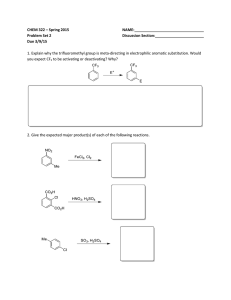

lOMoARcPSD|13198428 Siwes - Industrial work experince technival report Computer Science (Ahmadu Bello University) StuDocu is not sponsored or endorsed by any college or university Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 CHAPTER ONE 1.0 INTRODUCTION The growing concern among our industrialists that graduates of our institutions of higher learning, lack adequate practical background studies preparatory for employment in industries, led to the formation of Students Industrial Work Experience Scheme (SIWES) by ITF in 1993/1994. (Information and Guideline for SIWES, 2002). ITF has one of its key functions; (1) to work as cooperative entity with industries and commerce where students in institution of higher learning can undertake mid-career work experience attachment in industries which are compatible with students area of study (Okorie 2002, in Asikadi 2003). 1.1 DEFINITION OF SIWES: The students industrial work experience scheme (SIWES) is a skill training programme designed to expose and prepare Nigeria Students studying occupationally-related courses in higher institutions the experience that would supplement their theoretically learning. It seeks to bridge the gap existing between theory and practice of Engineering, Agriculture, Technology, Environmental Science, Medical Sciences, Pure and Applied Science Programme in the Nigeria tertiary institution. 1.2.0 PURPOSES OF SIWES It is aimed at exposing students to machines and equipment professional work methods and ways of say guiding the work areas and workers in the industries and other organization. The scheme is a tripartite programme involving the tertiary institution and industry (the employers of labour) and the industrial training fund. 1 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 1.2.1 OBJECTIVES OF SIWES The objectives of SIWES among others include; Prepare students for the industrial work situation which they are likely to meet after graduation. Provide an avenue for students in institutions of higher learning to acquire industrial skills and experience in their approved course of study. Expose students to work methods and techniques in handling equipment and machinery not available in their institutions. Provide students with an opportunity to apply their knowledge in real work situation there by bridging the gap between theory and practices. Enlist and strengthen employer’s involvement in the entire educational process and prepare students for employment in the industry and commerce (information and guideline for SIWES 2002). 1.3 BRIEF HISTORY OF PLACE OF ATTACHMENT (KRPC) Kaduna Refining and Petrochemical Company Limited (KRPC) is a subsidiary of Nigerian National Petroleum Co-operation (NNPC). KRPC was commissioned by Alh. Shehu Shagari, President Commander-inChief of the Armed Forces Federal Republic of Nigeria on Saturday 25 th October, 1980. Its initial capacity was 100,000 Barrels per Stream Day (BPSD). As the third Refinery in the country, it was established to cope with the growing demand for petroleum products, especially in the Northern part of the Country. The refinery was designed to process both Nigerian and imported crude oils to fuels and lubes products. In December 1985, the fuels sections of the refinery was successfully debottle necked from 50,000BPSD to 2 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 60,000BPSD, bringing the total refinery installed capacity to 110,000BPSD. In March 1988, the 30,000MT per annum, Linear Alkyl Benzene (LAB) Petrochemical plant was commissioned. The petrochemical plant, being a downstream of plant of the refinery, derives its entire raw materials including utility supplies from the refinery. KRPC was established to efficiently and profitably process crude oil into refined petroleum products and manufacture (LAB), Tins and Drums for domestic consumption and export. PERSPECTIVE NNPC embarked on commercialization exercise the same year 1988 and it became necessary to merge the two plants (refinery and petrochemical plants) to form a single subsidiary company of NNPC known as Kaduna Refining and Petrochemical Company Limited (KRPC). 3 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 1.3.1 BROAD ORGANOGRAM FOR KRPC MANAGING DIRECTOR KRPC MANAGER SUPPORT STAFF MANAGER MAT. MANAGEMENT DEPUTY MANAGER, TOTAL QUALITY MANAGEMENT MANAGER PLANNING, BUDGET & MONITORIND DEPT. COMPANY SEC./LEGAL ADVISOR MANAGER AUDIT DEPUTY MANAGER COMMERCIAL EXECUTIVE DIRECTOR OPERATIONS EXECUTIVE DIRECTOR SERVICES MANAGER PRODUCTION MANAGER HUMAN RESOURCES MANAGER POWER PLANT & UTILITIES MANAGER FINANCE & ACCOUNT DEPARTMENT MANAGER PROD. PLANNING & QUALITY CONTROL MANAGER PUBLIC AFFAIR MANAGER FIRE, SAFETY & ENVI. POLLUTION MANAGER ADMIN SERVICES MANAGER MAINTENANCE DEPUTY MANAGER SECURITY MANAGER ENGR. & TECHNICAL SERVICES DEPT. MANAGER MANUFACTURING 1.4 INTRODUCTION TO SECTION OF INDUSTRIAL TRAINING Fig. 1.0: ORGANOGRAM OF KRPC 4 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Production department is the core of KRPC for it is where the refining of crude oil and the production of the petrochemical products are being carried out. Production department is headed by a Manager and has four sections each headed by Deputy Manager. Below are the sections; Fuels Section Lubes Section Linear Alkyl Benzene (LAB) Oil Movement. The fuels section is made up of area 1, area 2 and area 3, while the lubes section is made up of area 4, area 5 and area 6. Linear Alkyl Benzene is made of Area 1 and Area 2, same with the Oil movement. But the main focused is on linear Alkyl benzene section particularly Area 1and Area 2 , where I undertook my industrial training for a period of six (6) months. The linear alkyl benzene section also called the petrochemical department is charged with the sole aim of producing linear alkyl benzene as it final product 5 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 1.4.1: BROAD ORGANOGRAM OF UNITS IN PETROCHEMICAL (LAB) SECTION LA AR BE A 9 11 M T : // D A Y Fig1.1: LAB organogram. The area1 section of petrochemicals is made of three units namely; 1. Hydrogen desulphurisation unit (HDS) 2. Molecular extraction unit (MOLEX) 3. Hot oil system 6 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 The area2 section is also made of three units namely: 1. Paraffin conversion to olefin unit (PACOL) 2. Thermal hydro-de alkylation unit (THDA) 3. Hf alkylation unit. 1.4.2 Hydrogen desulphurization unit (HDS): this unit is also called unit 35 in KRPC, it is charged with the sole aim of producing treated kerosene from normal kerosene. This done by reacting purified and compressed hydrogen from compressor with normal kerosene at an elevated temperature of 280egree to remove elements like (sulphur, chlorine, oxygen nitrogen etc.) and hence producing treated kerosene, sour water and naphtha with much less or no sulphur content and with low specific gravity. The main product is treated kerosene while the by product is sour water (H2S, HCl, H20 NH3……). The essence this unit is to reduce/remove the sulphur content in the kerosene to make it easy for the MOLEX unit to break the molecules. C12H25SNOCL+3H2= C12H26 + (HS + HN3 + H2O + HCL) Kerosene hydrogen treated kerosene Sour water 1.4.3 Molecular extraction unit (MOLEX): this unit is called unit30. It uses treated kerosene from the HDS unit as it raw material. Here the kerosene molecules are broken by heating it up to a temperature of 285degree to produce paraffin, kerosene solvent and naphtha. (C12H26)n + heat = (C5H12)n + (C3H8)n + ((C2H5)n + (CH)n)n Treated kerosene paraffin kerosene solvent Naphtha 7 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 1.4.4 Hot oil system (HOS): the hot oil system is the main heating system in the petrochemical department. The system operates by heating up oil in the heater and pumping the heated oil through pipes to where heating services are required in the plant. The hot oil is mainly used to increase the temperature of fluids passing through pipes. 1.4.5 Paraffin conversion to olefin unit (PACOL): also called unit31 with the addition of heat, hydrogen and a catalyst (platinum) converts paraffin (saturated hydrocarbon) to olefin (unsaturated hydrocarbon). It is a chemical reaction called dehydrogenation reaction occurring at a temperature between 1700c-1800c (C5H12) n Paraffin + H = hydrogen (C5H11) n olefin + H2 + CH4 hydrogen gas naphtha The hydrogen gas obtained is purified, dried and recycled back into the compressor for further uses. The olefin obtained is one of the raw materials for production of linear alkyl benzene. 1.4.6 Thermal hydro-DE alkylation unit (THDA): The unit is also called unit35. It raw material is reformates from the refinery. Reformate is a compound containing light and heavy aromatics (benzene products) like xylene, toluene phenol, isoprene etc. with the aid of heat and purified hydrogen, the reformate is converted to benzene and other bye products some of which can be recycled in this unit. Several chemical reactions that are occurring in this unit are: hydro alkylation it is the principal reaction occurring in the THDA process unit, it is the hydro-alkylation of toluene to yield benzene and methane as naphtha 8 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 at a temperature of 7270c and the degree of conversion is governed by the reactor temperature, hydrogen partial pressure and resident time. Other substituted aromatics like xylene and propylbenzene can also be dealkylated. C7H8 + H2 = C6H6 Reformate hydrogen + CH4 benzene methane hydro cracking Compounds like paraffin and naphthalene are unstable at THDA process condition and can be hydro cracked to benzene and methane since they cannot be removed from benzene by fractionation. C7H16 + H2 = Reformate hydrogen C6H6 + benzene C7H16 + 2H2 = C3H8 + Heptanes hydrogen propane CH4 + 4H2 naphtha hydrogen 2C2H6 ethane hydrogenation it is a side reaction with advantages and disadvantages like the hydro cracking reaction, the function is to remove the sulphur in thiophene to form benzene and hydrogen sulphide. C7H4S + 4H20 Thiopene = hydrogen C6H6 + CH4 benzene + methane H2S hydrosulphide Aromatic ring condensation A major side reaction in the THDA unit is the condensation of benzene to produce biphenyl. This reaction is favoured by high temperature and low hydrogen-to-hydrocarbon ratio, the production of biphenyl is reduced by limiting the operation temperature and at high hydrogento-hydrocarbon ratio. 9 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 2C6H6 = C12H10 Benzene + 3H2 biphenyl hydrogen Coke formation Aromatic ring condensation as described above can contribute to the formation of polynuclear aromatics such as anthracites and fluorine. These compounds do not tend to reach equilibrium and have high tendency to form coke instead. CH4 = Methane C + carbon 2H2 hydrogen In this unit intermediate products like toluene, phenyl, xylene, ethyl benzene etc. are formed during the processes before the final product which is benzene is formed. The benzene formed is another raw material for the production of linear alkyl benzene. 