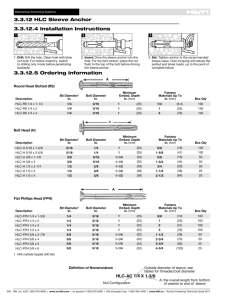

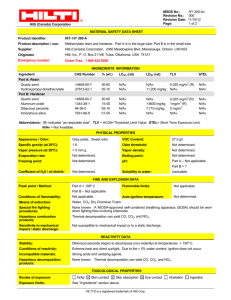

Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 1 20/04/2022 Specifier's comments: 1 Anchor Design 1.1 Input data Anchor type and diameter: HVU2 + HAS-U 5.8 M24 Item number: 2223881 HAS-U 5.8 M24x300 (element) / 2164560 HVU2 M24x210 (capsule) Effective embedment depth: hef,act = 210.0 mm, hnom = 210.0 mm Material: 5.8 Evaluation Service Report: ESR-4372 Issued I Valid: 01/09/2021 | 01/06/2022 Proof: Design Method ACI 318-08 / Chem Stand-off installation: without clamping (anchor); restraint level (anchor plate): 2.00; eb = 25.0 mm; t = 18.0 mm Hilti Grout: , precision, fc,Grout = 30.00 N/mm Anchor plate CBFEM : 2 lx x ly x t = 200.0 mm x 200.0 mm x 18.0 mm; Profile: Square bars (AISC), 1 - 1; (L x W x T) = 25.4 mm x 25.4 mm Base material: cracked concrete, 3000, fc' = 3,000 psi; h = 500.0 mm, Temp. short/long: 40/24 °C Installation: hammer drilled hole, Installation condition: Dry, Installation direction: vertical downward Reinforcement: tension: condition B, shear: condition B; no supplemental splitting reinforcement present edge reinforcement: none or < No. 4 bar Seismic loads (cat. C, D, E, or F) CBFEM no - The anchor calculation is based on a component-based Finite Element Method (CBFEM) Geometry [mm] & Loading [kN, kNm] Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 1 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 2 20/04/2022 1.1.1 Design results Case Description 1 Combination 1 Forces [kN] / Moments [kNm] Seismic Max. Util. Anchor [%] N = 20.000; Vx = 45.000; Vy = 0.000; Mx = 0.000; My = 0.000; Mz = 0.000; Nsus = 0.000; Mx,sus = 0.000; My,sus = 0.000; no 97 1.2 Load case/Resulting anchor forces y 3 Anchor reactions [kN] Tension force: (+Tension, -Compression) Anchor Tension force Shear force Shear force x Shear force y 1 7.216 11.197 11.197 0.086 2 7.581 11.304 11.303 -0.162 3 7.212 11.197 11.197 -0.086 4 7.587 11.304 11.303 0.162 4 Compression x Tension 1 2 resulting tension force in (x/y)=(1.5/0.0): 29.596 [kN] resulting compression force in (x/y)=(2.4/0.0): 9.764 [kN] Anchor forces are calculated based on a component-based Finite Element Method (CBFEM) 1.3 Tension load Capacity f Nn [kN] Utilization bN = Nua/f Nn Load Nua [kN] Status Steel Strength* 7.587 114.725 7 OK Bond Strength** 29.596 80.663 37 OK N/A N/A N/A N/A 29.596 70.415 43 OK Sustained Tension Load Bond Strength* Concrete Breakout Failure** * highest loaded anchor **anchor group (anchors in tension) 1.3.1 Steel Strength Nsa = ESR value f Nsa ³ Nua refer to ICC-ES ESR-4372 ACI 318-08 Eq. (D-1) Variables 2 2 Ase,N [mm ] futa [N/mm ] 353 500.00 Calculations Nsa [kN] 176.500 Results Nsa [kN] f steel f Nsa [kN] Nua [kN] 176.500 0.650 114.725 7.587 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 2 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 3 20/04/2022 1.3.2 Bond Strength Nag = (AA ) y Na Na0 ec1,Na y ec2,Na y ed,Na y cp,Na Nba ACI 318-11 Eq. (D-19) f Nag ³ Nua ANa = see ACI 318-11, Part D.5.5.1, Fig. RD.5.5.1(b) ANa0 = (2 cNa) cNa = 10 da 2 ACI 318-11 Table D.4.1.1 ACI 318-11 Eq. (D-20) √ t uncr 1100 ( ) ACI 318-11 Eq. (D-21) 1 y ec,Na = ' 1+ eN cNa £ 1.0 ACI 318-11 Eq. (D-23) y cp,Na (cc ) £ 1.0 c c = MAX( , 1.0 c c ) £ Nba = l a · t k,c · p · da · hef y ed,Na = 0.7 + 0.3 a,min ACI 318-11 Eq. (D-25) Na a,min Na ac ac ACI 318-11 Eq. (D-27) ACI 