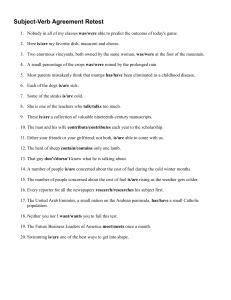

ARTICLE IN PRESS I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y 33 (2008) 3829 – 3836 Available at www.sciencedirect.com journal homepage: www.elsevier.com/locate/he A quick evaluating method for automotive fuel cell lifetime Pucheng Pei, Qianfei Chang, Tian Tang State Key Laboratory of Automotive Safety and Energy, Tsinghua University, Beijing 100084, China art i cle info ab st rac t Article history: Fuel cell vehicle commercialization and mass production are challenged by the durability Received 10 February 2008 of fuel cells and could be promoted by accelerated lifetime evaluating methods. In this Received in revised form paper, an arithmetic equation of fuel cell lifetime is presented, which is relating with load 15 April 2008 changing cycles, start–stop cycles, idling time, high power load condition and the air Accepted 16 April 2008 pollution factor. Basing on the practical data gathered from a fuel cell bus and the test Available online 16 June 2008 results of a fuel cell stack in laboratory, the calculated lifetime fits the bus real running Keywords: Fuel cell durability Accelerated test Lifetime evaluating method Potential lifetime prediction Open circuit voltage lifetime very well. It is shown that the automotive fuel cell lifetime mightily depends on driving cycles, and the potential lifetime in different operating mode can be effectively predicted by using this method with about 300 h test time. The test results also show that the effect of start–stop cycling on fuel cell lifetime can be almost ignored if the stack open circuit voltage is dispelled quickly after fuel cell stops operating. It is worthwhile that from this quick lifetime-evaluating method we can find many possible directions to improve fuel cell durability. & 2008 International Association for Hydrogen Energy. Published by Elsevier Ltd. All rights reserved. 1. Introduction The proton-exchange membrane fuel cells (PEMFCs) with the advantages of low-operating temperature, high current density, high potential for low cost and volume, fast start-up ability, and suitability for discontinuous operation become the most promising and attractive candidate for electric vehicle power [1–3]. However, some major technical issues are still to be solved for the wide-spread marketing of FC generators into the transportation area. Economical viability depends notably on improving the durability and the reliability of these new embedded generators. Fuel cell lifetime requirements vary significantly, from 5000 h for car applications up to 20 000 operating hours for bus applications [4–7]. However, practical experiments through a long time will spent much cost and often get lifetime results too late to follow the fuel cell technique progress. Therefore accelerated evaluating method for fuel cell lifetime is necessary. The method should shorten test time and be used to predict fuel cell potential lifetime [8–10]. It is widely accepted that there are two stages associated with the lifetime studies of fuel cells. The degradation sources with respect to various material selections and different operation conditions are identified in the first stage and in the second stage, mathematical models are developed to predict the lifetime of fuel cells, in which expressions of the aging phenomena and aging effects are incorporated into performance models through constitutive relations [10]. But in most literatures, the lifetime study of fuel cells remains in the first stage, with mostly experimental characterizations presented [11–13]. The reason why lifetime of automotive fuel cell is shorter than that of stationary fuel cell is the complex operation conditions undoubtedly, and so the effects of driving cycles, start–stop, high power load condition and idling condition should be seriously considered. The load on fuel cell stack frequently changes during running especially in vehicular Corresponding author. Tel.: +86 10 62789134; fax: +86 10 62789699. E-mail address: pchpei@tsinghua.edu.cn (P. Pei). 0360-3199/$ - see front matter & 2008 International Association for Hydrogen Energy. Published by Elsevier Ltd. All rights reserved. doi:10.1016/j.ijhydene.2008.04.048 ARTICLE IN PRESS 3830 I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y application, which will accelerate the fuel cell degradation [14]. Many studies on fuel cell long-term aging were conducted to evaluate fuel cell durability. Xie carried out a 2000-h fuel cell durability test and investigated two types of MEAs [15]. Wilkinson and St-Pierre took modified urban transit authority (UMTA) driving cycles to do their tests on a 8-cell stack and a 20-cell stack [11]. Liu carried out a study on a small fuel cell under cyclic current loading conditions, simulating the real road driving conditions for automotives, and established a phenomenological durability model to describe the aging process and cell performance at different time nodes [10]. Lee investigated the performance degradation of a fuel cell that exposed to repetitive on/off cycles [16]. In this paper, lifetime expression basing on operating conditions is studied. The effects of load changing cycles, start–stop cycles, idling cycles and high power condition on fuel cell durability are separately researched and the results show us the potential direction to prolong fuel cell lifetime. 