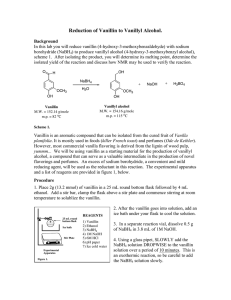

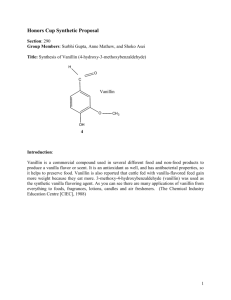

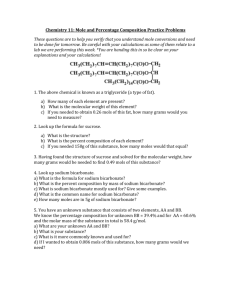

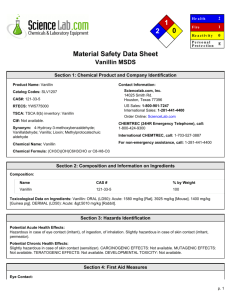

Food Chemistry 114 (2009) 791–797 Contents lists available at ScienceDirect Food Chemistry journal homepage: www.elsevier.com/locate/foodchem Thermal oxidation of vanillin affects its antioxidant and antimicrobial properties Ioannis Mourtzinos a, Spyros Konteles b, Nick Kalogeropoulos a, Vaios T. Karathanos a,* a Laboratory of Food Chemistry, Biochemistry and Physical Chemistry, Department of Nutrition and Dietetics, Harokopio University, 70 El. Venizelou Ave., Kallithea, 176 71 Athens, Greece Laboratory of Food Microbiology, Department of Food Technology, Technological Educational Institute of Athens, 12 Ag. Spyridonos St., Egaleo, 122 10 Athens, Greece b a r t i c l e i n f o Article history: Received 13 March 2008 Received in revised form 6 August 2008 Accepted 8 October 2008 Keywords: Vanillic acid GC–MS Differential scanning calorimetry Oxidation studies DPPH a b s t r a c t Accelerated oxidation of vanillin was studied by isothermal and non-isothermal differential scanning calorimetry (DSC) in model solutions. Exothermic peaks of DSC thermograms, due to the oxidation of vanillin, were observed. Vanillin oxidation to vanillic acid was confirmed by the detection of vanillic acid in heated vanillin samples using GC–MS. The effect of temperature on vanillin oxidation was studied by conducting DSC experiments with pure vanillin at several different final temperatures and by subsequent determination of vanillin and vanillic acid by GC–MS. Furthermore, the DPPH free radical assay was done on DSC-treated samples as well as on mixtures of vanillin–vanillic acid. The radical-scavenging activity of the samples was increased along with the vanillic acid content. Additionally, the antimicrobial activities and the minimum inhibitory concentrations (MIC) of solutions containing vanillin and vanillic acid against Staphylococcus aureus, Staphylococcus epidermidis, Bacillus cereus, Enterobacter aerogenes, Escherichia coli and Yersinia enterocolitica were determined by the agar well-diffusion method. All tested samples exhibited inhibitory activity against all of the bacteria. Yet, the higher the vanillic acid concentration, the lower was the MIC of the samples. It is concluded that the thermal treatment of vanillin-containing food may lead to products with improved antioxidant and antimicrobial properties. Ó 2008 Elsevier Ltd. All rights reserved. 1. Introduction Vanilla is a tropical, climbing orchid (Vanilla planifolia, Vanilla pompona or Vanilla tahitiensis). The cured or fermented beans or pods of the orchid are treated with alcohol and the extract is the natural vanilla. The main component of vanilla aroma is ‘‘vanillin” (4-hydroxy-3-methoxybenzaldehyde), that is accompanied with minor amounts of vanillic acid and up to 200 trace components (Boyce, Haddad, & Sostaric, 2003; Korthou & Verpoorte, 2007; Sinha, Sharma, & Sharma, 2007; Walton, Mayer, & Narbad, 2003). Vanillin is considered to be one of the most widely appreciated flavour compounds, with an odour threshold for humans equal to 11.8 1014 M, and has the unique characteristic that, even at high doses, the flavour is still pleasant (Korthou & Verpoorte, 2007). Vanillin is used as a flavouring agent and it is generally regarded as safe (GRAS). Currently, it is added in a wide range of products, e.g. pastry products, ice cream, soft drinks and baked products (biscuits, cereals), in concentrations ranging from 1 to 26 mM, depending on the nature of the product. Apart from flavouring properties, vanillin exhibits several bioactive properties (Sinha et al., 2007), e.g. antioxidant (Burri, Graf, Lambelet, & Loliger, 1989) and antimicrobial activities against yeasts, moulds (Cerruti & Alzamora, 1996; * Corresponding author. Tel.: +30 210 9549 224x306; fax: +30 210 9577 050. E-mail address: vkarath@hua.gr (V.T. Karathanos). 0308-8146/$ - see front matter Ó 2008 Elsevier Ltd. All rights reserved. doi:10.1016/j.foodchem.2008.10.014 Fitzgerald, Stratford, Gasson, & Narbad, 2004; López-Malo, Alzamora, & Argaiz, 1997; Tipparaju, Ravishankar, & Slade, 2004) and bacteria (Delaquis, Stanich, & Toivonen, 2005; Fitzgerald et al., 2004; Moon, Delaquis, Toivonen, & Stanich, 2006; Rupasinghe, Boulter-Bitzer, Ahn, & Odumeru, 2006; Tipparaju et al. 2004). Vanillin has also been reported to possess anticlastogenic, antimutagenic and antitumor properties and, therefore, it can be considered as a nutraceutical molecule (Durant & Karran, 2003; Gustafson et al., 2000; Keshava, Keshava, Whong, Nath, & Ong, 1998; Kumar, Ghosh, Devasagayam, & Chauhan, 2000; Lirdprapamongkol et al., 2005; Shyamala, Naidu, Sulochanamma, & Srinivas, 2007; Sinigaglia, Reguly, & de Andrade, 2004). Moreover, it has found applications as a constituent in perfume and pharmaceutical formulations. From a chemical standpoint, vanillin has both aldehydic and phenolic groups and it