318-11 Eq. (D-22) Variables t k,c,uncr [N/mm ] da [mm] hef [mm] ca,min [mm] aoverhead t k,c [N/mm ] 14.16 24.0 210.0 250.0 1.000 7.49 ec1,N [mm] ec2,N [mm] cac [mm] la 1.5 0.0 312.4 1.000 2 2 Calculations cNa [mm] ANa [mm ] ANa0 [mm ] y ed,Na 326.4 481,926 426,149 0.930 y ec1,Na y ec2,Na y cp,Na Nba [kN] 0.995 1.000 1.000 118.574 Nag [kN] f bond f Nag [kN] Nua [kN] 124.097 0.650 80.663 29.596 2 2 Results Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 3 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 4 20/04/2022 1.3.3 Concrete Breakout Failure Ncbg = (AA ) y Nc Nc0 ec,N y ed,N y c,N y cp,N Nb ACI 318-08 Eq. (D-5) f Ncbg ³ Nua ANc see ACI 318-08, Part D.5.2.1, Fig. RD.5.2.1(b) 2 ANc0 = 9 hef y ec,N = ( 1 ' 1+ 2 eN 3 hef ) ACI 318-08 Eq. (D-6) £ 1.0 ACI 318-08 Eq. (D-9) y cp,N c (1.5h ) £ 1.0 c 1.5h = MAX( , 1.0 c c ) £ Nb = kc l y ed,N = 0.7 + 0.3 a,min ACI 318-08 Eq. (D-11) ef a,min ac ACI 318-08 Eq. (D-1) ef ACI 318-08 Eq. (D-13) ac √f'c h1.5 ef ACI 318-08 Eq. (D-7) Variables hef [mm] ec1,N [mm] ec2,N [mm] ca,min [mm] y c,N 210.0 1.5 0.0 250.0 1.000 cac [mm] kc l fc [psi] 312.4 17 1 3,000 ' Calculations ANc [mm ] ANc0 [mm ] y ec1,N y ec2,N y ed,N y cp,N Nb [kN] 467,744 396,900 0.995 1.000 0.938 1.000 98.463 Ncbg [kN] f concrete f Ncbg [kN] Nua [kN] 108.330 0.650 70.415 29.596 2 2 Results Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 4 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 5 20/04/2022 1.4 Shear load Capacity f Vn [kN] Utilization bV = Vua/f Vn Load Vua [kN] Status Steel Strength* 11.304 50.880 23 OK Steel failure (with lever arm)* 11.304 13.667 83 OK Pryout Strength (Concrete Breakout Strength controls)** 45.000 152.397 30 OK Concrete edge failure in direction x+** 45.001 63.149 72 OK * highest loaded anchor **anchor group (relevant anchors) 1.4.1 Steel Strength Vsa = ESR value f Vsteel ³ Vua refer to ICC-ES ESR-4372 ACI 318-08 Eq. (D-2) Variables Ase,V [mm ] futa [N/mm ] aV,seis 353 500.00 0.700 Vsa [kN] f steel f eb f Vsa [kN] Vua [kN] 106.000 0.600 0.800 50.880 11.304 2 2 Calculations Vsa [kN] 106.000 Results Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 5 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 6 20/04/2022 1.4.2 Steel failure (with lever arm) M aM · M s Lb bending equation for stand-off Vs = Ms = Ms 0 Ms = (1.2) (S) (fu,min) ( 0 N 1 - f ua Nsa ) (1 - fNN ) ua resultant flexural resistance of anchor sa characteristic flexural resistance of anchor reduction for tensile force acting simultaneously with a shear force on the anchor 3 Lb p(d) 32 = z + (n)(d0) f VM s ³ Vua S = elastic section modulus of anchor bolt at concrete surface internal lever arm adjusted for spalling of the surface concrete ACI 318-08 Eq. (D-2) Variables aM fu,min [N/mm ] Nua [kN] f Nsa [kN] z [mm] n d0 [mm] 2.00 500.00 7.587 114.725 34.0 0.500 24.0 Ms [kNm] (1 - fNN ) Ms [kNm] Lb [mm] 0.561 0.934 0.524 46.0 Vs [kN] f steel f VM s [kN] Vua [kN] 22.778 0.600 13.667 11.304 2 Calculations 0 ua sa Results M Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 6 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 7 20/04/2022 1.4.3 Pryout Strength (Concrete Breakout Strength controls) Vcpg [(AA ) y Nc = kcp Nc0 ec,N y ed,N y c,N y cp,N Nb ] f Vcpg ³ Vua ANc see ACI 318-08, Part D.5.2.1, Fig. RD.5.2.1(b) 2 ANc0 = 9 hef y ec,N = ( 1 ' 1+ 2 eN 3 hef ) £ 1.0 ACI 318-08 Eq. (D-9) y cp,N Nb = kc l a,min ACI 