1.4.7 HF-ALKYLATION UNIT: this is the most important and complicated unit in the petrochemical department where the linear alkyl benzene (LAB) is produce. The raw materials for this section are benzene from THDA unit, olefin from PACOL unit and hydrofluoric acid (HF) which serves as a catalyst for the process and it is recovered at the end of the process. A lot of intermediate products like paraffin, naphtha, light and heavy aromatics and light and heavy alkylate and obtained during this process with the final product being linear alkyl benzene. C6H6 + C5H11 Benzene Olefin + HF = C6H5-C5H11 + H2+ HF hydrofluoric linear alkyl benzene hydrofluoric acid 10 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 1.5: FLARE: The flare is a long pipe through which unwanted, unreactive and incondensable gases are burnt away to the atmosphere. All unwanted flue gases, polymers and water pass through a common heater both from the refinery and petrochemical sections to a storage tank called 90D05 which help to remove liquid entrainment (polymer and water) from the flue gases before sending it to the flare for burning The air fin cooler around 90D05 helps to cool the flue gas to about 50 0C before it enters into the drum, it is designed such that 1kg/cm2 (98.07N/m2). A flare can be started using the following procedures Air and flue gas are mixed in the ratio of 2:3, with a plug that sparks up the fire. The fire started is called the pilot fire, and it is always and constantly on even the flue gases are not send to the flare. Flue gases come in contact with the pilot fire at the tip of plant to start the fire. If the liquid level in 90D05 is above 80%, flow regulatory control valve triggers the transmitter which send signal to the pumps to pick automatically to send the liquid to oil movement to ovoid over flow around the tank Although the gases are harmful to the environment, there is a lot of treatment down before the flue gases are sent through the header to tank 90D05 to the flare. 90D05 is called the knockout drum because it is use to knockout the liquid from the flue gases 11 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 f Fig1.2 the flare and knockout drum (90D05) CHAPTER TWO 2.0 SAFETY INDUCTION COURSE It is the culture of KRPC that every IT Students, SIWES, NYSC and New staffs taken most attend two days fire and safety induction course 12 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Before starting any work at the company. 2.1.0 SAFETY: May be defined as accident prevention or freedom from risk, harm and damage. 2.1.1 FUNDAMENTAL SAFETY PRINCIPLE There are three fundamental safety principle, these are; i. Accident are caused ii. Steps must be taken to control accident iii. Without correction, the same type of accident will occur. 2.2 HAZARD Hazard is a disaster which can occur in a place of work. It is also the potential to cause harm. 2.3 i. TYPE OF HAZARD Chemical Hazard: This is the type of hazard which involves chemical substances which can be inhale or expose to human in a work place especially chemical laboratory. ii. Mechanical Hazard: This is another type of hazard that occurs by the use of machineries i.e. unguarded machinery and moving machinery part. iii. Electrical Hazard: This can easily occur when there is any exposure of electrical conductor which can lead to electrical shock. iv. 2.4 Other types of hazard include Biological hazard and Ergonomic hazard. HARMFUL SUBSTANCES These are substance that causes harm to the human body or the environment. Some of the harmful substances are: i. HF-Hydrofluoric acid 13 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 ii. H2SO4- Tetraoxosulphate (vi) acid iii. TEL-Tetra Ethyl lead iv. CO-Carbonmo oxide v. NH3-Ammonia vi. H2S-Hydrogen Sulphide vii. RAS-Radioactive Source. viii. Benzene 2.5 HOW HARMFUL SUBSTANCES ENTER THE HUMAN BODY Inhalation-via nose Absorption-via skin Injection-via direct contact Ingestion-via mouth 2.6 PREVENTIVE MEASURES OF HARMFUL SUBSTANCES Eliminating the hazard Educate the workers Monitor the workers Guard the hazard Protect the workers Enforcement of safety rules and regulation Pay off the worker. 2.7 FIRE Fire is defined as rapid chemical combination of three components i.e. fuel, oxygen and heat. 2.7.1 CLASSES OF FIRE 14 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 I. Class A Fire: Fire resulting from burning materials e.g. wood, paper, textile plastic etc. it can be extinguished by cooling. II. Class B Fire: Fire from liquid hydrocarbon e.g. petrol, diesel, kerosene and cooking oil. It can be easily extinguished by smothering. III. Class C Fire: Fire from gaseous hydrocarbon e.g. cooking gas (LPG). It can be extinguished by starvation i.e. by preventing the source of the fuel. IV. Class D Fire: Fire resulting from metal and metallic compounds very reactive metals like Na, K, Ca, and compound like Tin-ethyl aluminium (TEA) when exposes to air, H2O Spontaneous explosion. V. Class E Fire: Electrical fire classified by American as class E. These fire from electrical appliance e.g. heater, meter etc it can easily be extinguished by disconnection. 2.8 PRINCIPLES OF ACCIDENT PREVENTION 2.8.1 DEFINITION OF ACCIDENT Accident is an unplanned event in a series of events that may lead to Injury of person, damage to property or both or all of the above. 2.8.2 TYPE OF ACCIDENTS There are three type of accidents (a) Injury accident (b) Property damage accident (c) Near miss event 2.8.3 CAUSES OF ACCIDENT The two main causes of accident are: 1. Unsafe acts 2. Unsafe condition 15 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Other causes are: Lack of knowledge , Careless attitude, Working without authority, Lack of ability, Poor/Defective working tools and/or equipment, Taking short cuts etc. 2.8.4 THE REASONS FOR ACCIDENT PREVENTION There are three (3) major reasons for preventing accidents to personnel. a. Moral b. Economic c. Legal 2.8.5 ACCIDENT PREVENTIVE The various methods employed for accident prevention are:• Posters – planned campaigns • Personal reminders of working practices /hazards • Safety sticker display of known hazards • Workers briefing on hazards, either general or specific (Tools box Safety Talk) • Miscellaneous literature to provide information • Shop floor publication/company newspapers • Technical advice reference and data books 2.9 WORK PERMIT: Permit work can be defined as a tools or procedure for proper control in hazardous conditions. 