See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/259484891

SPC and Process Capability Analysis – Case Study

Conference Paper · June 2009

CITATION

READS

1

5,149

2 authors:

Tatjana Sibalija

Majstorovic Vidosav

Metropolitan University

University of Belgrade

81 PUBLICATIONS 240 CITATIONS

86 PUBLICATIONS 306 CITATIONS

SEE PROFILE

SEE PROFILE

All content following this page was uploaded by Tatjana Sibalija on 31 December 2013.

The user has requested enhancement of the downloaded file. All in-text references underlined in blue are added to the original document

and are linked to publications on ResearchGate, letting you access and read them immediately.

International Journal ’’Total Quality Management & Excellence’’, Vol. 37, No. 1-2, 2009.

SPC AND PROCESS CAPABILITY ANALYSIS– CASE STUDY

UDC:

Tatjana V. ŠIBALIJA, Vidosav D. MAJSTOROVIĆ,

Faculty of Mechanical Engineering, University of Belgrade

Abstract: This paper presents one postulates of one of the most important quality engineering techniques

Statistical Process Control (SPC), embracing quality engineering tools: control charts and process

capability measurement. Their application is explained on a case study, which presents one part of Six

Sigma pilot project conducted in the observed manufacturing system.

Key Words: Statistical process control (SPC), control charts, process capability, Six Sigma.

1. INTRODUCTION

SPC implies application of statistical

methods for identification and control of special

causes of variation in the process. SPC presents a

set of control charts based on statistical

principles, which monitor the process behaviour

(via observed significant factors) and indicate

process behaviour changes in order to eliminate

the potential problem on time, before it occurs.

SPC program has two specific functions: (i)

as a monitor, to verify that process is under

control, or to indicate that a process is not in

control, based on interpretation of control-chart

abnormalities or other indicators; (ii) as a quality

improvement technique, for the purpose of

improving process capability [1].

Within SPC, control charts and capability

studies are the main tools used to describe

processes graphically. These two quality

engineering tools are explained in this paper, as

well as their application on a real case study.

2. SPC - BACKGROUND

Implementation of SPC for the observed

process/system is carried out according to the

following steps [2]:

1. Selection of quality characteristics / process

parameters (factors) relevant to the observed

product and/or process. Each control chart

follows the behaviour of the observed quality

characteristic with respect to process

parameters. Each point at the chart presents

characteristics of one sample, and it is

compared to prior points (measuring value

and distribution) in order to estimate the

process trend. Table 1. shows the instructions

for selection of the type of control chart

according to the nature of the quality

characteristic (attribute or numerical data) and

sample size. Data collection for attribute

control charts is faster and easier than for

numerical charts, but numerical control charts

are more eligible due to better quality of

information about the observed process. .

2. Quality of measuring system. In order to

provide reliable measurements of quality

characteristics, it is necessary to perform

measuring system analysis and approve

measuring system for measurement of the

observed

characteristics,

prior

to

implementation of SPC.

3. Initial data collection for control chart

formation. Prior to formation of control chart,

sampling plan must be determined at such

way to adequately represent the observed

characteristic of product and/or process and

initial measuring data must be collected.

Training of operators who will measure

characteristics and collect measuring data

must be properly performed.

4. Definition and documenting of OCAP (Out of

Control Plan Action). OCAP is the plan of

actions that must be carried out when the

observed characteristic is out of control. Each

control chart has its own OCAP. The purpose

of OCAP is to instruct the operator who

collects the measuring data how to react on

each particular problem that indicates out of

control condition.

5. Calculation of control limits is performed with

respect to the type of control chart.

Calculation of control Limits for X , R and

X , σ charts is explained in the section 2.1.

6. Estimation of control. After control chart

setup, it is possible to estimate weather the

process is statistically stable. The following

situations indicate that process is not

statistically stable:

• One or more points out of control limits;

• WER (Western Electric Rules) are special

rules indicating that process is not stable or

data are not correct (fig 1.), applicable only

for numerical data ( σ presents standard

deviation of the process with respect to the

observed characteristic):

International Journal ’’Total Quality Management & Excellence’’, Vol. 37, No. 1-2, 2009.

characteristic. If the same process is

performed on several machines, it is possible

to detect the machines (charts) with lower

capability with respect to the observed

characteristic and to react on time.