can undergo several types of reactions, amongst them oxidation. Vanillin oxidation may be either enzymic (Anklam, Gaglione, & Muller, 1997) or chemical with oxygen, in the presence of alkalies (Fricko, Holocher-Ertl, & Kratzl, 1980) or potassium bromate (Samaddar & Banerjee, 1982) solutions. In dairy products, the oxidation of vanillin to vanillic acid can take place during the processing of milk by the action of enzymes that are present in the milk, as well as by heat, during pasteurization. Furthermore, in milk and dairy products, vanillin can be oxidised into divanillin in the presence of peroxidase (Anklam et al., 1997). Oxidation of vanillin to vanillic acid, in dairy products, was studied by 792 I. Mourtzinos et al. / Food Chemistry 114 (2009) 791–797 Anklam et al. (1997). Also, in model solutions of shoshu (Japanese alcoholic beverage), it has been proved that ferulic acid, liberated from rice flour, is converted to 4-vinylguaiacol and then to vanillin and vanillic acid by microorganisms (Koseki, Ito, Furuse, Ito, & Iwano, 1996). Several methods have been developed to evaluate the oxidative stability of various molecules (lipids, antioxidants) under accelerated conditions. Amongst them, thermal analytical methods were included, such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) (Rudnik, Szczucinska, Gwardiak, Szulc, & Winiarska, 2001), either isothermal or non-isothermal. Isothermal DSC analysis has been used for evaluating the oxidation stability of vegetable oils and antioxidants (Giuffrida et al., 2007; Hu et al., 2007; Velasco, Andersen, & Skibsted, 2004) whilst nonisothermal or dynamic DSC analysis has been used for studying the thermo-oxidative degradation of antioxidants (Giuffrida et al., 2007), organic materials, polymers and petroleum products (Litwinienko, Kasprzycka-Guttman, & Jamanek, 1999). Non-isothermal DSC is much faster and it can provide more information about the oxidation processes than can isothermal DSC. Despite several reports on the antioxidant and the antimicrobial activities of vanillin, to our knowledge, the evaluation of these properties in samples heated under several time/temperature combinations has not yet been undertaken. In this work, pure vanillin was heat-treated, under either isothermal or non-isothermal conditions by DSC. In both cases the heat-treated samples were analysed by GC–MS. Moreover, the antioxidant and the antimicrobial properties of the samples were assessed by the 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical-scavenging assay and by the ‘‘agarwell” dilution method, respectively. 2. Materials and methods 2.1. Materials 2.1.1. Reagents and solvents Vanillin and vanillic acid were obtained from Sigma (St. Louis, MO, USA) and Serva (Heidelberg, Germany), respectively. 1,1-Diphenyl-2-picrylhydrazyl radical (DPPH) and bis-(trimethylsily)trifluoroacetamide (BSTFA), were obtained from Aldrich (Steinheim, Germany). 2.1.2. Bacterial strains and culture preparations Eleven bacterial strains (target-strains) – pathogenic and nonpathogenic – were used in this study. Salmonella dysenteriae NCTC 2966, Salmonella typhimurium NCTC 012023, Enterobacter aerogenes NCTC 0100006, Yersinia enterocolitica NCTC 10460, Escherichia coli O157:Y7 NCTC 009001, Staphylococcus aureus NTCT 006571, Staphylococcus epidermidis NCTC 011047, Bacillus cereus NCTC 7464 and Listeria monocytogenes NCTC 010357 were provided by Agrolab S.A. (Agrolab S.A., Athens, Greece). Lactobacillus bulgaricus ACA-DC 101 and Lactococcus lactis ACA-DC 1 were provided by the ACA-DC collection (Laboratory of Dairy Research, Agricultural University of Athens, Greece). L. bulgaricus and L. lactis working cultures were maintained on Man Rogosa and Sharpe (MRS, Merck, Darmstadt, Germany) agar slants whilst the remaining strains were maintained on Tryptone soy agar (TSA, Merck) supplemented with 0.6% yeast extract (Sigma, St. Louis, MO, USA), (TSYEA) slants, all stored at 4 °C. 2.2. Methods 2.2.1. Isothermal oxidation of vanillin by DSC Vanillin samples (5 mg, 0.033 mmole each), were placed in open aluminium pans and heated to 100, 120, 130 and 140 °C, at times varying from 10 to 90 min, in a Perkin–Elmer DSC instrument (DSC-6, Boston, MA, USA). The samples obtained after ther- mal treatment by DSC were diluted in 10 ml of ethanol:water 80:20 (v:v) and stored at 4 °C for subsequent analysis. By isothermal heating, the DSC instrument was operated as a heating apparatus, e.g. a reactor or an oven, kept at constant temperatures, in order to affect the oxidation of vanillin. 