2.10 TYPES OF WORK PERMIT i. Cold work permit ii. Hot work permit iii. Vessel/entry permit 16 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 iv. Excavation clearance certificate v. Electrical Isolation permit vi. Acid area work permit 2.11 P.P.E (PERSONAL PROTECTIVE EQUIPMENT) Head ---------------------------------- helmet Body ---------------------------------- Overall Eye ------------------------------------ Google Ear ------------------------------------ Ear muff Hand ---------------------------------- Hand glove Face ----------------------------------- Face shield Nose ---------------------------------- Musk Acid ----------------------------------- Acid Suits. Fig. 2.0: Safety Wears. CHAPTER THREE 3.0 DISTILLATION Distillation is a method of separating mixtures based on differences in their volatilities in a boiling liquid mixture. Distillation is a unit 17 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 operation, or a physical separation process. Commercially, distillation has a number of applications. It is used to separate hydrocarbons into more fractions for specific uses such as transport, power generation, heating and domestic uses. Distillation takes advantage of one of the physical characteristics of each hydrocarbon i.e. its boiling point. The basic mechanics consist therefore heating the crude (without changing the structure of any component) and then fractionating it into groups. The characteristics of these groups are linked to the market needs for directly commercial products, and to the specifications of the process plants for the products destined to undergo a subsequent treatment. The percentage of the products, meeting the specifications, depends solely on the type of crude processed and the industrial plant most commonly used for distillation is the topping unit. A typical fractionating Scheme can be divided as follows: Feed Preheating Preflash Heater Column for the stripping of side product Fractionating overhead system with its sub-units 3.1 FEED The feed is made up of kerosene, sometimes of particular products coming from previous treatments. To overcome pressure drops in the most equipment, the feed is introduced into the unit with high pressure 18 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 pumps (about 70kg/cm2). The pumps, because of a problem of the dimension of lines, are almost always installed in the tank zone. Furthermore, there are always standby pumps for the feed and booster pumps to ensure the continuity of the feed, and for emergencies they are protected by an automatic blocking system. The flow rate is measured in the unit area, on the cold product, up-stream of the water and soda injection. Also the flow rate is measured on the delivery of the feed pump. 3.1.1 TOPPING FEED DIFFERENT LAY-OUTS REFINARY PLANTS AREA TOPPING UNIT Battery Limit Kerosene Tank Fig 3.0: topping feed 3.2 PREHEATING OF THE FEED Preheating is carried out by heat exchangers, recovering heat from the products to storage and from the various refluxes. Floating heat 19 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 exchangers are usually used to preheat the feed to certain temperature, conserve energy, heat recovery and heat maximization. Fig. 3.1: typical heat exchanger arrangement in LAB section 3.3 PREFLASHING The pre-flash column is usually introduced to separate the gases and sour water from the kerosene in order to avoid pressure built up in the heater 20 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 or fractionating Column. The gases that are separated may be treated for flaring or re-injected for further kerosene production or distributed to companies in need of them. This is illustrated in figure 3.2 PURPOSE OF PRE-FLASHING To top hydrocarbon to avoid overpressure in the main fractionating column Pre-flash Column Furnace Main Column Light naphtha Heavy naphtha Linear alkyl benzene Light alkylate Heavy alkylate Residue Hydrocarbon Fig3.2: pre-flashing of feed 3.4 HEATER 21 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 The heater or furnace is the last piece of equipment that supply the heat to the hydrocarbon before it enters the main fractionating column, it is a piece of equipment designed to generate heat. The temperature at which the crude kerosene enters into the heater is usually about 220 0C. The heater supplies the heat required to the crude oil in order to reach the process temperature i.e. 3100C to 3500C by burning refinery fuel gas and/or fuel oil. In KRPC heater heat is generated by using the basic principles of combustion which is produce with burners that combine fuel and air and the mixture is burnt at the burner tip, in some cases the system is provided with pre heaters for the air and two fans i.e. force draft fan and induced draft fan. The force draft fan is for the air to be pre-heated, while the induced draft fan is to suck the flue gas to send to the stack after the heat exchanger. The heater can be considered as divided into two section such as radiation and convection section. The radiation section is directly included in the combustion and is therefore subjected to considerably high temperature while the convection section is instead with the combustion products. KRPC heaters are provided with soot blowers to remove soot from tubes. Heat supplies by the heater are supply to the hydrocarbon by means of coils which are arranged in parallel, for the rational exploitation. The first spirals are place in the convection and the other in the radiation section; the coil to superheat the steam needed for the stripping is also installed in the convection section. Furthermore, on the combustion chamber there are a number of holes through which a number of burners are fitted to produce combustion to generate heat. Devices such as temperature and pressure indicators, flow rate controller, oxygen analyser are installed to control the rate at which heat is transferred and to monitor the working condition of the piece of equipment. 