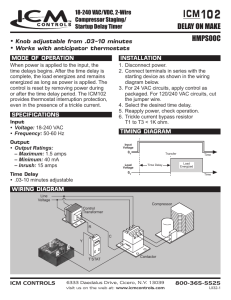

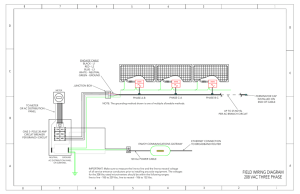

PRE-INSTALLATION GUIDE TruSpec TM July 2012 Thank-you for purchasing LECO analytical equipment. Installation by LECO service personnel is included as part of your purchase. The following information is provided so that the installation site can be properly prepared prior to the arrival of LECO personnel. Please follow the information for your new instrument carefully in order to assure proper site preparation. If any questions arise during site preparation, contact the LECO Service Department (Phone: 269-982-5497 Fax: 269-983-1477). PRE-INSTALLATION GUIDE INSTRUCTIONS 1. Prepare your installation site according to the information listed (in regards to: floor space, power requirements, gas supplies, gas tank regulators, and environment characteristics). Complete the Site Preparation Checklist (page 6) and fax the completed form to the LECO Service Department at (269) 983-1477. 2. When your instrument arrives, inspect all boxes and crates for outer damage. Carefully unpack all boxes and crates to cross-check the contents with the packing list accompanying each box. 3. Call your LECO Sales Representative and inform them that you have received your instrument and would like information sent for your specific application(s). 4. Call the LECO Service Department at 269-982-5497 to arrange an installation date. Keep in mind that all dates agreed upon are tentative and subject to change. Also, if anything is missing from your shipment or if anything was damaged during shipping, please inform the Service Department at this time. 5. Once you have scheduled an installation date, please provide adequate security for the instrument and the contents of the boxes shipped to ensure nothing is missing when the LECO Service Technician(s) arrives. 6. After scheduling, make arrangements for the appropriate personnel to be present at the installation and training sessions. In most cases, installation is completed within the first day and training takes place for the remainder of the first day and most of the second day. 7. Following all of the above steps will aid the LECO Service Team in providing you with the highest quality installation and training. NOTE: If the above steps are not followed, LECO will not be responsible for delays, cancellations, or rescheduling of installations. 1 TruSpec FLOOR SPACE Before your instrument arrives, make sure you know where it will be installed. When factoring overall floor space requirements, a minimum 6-inch (15 cm) access area should be factored in around each unit. Also factor in appropriate space for PC, monitor, keyboard, and printer to be used with the unit. * COUNTER TOP OPTIONAL PRINTER PC TOWER 28-inches (71 cm) TRUSPEC OPTIONAL BALANCE MONITOR KEYBOARD 63-inches (160 cm) FLOOR 27-inches (69 cm) * * 76.5-inches to 90-inches (194 cm to 229 cm) NOTE: * = 6-inch (15 cm) access area TruSpec Height Width Depth Weight 31-inches (79 cm) 27-inches (69 cm) 28-inches (71 cm) 273 lbs. (124 kg) NOTE: The PC should be placed next to the TruSpec. 2 TruSpec POWER REQUIREMENTS - ELECTRICAL WIRING DIAGRAMS A detachable line cord is supplied with each package. A female receptacle is provided with each 230 VAC package. Refer to the electrical wiring diagrams on this page. TruSpec ............................................................... 230 VAC 10% at max load, 50/60 Hz, 12 amps. NOTE: If line voltage is 210 VAC or less, LECO strongly recommends the use of a step-up transformer. LECO offers three options for power purification: 1) a basic auto-transformer (LECO part number 625-401-350) that does not require hard-wiring. This is a step-up transformer only with no power conditioning. 2) the 621-325 Transformer/Power Conditioner which also does not require hard-wiring. This option is for use with Truspecs that have either the Sulfur or Oxygen add-on module (both units connected). 3) the 621-376 Power Purifier is for stand alone Truspecs. This unit offers no support for add-on modules. Contact LECO for a quote on any of the above items. Computer ............................................................ 115 / 230 VAC ±10%, 50/60 Hz, 5 / 3 amps Monitor ................................................................ 90 to 264 VAC, 50/60 Hz, 1.6 amps Power Purifier (optional) Model 621-325 ............................................... Model 621-376 ............................................... Model 621-377 ............................................... 