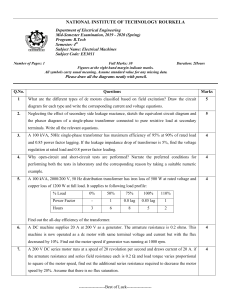

Lebanese University Faculty of Sciences (I) Physics and Electronics Department ELEC 3305 Electric Machines Laboratory Manual 2020-2021 ELEC 3305 Electric Machines Laboratory Manual [1] SAFETY PRECAUTIONS There is high voltage AC and current so, when taking measurements we take care that the connections are secure. We don't make connections with the power on. We ensure that the power is turned off after taking the measurements. Nine rules for safe practice and to avoid electric shocks: 1. Be sure of the conditions of the equipment and the dangers present BEFORE working 2. 3. 4. 5. on a piece of equipment. Many sportsmen are killed by supposedly unloaded guns; many technicians are killed by supposedly “dead”. Circuits, NEVER rely on safety devices such as fuses, relays and interlock systems to protect you. They may not be working and may fail to protect when most needed. NEVER remove the grounding prong of a three wire input plug .this eliminates the grounding feature of the equipment making it a potential shock hazard. Disorganized mess of connecting leads, components and tools only leads to careless thinking circuits, shocks and accidents. DO NOT WORK ON WET FLOOR Do not work on wet floor or bare footed. Always work on a rubber mate or an insulated floor. 6. DO NOT WORK ALONE. It’s just good to have someone around to shot off the power give artificial respiration and to call a doctor. 7. WORK WITH ONE HAND WHILE WORKING WITH ELCTRIC CIRCUITS A current in between a hand’s crosses your heart and can be more let than a current from hand to foot .a wise technician always work with one hand .watch your service man 8. NEVER TALK TO ANYONE WHILE WORKING Do not let yourself distracted. Also do not talk to anyone, if he is working on dangerous equipment. Do not be the cause of an accident. 9. ALWAYS MOVE SLOWLY When work around electrical circuits. Violent and rapid movements lead to accidental shock and short circuits. ELEC 3305 Electric Machines Laboratory Manual [2] Content 1- Transformer - No-Load Test - Short-Circuit Test - 3 Phase transformer o Star-Star o Star- Delta 1- DC Machine - Analysis of separately excited machine - Analysis of series excited machine 2- AC Machine Asynchronous machine aSCIM bSlip-rings motor ELEC 3305 Electric Machines Laboratory Manual [3] Report Format 1-Objective/ Objectif 2-Brief Theory/ Brève théorie 3-Equipment/ Matériel 4-Circuit diagram/ Schéma du circuit 5-Tables of readings and calculations/ Tableaux des mesures et des calculs 6-Sketches of the characteristics/ Schéma des caractéristiques 7-Results and analysis/ Résultats et analyse ELEC 3305 Electric Machines Laboratory Manual [4] Transformer ELEC 3305 Electric Machines Laboratory Manual [5] Single Phase Transformer Testing I. INTRODUCTION The transformer is extremely important as a component in many different type of electrical circuit from small signal electronic circuit to high-voltage power transmission system, the most common functions of transformers are: 1. Changing the voltage and current levels in an electrical system. 2.Impedance matching. 3.Electrical isolation. -The first of these functions is probably best known to the reader and is typified by the distribution transformer in the near by electric pole that steps down the voltage on the distribution lines from, say 2300(v) , to the household voltage of 115/230(v). -The second function is found in many communication circuits and is used for example, to match a load to a line for improved power transfer and minimization of standing waves -The third feature is used to eliminate electromagnetic noise in many types of circuits , blocking dc signals and user safety in electrical instruments and appliances. Transformer are used in circuits of all voltage levels, from the micro volt of some electronic circuits to the highest voltage used in power systems which, today, is approximately 750,000V. 1 . 