318-08 Eq. (D-11) ef a,min ac ACI 318-08 Eq. (D-2) ACI 318-08 Eq. (D-6) c (1.5h ) £ 1.0 c 1.5h = MAX( , 1.0 c c ) £ y ed,N = 0.7 + 0.3 ACI 318-08 Eq. (D-31) ef ACI 318-08 Eq. (D-13) ac √f'c h1.5 ef ACI 318-08 Eq. (D-7) Variables kcp hef [mm] ec1,N [mm] ec2,N [mm] ca,min [mm] 2 210.0 0.0 0.0 250.0 y c,N cac [mm] kc l fc [psi] 1.000 312.4 17 1 3,000 ' Calculations ANc [mm ] ANc0 [mm ] y ec1,N y ec2,N y ed,N y cp,N Nb [kN] 467,744 396,900 1.000 1.000 0.938 1.000 98.463 Vcpg [kN] f concrete f Vcpg [kN] Vua [kN] 217.710 0.700 152.397 45.000 2 2 Results Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 7 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 8 20/04/2022 1.4.4 Concrete edge failure in direction x+ Vcbg = (AA ) y Vc Vc0 ec,V y ed,V y c,V y h,V y parallel,V Vb f Vcbg ³ Vua AVc see ACI 318-08, Part D.6.2.1, Fig. RD.6.2.1(b) 2 AVc0 = 4.5 ca1 1 y ec,V = ( ) ' 1+ ACI 318-08 Eq. (D-23) ACI 318-08 Eq. (D-26) c (1.5c ) £ 1.0 ACI 318-08 Eq. (D-28) a2 a1 √1.5ch ³ 1.0 l = (7 ( ) √ d ) l d y h,V a1 = ACI 318-08 Eq. (D-2) £ 1.0 2ev 3ca1 y ed,V = 0.7 + 0.3 ACI 318-08 Eq. (D-22) ACI 318-08 Eq. (D-29) a 0.2 e Vb a a √f'c c1.5 a1 ACI 318-08 Eq. (D-24) Variables ca1 [mm] ca2 [mm] ecV [mm] y c,V ha [mm] 250.0 - 0.0 1.000 500.0 le [mm] l da [mm] fc [psi] y parallel,V 192.0 1.000 24.0 3,000 1.000 ' Calculations AVc [mm ] AVc0 [mm ] y ec,V y ed,V y h,V Vb [kN] 327,000 281,250 1.000 1.000 1.000 77.591 Vcbg [kN] f concrete f Vcbg [kN] Vua [kN] 90.212 0.700 63.149 45.001 2 2 Results 1.5 Combined tension and shear loads z bN bV z Utilization bN,V [%] Status 0.420 0.827 5/3 97 OK z bNV = bN + bV <= 1 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 8 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Apr 20, 2022 Page: Specifier: E-Mail: Date: 9 20/04/2022 1.6 Warnings • The anchor design methods in PROFIS Engineering require rigid anchor plates as per current regulations (ETAG 001/Annex C, EOTA TR029, etc.). This means load re-distribution on the anchors due to elastic deformations of the anchor plate are not considered - the anchor plate is assumed to be sufficiently stiff, in order not to be deformed when subjected to the design loading. PROFIS Engineering calculates the minimum required anchor plate thickness with CBFEM to limit the stress of the anchor plate based on the assumptions explained above. The proof if the rigid base plate assumption is valid is not carried out by PROFIS Engineering. Input data and results must be checked for agreement with the existing conditions and for plausibility! • Condition A applies where the potential concrete failure surfaces are crossed by supplementary reinforcement proportioned to tie the potential concrete failure prism into the structural member. Condition B applies where such supplementary reinforcement is not provided, or where pullout or pryout strength governs. • ACI 318 does not specifically address anchor bending when a stand-off condition exists. PROFIS Engineering calculates a shear load corresponding to anchor bending when stand-off exists and includes the results as a shear Design Strength! • Design Strengths of adhesive anchor systems are influenced by the cleaning method. Refer to the INSTRUCTIONS FOR USE given in the Evaluation Service Report for cleaning and installation instructions. • The present version of the software does not account for special design provisions for overhead