22 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig. 3.3 10 H01 HEATER 3.5 MAIN FRACTIONATING COLUMN 23 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fractionating column is a column where the actual process of separating fraction by ‘fractional distillation’ of treated kerosene takes place. The main column can be considered and divided into three parts such as; 1. Flash section/zone at the feed inlet 2. Stripping section for the residue 3. Fractionating and extraction section for all the other products. The stripping section contains some trays (usually 6) and the fractionation section instead has about 50 trays. The pre- flashed kerosene heated up to the designed temperature about (310-3500C) by the heater is fed to the flash zone in the main fractionation where the vaporised kerosene is flashed and separated into vapour and liquid, the heater discharge temperature must be sufficiently high to cause vaporization of all the products withdrawn above the flash zone plus the run back rate taking account of the effect of the bottom stripping team injection. Superheated steam is introduced between the bottom liquid level and the first tray, the steam by lowering the partial pressure (temperature and pressure being equal), allows further vaporization and therefore a more selective fractionation. 24 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig. 3.4: Main Fractionation Column & Stripper 3.5.1 STRIPPING COLUMN-SIDE PRODUCT Stripping column is a column installed close to the main fractionators to strip the distillate or side products drawn off from the fractionators. Each side product drawn off from the main column has its own stripping column. Stripping system is employed in HF-Alkylation unit. 25 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 In the case of HF-Alkylation unit the fractionating column has side stripper i.e. Hydrofluoric acid stripper Polymer (continuous boiling mixture ) stripper Alkylates stripper Linear alkyl benzene stripper Normally the strippers have some trays in particular cases; they have five in the LAB section. The inlet for the product coming from the main column is in the upper part and superheated stem is introduced between the bottom liquid level and the first tray. As in the main column the stem by modifying the equilibrium allows subsequent vaporization of the very light part of which is left in the extracted product (the flash point). The vaporized parts ant the steam return to the main column in the section higher than the one they came from. 3.5.2 FRACTIONATION OVERHEAD SYSTEM The vaporised fraction in the fractionating column which are not drawn off from the column passed to the top of the column and leave since the product leaving the top of the column are in vapour state, it is therefore necessary to return the condensable one to the liquid state and cool the incondensable ones. In unit 32, the vapours to be condensed go through the first exchanger of the unit, a group of air coolers and a water cooler in that order. However, condensed or uncondensed the reach the overhead accumulator, in which the separation of hydrocarbon/water and liquid phase/gas take places. 26 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 3.6 PRODUCTS The products obtained from linear alkyl benzene section after the Heating fractionation, distillation and condensation of kerosene and reformate are as follows: i. Whole Naphtha ii. Treated kerosene iii. Kerosene solvent and paraffin iv. olefin v. toluene and benzene vi. linear alkyl benzene 3.6.1: WHOLE NAPHTHA Whole naphtha from petrochemical department is defined as an overhead product which is composed of gas, light naphtha and heavy naphtha fractions. This product is sent directly to the naphtha hydro treating unit in the refinery without intermediate tank storage, because of high vapour pressure. ASTM endpoint of whole naphtha shall not exceed 1700C, since binaphthenic compounds contained in the heavier fraction of Nigerian crude oil will behave as a catalyst poison for the catalytic reforming unit (CRU). 3.6.2: Treated kerosene: this product is obtained from the hydrogen desulphurization unit. Treated kerosene is kerosene with little or no amount of sulphur presents it, it also has other elements like: nitrogen oxygen chlorine removed from it. Treated kerosene can be used for cooking as insecticide raw material and for making spirits and mainly as raw material in the MOLEX unit to produce kerosene solvent and paraffin. 27 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 3.6.3: Kerosene solvent: it is a by-products obtained in the MOLEX unit during the molecular extraction of treated kerosene. Kerosene solvent is very important in the petrochemical industries because it is pure and lighter than kerosene and as such can be used as raw material for several petrochemical products like: insecticides, spirits G.B etc. 3.6.4: Paraffin: paraffin is a saturated hydrocarbon (alkanes) obtained after heating kerosene and breaking it long molecular chain in the MOLEX unit. The paraffin produced can be used in making candle wax, producing insecticides and as raw materials in the PACOL unit to produce olefin. 3.6.5: Olefin: olefin is one of the major raw materials for the production of linear alkyl benzene. It is produced by dehydrogenating paraffin, making unsaturated and more reactive. The olefin is used directly with benzene to produce linear alkyl benzene. 3.6.6: Benzene: benzene is a product obtained after a long and complicated process in the thermal hydro-DE alkylation unit of the petrochemical section of KRPC. The raw materials are reformates from the refinery which is processed using heat and hydrogen to remove the alkyl group and other compound attached to the benzene ring called reformate. The benzene obtained can be sold and also use as raw material for production of linear alkyl benzene. 