2. Formula for fuel cell lifetime Many FC lifetime tests have shown the performance degradation is linear with time. So if we get the linear rate and know the life end point, then the lifetime can be doped out on the performance aging line. The lifetime can be given by Tf ¼ DP , rd 33 (2008) 3829 – 3836 prolonged by better powertrain configuration in FC vehicles? We make a calculate formula of vehicular FC available lifetime Tf as following: Tf ¼ DP , kp ðP01 n1 þ P02 n2 þ P03 t1 þ P04 t2 Þ where P01 ; P02 ; P03 and P04 are performance deteriorate rates resulted in by large-range load change cycling, start–stop cycling, idle condition and high power load condition separately, measured in laboratory; n1, n2, t1 and t2 are load changing cycle times, start–stop cycle times, idle time and high power load time per hour, gained from vehicular driving cycle. 3. Parameters confirm and formula validation 3.1. Parameters n1, n2, t1 and t2 in driving conditions In last two years, one of our demonstrating fuel cell buses run on a fixed route everyday, and it completed 43 000 km until now. From data gathered in all range trial, we get n1 ¼ 0.99 cycles/h, t1 ¼ 13 min/h and n1 ¼ 56 cycles/h, t2 ¼ 14 min/h in average. Fig. 1 shows the fuel cell system power in 1 h driving cycle of this fuel cell bus. (1) where rd is the fuel cell performance decay rate; DP stands for the limited decreased value of fuel cell performance from beginning to the lifetime end according to its definition. It is often not completely the same for the fuel cell lifetime test results between in laboratory and on road, by reason of the air quality difference and operating conditions. Then the lifetime formula can be written by Tf ¼ DP . kp rd (3) (2) Here kp is the accelerating coefficient. Different driving mode always results in a different lifetime range even for the same fuel cell. How much difference between different driving cycles and how many hours Fig. 2 – Fuel cell bus trial results. Fig. 1 – Fuel cell bus real driving cycle on road. ARTICLE IN PRESS I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y 33 (2008) 3829 – 3836 3831 Fig. 3 – Stack test on driving cycle in laboratory. Fig. 4 – Performance change in start–stop cycles. 3.2. The limited performance decreased value DP and the accelerate coefficient kp Fig. 2 is the fuel cell bus trial results with average speed of 32 km/h. In order to protect our fuel cells, at the first 1 min of the trial, big electric current is not allowed to use. So 0.7 V is the limited voltage by our definition. And at the first time of the trial, the electric current of 0.7 V is the limited electric current by our definition. After the fuel cell bus ran 35 000 km, about 1100 h, with the cell voltage decreased by 10% at the limited electric current, the fuel cell stack power became decreasing faster. So we define the time when the cell voltage decreases by 10% from rated power condition as the fuel cell life end time, where DP ¼ 10%. To get kp, driving cycle test in laboratory was performed on a 100-cell PEM fuel cell stack with 280 cm2 effective area in every cell, which is the same as used in the above fuel cell bus, and the driving cycle taken in this test is the same as the fuel cell bus. Fig. 3 is the results of 100 h stack test. Result shows the performance decay rate rd is 0.00534%/h. Comparing it with the voltage decreasing rate in Fig. 2, or using Formula 2, therefore we get the accelerating coefficient as kp ¼ 1.72. Of course, for fuel cells operated in a certain driving cycle, the lifetime can be calculated from Formula 2 basing on ARTICLE IN PRESS 3832 I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y 33 (2008) 3829 – 3836 Fig. 5 – Idling test cycles. Fig. 6 – Performance change in idling cycles. hundreds hours driving cycle test like this. But this method cannot meet our demands to predict lifetimes of fuel cells operating in different driving cycles. 3.3. Parameters P01 ; P02 ; P03 and P04 gained in laboratory Different operation conditions, such as styles of start–stop, idling current and load changing rate, will lead to different lifetime results. To evaluate fuel cell lifetime simplified, the same fuel cell stack and the same operation conditions were taken as in the fuel cell bus. In the bus, five fuel cell stacks are used and in the laboratory, one same fuel cell stack is used. 3.3.1. Start–stop cycling The fuel cell stack start–stop cycling test was carried out in the strict process—start-up, idling 1 min at constant current of 10 mA/cm2, stop, purging hydrogen by nitrogen gas, waiting until the stack voltage falls to zero, and then to the next cycle. Every ten start–stop cycling tests later, the fuel cell stack performance was