2.2.2. Non-isothermal oxidation of vanillin by DSC Non-isothermal DSC is a scanning procedure over a wide range of temperatures. It offers valuable information on various thermal transitions, which occur over the range of temperatures, such as glass transition, melting, crystallisation, oxidation, decomposition, evaporation and others and gives the range of temperature at which these transitions take place (Clas, Dalton, & Hancock, 1999; Widman, 1987). All the non-isothermal heat treatments were carried out in a DSC instrument. Vanillin samples, 5 mg each, were placed in open aluminium pans and heated, in an oxygen atmosphere, from room temperature (approximately 20 °C) to 120 °C, at a rate of 90 C° per min. The samples were left at 120 °C for one minute, to ensure uniform temperature distribution in them, and they were then heated at a rate of 10 C° per min. The oxygen flow rate was 20 ml/s. This latter procedure was applied eight times with the following final temperatures: 131, 179, 210, 230, 258, 262, 273 and 280 °C. The heat-treated samples at each of the above temperatures were diluted in 10 ml of ethanol:water 80:20 (v:v) and stored at 4 °C for the subsequent GC–MS and DPPH analyses. 2.2.3. Preparation of vanillin–vanillic acid solutions Solutions containing vanillin and vanillic acid with the ratios (w:w), 100:0, 77:23, 53:47, 25:75, 0:100, were prepared in 10 ml of ethanol: water (80:20). Prior to antimicrobial testing, the samples were filter-sterilised through a 0.22 lm membrane filter (Gelman Sciences, Inc., Ann Arbor, Michigan, USA). In order to determine the MIC (minimum inhibitory concentration) of the samples over the range of target-strains used, several dilutions of the samples were made (0, 1:2, 1:4, 1:8, 1:16) in ethanol:water 80:20 (v:v) solution. 2.2.4. Gas chromatography/mass spectrometry analysis Aliquots of ethanol:water solutions of DSC-treated samples (50 ll) or aliquots of mixtures of vanillin–vanillic acid solutions were transferred to GC vials containing 50 ll of internal standard, (3-(4-hydroxy-phenyl)-1-propanol, 19.2 lg/ml), evaporated to dryness under a stream of nitrogen, and derivatized by adding 250 ll of BSTA, followed by incubation at 70 °C for 20 min (Soleas, Diamandis, Karumanchiri, & Goldberg, 1997). An aliquot (1 ll) of each sample was injected into the gas chromatograph (GC) at a split ratio of 1:50. An Agilent GC (Wallborn, Germany) series 6890N, coupled with an HP 5973 Mass spectrometer (MS) detector (EI, 70 eV), split–splitless injector and an HP 7683 autosampler was used for the analysis. Sample separation was achieved using an HP5 MS capillary column (5% phenyl–95% methyl siloxane, 30 m length, 0.25 mm inner diameter, 250 lm film thickness). Helium was used as a carrier gas at a flow rate 0.6 ml/min. The injector and transfer line temperatures were set at 280 and 300 °C, respectively. The oven temperature programme was: initial temperature 70 °C for 5 min, 70–130 °C at 15 °C per min, 130–160 °C at 4 °C per min, held for 15 min, 160–300 °C at 10 °C per min, and finally held at 300 °C for 15 min. Under these conditions, vanillin and vanillic acid were eluted after 17.30 and 25.89 min, respectively. A selective ion monitoring (SIM) GC/MS method was applied for the detection of vanillin and vanillic acid. Detection of compounds was based on the ±0.05 RT presence of target and qualifier ions of the standards at the predetermined ratios. Target and qualifier ions (T, Q1, Q2) for the compounds were set as follows: vanillin: 194, 209, vanillic acid: 297, 267, 312. 793 I. Mourtzinos et al. / Food Chemistry 114 (2009) 791–797 % DPPH scavenging ¼ ½ðAcontrol Asample Þ=Acontrol 100 where Asample is the absorbance of sample after the time necessary to reach the plateau (30 min) and Acontrol is the absorbance of DPPH. 2.2.6. Antibacterial assay The inhibitory activities of vanillin:vanillic acid solutions were qualitatively and quantitatively analysed by a modified ‘‘agar-well” diffusion assay as described by Schillinger and Lucke (1989). Plates were filled with 12 ml of agar–agar (Merck) and, when the medium was solidified, overlaid with 10 ml of TSYE soft agar (8 g/l, agar) that had been, previously inoculated with 100 ll of the proper target cell suspension. For Lactobacillus and Lactococcous strains, the overlaid medium was MRS soft agar. The cell suspensions were made by diluting overnight cultures of the target strain into saline solution to, approximately, 107 cfu/ml, using McFarland turbidity standards (bioMerieux S.A., Marcy l’Étoile, France). The plates were dried for 1 h and then, using a sterile cylinder, wells of 7.0 mm diameter were made and filled up with 100 ll of the sample. In order to obtain comparable results, all samples were treated under the same conditions in the same plate. The plates were incubated for 24 h at 37 °C and the results were recorded. Lactobacillus and Lactococcous strains were incubated under anaerobic conditions (BBL GasPak system, Becton Dickinson microbiology systems, Cockeysville, MD) for 48 h at 37 °C. The inhibitory activities of the samples were detected as a clear zone around the wells and expressed in millimetres (mm). Minimum inhibitory concentration (MIC) was defined as the lowest concentration of the sample that caused a zone of inhibition (1–3 mm). As negative control, the ethanol:water (80:20) (v:v) solution was used. 2.2.7. Statistical analysis DSC experiments were duplicated. DPPH analyses, as well as antimicrobial tests, were performed in triplicate (n = 3). The results presented are the averages of the obtained values. Simple descriptive statistics were analysed using Microsoft excel. 