It is important to clarify two key terms in

SPC: (i) Variability: Each process contains

certain level of variability. Usual sources of

variation cause the variation within the process

but do not affect its stability, so the response is

predictable. Such process is called statistically

controlled (stable). Special sources of variation

affect the variation distribution, and in such case,

process response is not predictable until the

special causes of variation are detected and

eliminated. (ii) Sampling: SPC uses samples of

data in order to measure behaviour of the process

for the given moment of time. The goal is to

obtain maximum quality information with

minimum quantity of data. Appropriate sample

size and frequency of sampling is of the special

importance for proper implementation of SPC.

For the effective application of SPC,

following points should be thoroughly

considered: optimal sample size; control of

process characteristics rather than control of

product characteristics; control of numerical

characteristics

rather

than

attribute

characteristics; accurate measurements; regular

process control and stopping on time (before it

produces defective products).

- 7 consecutive points above or below average

value of characteristic ( X ),

- 7 consecutive points in ascending or

descending sequence (trend),

- 2 from 3 points in zones [–3σ ; –2σ] and [+

2σ ;o +3σ] (zone A),

- 4 from 5 points in zones [–2σ ; –σ] and [+ σ

; +2σ] (zone B),

- 15 points in zone [–σ ; + σ] (zone C),

- 8 points in zones [ –2σ ; –σ] and [+ σ ; +2σ]

(zone B) or bellow,

- 14 consecutive points alternating up-down.

• One or more individual values within the

observed sample out of specification limits.

7. Identification of the cause of instability by

data analysis. After detection of data that

show process instability, the cause of

instability could be found and eliminated by

following the responding OCAP. For the

considered point showing instability or out of

control condition, the cause and appropriate

action should be entered, from the list of

causes and actions in the OCAP.

8. Calculation of process capability indices (Cp

and Cpk), in order to perform benchmarking

and to compare with prior process behaviour

(aiming to continuously improve the process).

9. Process control and focus on chart

(characteristics) with low Cpk value. Control

charts with low Cpk value indicate possible

instability or out of control condition of

process, with respect to the observed

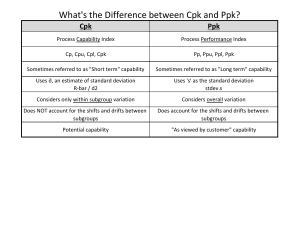

Table 1: Selection of the type of control charts [3].

Data type

Definition

Sample size

constant

Number of defects in unitAttribute data

product

variable

(continual and

Number of defective products constant sample size > 50

discrete values)

constant sample size > 50

Data

sample size =1

Numerical data

sample size <10

(continual values)

sample size ≥10

Type of control chart

"c" chart (number of defects)

"u" chart (defects per unit-product)

"np" chart

"p" chart (defective units portion)

X , Rm chart with moving range

X , R chart

X , σ chart

avergae characteristic

value in the sample

+3σ

zone A

+2σ

+σ

zone B

X

zone C

-σ

-2σ

zone B

-3σ

zone A

sample number

Figure 1. Allocation of zones at the control chart for numerical data, for the application of WER [3].

2

International Journal ’’Total Quality Management & Excellence’’, Vol. 37, No. 1-2, 2009.

2.1.1.

Control charts

Control charts are quality engineering tool,

used separately or within SPC to measure and

control process variation and detection of special

causes of variation.

Control charts are composed of sampling

results taken over time that are plotted as points

on charts. Different kinds of control charts

accommodate variable (continuous distributions)

or attribute (continual and discrete distributions)

sampling. Variable control charts are composed

of two graphs. The top graph monitors process

statistical location (the average sample measuring

value). It measures whether the process is

adjusted properly, comparing the calculated

process average to the nominal or target value.

The bottom graph monitors process variation

(range or standard deviation of the sample).

Attribute control charts are composed of only one

graph that monitors lot-to-lot variations in terms

of percent or number of nonconforming

(defective products or defects).

Depending of the sample size, X , R and X , σ

are the most commonly used control charts in

industrial practice. The first step in chart

formation is to determine the sample size and

frequency of sampling. Usual practice is to

consider smaller sample size and regular

sampling, since the purpose is to detect process

changes over time and not to disturb the regular

process realization. The second step implies

collecting of initial sampling data (approximately

20 samples). Based on initial data, the average

value and the range or standard deviation of

characteristic should be calculated.

If sample size is n ≤10 than X , R control chart

is formed and control limits are calculated

according to following [4]:

• for the average ( X ) chart:

- upper control limit: UCL = X + A2 R

- lower control limit: LCL = X - A2 R

• for the range ( R ) chart:

- upper control limit: URL = D4 R

- lower control limit: LRL = D3 R

where A2, D4 and D3 are coefficients which value

depends of the sample size, and R is average

value of ranges of all observed samples.