applications. Refer to related approval (e.g. section 4.1.1 of the ICC-ESR 2322) for details. • For additional information about ACI 318 strength design provisions, please go to https://submittals.us.hilti.com/PROFISAnchorDesignGuide/ • The anchor design methods in PROFIS Engineering require rigid anchor plates, as per current regulations (AS 5216:2021, ETAG 001/Annex C, EOTA TR029 etc.). This means that the anchor plate should be sufficiently rigid to prevent load re-distribution to the anchors due to elastic/plastic displacements. The user accepts that the anchor plate is considered close to rigid by engineering judgment." Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 9 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 10 20/04/2022 1.7 Installation data Anchor type and diameter: HVU2 + HAS-U 5.8 M24 Item number: 2223881 HAS-U 5.8 M24x300 (element) / Profile: Square bars (AISC), 1 - 1; (L x W x T) = 25.4 mm x 25.4 mm 2164560 HVU2 M24x210 (capsule) Hole diameter in the fixture: df = 26.0 mm Maximum installation torque: 200 Nm Plate thickness (input): 18.0 mm Hole diameter in the base material: 28.0 mm Hole depth in the base material: 210.0 mm Drilling method: Hammer drilled Cleaning: Compressed air cleaning of the drilled hole according to instructions Minimum thickness of the base material: 270.0 mm for use is required Hilti HAS-U threaded rod with HVU2 capsule mortar with 210 mm embedment h_ef, M24, Steel galvanized, Hammer drilled installation per ESR-4372 1.7.1 Recommended accessories Drilling Cleaning Setting • Suitable Rotary Hammer • Properly sized drill bit • Compressed air with required accessories to blow from the bottom of the hole • Proper diameter wire brush • HVA square drive shafts • Torque wrench y 100.0 39.0 100.0 100.0 4 122.0 3 100.0 2 39.0 1 x 39.0 122.0 39.0 Coordinates Anchor [mm] Anchor x y c-x c+x c-y c+y 1 2 3 4 -61.0 61.0 -61.0 61.0 -61.0 -61.0 61.0 61.0 250.0 372.0 250.0 372.0 372.0 250.0 372.0 250.0 - - Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 10 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: 11 Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 20/04/2022 2 Anchor plate design 2.1 Input data Anchor plate: Shape: Rectangular lx x ly x t = 200.0 mm x 200.0 mm x 18.0 mm Calculation: CBFEM Material: ASTM A36; Fy = 248.21 N/mm²; εlim = 5.00% Anchor type and size: HVU2 + HAS-U 5.8 M24, hef = 210.0 mm Anchor stiffness: The anchor is modeled considering stiffness values determined from load displacement curves tested in an independent laboratory. Please note that no simple replacement of the anchor is possible as the anchor stiffness has a major impact on the load distribution results. AISC and LRFD-based design using component-based FEM eb = 25.0 mm (Stand-off with grouting); t = 18.0 mm Design method: Stand-off installation: Profile: 1 - 1; (L x W x T x FT) = 25.4 mm x 25.4 mm x - x Material: ASTM A36; Fy = 248.21 N/mm²; εlim = 5.00% Eccentricity x: 0.0 mm Eccentricity y: 0.0 mm Cracked concrete; 3000; fc,cyl = 20.68 N/mm²; h = 500.0 mm Base material: Welds (profile to anchor plate): Mesh size: Type of redistribution: Plastic Material: E70xx Number of elements on edge: 8 Min. size of element: 10.0 mm Max. size of element: 50.0 mm 2.2 Summary Description 1 Combination 1 Profile Anchor plate sEd [N/mm²] ePl [%] sEd [N/mm²] ePl [%] 1,098.73 424.94 71.77 0.00 Hole bearing [%] 7 Welds [%] Concrete [%] 161 3 2.3 Anchor plate classification Results below are displayed for the decisive load combinations: Combination 1 Anchor tension forces Equivalent rigid anchor plate (CBFEM) Anchor 1 Anchor 2 Anchor 3 Anchor 4 4.908 kN 5.092 kN 4.908 kN 5.092 kN Component-based Finite Element Method (CBFEM) anchor plate design 7.216 kN 7.581 kN 7.212 kN 7.587 kN User accepted to consider the selected anchor plate as rigid by his/her engineering judgement. This means the anchor design guidelines can be applied. 2.4 Profile/Stiffeners/Plate Profile and stiffeners are verified at the level of the steel to concrete connection. The connection design does not replace the steel design for critical cross sections, which should be performed outside of PROFIS Engineering. 2.4.1 Equivalent stress and plastic strain Part Plate Profile Load combination Combination 1 Combination 1 Material fy [N/mm²] elim [%] sEd [N/mm²] ePl [%] Status ASTM A36 ASTM A36 248.21 248.21 5.00 5.00 71.77 1,098.73 0.00 424.94 OK NOT OK Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 11 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Apr 20, 2022 12 Page: Specifier: E-Mail: Date: 20/04/2022 2.4.1.1 Equivalent stress Results below are displayed for the decisive load combination: 1 - Combination 1 248.21 N/mm² 0.00 N/mm² 2.4.1.2 Plastic strain Results below are displayed for the decisive load combination: 1 - Combination 1 5.00% 0.00% 2.4.2 Plate hole bearing resistance, AISC 360-16 Section J3 Decisive load combination: 1 - Combination 1 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 12 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: 13 Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 20/04/2022 Equations Rn = min(1.2 lc t Fu , 2.4 d t Fu) FRn = 0.75 Rn V ≤ (AISC 360-16 J3-6a, c) FRn Variables lc [mm] 26.0 96.0 26.0 96.0 Anchor 1 Anchor 2 Anchor 3 Anchor 4 t [mm] 18.0 18.0 18.0 18.0 Fu [N/mm²] 399.90 399.90 399.90 399.90 d [mm] 24.0 24.0 24.0 24.0 Rn [kN] 224.591 414.612 224.591 414.612 Results FRn [kN] V [kN] 11.197 11.304 11.197 11.304 Anchor 1 Anchor 2 Anchor 3 Anchor 4 Utilization [%] 7 4 7 4 168.444 310.959 168.444 310.959 Status OK OK OK OK 2.5 Welds Profiles are modeled without taking the corner radius into account. Special rules for welding (e.g. for cold-formed profiles ...) are not taken into account by the software. 2.5.1 Anchor plate to profile Decisive load combination: 1 - Combination 1 Equations Fnw = 0.6 FEXX (1.0 + 0.5sin1.5 Q) FRn = Utilization = F Fnw Aw Fn F Rn Variables Edge Member 1-bfl 1 Member 1-bfl Xu E70xx E70xx Th [mm] 4.0 4.0 Ls [mm] 5.7 5.7 L [mm] 25.3 25.3 Lc [mm] 8.4 8.4 FEXX [N/mm²] 482.63 482.63 Q [°] 73.1 73.1 Aw [mm²] 34 34 Results Edge Member 1-bfl 1 Member 1-bfl Fn [kN] 17.239 17.242 FRn [kN] 10.734 10.734 Utilization [%] 161 161 Status NOT OK NOT OK 2.6 Concrete Decisive load combination: 1 - Combination 1 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 13 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: 14 Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 20/04/2022 2.6.1 Compression in concrete under the anchor plate 2.11 N/mm² 0.00 N/mm² 2.6.2 Concrete block compressive strength resistance check, AISC 360-16 Section J8 Equations Fp = fp,max = s = Utilization = F fp,max 0.85 fc' √( A2 A1 ) ≤ 1.7 fc; √( A2 A1 )≤2 N A1 s Fp Variables N [kN] 9.764 fc' [N/mm²] 20.68 Load