1 Transformer construction and electromagnetic structure. • The magnetic structure of transformer consists of one or more electrical winding linked together magnetically by a magnetic circuit or core. The magnetic circuit of most transformers is constructed of a magnetic material, but nonmagnetic material often called “air cores” are found in some application. The two basic winding are often called primary and secondar. • A simple two -winding transformer model is shown below. ELEC 3305 Electric Machines Laboratory Manual [6] The construction of transformer varies greatly, depending on their application, winding voltage and current rating and the operating frequencies. In general, the electromagnetic structure is contained within a housing or case for safety and protection. In electronic transformer a viscous insulating material is used and, in many power transformer, a nonflammable insulating oil called transformer oil is used. The winding of large power transformer insulation generally use conductors with heavier than magnet wire insulation. 1.2 Transformer Classification: 1.Transformer used in power distribution and transmission system called power system transformer. 2.Electronic transformers: transformers of many different types and applications used in electronic circuits. Sometimes electronic transformer are considered as those transformers with rating of 300 VA and below. 3. Instrument transformer: transformer used to sense voltage or current in both electronic circuits and power system often called potential transformer and current transformers. And used in protection of electrical equipments. ELEC 3305 Electric Machines Laboratory Manual [7] EXPERIMENT 1 No-Load Test AIM: To perform open circuit test on a single phase transformer. APPARATUS REQUIRED: 1. 2. 3. 4. 5. 6. Wattmeter AC/DCvoltmeter AC/DC ammeter- 0- 10 A Autotransformer, 220V,10A,50Hz,1-phase Transformer Connecting wire THEORY: From this test it is possible to determine the equivalent circuit of the transformer. This test is carried out to determine the no load loss or core loss and no load current, magnetization current and core loss current. The open circuit test is performed at rated voltage i.e. On low voltage side of transformer and secondary side is kept open or connected to a voltmeter. Since the secondary is open, the current drawn by the primary is no load current Io measured by ammeter A. The value of Io is very small. Wattmeter reading W represent the core loss or iron loss for all practical purpose. 𝑊 = 𝑉1 𝐼0 𝐶𝑜𝑠∅𝑜 ELEC 3305 Electric Machines Laboratory Manual [8] 𝐶𝑜𝑠∅0 = 𝐼µ = 𝐼𝑜𝑠𝑖𝑛ɸ𝑜 𝑊 𝑉1 𝐼0 𝐼𝑤 = 𝐼𝑜 𝑐𝑜𝑠ɸ𝑜 The open circuit test parameters can be find out by: 𝑋𝑜 = 𝑉1 / 𝐼µ 𝑅𝑜 = 𝑉1/ 𝐼𝑤 𝑌𝑜 = 𝐼𝑜/ 𝑉1 G0=W/ V12 Bo=√(Yo2 -G02 ) CIRCUIT DIAGRAM: ELEC 3305 Electric Machines Laboratory Manual [9] PROCEDURE: 1. 2. 3. 4. 5. 6. Make the connections as per circuit diagram. Make sure that secondary side of transformer is open . Keep the variac at zero position before switch on the supply. Switch on AC supply. By varying the variac apply full supply voltage i.e. 230 volt to the primary of the transformer and note the reading of wattmeter, voltmeter and ammeter. Keep the variac at zero position and switch off the supply. OBSERVATION TABLE: Sl.No Voltmeter reading, V (V1O) Ammeter reading, mA (I1O) Wattmeter (W) (P1O) Voltmeter reading V (V2O) Cos Φ Pcore RESULT: By using the reading calculate the value of following parameter: Ro , Xo , Yo , Go , Bo , W PRECAUTIONS: 1. 2. 3. Experiment should be performed at rated voltage. Connections should be neat and clean. Experiment should be performed carefully. ELEC 3305 Electric Machines Laboratory Manual [10] EXPERIMENT 2 Short-circuit Test AIM: To perform short circuit test on single phase transformer. APPARATUS REQUIRED: Same as above THEORY: This test is carried to determine the following: • Copper loss at full load • Equivalent impedance, resistance and reactance The connection diagram for short circuit test on transformer is shown in the figure. A voltmeter, wattmeter, and an ammeter are connected in HV side of the transformer as shown. The voltage at rated frequency is applied to that HV side with the help of a variac of variable ratio auto transformer. The LV side of the transformer is short circuited. Now with the help of variac applied voltage is slowly increased until the ammeter gives reading equal to the rated current of the HV side. After reaching at rated current of HV side, all three instruments reading (Voltmeter, Ammeter and Watt-meter readings) are recorded. The ammeter reading gives the primary equivalent of full load current IL. As the voltage applied for full load current in short circuit test on transformer is quite small compared to the rated primary voltage of the transformer, the core losses in transformer can be taken as negligible here. Hence wattmeter reading gives the copper loss in the transformer reading. ELEC 3305 Electric Machines Laboratory Manual [11] Wattmeter reading Wsc= Isc2× Ro Req=Wsc/ Isc2 Where Req is the equivalent resistance of the transformer. Zeq= Vsc/ IL Where Zeq is the equivalent impedance of the transformer. Xeq= √(Zeq2-Req2) Where Zeq is the equivalent reactance of the transformer. CIRCUIT DIAGRAM: ELEC 3305 Electric Machines Laboratory Manual [12] PROCEDURE: 1. 