3. Results and discussion 3.1. Isothermal oxidation of vanillin The heat stability of vanillin under isothermal conditions was investigated with DSC. Vanillin samples (0.032 mmole) were heated at 100, 120, 130 and 140 °C at time intervals varying from 3.2. Non-isothermal oxidation of vanillin The heat stability of vanillin under non-isothermal conditions was also studied. The temperature range studied was from 120 to 280 °C to examine possible thermal degradation, and oxidation phenomena occurred at relatively high temperatures, e.g. in the a Vanillin (mmol) 2.2.5. Radical-scavenging activity (antioxidant activity) The effect of the oxidised vanillin samples, as well as vanillin:vanillic acid mixtures, on DPPH was estimated according to the procedure described by Brand-Williams, Cuvelier, and Berset (1995). Briefly, each sample was diluted in ethanol prior to the analysis (1 mg/ml). An aliquot (0.1 ml) of the solution was added to 3.9 ml of DPPH solution (6 105 M in ethanol), thoroughly mixed, and the absorbance of the sample at 515 nm was recorded after the time necessary for the reaction to reach a plateau, which was 30 min, as proposed by Brand-Williams et al. (1995). The absorbance of DPPH solution in ethanol, without any antioxidant (control), was also measured. The percentage of remaining DPPH was calculated as follows: 10 to 90 min, and the vanillin remaining after the thermal treatment was determined by GC/MS. As can be seen in Fig. 1a, the longer the time of heat treatment, the less vanillin remained in the samples. Moreover, the vanillin decrease was faster as the temperature increased from 100 °C to 140 °C, resulting in a drop of the vanillin ‘‘half-life” from 53–55 min at 100–120°C to 47 min at 130°C and just 15 min at 140°C. On the other hand, vanillic acid, an oxidation derivative of vanillin, was gradually formed in the samples (Fig. 1b). The results showed that both temperature and heating time governed the vanillic acid formation. Regarding the effect of temperature, the general trend was that vanillic acid formation was favoured at higher temperatures; for example, the vanillic acid concentrations formed after 30 min at 120, 130 and 140°C were, respectively, 3, 6 and 16 times higher than that formed at 100 °C. By contrasting Fig.1a and b, it appears that the total amounts of vanillin and vanillic acid (in mmoles) did not remain constant but decreased along with temperature and time, most likely due to evaporation and/or thermal degradation of both substances. The combined effect of vanillic acid formation from vanillin and the thermal decomposition of both substances resulted in time–profile curves showing a maximum (Fig. 1b) at the points where the production and deterioration rates of vanillic acid were equal, especially at temperatures above 120 °C. These maxima appeared earlier as the temperature increased, being >90 min at 100 °C, around 60 min at 120–130 °C and around 30 min at 140 °C (Fig. 1b). 0.040 100°C 0.035 120°C 0.030 140°C 130°C 0.025 0.020 0.015 0.010 0.005 0.000 0 10 20 30 40 50 60 70 80 90 100 Time (min) b 0.0006 100°C Vanillic acid (mmol) The identification of chromatographic peaks was achieved by comparing the retention times and ratios of the fragment ions of each compound with those of reference compounds whilst quantification was carried out using 3-(4-hydroxy-phenyl)-1-propanol as an internal standard with target ion m/z 206 and qualifiers 191 and 179. Very good linearity (R2 > 0.999) was obtained for both compounds within the concentration range studied. 120°C 0.0005 130°C 140°C 0.0004 0.0003 0.0002 0.0001 0 0 10 20 30 40 50 60 70 80 90 100 Time (min) Fig. 1. Time profile of: (a) vanillin oxidative loss and (b) vanillic acid formation during heating of pure vanillin at different temperatures. oven or during production of low-moisture foods, such as by extrusion cooking. The final temperature of the DSC programme (280 °C) was selected in order not to exceed vanillin’s boiling point at 285 °C. An exothermic event was observed at temperatures starting at 131 °C, with a maximum at 210 °C, and then the thermogram curve decreased until 258 °C. Over this temperature range (131– 258 °C) the thermal event was not, most likely, an oxidation phenomenon since the vanillic acid formation at some selected temperatures (131, 179, 210 and 230 °C) was relatively limited, 0.2%, 0.5%, 1.2% and 3.7%, respectively. The chemical analysis of vanillin and vanillic acid (mmole) and their ratio was done by GC–MS (Table 1) after the contents of DSC pans at each temperature were dissolved in ethanol:water (80:20 v/v) solution. Non-isothermal DSC scans were conducted by Svard, Gracin, and Rasmuson (2007) and Widman (1987), who studied the glass transition, crystallization and fusion of vanillin. All of these phenomena occurred at