combination Combination 1 Fp [N/mm²] 22.86 F 0.65 A1 [mm²] 16,805 A2 [mm²] 356,330 Utilization [%] 3 Status OK Results s [N/mm²] 0.58 Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 14 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Apr 20, 2022 Page: Specifier: E-Mail: Date: 15 20/04/2022 2.7 Symbol explanation A1 A2 Aw d Loaded area of concrete Supporting area Effective area of weld critical element Nominal diameter of the bolt Limit plastic strain elim ePl Plastic strain from CBFEM results fc fc' FEXX Fu Fn Fnw Fp fp,max fy lc L Lc Ls N s sEd F FRn Rn t Concrete compressive strength Concrete compressive strength Electrode classification number, i.e. minimum specified tensile strength Specified minimum tensile strength of the connected material Force in weld critical element Nominal stress of the weld material Concrete block design bearing strength Concrete block design bearing strength maximum Yield strength Clear distance, in the direction of the force, between the edge of the hole and the edge of the adjacent hole or edge of the material Length of weld Length of weld critical element Leg size of weld Resulting compression force Average stress in concrete Equivalent stress Resistance factor Factored resistance Q Resistance Thickness of the anchor plate Angle of loading measured from the weld longitudinal axis Th V Xu Throat thickness of weld Resultant of shear forces Vy, Vz in bolt. Filler metal tensile strength 2.8 Warnings ● By using the CBFEM calculation functionality of PROFIS Engineering you may act outside the applicable design codes and your specified anchor plate may not behave rigid. Please, validate the results with a professional designer and/or structural engineer to ensure suitability and adequacy for your specific jurisdiction and project requirements. ● The anchor is modeled considering stiffness values determined from load displacement curves tested in an independent laboratory. Please note that no simple replacement of the anchor is possible as the anchor stiffness has a major impact on the load distribution results. Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 15 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: 16 Page: Specifier: E-Mail: Date: | Concrete - Apr 20, 2022 20/04/2022 3 Summary of results Design of the anchor plate, anchors, welds and other elements are based on CBFEM (component based finite element method) and AISC. Anchors Anchor plate Welds Concrete Profile Load combination Combination 1 Combination 1 Combination 1 Combination 1 Combination 1 Max. utilization 97% 29% 161% 3% 443% Status OK OK NOT OK OK NOT OK Fastening does not meet the design criteria! Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 16 Hilti PROFIS Engineering 3.0.77 www.hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/Indonesia.html Company: Address: Phone I Fax: Design: Fastening point: | Concrete - Apr 20, 2022 Page: Specifier: E-Mail: Date: 17 20/04/2022 4 Remarks; Your Cooperation Duties ● Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a specific application. ● You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or damaged data or programs, arising from a culpable breach of duty by you. Input data and results must be checked for conformity with the existing conditions and for plausibility! PROFIS Engineering ( c ) 2003-2022 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan 17