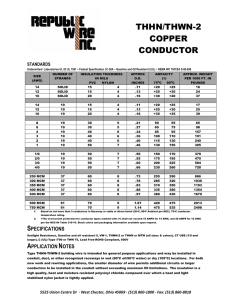

COPPER BUILDING WIRE TYPE THHN/THWN - 2 Copper 600V 90°C Dry or Wet PVC Insulated and Polyamide (Nylon) Jacketed, Single Core Nylon Copper Conductor Application Lead-Free PVC (UL-Listed) Detailed Description or Construction Conductor Annealed copper, solid or stranded sizes 2.0mm² up to 500mm² Insulation Premium grade flame retardant, lead-free, UL-listed polyvinyl chloride Jacket Tough Polyamide (Nylon) Standards / Testing Specifications THHN/THWN-2 conforms to the following standards: • UL 83 for Thermoplastic Insulated Wires and Cables (THHN/THWN-2) • UL 758 for Appliance Wiring Materials (AWM) • UL 1063 for Machine Tool Wire (MTW) (stranded conductors only) • PNS 35 Thermoplastic Insulated Copper Wires and Cables 600 Volts Executive office: 2/F BCS Prime Bldg. 2297 Pasong Tamo Ext. Makati City, Philippines T. (632) 813-2529 F. (632) 893-4990 Ideal for cable tray installation, wire ways, open wiring, conduits, service entrance, feeders, and branch circuits for permanent installations. Suitable for power and lighting installations in residential, commercial, and industrial establishments. Temperature rating not to exceed: • THHN/THWN: 90°C dry and damp, 600V • THHN/THWN: 75°C wet or in oil, 600V • THWN-2: 90°C dry, wet or in oil, 600V Features • CT-rated lead-free THHN/THWN cables are insulated with special PVC formulation that makes it more flame retardant than ordinary THHN cables. • More tolerant to heat with its better flame retardant PVC. • The insulation is made of materials that do not contain lead as stabilizer making it "environment friendly". • The nylon jacket offers mechanical protection and resistance to petroleum byproducts, chemical reagents, and oils. It is also abrasion-resistant, allows higher gliding and greater ease in installation. • Available in black, white, red, blue, green, and yellow colors. Other colors available upon request. Manufacturing Plant: Luisita Industrial Park San Miguel, Tarlac City Philippines T. (6345) 985-1088 to 91 customercare@phelpsdodge.com.ph COPPER BUILDING WIRE TYPE THHN/THWN - 2 Copper 600V 90°C Dry or Wet PVC Insulated and Polyamide (Nylon) Jacketed, Single Core Sizes Equivalent sizes Conductor diameter Cable diameter Cable weight Cable ampacity Ohm to neutral per 305 m 3 conductors in*** mm mm kg / km A** PVC conduit Radius 8 x cable OD Steel conduit mm Packaging scheme 1.6 mm Sol 14 AWG 1.6 2.6 22 25+ 2.70 2.70 21 150m / box 2.0 mm Sol 12 AWG 2.0 3.0 33 30+ 1.70 1.70 24 150m / box 2.6 mm Sol 10 AWG 2.6 3.8 55 40+ 1.10 1.10 30 150m / box 3.2 mm Sol 8 AWG 3.2 5.1 88 55 0.69 0.70 41 100m / box 2.0 mm² Str 14 AWG 1.8 2.8 24 25+ 2.70 2.70 22 150m / box 3.5 mm² Str 12 AWG 2.3 3.3 37 30+ 1.70 1.70 26 150m / box 5.5 mm² Str 10 AWG 2.9 4.1 58 40+ 1.10 1.10 33 150m / box 8.0 mm² Str 8 AWG 3.6 5.5 96 55 0.69 0.70 44 100m / box 14 mm² Str 6 AWG 4.6 6.5 147 70 0.44 0.45 52 150m / coil 22 mm² Str 4 AWG 5.7 8.1 232 90 0.29 0.30 65 150m / coil 30 mm² Str 2 AWG 6.7 9.0 311 115 0.19 0.20 72 150m / coil 38 mm² Str 1 AWG 7.8 10.8 414 130 0.16 0.16 86 300m / reel 50 mm² Str 1/0 AWG 8.8 11.8 514 150 0.13 0.13 94 300m / reel 60 mm² Str 2/0 AWG 9.8 12.7 625 170 0.11 0.11 102 300m / reel 80 mm² Str 3/0 AWG 11.2 14.2 813 205 0.088 0.094 114 300m / reel 100 mm² Str 4/0 AWG 12.7 15.7 1,026 225 0.074 0.080 126 300m / reel 125 mm² Str 250 MCM 14.3 17.8 1,298 265 0.066 0.073 142 300m / reel 150 mm² Str 300 MCM 15.7 19.3 1,556 295 0.059 0.065 154 300m / reel 175 mm² Str 350 MCM 17.0 20.8 1,741 325 0.054 0.060 166 300m / reel 200 mm² Str 400 MCM 17.8 21.4 1,967 355 0.049 0.056 171 300m / reel 250 mm² Str 500 MCM 20.2 23.8 2,519 400 0.045 0.050 190 300m / reel 300 mm² Str 600 MCM 22.3 26.3 2,964 447 0.042 0.048 210 300m / reel 325 mm² Str 650 MCM 22.9 26.9 3,218 470 0.040 0.047 215 300m / reel 375 mm² Str 750 MCM 25.0 29.6 3,677 500 0.037 0.044 237 300m / reel 400 mm² Str 800 MCM 25.5 29.7 3,974 515 0.036 0.043 238 300m / reel 500 mm² Str 1000 MCM 28.2 32.2 4,809 580 0.032 0.040 258 300m / reel *Unless otherwise specifically permitted, the overcurrent protection shall both exceed 15A for 2.0mm² (1.6mm); 20A for 3.5mm² (2.0mm) and 25A for 5.5mm² as per PEC. **Ampacity is based on 90°C not more than three current carrying conductors in conduit based on ambient temperature of 30°C as per PEC 2000. ***Effective impedance for three conductors in conduit 60Hz, 75°C and 600 Volts at P.F. multiplying current by effective impedance gives a good approximation for line to neutral voltage drop. +Diagrams of cables are illustrative only and not necessarily to scale. PDP reserves the right to change or vary the construction of any of their products without notice. While every care has been taken in the preparation of this data sheet, PDP accept no liability of any kind and are not responsible for the results of any actions taken on the basis of this information or resulting from errors or omissions. This technical data sheet is intended as a guide only; any person using it must make reference to the appropriate local standards or authorities. Executive office: 2/F BCS Prime Bldg. 2297 Pasong Tamo Ext. Makati City, Philippines T. (632) 813-2529 F. (632) 893-4990 Manufacturing Plant: Luisita Industrial Park San Miguel, Tarlac City Philippines T. (6345) 985-1088 to 91 customercare@phelpsdodge.com.ph