply and note down the corresponding Vrms, Vdc and Idc in steps. `Then decrease the rheostat and switch off the supply. 67 ENGINEERING PRACTICES LABORATORY MANUAL RESULT: Thus the ripple factor and regulation characteristics of full wave rectifier with and without filter are studied. 68