2. 3. 4. Connect the circuit as shown in fig and set up the auto transformer to zero position. Switch on the supply and apply the voltage gradually with the secondary winding terminals short circuit. By varying the variac supply rated current in the primary winding and note the reading of wattmeter, voltmeter and ammeter. Switch off the supply. OBSERVATION TABLE: Sl.No Voltmeter reading, V (V1SC) Ammeter reading, A (I1SC) Wattmeter (W) (P1SC) Ammeter reading, A (I2SC) Cos Φ P1SC RESULT: Copper loss in the transformer windings =…….. and Voltage regulation at pf…… is………. Resistance (Req) = ; Reactance (Xeq) = PRECAUTIONS: 1. 2. 3. Connections should be neat, tight and clean. Experiments should be performed carefully. Rated current should not be exceeded. ELEC 3305 Electric Machines Laboratory Manual [13] ; Impedance (Zeq) = THREE-PHASE TRANSFORMER CONNECTIONS A three phase transformer or 3φ transformer can be constructed either by connecting together three single-phase transformers, thereby forming a socalled three phase transformer bank, or by using one pre-assembled and balanced three phase transformer which consists of three pairs of single phase windings mounted onto one single laminated core. The advantages of building a single three phase transformer is that for the same kVA rating it will be smaller, cheaper and lighter than three individual single phase transformers connected together because the copper and iron core are used more effectively. The methods of connecting the primary and secondary windings are the same, whether using just one Three Phase Transformer or three separate Single Phase Transformers. The primary and secondary of the transformer can be independently connected either in star or delta. There are four possible connections for a 3phase transformer bank. 1. 2. 3. 4. Δ – Δ (Delta – Delta) Connection Υ – Υ (Star – Star) Connection Δ – Υ (Delta – Star) Connection Υ – Δ (Star – Delta ) Connection The choice of connection of three phase transformer depends on the various factors likes the availability of a neutral connection for grounding protection or load connections, insulation to ground and voltage stress, availability of a path for the flow of third harmonics, etc. ELEC 3305 Electric Machines Laboratory Manual [14] EXPERIMENT 3 THREE-PHASE TRANSFORMER AIM: To measure the voltage on the primary and secondary winding of a threephase transformer for different configurations. APPARATUS REQUIRED: 1. AC/DCvoltmeter- (0-500V) 2. Transformer ( 3Phase) 3. Connecting wire What’s required: - Measure the Line to line voltages on the primary and secondary sides of a 3 phase transformer for the 2 configurations: Υ – Υ (Star – Star) Connection Υ – Δ (Star – Delta ) Connection - Find the transformation ratio Calculate the rated curent of the primary and secondary. ELEC 3305 Electric Machines Laboratory Manual [15] PROCEDURE: 1. 2. 3. Connect the circuit as shown in figures. Take the required measurement. Switch off the supply. OBSERVATION TABLE: Sl. no Voltmeter Voltmeter reading(V) reading(A) Υ–Υ Υ–Δ L1L2 (Prim.) U1U2 (Second.) L1L3 U1U3 L2L3 U2U3 ELEC 3305 Electric Machines Laboratory Manual [16] AC Machine ELEC 3305 Electric Machines Laboratory Manual [17] INTRODUCTION on INDUCTION MACHINE 1.1 Development: In 1889 Testa and Ferraris published a description of methods of producing at Poly-phase current, and the former exhibited a crude type of three phase motor the Frankfort exhibition 1891. An improved construction, with a distributed stator winding and a cage rotor was then built in 1893. The slip ring rotor was developed at the turn of the century. Since then, besides the development and improvement of the cage and slip ring M/C The inherent limitiation of the induction motors as regards its speed and its power factor have been the subjects of numerous patents and investigations. The chief variants