208/240 VAC, 60 Hz, single phase, 60 amp, 10 kVA 208/240 VAC, 60 Hz, single phase, 50 amp, 7.5 kVA 208/240 VAC, 60 Hz, single phase, 50 amp, 15 kVA NOTE: Outlet must be within 4 feet of the instrument’s designated area. NEMA 6-15 DETERMINATOR POWER CORD BLACK POWER 230 V~ RED NEUTRAL 0 V~ GREEN GROUND CHASSIS (CABINET) GROUND 230 V~ 3 WIRE WIRING DIAGRAM 3 TruSpec GAS SUPPLIES Gas supplies will require regulators. Refer to the Gas Regulator chart. NOTES: Supply or supply lines must be within 6 feet of the instrument’s designated area. A 4-inch long piece of ¼-inch copper tubing cleaned for oxygen service may be required. Carrier Gas .............................................. Helium, 99.99% pure, 35 psi (2.4 kg/cm2) 10%. Combustion Gas ..................................... Oxygen, 99.99% pure, 35 psi (2.4 kg/cm2) 10%. Pneumatic Gas........................................ Compressed Air, 40 psi (2.8 kg/cm2) 10%. Source must be oil and water free. GAS REGULATORS GAS LECO PART NO. DELIVERY RANGE INLET CONNECTION OUTLET CONNECTION Helium 619-592-405 0 to 125 psi CGA 580 Oxygen 619-592-403 0 to 125 psi CGA 540 Compressed Air 619-592-407 0 to 125 psi CGA 346 ¼-inch Swagelok with ¼-inch to 1/8-inch Swagelok adapter 4 TruSpec ENVIRONMENTAL CHARACTERISTICS Nominal Operating Conditions Operating Temperature ................................. 59 to 86oF (15 to 30oC) Storage Temperature .................................... 32 to 122oF (0 to 50oC) Relative Humidity ........................................... 20 to 80% (non-condensing environment) Cleanliness .................................................... For best performance, area and room should be kept free of excess dust. Circulation ...................................................... Good air circulation is recommended due to running temperature of instrument. Ventilation ...................................................... Ability to vent the room or instrument exhaust depending on application. Heat Dissipation ................................................... 5 9,500 BTU/hr TruSpec TruSpec Site Preparation Checklist Installation will not be scheduled until all items are ready at the user site. Confirm site preparation by checking each item and faxing the completed form to the LECO Service department at (269) 983-1477. FLOOR SPACE 76.5 to 90-inches x 63-inches (194 to 229 cm x 160 cm) POWER REQUIREMENTS Computer - 115 / 230 VAC 10%, 50/60 Hz, 5 / 3 amps Monitor - 90 to 264 VAC, 50/60 Hz, 1.6 amps TruSpec - 230 VAC 10% at max load, 50/60 Hz, 12 amps Acknowledgement of reading and understanding the line voltage note on page 3. Check and record voltage at each leg of line: Line 1: ______ Line 2: ______ Total: ______ Power Purifier (optional) Model 621-325 - 208/240 VAC, 60 Hz, single phase, 60 amp, 10 kVA Model 621-376 - 208/240 VAC, 60 Hz, single phase, 50 amp, 7.5 kVA Model 621-377 - 208/240 VAC, 60 Hz, single phase, 50 amp, 15 kVA GAS SUPPLY RECOMMENDATION Helium, 99.99% pure, 35 psi (2.4 kg/cm2) 10% Oxygen, 99.99% pure, 35 psi (2.4 kg/cm2) 10% Compressed Air, 40 psi (2.8 kg/cm2) 10%. Source must be oil and water free. NOMINAL OPERATING CONDITIONS Temperature 59 to 86oF (15 to 30oC) Relative humidity 20 to 80% (non-condensing environment) Ability to vent room or instrument exhaust depending on application Area clear of excess dust Good air circulation GENERAL Unit has arrived at installation site, been inspected and missing parts (if any) ordered Material and element being analyzed: _________________________________________________ Expected Result / Range (in ppm or %): _______________________________________________ Name: (please print) ________________________________________________________________________ Company: _________________________________________________________________________________ Address: _________________________________________________________________________________ City: _________________________________ Phone: (______)________________ State: ________________ Fax: (______)_______________ Zip: __________________ e-mail: ________________________________ By signing below I certify that site preparation is complete. I understand that if the site is not prepared properly and completely, installation and training will have to be rescheduled. I also understand that if installation and training must be rescheduled due to incomplete site preparation, my company will be billed at normal LECO service rates for installation and training. Signature: _________________________________________ Date: ___________________________ Job Title: __________________________________________________________________________________ Fax this form when completed to the LECO Service Department at (269) 983-1477 and then call (269) 982-5497 to arrange an installation date. 6 TruSpec