temperatures below 100 °C, with melting occurring at around 80.9 °C. Unfortunately, to our knowledge, there is a lack of DSC data at higher temperatures. Thus we may propose (as possible causes of the exothermic peak in this temperature range) a partial decomposition or degradation of vanillin. After the end-point (258 °C) of the previous exothermic peak, a second exothermic thermal event was initiated. This event most likely corresponded with vanillin’s oxidation to vanillic acid. This was proved by the formation of increased amounts of vanillic acid, as determined by GC–MS at higher temperatures. It should be emphasised that, whilst over the temperature range 131–258 °C, only 9.4% of the vanillin had been oxidised to vanillic acid, in the much narrower range of temperatures 258–273 °C, the amount of oxidised vanillin was changed drastically, since it was increased from 9.4% to 47.0% (Fig. 2). 3.3. Radical-scavenging activity The antioxidant activity of vanillin, in comparison to o-vanillin as a scavenger of the DPPH radical, has been studied previously (Santosh-Kumar, Priyadarsini, & Sainis, 2002). To our knowledge, there are no data about the antioxidant activity of vanillin in the presence of its oxidation product, vanillic acid. Brand-Williams et al. (1995) reported that vanillin, and also vanillic acid, phenol, coumaric acid and c-resorcylic acid, were amongst the substances that reacted relatively slowly and very poorly with the DPPH reagent. For this reason, a relatively long reaction time (30 min) was chosen and the results of the assay were used for comparison of the radical-scavenging activities of several different mixtures of vanillin and vanillic acid rather than for determination of their antioxidant potential. The antioxidant activity of vanillin in the presence of vanillic acid, in terms of DPPH-scavenging, was determined both in the DSC-treated vanillin samples and in solutions of vanillin–vanillic acid and the results are presented in Table 1 and Fig. 3, respectively. Table 1 shows that vanillin itself had an antioxidant activity, as expected and reported in the literature (Burri Heat Flow (endo down,mW) I. Mourtzinos et al. / Food Chemistry 114 (2009) 791–797 16.5 210oC 17 17.5 230oC 179oC 18 18.5 273oC 258oC o 131 C 19 19.5 262oC 20 120 140 160 180 200 220 240 260 280 Temperature (°C) Fig. 2. DSC thermogram of pure vanillin under oxidative conditions. The sampling points are spotted. 45 % Radical scavenging 794 40 35 30 25 20 y = 0.2793x + 10.657 R 2 = 0.9847 15 10 5 0 0 20 40 60 80 100 %Vanillic acid Fig. 3. Regression of DPPH radical-scavenging activity (%) on vanillic acid contents (%) of vanillin–vanillic acid mixtures. et al., 1989). The results in Table 1 also show that the antioxidant activity of vanillin–vanillic acid mixtures, obtained after thermal treatment of pure vanillin, increased as the percentage of vanillic acid increased and was almost doubled when the vanillic acid reached 47% w/w of the mixture. The same trend was observed in the case of mixtures of pure vanillin and vanillic acid, the antioxidant activity of which increased as the vanillic acid content increased and there was a linear relationship between the % radicalscavenging and % vanillic acid (Fig. 3). Given that both vanillin and vanillic acid exhibited antioxidant activity (Table 1 and Fig. 3), with that of vanillic acid being more profound, it could be estimated from Fig. 3 that the antioxidant activity of vanillic acid was about 3.3 times that of vanillin on an equimolar basis. A similar effect of heat-processing on the antioxidant activity of a natural compound has been reported by Kang, Kim, Pyo, and Yokozawa (2006). They found that steaming of raw ginseng at 98–100 °C for 3 h resulted in increased antioxidant activity, compared to non-heated ginseng. The authors attributed the increased antiradical potency of heated ginseng to the phenolic compounds of ginseng, amongst them vanillic acid. Table 1 Radical-scavenging (%) and vanillic acid (%) on the basis of GC–MS data of DSC-treated samples. Temperature (°C) Vanillin + Vanillic acid (lmole) Vanillin (lmole) Vanillic acid (lmole) Vanillic acid% (w/w) Radical-scavenging (%) of thermally treated vanillin 131 179 210 230 258 262 273 21.4 ± 0.3a 23.2 ± 0.2 22.7 ± 0.5 20.2 ± 0.3 21.8 ± 0.2 17.9 ± 0.6 15.1 ± 0.6 21.4 ± 0.3 23.1 ± 0.2 22.5 ± 0.5 19.5 ± 0.3 19.9 ± 0.4 14.1 ± 0.4 8.4 ± 0.2 0.04 ± 0.01 0.10 ± 0.02 0.19 ± 0.02 0.71 ± 0.05 1.90 ± 0.44 3.83 ± 0.32 6.71 ± 0.40 0.2 ± 0.1 0.5 ± 0.1 1.2 ± 0.1 3.7 ± 0.2 9.4 ± 2.0 23.2 ± 1.1 47.0 ± 1.8 11.4 ± 0.53 11.6 ± 0.40 13.7 ± 0.31 15.2 ± 1.14 17.0 ± 0.50 20.6 ± 1.15 22.2 ± 1.93 a ±S.D. Table 2 Antimicrobial activity of vanillin–vanillic acid mixtures towards selected strains of Gram (+) and Gram () bacteria and yeasts. Ratios Vanillin:vanillic acid (mM) pH Serial dilutions Target strains Salmonella enteritidis Mean of inhibition zone (mm) Salmonella typhimurium Yersinia enterocolitica Enterobacter aerogenes Bacillus cereus Staphylococcus aureus