3.6.7: Linear alkyl benzene: this is the final and most important product in the LAB section of KRPC. In fact the section linear alkyl benzene is named after the final product its produces. A truck of linear alkyl benzene is worth 9million naira. The product is mainly of detergent quality and is used to produce all kinds of detergents. It raw materials are benzene, olefin, hydrofluoric acid and heat. 3.6.8: By-products: these are intermediate products obtained in almost all the units in the LAB sections in KRPC. These intermediate products are recycled, sold or discarded, they are: light and heavy naphtha (all units), sour water (HDS 28 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 unit), and kerosene solvent (MOLEX unit), toluene and xylene (THDA unit), continuous boiling mixtures, polymer and light and heavy alkylates in hfalkylation unit 3.7. Raw materials The major raw materials in LAB sections are: 3.7.1 Kerosene: the kerosene is sent to LAB section from the refinery section of KRPC. The kerosene usually sent is of the form C15 (heavy kerosene) or C9 (light kerosene) but the common one is C12. It also contains other elements like sulphur, nitrogen, chlorine, oxygen and some radicals. The kerosene enters LAB through the HDS unit i.e. tank (tk96). 3.7.2: Reformates: Reformate is a compound containing light and heavy aromatics (benzene products) like xylene, toluene phenol, isoprene etc. it is also sent from the refinery in form of heavy and light aromatic compounds which is reduced to simpler forms become entering the THDA unit of LAB. 3.7.3: Hydrogen: the hydrogen is sent from the refinery to both the HDS and THDA units in LAB. Where they are dried and purified by the compressors before sending it into the systems, its major functions react with the other compounds attached to the kerosene and reformate to produce their pure forms. CHAPTER FOUR 29 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 4.0 PROCESS DESCRIPTION OF HYRODEN DESULPURIZATION UNIT In the hydrogen desulphurization unit (HDS), kerosene undergoes several stages of processing before reaching it final stage where the final product is obtained. The main aim of this unit is remove sulphur and other contaminants from the kerosene since the MOLEX unit does not tolerate sulphur above 5ppm. Kerosene between C3 and C25 from refinery contains contaminants like sulphur, nitrogen, chlorine, oxygen and some free radicals which are not easily removed. HDS unit uses hydrogen and molybdenum alumina as a catalyst to remove the contaminants forming a product called sour water (H2S, HCL, NH3, H2O etc.) Kerosene from tank (90tk30) enters into the storage drum (35D01) and pumped by pumps (35P02A and 35P02B) at 70kg/cm 2 through the pipes to heat exchangers (35E01A and 35E01B) where it is preheated to temperature of about 1100c by hot product passing counter-currently and hot oil. Compressor (35K01A and 35K01B) compresses purified hydrogen from the refinery from 20kg/cm2 to 56kg/cm2 and pumped by pumps (35P01A and 35P01B) through pipes to meet with the kerosene before entering the heater (35H01) which heat the feed to a temperature of about 2700c-2800c. From the heater the feed enters into a continuous stir tank reactors (35R01A and 35R01B) connection in series to provide enough resident time and ensure maximum conversion, the reaction is exothermic, the product leaves the reactors at a temperature between 2800c-3150c and passes through heat exchanger (35E01A and 30 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 35E01B) again counter-currently to preheat the feed so as the enhance heat recovery and heat maximization. The product is then passed through air fin cooler (35A01), a condenser to cool the product before entering a high pressure separator drum (35D03) where sour water is removed through the boot, excess hydrogen comes out at the top to the compressor called recycled hydrogen, kerosene comes out from the bottom to a low pressure separator drum (35D05) where hydrogen sulphide (H2S) is knocked off and sent to the flare for combustion. Product from bottom of 35D05 passes through heat exchanger (35E03) where is heated up and enters into the stripper column (35C01) where it is heated with hot oil through heat exchanger (35E05), the top product with naphtha containing small of H 2S is send to the refinery for PMS production and some of the naphtha is recycled, the bottom product which is treated kerosene containing none or less than 1ppm of sulphur is pumped by pumps (35P03A and 35P03B) to the MOLEX unit and treated kerosene storage tank. Drum (35DA852) is design to teat sour water from drum (35D03), it has a heater and heat exchanges to do the heating and separates the sour water into less harmful components. 31 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.0: process flow sheet for hydro-desulphurization. 32 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 4.1 PROCESS DESCRIPTION FOR PARAFFIN CONVERSION TO OLEFIN UNIT The conversion of paraffin to olefin is a chemical reaction called dehydrogenation reaction at a temperature between 1700c to 1800c using a platinum based catalyst (DCH-t). Paraffin from MOLEX unit and recycled paraffin from the PACOL unit are store in a drum (31D01) From (31D01) it is pumped by (31P01A&B) through heat exchanger (31E01A&B) to heat it up to heater (31H01) where paraffin is heated counter currently at temperature between 6500c to 7000c , purified hydrogen gas from the compressor mixed with the paraffin before entering into the heat exchanger (31E01A&B). The mixture enters into reactors (31R01A&B) where reaction occurs, the product moves out of the reactors and through (31E01A&B) to pre-heat the incoming paraffin and itself being cooled, it then goes through the air fin cooler (31A01) for further cooling. The cooled product enters in the high pressure separator drum (31D03) where hydrogen gas is separated from the liquid mixture. The hot hydrogen gas containing water and particles is taken by pump (31P02) to (31D04) a drum having a boot which separates the particles allowing only the pure dry hydrogen gas to leave through the top and recycled back into the compressor, if the hydrogen is in excess, it is sent to the hot oil heater or flare for combustion. The liquid part containing paraffin, olefin and naphtha leaves (31D04) and pass through (31EO2) to be heated up to a fractionating column (31C01). The column is heated from the bottom with hot oil and medium pressure steam, the top product being naphtha is pumped by (31P03) to the refinery. The stripper containing paraffin and olefin is sent by pumps (31P04) to the HF-Alkylation unit where olefin serves as raw material for the production of linear alkyl benzene, and the paraffin recycled back to the PACOL unit. Only 10-20% of paraffin is converted to olefin in the PACOL unit. 33 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.1: process flow diagram for paraffin conversion to olefin. 