For sample size n >10 X , σ chart is

considered and control limits are calculated as

follows [4]:

• for the average ( X ) chart:

- upper control limit: UCL = X + A1 σ

- lower control limit: LCL = X - A1 σ

for the standard deviation ( σ )chart:

- upper control limit: URL = B4 σ

- lower control limit: LRL = B3 σ .

where A1, B4 and B3 are coefficients which value

depends of the sample size, and σ is average

value of standard deviations of all observed

samples.

•

2.1.2.

Process Capability

Capability studies are used to predict the

overall ability of a continuous distribution

(variable type) process to make products within

the required specifications. Capability indices

used to express process capability and

performance are [5]:

• Cp = Process Capability (simple and

straightforward

indicator

of

process

capability);

• Cpk = Process Capability Index (adjustment

of Cp for the effect of non-centred

distribution);

• Pp = Process Performance (a simple and

straightforward

indicator

of

process

performance);

• Ppk = Process Performance Index

(adjustment of Pp for the effect of noncentred distribution).

Mathematical formulations of the above

indices are:

Cp = Tolerance

6σ

Cpk = minimum { USL − X ; X − LSL }

3σ

3σ

where σ is standard deviation of process with

respect to the observed characteristic:

σ = R / d2

d2 is coefficient which depends on sample size,

6σ is natural process tolerance, Tolerance is

specification tolerance of the process (Tolerance

= USL – LSL, where USL is upper and LSL is

lower specification limit, with respect to the

observed characteristic (fig. 2.)).

Process with Cp = 1.0 or greater provides

response (products) that meet customer

specification, if process is centred in the middle

of the specification range. But, if average value

of the observed characteristic is changed than

distribution could be shifted so the process could

be shifted with respect to specifications. Cp does

not consider the location of the process, in

contrast to Cpk. Cpk presents the specification

width (USL – LSL) with respect to how well the

process spread is located about the target and the

specification limits. A Cpk=1.0 or greater implies

that a process which is in control is predictable

International Journal ’’Total Quality Management & Excellence’’, Vol. 37, No. 1-2, 2009.

found that vital defects are mainly related to

product characteristic - pot enamel thickness.

Ishikawa diagrams were used to analyse vital

defect and their main causes. They revealed that

the majority of the defects are related mainly to

sub-processes A5.2. – Base enamelling and

A.5.4. – Cover enamelling ([6]-[9]). Measuring

system analysis was performed in the Measure

phase: the observed measuring system used to

measure the most important product quality

characteristic - pot enamel thickness was found as

adequate for the observed measurements [10].

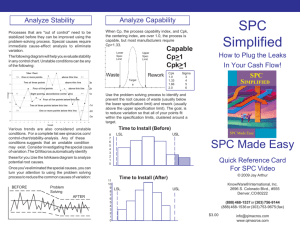

The analysis of process A5 - Automatic

enamelling was performed using SPC. Based on

two-weeks sample data for production performed

on Automat 2, X , R control charts were created

for base enamel thickness (fig. 3.) and for total

(base plus cover) enamel thickness (fig. 4.).

Sample size was 5 measurements at one part

(pot) and sampling frequency was 2 hours ([6][9]). Specification limits for base enamel

thickness are: LSL÷USL = 80÷120 µm ([8]-[9]),

and for total enamel thickness: LSL÷USL =

180÷300 µm ([7]). Control limits for both charts

were set according to the "6σ" requirements:

LCL/UCL = Average -/+ 3 σ ([4]).

From fig. 3 and fig. 4, following conclusions

could be drawn ([8]-[10]):

- data for base enamel thickness characteristic

are normally distributed (P<0.005),

- X , R chart for base enamel thickness is in

control (there are no points out of control

limits),

- process capability indices (Cp=Cpk=1.41,

Pp=1.5, Ppk=1.22) do not satisfy "6σ"

requirements: Cp, Cpk, Pp, Ppk > 2 ([4]);

- from capability histogram it is visible that

process was off-centre, with respect to base

enamel thickness;

- data for total enamel thickness are normally

distributed (P<0.005),

- X , R chart for total enamel thickness is out of

control; data at the chart are gathering into

two groups, with no visible criteria for their

distinguishing; this indicates dispersion

problem;

- process

capability

indices

(Cp=5.58,

Cpk=4.43, Pp=3.24, Ppk=2.57) are very good

and meet "6σ" requirements.

This indicated that process needs optimisation

with respect to base enamel thickness ([8]-[9])

and with respect to cover enamel thickness ([7]).