Staphylococcus epidermidis L.isteria monocytogenes Lactobacillus bulgaricus Lactococcus lactis +++ ++ +++ ++ ++++ ++ + ++++ ++ ++ + ++++ +++ ++ + +++ ++ +++ ++ ++++ ++ + ++++ ++ ++ + ++++ +++ ++ + +++ ++ +++ ++ ++++ ++ + ++++ ++ ++ + ++++ +++ ++ + ++ + ++ + +++ ++ + ++++ ++ + ++++ +++ ++ + ++ + ++ + ++++ ++ + ++++ +++ ++ + ++ + ++ + ++++ ++ + ++++ +++ ++ ++ + ++ + +++ ++ + ++++ ++ + ++++ +++ ++ ++ + ++ + +++ ++ + ++++ ++ + ++++ +++ ++ ++ + ++ + +++ ++ + ++++ ++ + ++++ +++ ++ Zone of inhibition (mm) 100:0.0 5.94 77:23 5.46 53:47 5.33 25:75 5.06 0:100 4.87 0 1:1 1:2 1:4 0 1:1 1:2 1:4 0 1:1 1:2 1:4 0 1:1 1:2 1:4 0 1:1 1:2 1:4 +++ ++ +++ ++ ++++ ++ + ++++ ++ ++ + ++++ +++ ++ + +++ ++ +++ ++ ++++ ++ + ++++ ++ ++ + ++++ +++ ++ + 5.0 2.7 – – 5.5 2.9 – – 7.8 3.9 2.0 – 10.5 4.4 3.1 1.7 12.6 9.6 4.0 2.3 I. Mourtzinos et al. / Food Chemistry 114 (2009) 791–797 Escherichia coli O157:H7 () No antimicrobial activity <1 mm zone of inhibition. (+) Weak antimicrobial activity 1–3 mm zone of inhibition. (++) Moderate antimicrobial activity 3–5 mm zone of inhibition. (+++) Strong antimicrobial activity 5–7 mm zone of inhibition. (++++) Very strong antimicrobial activity >7 mm zone of inhibition. 795 796 I. Mourtzinos et al. / Food Chemistry 114 (2009) 791–797 3.4. Antimicrobial activity The antimicrobial activity of vanillin–vanillic acid solutions was tested against a range of Gram-positive and Gram-negative bacteria. Vanillin exhibited the weakest inhibitory activity against all the target strain bacteria that were tested (Table 2). The antibacterial activity of the samples was increased, along with vanillic acid concentration, and the strongest inhibition was observed in the 100% vanillic acid sample. The antimicrobial activity of vanillin against a broad variety of bacteria and yeasts is well documented (Cerruti & Alzamora, 1996; Fitzgerald et al., 2004; Moon et al., 2006). Yet, the inhibitory activity of vanillic acid against Listeria spp. has been studied by Delaquis et al. (2005) and it was found to be pH-dependent, with the highest antilisterial activity recorded at pH 5.0. In the same work, it was reported that, at low pH (pH 5.0) the aqueous solutions of vanillic acid had stronger inhibitory activities than had vanillin solutions. The MIC of the samples was affected by the vanillic acid concentrations. In general, the higher the vanillic acid concentration, the lower was the MIC observed. Regarding pure vanillin, the MIC for Escherichia coli O157:H7, Listeria monocytogenes and Lactobacillus bulgaricus was 50 mM. Fitzgerald et al. (2004) have reported MIC values of 15, 15 and 75 mM for E. coli, Listeria innocua and Lactobacillus plantarum, respectively. Rupasinghe et al. (2006), also, reported a dose-dependent inhibitory activity of vanillin against E. coli, Enterobacter aerogenes, Salmonella. enterica subsp. enterica serovar Newport and Lactobacillus casei, with MIC ranging from 6–19 mM. Though our results are in agreement, from a qualitative standpoint, with the findings of the latter work, there are discrepancies concerning the corresponding MIC. This could be attributed to the different strains and different methods of testing of the antimicrobial activity. The MIC for pure vanillic acid was 12.5 mM for E. coli, whilst the corresponding MICs for Listeria monocytogenes and Lactobacillus plantarum were 25 mM. It seems that Gram-negative bacteria are more sensitive to vanillic acid than are Gram-positive ones. Rodriguez-Vaquero, Alberto, and Manca de Nadra (2007) studied the antimicrobial effect of phenolic compounds from different wines and reported that vanillic acid showed inhibitory activity against E. coli but not against S. aureus. This confirms that Gramnegative bacteria, like E. coli, are more sensitive to vanillic acid than are Gram-positive (S. aureus). The non-inhibition of S. aureus could be attributed to the very low vanillic acid concentration used, that was 1 g/l, corresponding to 5.95 mM. Though the exact mode of vanillin’s antimicrobial action is not fully understood, it is considered as a membrane-active compound that destabilizes the bacterial membrane integrity, resulting in the dissipation of ion gradients, and therefore inhibiting the bacterial respiration (Fitzgerald et al., 2004). It has been shown (Delaquis et al., 2005) that pH is a critical factor for the inhibitory activity of both vanillin and vanillic acid. In our set of samples, as the vanillic acid concentrations increased, the pH dropped (Table 2) and the antimicrobial activity increased. Vanillic acid has two pKa values at 25 °C (pKa1 4.51 and pKa2 9.39). Therefore, at pH 5.0, most of the vanillic acid molecules are in the non-dissociated form, which exhibits antimicrobial activity. Also vanillin, although it is an aldehyde, exhibits acid–base behaviour with pKa 7.4 at 25 °C, a value close to the pH of pure vanillin solution. Therefore, at higher pH values, vanillin is expected to exhibit higher antibacterial activity, as was confirmed by our findings. Vanillin is