recorded. We spent 80 h for this test item and get the fuel cell performance deteriorating history. As it is shown in Fig. 4, the cell voltage decays 0.00196% in every start–stop cycle, then p02 ¼ 0:00196%=cycle. Please note that if the test cycle number is not enough, the decay rate precision will be much poor. 3.3.2. Idling condition operation When the fuel cell works under idling cycle, the power is not big, so the water which made by the hydrogen and oxygen’s reaction is not much. When the gas flows in the channels, the MEA will be easy to be dry. In our fuel cell bus, the idling voltage must be set lower in order to prolong fuel cell lifetime. ARTICLE IN PRESS I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y 33 (2008) 3829 – 3836 3833 Fig. 7 – Load changing cycles test mode. Fig. 8 – Performance change in load changing cycles. We set the idling condition at cell voltage no more than 0.9 V in the bus. In this test, we set idling current density of 10 mA/cm2, and made an automatic program in which the fuel cell performance is recorded after every 15 min idling time, shown in Fig. 5. In the test period, we kept the operating temperature no more than 60 1C, the air stoichiometric ratio 2.5 and hydrogen stoichiometric ratio 1.2. Considering of the fuel cell bus operates day and rests night, we performed the test 5 h everyday from morning to afternoon with one start and one stop. Fig. 6 shows 50 h test result, in which the fuel cell performance gets almost full recovery at every beginning, with a little decay rate beyond retrieve. From this figure, we get the voltage decay rate P03 ¼ 0:00165% 0:00196% ¼ 0:00126%=h. 5 It is significative that although we took test in irregular way for 10 h after 25 h, the following test results show the same changing rate as the former test. To enhance the decay rate accuracy, it is important to keep test process regularly and strictly. 3.3.3. Load changing operation Load changing test cycle was set as Fig. 7, where the load changes from idling condition to rated power condition, and ARTICLE IN PRESS 3834 I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y 33 (2008) 3829 – 3836 Fig. 9 – Performance change in high power load cycles. Fig. 11 – Voltage changing history after stop. Fig. 10 – Performance deterioration related with operating factors. the fuel cell performance is measured after every 200 loading cycles. Everyday we took 30 min idling time to warm fuel cell to above 40 1C, and then carried out 2000 loading cycles. Fig. 8 shows all test points shape in orderliness with decay rate of 0.0000606%/cycle. Subtracting the effects of idling factor and start–stop factor, we gain: 0:00196% þ 0:00126% 30=60 2000 ¼ 0:0000593%=cycle. P01 ¼ 0:0000606% This test item can be completed in about 80 h. In Fig. 8, the fuel cell performance tends to steady after 1000 loading cycles. So the performance decay rate may be gotten in much shorter time if we perform the test continually after start up without mid shutdown. 3.3.4. High power load operation The steady high power load cycling test was carried out in a strict process also, in which the first step is start up and then warm up to above 40 1C, the second step is to load high power in steady, and make a performance test every 15 min. The high power load condition was set according with the limited voltage in fuel cell bus. Test was performed for 5 h with 30 min warming time and one start–stop cycle everyday. Fig. 9 shows all days test points shape orderliness, and then the voltage decay rate contributed to high power load cycles can be written: 0:00196% þ 0:00126% 30=60 5 ¼ 0:00147%=h. P04 ¼ 0:00199% 3.4. Lifetime calculation Basing on all above parameters, the fuel cell lifetime calculated by Formula 3 is TfE1000 h. Compared this result with the real fuel cell bus running lifetime of 1100 h, they are approximative. So Formula 3 is available and can be used to predict fuel cell lifetime in every operating mode. Maybe different fuel cell stacks work in different operations, but every automotive fuel cell life can be evaluated in ARTICLE IN PRESS I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y 33 (2008) 3829 – 3836 3835 Fig. 12 – Performance change in start–stop cycles with aftertreatment. 5. Formula 3. In different vehicle driving cycle, n1, n2, t1 and t2 may be different. 