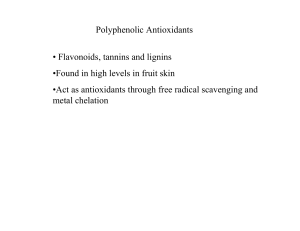

Quantitative determination of antioxidants in latex and latex compounds Dr Jean-Luc Madelaine Eliokem, 14 Avenue des Tropiques, Z A de Courtaboeuf 2, Villejust, 91955 Courtaboeuf Cedex, France Jean-luc Madelaine received his M.S in Organic Chemistry from the University of Caen and Ph.D. in Chemical Engineering from the University of Compiègne in France. He joined Goodyear Chemicals Europe (now Eliokem) in 1986 as an engineer in charge of the process optimization of antioxidants and antiozonants. Since then, he spent most of his career in the field of antioxidants, from product and process development to application development and customer technical service. Jean-luc is currently technical manager for the antioxidants at Eliokem European technical center, which employs about 30 scientists and technicians, located at Eliokem Headquarters in Villejust, 20 km south of Paris in France. INTRODUCTION Phenolic antioxidants are commonly added to synthetic latex and latex compounds as well as to natural rubber compounds in order to protect the polymer and the finished articles against oxidation during storage, transport and service life. Typical addition levels are 0.3 to 0.5 phdl (parts per hundred dry latex) in synthetic latex and 0.5 to 1.5 phdl in natural rubber latex compounds used for thin gloves or elastic thread manufacturing. Quantitative determination of the antioxidant into the latex, the latex compound or the finished product may be necessary for various purposes such as product and application development, troubleshooting studies (typically claims investigations, quality issues in production), customer technical support… Most often, such analyses are performed in order to check that the polymer contains the expected concentration of the additive or to assess how much of the additive is remaining in the polymer after storage or ageing. This paper will review briefly the most commonly used technique for antioxidant quantification based on extraction followed by a chromatographic analysis and its limitations in the case of multi-component antioxidants or antioxidants blends. Another approach based on the use of differential scanning calorimetry (DSC) will then be discussed and illustrated with some results in synthetic latex. Antioxidants description 3 different antioxidants have been used in the various examples reported in this paper: the monophenol BHT and 2 antioxidants from Eliokem sold under the ® Wingstay trade name for the protection of synthetic latex (typically carboxylated acrylonitrile-butadiene and styrene-butadiene latex) and natural rubber articles: - BHT (butylated hydroxy toluene) ® Wingstay L: the butylated reaction product of pcresol and dicyclopentadiene Wingstay® T: butylated, octylated phenol - The chemical formula and average molecular weight of these antioxidants are reported figure 1. OH OH OH CH3 CH3 CH3 1,2…n ® BHT Mw = 220 Wingstay L Mw = 650 OH R2 R1 R3 R1, R2, R3 = H, C4H9 or C8H17 ® Wingstay T Mw =340 Figure 1: Antioxidants formula THE “ANALYST APPROACH” Numerous methods have been used for identifying and quantifying additives from polymers and rubbers (1). These methods can be divided into direct determination methods and methods which require preliminary extraction of the additive from the polymer matrix. Although spectrometric techniques (UV, IR, Raman) which belong to the first type have seen recent advances with the use of Chemometrics, the preferred methods for the analyst remain the extraction techniques followed by a chromatographic analysis which allows separation of the extract into individual additives in order to facilitate their identification and quantification. Various extraction procedures can be used for separation of the additives from a polymer: solvent extraction (Soxhlet solvent extraction, solvent reflux extraction, superfluid extraction, microwave solvent extraction…), fractional precipitation, fractional extraction… The most commonly used extraction procedure for separating antioxidants from rubbers or rubber compounds is the solvent extraction using typically alcohols (methanol, ethanol), ethers and ketones (acetone, MEK). The choice of the chromatographic technique depends on the chemical structure of the antioxidants to be quantified. Gas chromatography which has been used extensively for over 25 years for measuring trace amounts of volatile components and especially residual monomers in synthetic polymers is the preferred method for low molecular weight antioxidants. With the use of capillary columns, it offers a very good separation resolution, low detection limits as well as possible identification of the products when coupled with Mass Spectrometry. Liquid chromatography, especially reverse phase HPLC, is the most widely used separative technique for additives allowing analysing higher molecular weight additives than Gas chromatography. Gel Permeation