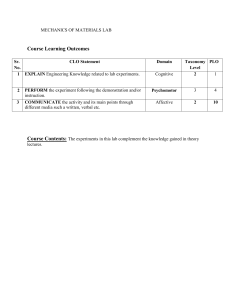

Primeasia University Faculty of Business Department of Business Administration Master of Business Administration Program OBE Course Outline: Operations Management Part: A 1. Course Code 2. Course Title 3. Course Type 4. Year/Level/Semester/Term: 5. Academic Session 6. Course Teacher/Instructor 7. Pre-requisite 8. Credit Value 9. Contact Hours 10. Total Marks : MGT 5105 : Operations Management : Core : Year/Level – 5, Semester/Term – 3 : As required : TBA : MGT 5101 :3 :3 : 100 11. Rationale of the Course : This course is designed to introduce the students of the program to the fundamentals of Production Management. With the increases in the global market competition, increased the need for competitive modern production and manufacturing system that can provide quality products to their target markets. This course addresses various functional areas of Production and Operation, and would facilitate students with the tools/techniques used in operations management decisions. 12. Course Objectives : The objectives of the course are to 1. Develop knowledge of dynamics of operations strategy, quality management & process movement for an organization. 2. Understand importance of quality management and statistical process control, a layout and location for a facility 3. Apply forecasting techniques and inventory management. 4. Analyze the concepts and techniques of project management. 5. Identify queuing models to determine waiting times in a waiting line. 13. Course Learning Outcomes (CLOs) and Mapping of CLOs with Program Learning Outcomes (PLOs) : Course Learning Outcomes (CLOs) CLO1 CLO2 CLO3 CLO4 CLO5 PLO1 PLO2 PLO3 PLO4 PLO5 PLO6 PLO7 PLO8 PLO9 PLO10 3 2 1 2 2 3 2 1 2 1 2 2 *Marking Values are 1=low, 2=Medium, 3= High 2 1 1 2 Part: B 14. Course plan specifying content, CLOs, co-curricular activities (if any) teaching learning and assessment strategy mapped with CLOs: Week/s Topic/s 1 Production and operations management: Functions within business organization, designing & operating production system, differentiating features of production systems, operation management process. Productivity, competitiveness and strategy: Productivity, competitiveness 2 3 4 5-6 7-8 Continuous improvement: Management requirements, the continuous improvement process, methods & tools Teaching Learning Strategy Lecture, Presentation, Learning Video Assessment Strategy -Attendance Lecture, Practical Demonstration, Problem Based Learning Lecture, Practical Demonstration, Problem Based Learning Attendance Process Selection and Facility Layout: the strategic importance of process selection, the basic processing types, the basic layout types, line-balancing problems Forecasting: the elements of a good forecast, the steps in the forecasting process, Compare and contrast qualitative and quantitative approaches to forecasting, describe averaging techniques, trend and seasonal techniques, and regression analysis, measure(s) of forecast accuracy, evaluating and controlling forecasts -Participation in Q&A session CLO 1 -Participation in Q&A session Attendance CLO 1 -Participation in Q&A session -Quiz-1 -Attendance Capacity planning: the importance of capacity planning, the determinants of effective capacity, major considerations related to developing capacity alternatives Corresponding CLOs CLO1 CLO 1 -Participation in Q&A session Lecture, Practical Demonstration, Problem Based Learning Attendance Presentation, Practical Demonstration, Learning Video, Problem Solving, -Attendance CLO 3 -Participation in Q&A session -Participation in Q&A session CLO 3 9 10-11 12 13 Management of Quality: The term quality, Why quality is important and the consequences of poor quality, The determinants of quality, The costs associated with quality, TQM, various quality tools Inventory Management: The term inventory, major reasons for holding inventories, The main requirements for effective inventory management, The nature and importance of service inventories, Periodic and perpetual review systems, The objectives of inventory management, The A-B-C approach, Economic Order Quantity (“EOQ”) model, Economic Production Quantity (“EPQ”) model, The quantity discount model, Reorder point models. Project Management: the behavioral aspects of projects in terms of project personnel and the project manager, the nature and importance of a work breakdown structure in project management, PERT/CPM, simple network diagrams, Activity Scheduling, networks with deterministic times, networks with probabilistic times, activity “crashing Management of Waiting Lines: Waiting lines form in systems, Implications of waiting line, Goal of waiting line management, Characteristics of waiting line, Measures of waiting line performance Queuing models – Infinite Source and Finite Source Constraint management Psychology of waiting Presentation, Practical Demonstration, Learning Video, open question and answer session among the students Presentation, Practical Demonstration, Learning Video, open question and answer session among the students Attendance Presentation, Practical Demonstration, Learning Video, open question and answer session among the students -Attendance Presentation, Practical Demonstration, Learning Video, open question and answer session among the students -Attendance CLO 3 -Participation in Q&A session -Quiz-2 -Attendance CLO 3 -Participation in Q&A session CLO 4 -Participation in Q&A session -Participation in Q&A session CLO 5 15 Operations strategy Supply Chain Management: Supply chain, The need to manage a supply chain and the potential benefits, objective of supply chain management, elements of supply chain management, The bullwhip effect. Group Presentation 16 Review class 14 Presentation, Practical Demonstration, Learning Video, open question and answer session among the students -Giving feedback on group presentation Reviewing the syllabus -Attendance -Participation in Q&A session -Quiz-3 Attendance Attendance CLO 1 15. Part: C Assessment and Evaluation : a. Assessment Strategy: Grades will be calculated as per the university grading structure and individual student will be evaluated based on the following criteria with respective weights. Assessment Strategies 1. Quizzes 2. Group Assignments & Presentation 3. Class Participation 4. Mid-Term Examination 5. Semester End Exam Total % of Marks 5 20 5 20 50 100 b. Marks Distribution – Continuous Assessment and Summative CIE- Continuous Internal Evaluation Bloom’s Class Test Mid-Term Participation in Class/Academic Category /Quiz Examination Activities/Co-curricular Activities /Assignments (20) (5) (25) Remember 05 05 05 Understand 05 05 Apply 05 05 Analyze 2.5 2.5 Evaluate 2.5 2.5 Create 05 16. SEE- Semester Examination (50 Marks) Bloom’s Category Remember Understand Apply Analyze Evaluate Create Test 10 10 15 5 5 5 Summary of Marks Distribution for Each Semester Category CIE SEE Total Marks 50 50 100 Part: D Learning Materials: Text Books: a) Operations Management by William J. Stevenson, McGraw-Hill Higher Education, latest edition Additional Textbook: a) Operations Management by Nigel Slack, Stuart Chambers, Robert Johnston, Pearson Education Limited, latest edition