Since it was not possible to measure cover

enamel thickness directly, chart presented at fig.

4 shows data for total thickness, which includes

base and cover thickness.

over time, and it is capable to meet customer

specifications with respect to the observed

characteristic. For processes that are expected to

meet "6σ" requirements, minimal required value

is Cpk=2 and Cp=2 [4].

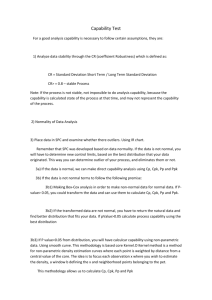

LSL

USL

6σ

Tolerance

Figure 2. Statistical presentation of process

capability.

In contrast to Cp and Cpk that are used for

short term, performance indices Pp and Ppk are

used for long term analysis. Cp and Cpk compute

the index with respect to the samples of data

(average values of the samples), while Pp and

Ppk take into account whole process (all

individual data within all samples). Standard

deviation for Ppk is calcuated as:

∑ (X − X

σ =

i

)2

i

N −1

where X is average value of characteristic, X i

is individual measuring value, N is total number

of measurements (i=1, .., N).

For both Ppk and Cpk the 'k' stands for

'centralizing facteur'- it assumes the index takes

into consideration the fact that data is maybe not

centred (hence, index shall be smaller). It is more

realistic to use Pp & Ppk than Cp & Cpk as the

process variation cannot be tempered with by

inappropriate subgrouping (samples). However,

Cp and Cpk can be very useful in order to know

if, under the best conditions, the process is

capable of fitting into the specifications or not.

The values for Cpk and Ppk will converge to

almost the same value when the process is in

statistical control, because the real standard

deviation and the sample standard deviation will

be identical [5].

3. CASE STUDY

The pilot-project Six Sigma, for the observed

manufacturing system, was conducted according

to DMAIC (Define-Measure-Analyse-ImproveControl) methodology. In the Define phase,

manufacturing system was mapped using IDEFO

method. In order to rank and analyse defect in the

manufacturing process A5 – Automatic

enamelling, Pareto analysis was performed. It

4

International Journal ’’Total Quality Management & Excellence’’, Vol. 37, No. 1-2, 2009.

Sample Mean

Xbar Chart

Capability Histogram

110

UCL=110,09

105

_

_

X=103,73

100

LCL=97,36

1

20

39

58

77

96

115

134

153

172

93

96

R Chart

102

108

111

114

20

_

R=11,03

10

0

LCL=0

1

20

39

58

77

96

115

134

153

172

90

100

Last 25 Subgroups

110

120

Capability Plot

112

Values

105

Normal Prob Plot

AD: 15,241, P: < 0,005

UCL=23,33

Sample Range

99

Within

Within

StDev 4,74309

Cp

1,41

Cpk 1,14

CCpk 1,41

104

Overall

StDev 4,44462

Pp

1,5

Ppk

1,22

Cpm *

Overall

96

Specs

170

175

180

Sample

185

190

Figure 3. X , R control chart for base enamel thickness [9].

Sample Mean

Xbar Chart

232

111111121111111112 2212

5 2 2 22 22

552 2 2 2

2 22 2

224

86

22

2 58

1 1111111 111 1 11 1

1

11111111111111111111 11 1111 1

1

1

1

216

1

20

39

58

Capability Histogram

11

1 11

1

88 115222222122 115552221 21222222 122221222222

8 5 2 6 5 2 2 2

2

2

8 8 6 22 2 62

2 2

86

77

96

22

2

1

1

1

1

11111111

1

8

115

8

8

134

153

UCL=232.36

_

_

X=227.56

LSL

Specifications

LSL 180

USL 300

LCL=222.75

172

192 208 224 240 256 272 288

R Chart

Normal Prob Plot

AD: 11.136, P: < 0.005

20

Sample Range

USL

UCL=17.62

_

R=8.33

10

2

2222222222

3

0

1

20

39

2 2222

58

LCL=0

77

96

115

134

153

172

200

Last 100 Subgroups

240

Capability Plot

240

Values

220

Within

StDev 3.58161

Cp

5.58

Cpk 4.43

225

210

Within

Overall

Overall

StDev 6.1671

Pp

3.24

Ppk 2.57

Cpm *

Specs

100

120

140

Sample

160

180

Figure 4. X , R control chart for total (base and cover) enamel thickness [7].

International Journal ’’Total Quality Management & Excellence’’, Vol. 37, No. 1-2, 2009.

Thus, data at chart presented at fig. 4 contain

variation of base and of cover enamel thickness.