widely used as a GRAS flavouring agent in a variety of food products and acts as an effective antioxidant in foods containing polyunsaturated fatty acids, whilst it has also been identified as an antimicrobial agent. MIC values of vanillin, either for bacteria or yeasts and moulds, have been reported to be around 6 mM (Fitzgerald et al., 2004; López-Malo et al., 1997), which corre- sponds to 913 ppm. Considering that vanillin has a very low taste threshold (0.5 ppm in water) (Korthou & Verpoorte, 2007) its application as an antimicrobial agent may be problematic, since it will affect the original flavour of the product and hence its organoleptic acceptance. On the contrary, the vanillic acid is nearly odourless with a taste threshold value at 30 ppm that corresponds to 0.18 mM. According to our results and those of Delaquis et al. (2005), the MIC for vanillic acid – under acidic conditions – was about 10 mM. Consequently, vanillic acid seems to be a more applicable antimicrobial agent than vanillin for food systems. The results of the present study indicate that the antioxidant properties of heat-processed foods (e.g. cereals), now attributed only to vanillin, may also be partly due to its oxidised form, vanillic acid. Moreover, from a general point of view, our results suggest that oxidation products of some phenolic compounds may exhibit stronger antioxidant and/or antimicrobial activities than do their parent compounds in food systems, and further investigation in this direction should be carried out. 4. Conclusion In this work, vanillin was subjected to non-isothermal, as well as isothermal DSC analyses, followed by GC–MS analysis. The results confirmed the oxidation of vanillin to vanillic acid and allowed the monitoring of the oxidation process at different points of the thermograms. Moreover, heat-treated vanillin was proven to be more effective as a food constituent in terms of radical-scavenging and antimicrobial activities, as a result of the conversion of vanillin to vanillic acid during heating. The combination of DSC and GC–MS could be a useful tool for assaying stability of nutraceutical constituents. Acknowledgements We wish to thank the Laboratory of Dairy Research (Department of Food Science and Technology, Agricultural University of Athens, Greece) and Agrolab S.A. that kindly provided the bacterial strains used in this study. One of the authors (I. Mourtzinos) is thankful to the Greek Foundation of Fellowships for financial support. References Anklam, E., Gaglione, S., & Muller, A. (1997). Oxidation behaviour of vanillin in dairy products. Food Chemistry, 60, 43–51. Boyce, M. C., Haddad, P. R., & Sostaric, T. (2003). Determination of flavour components in natural vanilla extracts and synthetic flavourings by mixed micellar electrokinetic capillary chromatography. Analytica Chimica Acta, 485, 179–186. Brand-Williams, W., Cuvelier, M. E., & Berset, C. (1995). Use of free radical method to evaluate antioxidant activity. Lebensmittel Wissenschaft und Technologie, 28, 25–30. Burri, J., Graf, M., Lambelet, P., & Loliger, J. (1989). Vanillin: More than a flavouring agent-a potent antioxidant. Journal of the Science of Food and Agriculture, 48, 49–56. Cerruti, P., & Alzamora, S. M. (1996). Inhibitory effects of vanillin on some food spoilage yeasts in laboratory media and fruit purees. International Journal of Food Microbiology, 29, 379–386. Clas, S. D., Dalton, C. R., & Hancock, B. C. (1999). Differential scanning calorimetry: Applications in drug development. Pharmaceutical Science and Technology Today, 2(8), 311–320. Delaquis, P., Stanich, K., & Toivonen, P. (2005). Effect of pH on the inhibition of Listeria spp. By vanillin and vanillic acid. Journal of Food Protection, 68, 1472–1476. Durant, S., & Karran, P. (2003). Vanillins – A novel family of DNA-PK inhibitors. Nucleic Acids Research, 31, 5501–5512. Fitzgerald, D. J., Stratford, M., Gasson, M. J., & Narbad, A. (2004). The potential application of vanillin in preventing yeast spoilage of soft drinks and fruit juices. Journal of Food Protection, 67, 391–395. Fricko, P., Holocher-Ertl, M., & Kratzl, K. (1980). Zur Oxidation von kreosol mit sauerstoff in alkalischer losung-modellversuche zum sauerstoffaufschlub des Holzes. Monatshefte fur Chemie, 111, 1025–1031. I. Mourtzinos et al. / Food Chemistry 114 (2009) 791–797 Giuffrida, F., Destaillats, F., Egart, M. H., Hug, B., Golay, P. A., Skibsted, L. H., et al. (2007). Activity and thermal stability of antioxidants by differential scanning calorimetry and electron spin resonance spectroscopy. Food Chemistry, 101, 1108–1114. Gustafson, D. L., Franz, H. R., Ueno, A. M., Smith, C. J., Doolittle, D. L., & Waldren, C. A. (2000). Vanillin (3-methoxy-4-hydroxybenzaldehyde) inhibits mutation induced by hydrogen peroxide, N-methyl-N-nitrosoguanidine and mitomycin C but not 137Cs c-radiation at the CD59 locus in human–hamster hybrid AL cells. Mutagenesis, 15, 207–213. Hu, J.-Q., Wei, X.-Y., Dai, G.-L., Fei, Y.-W., Liu, C.