are the synchronous induction motor for the improvement of p.f. pole changing windings and cascade connection for speed control, and the introduction of the commutator for the adjustment of both speed and pf, these special M/C comprise, however, only a small friction of the total of a.c motors in use: Probably at least 80%of the world 's ac motors are plain polyphase induction motor, while many of the reminder are single-phase frictional horse-powers motors of while many thousand are manufactured for small plant. The general reversibility principle of electromagnetic machines applies to the induction machine. If its rotor is driven at a suitable speed, the machine operates as an induction generator. The machine can serves a useful but restricted role in supply system. 1.2 Construction Of Induction Motor: 1.2.1 General Arrangement The 3-phase induction motor differs in construction from the dc M/C in certain essentials: its short air gap, absence of a commutator, speed limitation, simple winding and laminated stator The stator core must be carried in a shell or housing which provides a means for protecting the stator, carrying the end covers, bearing and terminal box. 1.2. 2 Frame The frame of a motor may be cast or fabricated. The former method is still common for small and miniature motors, but medium size and large machine are almost exclusively fabricated. 1.2.3 Core The stator and rotor cores are built up of thin sheet of special core steel, insulationis done by means of paper, varnish or sprayed chin clay, the gap surfaces of the plates have suitable slots ELEC 3305 Electric Machines Laboratory Manual [18] punched out, either open, semi closed, or completely closed. For small M/C, both the stator and the rotor punching are complete rings, the waste of material and difficulty of handling make it necessary to employ sectional plates , suitably keyed to the housing. 1.2.4 winding For large motor or these for high voltage the stator phases maybe formed by single-layer concentric coils, but even here, as for most medium-sized machines, the double layer lattice winding is common. In slip rotors of large size, a bar winding can be used because the choice of the voltage is usually free. For smaller machine wire-wound rotors can be used with coil arrangements similar to that of the stator. 1.2.5 Shafts, The shaft of an induction motor is made in order to keep as small as air gaps as is mechanically possible . The use of of the ball and the roller bearings makes accurate centering of the rotor rather simpler than with journal bearing ,and the reduction in over all length is an advantage .Ball and roller bearing are packed with grease and sealed after manufacture and can generally be relied upon to work for long periods without attention. 1.3 Speed Control The plain induction motor is essentially a constant-speed, shunt characteristic machine, its action being initially connected with its synchronous speed. Its nearly constant speed and low power factor constitute its chief advantage. Much investigation has made since the invention of the motor to overcome the restrictions on speed control and pf without sacrificIng the admirable and valuable simplicity and robust construction of the plain induction motor. Of the several method in use, some control speed ,while others deliberate affect the power factor also. The chief method of speed control involves no special prevision for the compensation of low power factor are: A) Resistance in rotor circuit B) Pole changing. C) Cascade connection and variants of it D) Change of supply frequency. 1.4 induction motor testing 1.4.1 Objective of tests A manufacture has his motor tested to obtain a brief 'ream' of the motor characteristics, in order that its guarantees may be satisfied. As most motor are now produced in stock lines, ELEC 3305 Electric Machines Laboratory Manual [19] only a few machines may receive any thing like a complete test, others will only have inspection for electrical and mechanical soundness. Where new types are developed or changes made in design, a more detailed investigation is fruitful, for the wise designer bases his judgements on test result. For the investigation of electromagnetic phenomena and for an insight into the behavior of a machine, many more or less elaborate test can be applied. 