Chromatography which is very close to HPLC technique can also been used for rubber extracts. It has to be noted that beside these separative chromatographic methods, a popular method for estimating phenolic antioxidants in polymer extracts is direct analysis of the extract by UV-visible spectroscopy which consists in oxidising or coupling the antioxidant to form coloured products and measuring the resulting absorbance in the visible region. However, this method is not specific for individual antioxidants but for phenolic in general. An easy case: Quantification of BHT in NBR rubber The extraction–chromatography technique is illustrated below by the quantification of BHT - a volatile low molecular weight antioxidant which can be easily quantified by Gas Chromatography- into NBR rubber. The method consists simply in extracting BHT from the rubber with methanol during 24 hours at room temperature and then analysing the extract by Gas Chromatography on a capillary column with flame ionisation detection. Figure 2 shows the GC Chromatogram of the extract where BHT is easily identified. measured BHT, % 2 1.8 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 0 0.5 1 1.5 2 added BHT, % Figure 3: Measured vs. added BHT in NBR rubber Extraction-chromatography technique for quantification of antioxidants in latex The above example is an ideal case with a singlecomponent antioxidant, easily extracted from the rubber, and added at a fairly high dosage. Most synthetic latex are today stabilised with higher molecular weight antioxidants which are often not a single component material but multi-component products, and generally at quite low dosages, below 0.5 phdl. Typical examples of chromatographic fingerprints of such materials are reported figure 4 (CG analysis) and 5 (GPC analysis). Obviously, the quantification by chromatographic analysis of such materials becomes more difficult because firstly the level of each individual component is lower than the antioxidant dosage and secondly the optimization of the analytical conditions, including the calibration, for such products requires a good knowledge of their chemical composition. FID1 A , (WS07044\003F0301.D) c ounts 140000 120000 FID1 A, (CGP04091\CGP00007.D) counts 100000 BHT 60000 80000 50000 60000 40000 40000 30000 20000 20000 0 2.5 5 7.5 10 ® Figure 4: Gas chromatogram of Wingstay octylated phenol) 10000 0 2.5 5 7.5 10 12.5 min Figure 2: Gas chromatogram of extract from NBR rubber 3 samples of NBR stabilised respectively with 0.55, 0.90 and 1.8% BHT were analysed using this procedure. The measured BHT content were found at 0.6, 0.9 and 1.7% showing a good fit with the expected values as shown in Figure 3. 12.5 min T (butylated In addition, it is quite common to use blends of antioxidants in synthetic latex -such as blends of phenolic antioxidants, synergistic blends of phenolic and thioesters antioxidants- which also make the quantification more difficult. material but more difficult for the antioxidant user such as latex producers or manufacturers of finished latex goods. A DC1 B, A DC1 CHA NNEL B (MH01\MH010003.D) dRI 30 29 QUANTIFICATION OF ANTIOXIDANTS BY DSC 28 27 Oxidative Induction Induction Time 26 25 24 23 22 20 22.5 25 27.5 ® 30 min Figure 5: GPC chromatogram of Wingstay L (butylated reaction product of p-cresol and DCPD) Another limitation with the extraction-chromatography technique resides in the extraction process itself which sometimes gives yields lower than 100% due for example to losses in the case of volatile antioxidants or incomplete extraction with high molecular weight materials. This may result in determined quantities lower than expected in the latex or in the finished product. In this respect, it is advisable to include in the analysis a reference sample with a known antioxidant content, but such samples are not always available. Figure 6 below shows the result of the quantification of ® Wingstay L, the workhorse antioxidant for natural rubber gloves, in powdered and chlorinated gloves as a function of the theoretical content added in the gloves, determined by extraction with HITM solution (isopropanol / toluene / water mixture) at room temperature followed by Gas Chromatographic analysis of the extract. (2) 1 Temperature and Oxidative Differential Scanning Calorimetry (DSC) belongs to the thermal analysis techniques, in which a physical property of a substance is measured versus a reference as a function of temperature. In DSC, energy changes (heat flows) as a function of temperature are measured. It is used extensively in polymer science for precise determination of glass transition temperatures (Tg) and crystallisation and melting temperatures of polymeric materials, due to the endothermic or exothermic nature of these transformations. When the polymer is subjected to an oxidising atmosphere - such as air or oxygen - during the heating process in the DSC oven, the oxidative stability of the