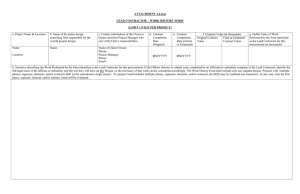

Collaborative Infrastructure Procurement in Sweden and Netherlands

advertisement