4.2 PROCESS DESCRIPTION FOR THERMAL HYDRO-DEALKYLATION UNIT. The reformate coming from the refinery catalytic reformer is stored in the reformate tank (90tk30) and it is sent to the thermal hydrodealkylation unit by the reformate pump (90P11A&B). Reformate with aromatic within C8-C10 is passed through heat exchanger (33E01A&B) to heat it up from 600c t0 800c which then enters the prefractionator (33C01) heated up by hot oil to about 1200c. The light product collected as top product and sent to a condenser(33A01) called air fin cooler and then taken to drum(33D01) where pumps(33P03A&B) are used to recycle some of the light end back into the column(33C01) to maintain temperature, pressure and increase the purity of the product. The other light end is further cooled in a condenser (33E05) called trim cooler and then send to the refinery as naphtha, some of the naphtha is recycled back into the prefractionator. 34 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 The bottom product which is heavy aromatic is pumped by pumps (33P01A&B) through another header to the refinery. The main product which is toluene is distilled at the middle of the column at a temperature of 1110c and is passed through heat exchanger(33E03) to be cooled and subsequently heat the incoming reformate. The toluene is pumped by pumps (33P02A&B) to drum (33D03) where a slit ring system is used to move fuel gas in and out of the drum to maintain a pressure of 1.5kg/cm2 Some of the toluene is pumped to tank (90tk35) for distribution. The other reformate is pumped by pumps(33P04A&B) through heat exchangers (33E06A,B&C) and (33E07A,B&C) to raise the temperature which then enters the heater(33H01) to heat toluene to about 650 0c7000c at a pressure between 28-32kg/cm2 Sulphur is injected into the toluene before entering the heater to protect the wall of the pipe and prevent toluene from sticking to it. Toluene from the heater enters into reactors (33R01A&B) connected in series to ensure maximum conversion and yield, hydrogen from compressor (33K01A&B) is added to toluene in the reactor (33R01A). The reaction is highly exothermic, so the product is passed through heat exchanger(33E17) called steam generator where boiler feed water from drum(33D07) goes into the steam generator to cool the product and goes out as steam into (33D07) and then to medium pressure steam generator(M.P steam). The product goes out at the top of (33E17) and passed through heat exchangers(33E06A,B&C) and (33E07A,B&C) to be cooled and subsequently heat the toluene feed, it is further cooled by air fin cooler(33A02) and then enters drum(33D03) called high pressure separator. At low temperature and high pressure excess hydrogen goes out from the top of the drum, part of the hydrogen is send to drum(33D06) from where it goes to the compressor(33K01A&B) as recycled hydrogen, the other part of the excess hydrogen is taken to M.P steam. 35 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 The product is passed through heat exchanger (33E08 and 33E18) for further cooling which enters drum (33D04) where the product is separated from the remaining hydrogen. The pure hydrogen from(33D04) is passed through (33E08) where some part goes to the fuel gas and the other part joins the hydrogen from the refinery and stored in drum(33D05) as the makeup hydrogen for purification at (33Z01,2 & 3). The c1 and c2 from the hydrogen is stored in drum(33D11) and then taken to the flare, pure hydrogen is taken to the compressor’s make-up side and is also used to boost the product going to (33D08) and then pumped by (33P05A&B) to (33D08). Some of the product is recycled back into (33D08) and the main part goes into a clay pot (33C03A&B) to change the colour to gold colour, it then passes through (33E10) for heating and then to fractionating column (33C05) where benzene is produced. Medium pressure steam and heat exchanger (33E15) heats (33C05), benzene goes out close to the top at 800c goes through trim cooler (33E16) and then pumped by (33P07A&B) to benzene storage tank. The top product (naphtha, benzene drag and CH4) goes into air fin cooler (33A03) where it is cooled and then to drum (33D09) for storage. Pumps (33P08A&B) pumps the benzene drag where some part is recycled back into (33C05) and the other part to benzene drag storage tank. The bottom contain heavy aromatic which is heated by (33E15) and M.P steam and pumped by (33P06A&B) to fractionation column(33C04) which is further heated by (33E14), where the light aromatic is recycled back into (33C05) and the heavy aromatic is pumped by (33P09A&B) and are discharged as fuel to the heater. 