material can be assessed by determination of the temperature at which the exothermic degradation begins. Figure 7 shows a typical DSC curve for a carboxylated SBR latex film heated from 50 to 250°C at 2°C/min under an Oxygen flow of 50 ml/min. The start of the oxidative process is determined as the onset of the DSC curve and is known as the OIT, Oxidative Induction Temperature, expressed in Celsius degrees. ^exo m easured conc. (phr) 0.8 0.6 0.4 OIT=207.0°C Onset 208.98 °C 0.2 Pow der gloves Chlorinated gloves 60 0 0 0.4 0.6 0.8 Added level (phr) 1 1.2 ® Figure 6: Dosage of Wingstay L in NR gloves. The amount determined in the gloves is about 70% of the theoretical levels for the powdered gloves and 55% for the chlorinated gloves. It is not possible to assess if these lower than expected levels are due to incomplete extraction from the gloves or to losses during the production of the gloves, the later assumption being unlikely due to the high persistence of this antioxidant in the polymer. As a conclusion about the analyst approach, we can state that for the determination of low levels of complex antioxidants in latex and latex products, the development of specific chromatographic conditions for each antioxidant is required, which is achievable by the antioxidant producers knowing well the composition of the 80 10 ELIOKEM: SL 100 20 120 30 140 40 160 50 Figure 7: DSC curve of X-SBR film 180 60 200 70 220 80 240 °C 90 min e METTLER TOLEDO STAR System Comparison of OIT values is widely used for investigating the efficiency of antioxidants in polymers and more specifically in polyolefins (3). A variation to the measurement of the Oxidative Induction Temperature run under a temperature gradient consists in running an isothermal test in which the material is initially heated in an inert gas (nitrogen) to a given temperature, after which the atmosphere is changed to air or pure oxygen and the time to the exotherm is measured (3). The pattern of the curve is very similar to the figure 7 except that the x-axis is the time instead of the temperature. This is known as the Oxidative Induction time (expressed in minutes), which is also abbreviated as OIT. This test is standardized for polyolefins as an ASTM standard (4). Variation of the OIT as a function of antioxidant concentration Correlation between the Oxidative Induction Time and the concentration of a phenolic antioxidant into low-density polyethylene has been reported earlier, the OIT being not determined by DSC but by thermo-gravimetric analysis as the time for the beginning of a weight change of the sample due to oxygen absorption (5). However, little work has been reported on the use of OIT for determination of antioxidant levels in rubber or latex products. The variation of the Oxidative Induction Temperature, determined by DSC, as a function of the antioxidant dosage in a given polymer is illustrated in the figure 8 below showing the OIT of ABS powder as a function of ® the dosage of Wingstay L added in the ABS latex. OIT (°C) 215 Dosage of a single antioxidant Figure 9 shows the calibration curve for the dosage of a ® multi-component phenolic antioxidant - Wingstay L- in a carboxylated SBR latex. This antioxidant is quite difficult to quantify by the extraction-chromatography technique due to its high molecular weight and complex GPC fingerprint (Figure 5). After establishing the calibration curve, the OIT of 2 latex ® samples stabilised with 0.11 and 0.26 phdl Wingstay L were then determined and the concentration calculated using the calibration curve (black squares on the curve) . The calculated concentrations were respectively 0.115 and 0.22 phdl, close to the theoretical values. The better accuracy found for the lower concentration is not surprising considering the shape of the OIT vs. concentration curve (see discussion about the precision of the method) 220 OIT (°C) 218 216 210 205 214 212 200 210 208 195 190 206 204 185 180 202 200 175 0 0.05 0.1 0.15 0.2 Wingstay® L dosage, % 0.25 0 0.3 0.05 0.1 0.15 0.2 Concentration (phdl) 0.25 0.3 ® Figure 8: OIT curve for ABS powder Figure 9: OIT of X-SBR latex vs. Wingstay L dosage As can be seen on this curve, there is a direct correlation between the OIT value and the antioxidant dosage. We can therefore consider determining the antioxidant dosage from a given sample by measuring its OIT after establishing a calibration curve from samples containing known amounts of the antioxidant. Figure 10 gives the same calibration curve for a NBR latex, showing the same shape as the X-SBR latex but with a different OIT range. 