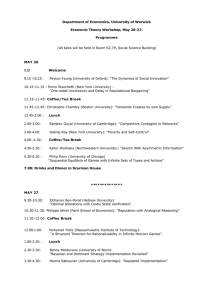

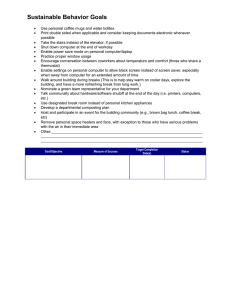

ISAT 211 Jessica Reilly Lab 9 – Lean Six Sigma Current Process Wastes in Initial Coffee Making Process ➢ ➢ Waste of overproduction: Excess of coffee grinds and water Waste of waiting time: Excess water caused longer brewing time and the coffee machine had to be moved to the edge of the counter in order to transfer coffee into the carafe ➢ ➢ Waste of over processing: Used a carafe that was too large for the coffee machine Waste of inventory: Pitcher wasn’t necessary to complete the process, use a reusable coffee filter ➢ Waste of movement: Items were accessible from one single area, rather they were scattered across the kitchen, start with all necessary items in one reachable place ➢ Waste from product defect: Consumer didn’t approve of the outcome Redesigned Process Making Coffee 0 100 Duration (sec) 200 300 400 500 Fill Water Tank With The Correct Water To Grinds… 25 Locate Coffee Grounds Canister Locate Measuring… Tasks Fill Coffee Filter With Grounds Refill Canister Put Spoon Into The Sink Return Coffee Grounds… Start Coffee Maker and Let Run Until It's Done Fill Insulated Carafe With Coffee Relocate The Pitcher To The Table Where The Coffee… Fill Coffee Cups With Coffee And Stir In Add-Ins At… Deliver Coffee To Customer 10 79 8 325 20 4 17 4 ISAT 211 Jessica Reilly Current Process Redesigned Process