4. Analysis and discussion The effect of every operating condition factor on fuel cell lifetime can be showed in Fig. 10. The load change cycling and the start–stop cycling are the main factors contributing to fuel cell performance decay. One third of deterioration is resulted in by start–stop cycling and 56% is by load change cycling. Modifying start–stop cycling and load change cycling or decreasing their times, the fuel cell lifetime will be prolonged undoubtedly. In the period of start–stop cycling, the fuel cell deterioration is related with the high open circuit voltage [17]. It was found that the stack often maintains open voltage for more than 25 min, especially with voltage of above 0.8 V/cell for 5 min after every start–stop cycling, shown in Fig. 11. It is delectable that the effect of start–stop cycling on the fuel cell lifetime is much less, which almost can be ignored, while the fuel cell voltage remainder was dispelled betimes after every start–stop cycle. Fig. 12 shows the performance decreasing rate is 0.0000234%/cycle, much lower than the above decreasing rate of 0.00196%/cycle. In this operating mode, the fuel cell lifetime can be predicted as TfE1500 h, prolonged 50% more than the former normal operating mode, with just being modified the stop aftertreatment. From Formula 3, if the fuel cell load-changing time decreases, the fuel cell lifetime will be increased. This can be realized in fuel cell—battery hybrid vehicles and there must be an optimized driving cycle. Furthermore, if fuel cell vehicle runs in unpolluted environment, the fuel cell lifetime will be further prolonged. Conclusions An accelerated evaluating method for automotive fuel cell lifetime was brought up, and the calculated fuel cell lifetime and data recorded from the practical fuel cell bus shows the same result. Conclusions can be drawn from above as followings: (a) It is reasonable to define the cell voltage decrease of 10% at a constant current as the fuel cell life end. (b) The lifetime formula including factors of start–stop cycling, idling cycling, load change cycling and steady high power load cycling seems feasible. (c) Using the evaluating method described in this paper the fuel cell lifetime could be predicted basing on no more than 300 h test in laboratory. (d) The effect of start–stop cycling on fuel cell lifetime can be ignored when the stack voltage is dispelled betimes after fuel cell stops operating. (e) Fuel cell installed in vehicles could run much longer in clean environment without any pollution. Acknowledgments This work was financially supported by the National High Technology Research and Development Program of China. The authors would like to express their sincere gratitude to Shanghai Shen-li High Tech Company for providing fuel cell stacks. R E F E R E N C E S [1] Pan C, He R, et al. Integration of high temperature PEM fuel cells with a methanol reformer. J Power Sources 2005;145: 392–8. ARTICLE IN PRESS 3836 I N T E R N AT I O N A L J O U R N A L O F H Y D R O G E N E N E R G Y [2] Hana J, Leea SM, Chang H. Metal membrane-type 25-kW methanol fuel processor for fuel-cell hybrid vehicle. J Power Sources 2002;112:484–90. [3] Mikhail G, Ibrahim D, Marc AR. Life cycle assessment of hydrogen fuel cell and gasoline vehicles. Int J Hydrogen Energy 2006;31:337–52. [4] Wahdame B, Candusso D, Franc-ois X, Harel F, Péra MC, Hissel D, et al. Comparison between two PEM fuel cell durability tests performed at constant current and under solicitations linked to transport mission profile. Int J Hydrogen Energy 2007;32:4523–36. [5] Lattin WC, Utgikar VP. Transition to hydrogen economy in the United States: a 2006 status report. Int J Hydrogen Energy 2007;32:3230–7. [6] Martin W, Philipp S. Economic impacts of hydrogen as an energy carrier in European countries. Int J Hydrogen Energy 2007;32:3201–11. [7] Fowler MW, Mann RF, Amphlett JC, Peppley BA, Roberge PR. Incorporation of voltage degradation into a generalized steady state electrochemical model for a PEM fuel cell. J Power Sources 2002;106(1–2):274–83. [8] Taniguchi A, Akita BT, Yasuda BK, Miyazaki Y. Analysis of electrocatalyst degradation in PEMFC caused by cell reversal during fuel starvation. J Power Sources 2004;130:42–9. [9] Mattsson B, Ericsona H, Torella LM, Sundholm F. Degradation of a fuel cell membrane, as revealed by micro-Raman spectroscopy. Electrochim Acta 2000;45:1405–8. 33 (2008) 3829 – 3836 [10] Liu D, Case S. Durability study of proton exchange membrane fuel cells under dynamic testing conditions with cyclic current profile. Journal of Power Sources 2006;162:521–31. [11] Wiklinson DP, St-Pierre J. Durability. In: Wielstich W, Gasteiger HA, Lamm A, editors. Handbook of fuel cells— fundamentals, technology, applications. New York: Wiley; 2003 [Chapter 47]. [12] Luo Z, Li D, Tang H, Pan M, Ruan R. Degradation behavior of membrane–electrode-assembly materials in 10-cell PEMFC stack. Int J Hydrogen Energy 2006;31:1831–7. [13] Hou J, Yi B, Yua H, Hao L, Song W, Fu Y, et al. Investigation of resided water effects on PEM fuel cell after cold start. Int J Hydrogen Energy 2007;32:4503–9. [14] Yan X, Hou M, Sun L, Liang D, Shen Q, Xu H, et al. AC impedance characteristics of a 2 kWPEM fuel cell stack under different operating conditions and load changes. Int J Hydrogen Energy 2007;32:4358–64. [15] Xie J, Wood DL, Wayne DM, et al. Durability of PEFCs at high humidity conditions. J Electrochem Soc 2005;152(1): A104–13. [16] Lee SY, Cho EA, Lee JH, Kim HJ, Lim TH, Oh IH, et al. Effects of purging on the degradation of PEMFCs operating with repetitive on/off cycles. J Electrochem Soc 2007;154(2):B194–200. [17] Maassa S, Finsterwaldera F, Franka G, et al. Carbon support oxidation in PEM fuel cell cathodes. J Power Sources 2008;176:444–51.