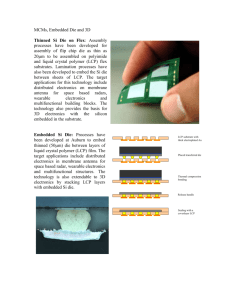

LIQUID CRYSTAL POLYMER (LCP) METALLIZATION Feng Liu and Joseph Law June 8 SUR/FIN 2022 Plating on Functional Plastics Megatrends ❑ High Speed High Frequency ❑ Increased Functionality, Integration, & Miniaturization ❑ Electronic & Autonomous Vehicles Telecom & Data Center Market Needs ❑ Signal Integrity & Reliability ❑ Thermal Management ❑ Reduced Weight and Design Flexibility Automotive Plating on functional plastics reduces weight, simplifies manufacturing, and offers functions from connection, EMI shielding to thermal management 2 Liquid Crystal Polymer (LCP) Introduction • LCP is a high melting point thermoplastic material, typically based on rigid rod-shaped aromatic polyesters, with different types of reinforcement or fillers added to the polymer network ❑ ❑ ❑ ❑ Glass fiber Mineral (mica/talc/clay) Carbon fiber Conductive carbon black • Other types of LCP based on amides, imides, and carbonates are also commercially available Solid state Molten state Conventional polymer (ABS, PC…) Molding Random Coil Liquid crystal polymer (LCP) Folded Structure Molding Liquid Crystal Oriented Structure Polymer chain 3 Why Plate LCP? • The excellent mechanical, thermal and electrical properties of LCP make it a growing option for many applications in automotive, telecom, HSHF circuits, and electronic connectors ❑ Good flowability in molding ❑ High dimensional stability ❑ Low moisture absorption Comparison of selected properties: LCP vs ABS ABS LCP 2.0 – 2.6 GPa 11 – 24 GPa Elongation at Break (%) 3.5 – 50 % 1.0 – 3.0 % Heat Deflection Temp. at 1.82 MPa 76 – 110 oC 240 – 270 oC ~ 0.05 – 1.8 % 0.02 – 0.05 % ❑ Low dielectric constant Elastic Modulus Moisture Absorption (ASTM D570) 4 Challenges and Approaches in LCP Metallization • LCP metallization seed layer can be achieved by sputtering, lamination of metal foil with adhesives, or embedded catalyst • An all-liquid approach offers reduced cost and flexibility to complex design shapes, with some challenges to solve Finishing layer (e.g. Sn, Ni) ❑ Weak adhesion of LCP to plated metal seed layer ❑ Some types of fillers difficult to plate ❑ Molding conditions effect on plating • DuPont TELEPOSIT™ 8000 approach focuses on achieving ❑ Required surface for strong metal adhesion ❑ Optimum catalyzation for full coverage, even on tough fillers Electrolytic Cu or full build-up e’less Cu Seed metal layer (e’less Cu / Ni) LCP substrate 5 TELEPOSIT™ 8000 LCP Metallization Process TELEPOSIT™ 8000 LCP Metallization Process Function TelepositTM 8010 Sweller TelepositTM 8100 Conditioner G Prepare the surface TelepositTM 8200 Conditioner M • Customer preference and patterning technique determine the choice of electroless Ni or Cu as seed layer TM Teleposit 8300 Conditioner TelepositTM 8440 Catalyst TelepositTM 8500 Accelerator Activate the surface and plate seed layer TelepositTM 8600 Electroless Ni OR TelepositTM 8700 Electroless Cu TelepositTM 8800 Electrolytic Cu Required finishing • Filler type determines selection of surface preparation and conditioner • A strong, conductive and ductile electrolytic copper is typical and followed by the required finishing Functional and protective Finishing 6 Surface Preparation • Traditional mechanical roughening (e.g. sand blasting) is not well controlled and is not a fully 3D process • All liquid process with TELEPOSIT™ 8000 LCP Metallization allows for processing of complex parts and tuning of surface preparation for specific LCP types LCP with glass fiber & mineral, 30% Surface texture Mineral filler 500X Glass fiber 500X Before Processing After Teleposit™ 8000 Process Surface Preparation 7 Surface Preparation Process for LCP Metallization Selection of surface preparation chemicals and baths can be modified based on the filler types in LCP Surface Preparation LCP with Glass Fiber LCP with GF & Mineral LCP with Mineral TelepositTM 8010 Sweller √ √ √ TelepositTM 8100 Conditioner G √ √ TelepositTM 8200 Conditioner M √ After sweller √ After sweller and Conditioner 8 Optimization of Surface Preparation - Roughness The Teleposit™ 8010 Sweller breaks down LCP polymer bonds without an additional oxidizer etch • Surface morphology and roughness monitored by dwell time As is 1X 1.5X 2X 2.5X 3X Surface Roughness Ra (mm) 6 5 4 3 2 1 0 Dwell time