Due to his fact, it is necessary first to optimise

the process A5 with respect to base enamel

thickness (optimisation of sub-process A5.2.) in

order to solve location problem (since previous

and current process is off-centre). Then,

optimisation of the process with respect to cover

enamel thickness (optimisation of sub-process

A5.4.) should be performed [2], [11]. The

purpose of such optimisation is to find optimal

process parameters setting (for both subprocesses A5.2. and A5.4) that meet

specifications for the target base and total enamel

thickness and to reduce variability of process

with respect to both characteristics.

6. CONCLUDING REMARKS

SPC and process capability analysis present

powerful means for the analysis of current and

previous process behaviour and they provide

information that serve as a basis for the process

improvement. Correct implementation of SPC

assures possibility to detect special causes of

process variation on time, in order to eliminate

them before generating defective products.

Process capability analysis entails comparing the

performance of a process against its

specifications, thus enabling analysis of previous

and current process performance, as well as

benchmarking. This is of special importance

when comparing previous or current process

performance with the process performance after

improvement.

SPC and process capability analysis are

inevitable steps in implementation of Six Sigma

methodology for the existing process and/or

system according to DMAIC cycle. Within the

scope of plot-project for the observed process

(A5 - Automatic enamelling) improvement

according to DMAIC methodology, SPC and

process capability analysis were used in Analyse

phase. Their application revealed the location

problem in sub-process A5.2 and dispersion

problem in sub-process A5.4.

In the Improve phase of DMAIC approach

DoE was used to identify the optimal settings of

critical-to-quality factors (process and enamel

parameters), for automatic enamelling process

[11]. By implementing the optimum parameters

into practices, it is expected that the process

performance will be improved, therefore

improving process robustness and capability. In

order to ensure sustainability, achieved results

will be followed through Control phase of

DMAIC approach. The improved data on

View publication stats

significant factors, as identified from the

experimental design, will be monitored and the

whole process will be documented to ensure that

improvements are maintained beyond the

completion of the pilot- project. The achieved

process improvements will be monitored and

verified in everyday practice by using control

charts and process capability analysis with

respect to base and total enamel thickness

characteristics.

REFERENCES

[1] Šibalija, T., Attaining Process Robustness through

Design of Experiment and Statistical Process Control,

Proceedings of the 11th CIRP International Conference

on Life Cycle Engineering – LCE 2004, pp.161–168,

Belgrade, 2004.

[2] Majstorović, V., Šibalija, T., Implementation of

SPC, Report on researches conducted in Six Sigma

pilot-project No.01.01.B. 2007/1, Faculty of

Mechanical Engineering, University of Belgrade,

2007 (on Serbian language).

[3] Majstorović V., Šibalija T, Soković M., Pavletić

D., Monograph: “Tempus ETIQUM – Six Sigma

Model and Application” - in progress (on Serbian

language).

[4] Pyzdek T., The Six Sigma Handbook, McGrawHill Companies, Inc, 2003.

[5] www.isixsigma.com

[6] Šibalija, T., Majstorović, V., Six Sigma

Methodology – Case Study, Proceedings of the 8th

International Conference on The Modern Information

Technology in the Innovation Processes of the

Industrial Enterprises–MITIP, pp.246-252, Budapest,

Hungary, 2006.

[7] Šibalija, T., Majstorović, V. Six Sigma

Methodology

Implementation

in

Serbian

Manufacturing enterprise, International Journal

’’Total Quality Management & Excellence’’, No.3,

Vol. 35, pp. 17-22, 200 7.

[8] Majstorović, V., Šibalija, T., An Application of

DMAIC Approach to Process Quality Improvement –

Case Study, Proceedings of IFAC Workshop on

Manufacturing, Modelling, Management and Control MIM 2007, Budapest, Hungary, 2007.

[9] Šibalija, T., Majstorović, V. An Application of

DMAIC Approach – Case Study from Serbia,

Proceedings of International Conference on Advances

in Production Management Systems–APMS 2008,

pp.120-126, Espoo, Finland, 2008.

[10] Šibalija, T., Majstorović, V., Measuring System

Analysis in Six Sigma methodology application – Case

Study, Proceedings of the 10th CIRP Seminar on

Computer Aided Tolerancing - CAT 2007, Erlangen,

Germany, 2007.

[11] Šibalija, T., Majstorović, V., (2007) An Example

of DoE Application For Automatic Enamelling

Process Improvement, International Journal ’’Total

Quality Management & Excellence’’, No.1-2, Vol.35,

pp.405-410, 2007.