200 OIT (°C) 195 Determination of antioxidants concentrations synthetic latex from OIT measurements in The method developed for determination of the antioxidant concentration in a synthetic latex is outlined below: - Preparation of standard samples: several samples with antioxidant levels in the range of the concentration of the sample to be analysed are prepared by adding the antioxidant emulsion or dispersion to a latex sample without antioxidant. - Preparation of latex films. Thin latex films are prepared from the standard samples and from the sample to be analysed by coating the latex onto a glass plate, using a 500µ calibrated coater. After drying at room temperature and 30 minutes at 105°C to eliminate any residual moisture, a 5 mg sample is cut from the film. - DSC measurement: The sample is placed into a aluminium DSC crucible with a 3-hole perforated cover and heated in the DSC oven from 50 to 250°C at 2°C/min under an oxygen flow of 50 ml/min. - The OIT is calculated from the DSC curve as the onset of the energy vs. temperature curve (shown in figure 7). 190 185 180 175 170 165 0 0.05 0.1 0.15 0.2 0.25 Concentration (phdl) 0.3 0.35 Figure 10: OIT of NBR latex vs. Wingstay® L dosage Dosage of antioxidant blends The same method can be used for measuring the concentration of antioxidant blends, for example a blend ® ® of 2 phenolic antioxidants (Wingstay T/ Wingstay L) commonly used in synthetic latex as an emulsion, as illustrated in Figure11 for the X-SBR latex. 214 OIT (°C) 214 212 212 210 210 208 208 206 206 204 204 202 202 200 OIT (°C) 200 0 0.05 0.1 0.15 0.2 0.25 Concentration (phdl) 0.3 0.35 ® Figure 11: OIT of X-SBR latex vs. dosage of Wingstay L/ ® Wingstay T blend. Precision of the method The magnitude of variation of the OIT over the range of the antioxidant concentration (0-0.3 phdl) depends upon the antioxidant and the latex type: from 10°C to 30°C in the above reported examples. Furthermore, the stabilisation - hence the OIT value- is not increasing linearly with the antioxidant concentration but is levelling out so that the slope of the OIT vs. concentration curve becomes very low when the concentration reaches the plateau of the curve. It is therefore necessary to measure the OIT value with a good precision. The repeatability of the method was checked my measuring 5 times the same sample of X® SBR latex stabilised with 0.2 phdl of the Wingstay L/ ® Wingstay T blend. The OIT values were 207.8, 208.1, 208.3, 208.5 and 208.7°C, i.e. a standard deviation of 0.32°C for an average value of 208.3°C which is acceptable for getting a good precision in the concentration calculated from the OIT especially for concentrations in the first part of the curve. However, when the concentration approaches the plateau of the curve (above 0.2-0.25 phdl), the accuracy becomes poor due to the low slope of the curve. This likely explains the lower accuracy found in the second sample for the X-SBR latex stabilised with Wingstay® L (0.22 vs 0.26 phdl). One way to overcome this problem would be to dilute the sample to be analysed with some latex without antioxidant, in order to bring down the antioxidant concentration to the region of higher slope. Determination of antioxidants concentrations in latex products The DSC method can also be used for the quantification of antioxidants in synthetic or natural latex finished products. In figure 12 below, the OIT measured on the NR powdered gloves discussed in the first part of this paper (figure 6) is reported as a function of the Wingstay L dosage in the glove. Although the OIT was not measured with a high precision in this study, the curve shows a good correlation between the OIT and the antioxidant dosage, after discarding the value at 0.875 phr which is an outlier. 0.4 0.6 0.8 Concentration (phr) 1 1.2 ® Figure 12: OIT vs. Wingstay L dosage in NR powder gloves. CONCLUSION Antioxidants concentrations in latex or latex finished products can be determined with a good accuracy from the measurements of the Oxidative Induction Temperature (OIT), using differential scanning calorimetry. When compared to the analyst approach based on extraction of the antioxidant followed by chromatographic analysis, the DSC method is simpler to implement as it does not require the development of chromatographic analytical methods often specific to a given antioxidant. However, the OIT method requires preparing standard samples for establishing the calibration curve and shows some limitations in the accuracy of the measurement when the antioxidant concentration reaches the plateau of the OIT vs. concentration curve. Another benefit of the OIT method is that the same procedure can be used for different antioxidants as well as for blends of antioxidants. REFERENCES 1. 2. 3. 4. 5. R Crompton, Determination of additives in polymers and rubbers, Rapra Technology, 2007. J Braden – Protection of chlorinated and nonchlorinated gloves with phenolic antioxidants, th presented at the 8 International Latex Conference, 2002. E Tury (ed.) - Thermal characterisation of polymeric materials, Academic Press, 1981 ASTM D3895-95 – Standard test method for oxidative induction time of polyolefins by Differential Scanning Calorimetry, American National Standard, 1995. H.E. Bair – Polym.Eng. Sci., 13,435-439, 1973.