1.4.2 No load lest One of the most information tests is the no load tests ,which gives the core and pulsation loss, friction and windages loss, magnetizing current and no load power factor. Further, any rnechanical unbalance , noise, faulty connection, etc, are revealed. The stator connection are made to a supply of normal frequency and variable voltage, and instruments are Included to measure the voltage, input power and current after having been started, the motor is run with its rotor in the normal running condition, i.e. short-circuited, and with the brushgear raised in the case of slip ring motors with this equipment. When the motor has run long enough for its bearing, to show distress if faulty, the applied voltage is raised about 20% over normal, and input power and current observed. The slip ring is measured, it is not sufficient to measure the speed , for the slip is very small and cannot be accurately found from the difference between running and synchronous speed. The reading are taken at lower values of voltage down to that at which the current starts again to rise. 1.4.3 Locked rotor test: This is analogous to the short-circuit test of transformer The rotor is held stationary and shortcircuited under its normal running condition. The test consequently reveals no mechanical defects, but is of importance as furnishing the short-circuit current and power factor which, with the no-load current and power factor. In addition the I2R losses measured by the test are necessary for the estimation of efficiency by loss -summation. The stator is supplied with a low voltage of normal frequency, to avoid excessive currents. The position in which the rotor is clamped may affect the current. If so, the variations are noted when the rotor is locked in various position and a main position found. Alternatively the rotor may be allowed to rotate very slowly during the progress of the test. The voltage is raised in steps, with readings of current and power input, until the current reaches not more than twice normal. The reading are taking quickly to avoid overheating . ELEC 3305 Electric Machines Laboratory Manual [20] 1.4.4 Measurement of resistance: The resistance is one of the important parameters of the electrical circuit. This element is an element which consumed the energy and convert this energy to heat, power loss, which is undesired form of energy in electrical machine .This element can be calculated by ohm's law which is a suitable method for measuring resistance in lab. As we know that the resistance varies with the temperature. So we must keep the machine working at full load for a suitable period to assure that the temperature is raised to the corresponding worked temperature to have the suitable value of the measure resistance . 1.4.5 Determination of turns ratio: When there are two coil or more than one coil, besides each others there will be mutual flux collected between them if any coil is excited. For example, there are two coils if the first one is excited by AC voltage, there will be induced emf across the terminal of the second coil . This emf depends on the ratio between the turns numbers of the coils. So from this principle we can determine the turns ratio by measuring the voltage across the terminal of both coils. 1.4.6 Load test In the case of a small motor, an absorption brake or a coupled calibrated generator may be used to load the machine. The motor is operated on normal voltage and frequency at loads between zero and 50% or 100% over load, reading being taken of voltage- current in all phases, total power and slip. When guarantees for pull-out torque or starting torque are to be furnished, these may also be investigated. 1.4.7 Detremination of torque slip curve Accurate knowledge of the torque slip characteristic of an induction motor is very essential to have an idea of its starting torque, max torque, slip at max torque in order to asses its suitability for a particular application. This would give information regarding the run-up performance, crawling, etc. While the normal equivalent circuit may help predicating the characteristics becomes essential for establishing the validity of the theoretical methods. ELEC 3305 Electric Machines Laboratory Manual [21] 1.5 Applications of Induction machine: 1.5.1 Application of cage motors Our main subsection are; 1. Motors with normal starting torque and current, having cages with low resistance resistance and reactance, low full load slip ,good efficiency and power factor, and high pull out torque . 