LCP with 30 % Glass Fibers and Mineral Fillers 9 Optimization of Surface Preparation - Adhesion Excellent metal adhesion on LCP achieved via optimization of dwell time, process temperature, and concentration TREATMENT TIME 0.5X 1X 1.5X 2X 2.5X 3X Adhesion Test of Seed Layer (w/ 0.7 μm e’less Cu) No peel off Cu peeled off Adhesion Test of Seed and Build-up Layers Baking Test (250 °C, 15min) No peel off Blistering Blistering Blistering Blister-free Blister-free Blister-free Best Adhesion 10 Surface Preparation: Mechanical vs Chemical Mechanical Sand Blasting TELEPOSIT™ 8000 Process Surface Morphology Sa = 8.65 μm Sa = 4.48 µm Plated Metal Appearance (Electroless Cu, Electrolytic Cu, and Electrolytic Sn Finish) Adhesion Tape Test ✓ Pass ✓ Pass Baking Test (250˚C, 15 min) ✓ Pass ✓ Pass Teleposit™ 8000 LCP Metallization provides good plated metal adhesion with lower surface roughness than mechanical roughening 11 Activating the Surface • TELEPOSIT™ 8000 Conditioner and Catalyst were formulated to achieve uniform catalyst adsorption • Uniform catalyst particles (2 – 5 nm) are very stable • DuPont offers both colloidal and ionic Pd catalysts • Even distribution on surfaces and inside complex design shapes • As a result, plated LCP samples have consistent plating thickness distribution on the surface 2 1 3 4 5 Uniform catalyst adsorption inside features Plating thickness (µm) • Broad compatibility with various substrates and filler types Uniform catalyst particle size 3 2 1 0 1 2 3 4 5 Location Even plating thickness distribution on the LCP surface 12 Plate Seed Layer Both the Teleposit™ 8600 Electroless Ni and Teleposit™ 8700 Electroless Cu provide full and uniform coverage for subsequent electroplating Factor Teleposit™ 8600 Electroless Nickel Teleposit™ 8700 Electroless Copper Deposit Conductivity • Lower than electroless Cu • Requires a strike prior to subsequent electroplate • No strike required Bath Life and Control • Typically long bath life • Simple analysis and replenishment based on [Ni] and pH • Typically shorter bath life • Replenish all components in ratio to [Cu] and adjust by routine analysis Environment • EDTA-free • Formaldehyde-free • Cyanide-free • Cyanide-free • Contains formaldehyde* and EDTA (*DuPont also offers ECOPOSIT™ XF-1000 Formaldehyde-free Electroless Cu) 13 Functional and Protective Finishing • The electroplated finish depends on the function and assembly of the LCP substrate • Provides strength, conductivity, ductility, and leveling • Teleposit™ 8800 Copper provides the optimum performance for LCP applications • Often applied over copper to prevent copper migration to the surface • DuPont offers both traditional and boric acid free electroplating options • Used as both an etch resist, or as a solder medium, for subsequent assembly • Solderon™ Tin products offer all appropriate options • Finishes that provide brightness, wear resistance, durability, corrosion resistance, or other performance requirements may also be applied. 14 Conclusions • LCP is an excellent material choice for applications in automotive, telecoms, electronic connectors and high-speed, high frequency circuits • TELEPOSIT™ 8000 LCP Metallization Process provides uniform plating and good adhesion with a smoother surface roughness than traditional mechanical roughening 15 Copyright © 2019 DuPont. All rights reserved. DuPont™ and the DuPont Oval Logo are trademarks or registered trademarks of DuPont or its affiliates. Nothing contained herein shall be construed as a representation that any recommendations, use or resale of the product or process described herein is permitted and complies with the rules or regulations of any countries, regions, localities, etc., or does not infringe upon patents or other intellectual property rights of third parties. The information provided herein is based on data DuPont believes to be reliable, to the best of its knowledge and is provided at the request of and without charge to our customers. Accordingly, DuPont does not guarantee or warrant such information and assumes no liability for its use. If this product literature is translated, the original English version will control and DuPont hereby disclaims responsibility for any errors caused by translation. This document is subject to change without further notice.