-C., Zong, Z. M., et al. (2007). Synergistic antioxidation of organic molybdenum complex with dithiocarbamate antioxidant evaluated by differential scanning calorimetry and thin film micro oxidation test. Thermochimica Acta, 453, 21–26. Kang, K. K., Kim, H. Y., Pyo, J. S., & Yokozawa, T. (2006). Increase in the free radicalscavenging activity of Ginseng by heat-processing. Biological and Pharmaceutical Bulletin, 29(4), 750–754. Keshava, C., Keshava, N., Whong, W. Z., Nath, J., & Ong, T. M. (1998). Inhibition of methotrexate-induced chromosomal damage by vanillin and chlorophyllin in V79 cell. Teratogenesis Carcinogenesis and Mutagenesis, 17, 313–326. Korthou, H., & Verpoorte, R. (2007). Vanilla. In R. G. Berger (Ed.), Flavours and Fragrances: Chemistry, Bioprocessing and Sustainability (pp. 203–217). Berlin: Springer. Koseki, T., Ito, Y., Furuse, S., Ito, K., & Iwano, K. (1996). Conversion of ferulic acid into 4-vinylguaiacol, vanillin and vanillic acid in model solutions of shochu. Journal of Fermentation and Bioengineering, 82, 46–50. Kumar, S. S., Ghosh, A., Devasagayam, T. P. A., & Chauhan, P. S. (2000). Effect of vanillin on methylene blue plus light-induced single-strand breaks in plasmid pBR322 DNA. Mutation Research, 469, 207–214. Lirdprapamongkol, K., Sakurai, H., Kawasaki, N., Choo, M.-K., Saitoh, Y., Aozuka, Y., et al. (2005). Vanillin suppresses in vitro invasion and in vivo metastasis of mouse breast cancer cells. European Journal of Pharmaceutical Sciences, 25, 57–65. Litwinienko, G., Kasprzycka-Guttman, T., & Jamanek, D. (1999). DSC study of antioxidant properties of dihydroxyphenols. Thermochimica Acta, 331, 79–86. López-Malo, A., Alzamora, S. M., & Argaiz, A. (1997). Effect of vanillin concentration, pH and incubation temperature on Aspergillus flavus, Aspergillus niger, Aspergillus ochraceus and Aspergillus parasiticus growth. Food Microbiology, 14, 117–124. Moon, K. D., Delaquis, P., Toivonen, P., & Stanich, K. (2006). Effect of vanillin on the fate of Listeria monocytogenes and Escherichia coli O157:H7 in a model apple juice medium and in apple juice. Food Microbiology, 23, 169–174. Rodriguez-Vaquero, M. J., Alberto, M. R., & Manca de Nadra, M. C. (2007). Antibacteral effect of phenolic compounds from different wines. Food Control, 18(2), 93–101. 797 Rudnik, E., Szczucinska, A., Gwardiak, H., Szulc, A., & Winiarska, A. (2001). Comparative studies of oxidative stability of linseed oil. Thermochimica Acta, 370, 135–140. Rupasinghe, V. H. P., Boulter-Bitzer, J., Ahn, J., & Odumeru, J. A. (2006). Vanillin inhibits pathogenic and spoilage microorganisms in vitro and aerobic microbial growth in fresh-cut apples. Food Research International, 39, 575–580. Samaddar, H., & Banerjee, A. (1982). Use of potassium bromate: Oxidation of aldehydes. Journal of the Indian Chemical Society, 59, 905–911. Santosh-Kumar, S., Priyadarsini, K. I., & Sainis, K. B. (2002). Free radical-scavenging activity of vanillin and o-vanillin using 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical. Redox Report, 7, 35–40. Schillinger, U., & Lucke, F. K. (1989). Antibacterial activity of Lactobacillus sake isolated from meat. Applied and Environmental Microbiology, 55, 1901–1906. Shyamala, B. N., Naidu, M., Sulochanamma, G., & Srinivas, P. (2007). Studies on the antioxidant activities of natural vanilla extract and its constituent compounds through in vitro models. Journal of Agricultural and Food Chemistry, 55, 7738–7743. Sinha, A. K., Sharma, U. K., & Sharma, N. (2007). A comprehensive review on vanilla flavor: Extraction, isolation and quantification of vanillin and others constituents. International Journal of Food Sciences and Nutrition, 59, 299–326. Sinigaglia, M., Reguly, M. L., & de Andrade, H. H. (2004). Effect of vanillin on toxicant-induced mutation and mitotic recombination in proliferating somatic cells of Drosophila melanogaster. Environmental and Molecular Mutagenesis, 44, 394–400. Soleas, G., Diamandis, E., Karumanchiri, A., & Goldberg, D. (1997). A multi-residue derivatization gas chromatographic assay for fifteen phenolic constituents with mass selective detection. Analytical Chemistry, 69, 4405–4409. Svard, M., Gracin, S., & Rasmuson, A. K. (2007). Oiling out or molten-hydrate. Liquid–liquid phase separation in the system vanillin–water. Journal of Pharmaceutical Sciences, 96(9), 2390–2398. Tipparaju, S., Ravishankar, S., & Slade, P. J. (2004). Survival of Listeria monocytogenes in vanilla-flavored soy and dairy products stored at 8 °C. Journal of Food Protection, 67, 378–382. Velasco, J., Andersen, M. L., & Skibsted, L. H. (2004). Evaluation of oxidative stability of vegetable oils by monitoring the tendency to radical formation. A comparison of electron spin resonance spectroscopy with the Rancimat method and differential scanning calorimetry. Food Chemistry, 85, 623–632. Walton, N. J., Mayer, M. J., & Narbad, A. (2003). Vanillin. Phytochemistry, 63, 505–515. Widman, G. (1987). DSC of amorphous materials. Thermochimica Acta, 112, 137–140.