2. Motors with normal starting torque and low starting current ,having larger-rotor reactance but the same slip and efficiency as (1).The power factor and pull -out torque are less. These motors may be started by direct switching up to lager sizes than those in (1). 3.Motors with high starting torque and low starting current, using deep bar or double cage rotors . A 200% starting torque with moderate current is obtained on full voltage. The efficiency, power factor and pull-out torque are lower than for (1).The motors are useful for starting against load. 4.Motors with high flux load slip, using a comparatively high - resistance cage, with large starting torque, low starting current and low efficiency used for drives with heavy starting but light running duty. If employed for loads with rapidly fluctuating torque, they may be attached to flywheels for load-peak equalization. 1.5.2 application of slip ring motors Slip ring motors suitable for heavy, frequent starting and acceleration duty cycle. A high starting torque is obtained with a low starting current at high power factor. The rotor losses are mainly in the external resistance, easing the problem of rotor Cooling. ELEC 3305 Electric Machines Laboratory Manual [22] EXPERIMENT 7 No load and Blocked rotor tests on a 3 phase – Squirrel Cage Induction Motor (SCIM) Objective: To study the characteristics of a 3-phase squirrel cage Induction motor 1- To obtain the performance characteristics of a three-phase induction motor. 2- To perform Load and no-load test. Apparatus: - Voltmeter 0-10 A A.C. Ammeter 3.0 KW A.C. Wattmeter 2000 rpm A.C. Tachometer Motor Ratings : Power:3.7 KW Voltage : 415 Volts Current : 7.9 Amps Speed: 1430 rpm Connection: Star, later delta Theory: This test is used to determine the no load current Io, power factor, cosф, wind age & friction losses, core losses, no load resistance Ro and magnetizing reactance Xo. The motor is uncoupled from its load and rated voltage is applied to the stator. Since there is no output, the power supplied to-the stator is the some of its copper losses, core losses and friction and wind-age losses. ELEC 3305 Electric Machines Laboratory Manual [23] Procedure : No-Ioad Test : • Connect the circuit as shown in below. • Push the start button, the voltmeter reads the phase voltage,380V. • Record the No-load current, voltage, power drawn in each phase and speed Wye Connectio n 1 2 3 4 5 DeltaConnection I(A) VLL(V) P (W) N(rpm) PF ELEC 3305 Electric Machines Laboratory Manual [24] Load Test Repeat the above steps for a loaded motor. For each step of load take reading of all instruments. Take care not to exceed the rated current of the IM when loaded. Wye Connection 1 2 3 4 5 I(A) VLL(V) P (W) N(rpm) PF ELEC 3305 Electric Machines Laboratory Manual [25] DeltaConnection EXPERIMENT 8 Test on a 3 phase – slip ring Induction Motor Objective To study the characteristics of a 3-phase slip ring IM - Reversing the rotation of the IM -Locked rotor Voltage and current - control the speed of a slip ring IM Apparatus Same as above Procedure 1- Start the motor, observe the direction of rotation and measure the speed with the digital handheld tachometer. 2- Turn-off the motor and swap two of the three supply leads at the motor (e.g L1 on V1, L2 on U1, L3 remains on W1) Start the motor again; observe the direction of rotation and measure the speed with the digital handheld tachometer again. 3- Turn-off the motor and make the circuit changes shown below: ELEC 3305 Electric Machines Laboratory Manual [26] Start the motor and measure the locked rotor voltage. Turn-off the motor and replace the voltmeter by an ammeter; then repeat the above experiment, this time to measure rotor current (rotor terminal L and M are to be short-circuited with one-another for this test) 4- Turn-off the motor, remove the ammeter and shorting bridge the connect the rotor starter. Test the motor’s startup behaviour with various settings of the starter resistor. For each new start, measure the no-load speed with the digital handheld tachometer. Position 6 n/rpm 5 4 3 2 1 Table 1.1 No-load speeds with various starter resistances (Position 6: 0 resistance, Position 1: Highest resistance) ELEC 3305 Electric Machines Laboratory Manual [27]