36 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.2: process description for thermal hydro-dealkylation unit 37 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 4.3 PROCESS DESCRIPTION FOR HF-ALKYLATION UNIT The raw materials for this unit are benzene, olefin (alkyl group) and hydrofluoric acid, recycled hydrogen is preferred because it is sharper and more reactive. Benzene from THDA and recycled benzene and olefin from PACOL unit from the HF-Alkylation unit pass through heat exchanger (32E01A, B&C) to be heated, then to a trim cooler (32E02) for cooling. Water is pumped by (32P01) from water break tank (FA-70B) to mixed the fresh and recycled benzene. Hydrofluoric acid from drum (32D15) is added to the other raw materials and pass through trim cooler (32E03) to fractionating column (32C01) where 90% of the reaction takes place, the product then settles in drum (32D01). Since linear alkyl benzene is lighter it goes out from the top of (32D01), the HF acid goes out from the bottom based on density and physical properties. The HF acid is pumped by (32P01A,B&C) to column (32C02), some of the HF pass through a reboiler (32E04) to (32C03) for regeneration, the others are recycled back to (32C02). The stripper (32C03) called the regenerator is where hydrofluoric acid is regenerated, pure HF goes out from the top and heated by hot oil (32E06) and taking back into the system, HF from (32C03) enters into (32D03) a vent drum (receiver & stabilizer) then to (32D04) called the HF distributor from where the unwanted HF is sent to the flare. The linear alkyl benzene goes into (32DO2) for final settling and 10% reaction, water is introduced to create interface because it has high affinity for HF which easily dissolves in it. The bottom of (32C03) contain polymers, continuous boiling mixtures (CBM) and HF acid, benzene is sent into the column from the middle to create a partial pressure so that HF which has lower boiling point (300c) vaporises with benzene since temperature at the bottom of the column is 1200c. 38 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 The polymer and CBM goes into (32D09) and (32D10), the top product of (32D10) is taken as fuel gas to the heater. Bottom of (32D09) contain caustic which is used to bubble polymer into (32D10), pumps (32P15A&B AND 32D16A&B) is use to pump potassium hydroxide to (32CO8) and back to (32D10). HF and other products goes into (32D11) from the top of (32D09) in form of gas, (32D11) retain all the unwanted and unprocessed products in the HF- Alkylation unit, if it is filled up pressure relief valve open to send some into drum (32D12) and if that is filled up, it is send to (32C8). KOH enters (32D09) from the top counter currently to extract the HF from the mixture, the pure gas is sent to the flare and the liquid part to the eductor (32J01). The product from (32D02) is passed through (32E01A,B&C) to heat the raw material coming in and create a colour change due to change of phase in the product and goes into the stripper (32C04) where it is heated at the bottom by hot oil and a reboiler (32E08). The remaining HF acid goes out from the top to the vent drum (32D03) where it is treaded and sent to the flare. The product comes down to (32C05) called the benzene column, where the unreacted and polymerised benzene is removed from the top, passed through air fin cooler (32A01) to (32D06) called the off specification drum, then pumped by (32P06A&B) and heated by (32E10) to benzene drag tank. Some of the benzene are recycled back to (32C05) and to the benzene header. The bottom of (32C05) is pumped by (32P07A&B) to the paraffin column where paraffin is removed from the product by heating with hot oil and 39 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 sent to PACOL unit as start up by-pass, paraffin comes out and enters into (32D17) and some part is used to flush HF acid out of the pipes. The paraffin stored in (32D17) is pumped by (32P12A&B) though heat exchanger (32E13) to filters (32F01A&B) which filters the paraffin before sending it to flush the pipes through the flush header. The remaining paraffin is sent to paraffin recycled tank at PACOL. the incondensable gasses goes out from the top of to the ejector which is used to remove the gases from the vessels to (32D09), nitrogen and medium pressure steam is use to pressurize the gases and cooled by (32E17, 18 &19) before sending them to (32D07) as liquid, part of the gases are sent to heater (34H01) and the liquid from the bottom enters condensate to chemical sewer where they are neutralized by caustic. The product in (32C07) is heated with hot oil from the bottom and (32E14), the heavy alkylate goes out through the bottom to the heavy alkylate storage tank. The linear alkyl benzene comes out at the middle of the column moved by pumps (32P10A&B) through trim cooler (32E16) to the linear alkyl benzene storage tank. The product that those not meet specification is sent to the off specification tank. The light alkylate from the top is sent to light alkylate storage tank and some recycled. 40 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.3 process flow diagram for HF- Alkylation unit 4.4 OTHER PROCESS EQUIPMENT The main equipment used in LAB other than those that are mentioned and described before are as follows; Reactor Pump Valve Boiler Air Cooler/ condenser Trim Cooler Drum Compressor 41 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 4.4.1 REACTOR : A reactor is a container in which reaction takes place, in petrochemical section of KRPC, the reactors use are made up of high resistant materials that can withstand high temperature and resist corrosion, the reactors are usually connection in series to ensure maximum conversion and optimum yield. The reactors in most cases are located after the heaters or heating equipment. Fig 4.3: Reactor. 4.4.2 PUMP: A pump is a device which conveys fluid, chiefly liquid from a lower to a higher region or from a region of lower pressure to a region of higher pressure, if used to transport gases will cause cavitations. The two popular type of pumps used in petrochemical section are centrifugal and reciprocating pumps this is because it gives uniform and particular pumping rate, they are used to 42 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 transport chemicals, products and raw materials of precise amount and quantity, these pump are driven by either electric motor or steam turbine. Fig4.4: reciprocating pump. 4.4.3 VALVES: these devices which are used to regulate the flow, pressure, level and temperature of a fluid. Types of valves used in LAB are; gate valve, non-return valve, globe valve, control valve, pneumatic valves, and safety pressure valves and check valves. i. Gate valve is commonly used for isolating purposes or bypassing faulty equipment during operations. They are either fully open or closed. Control valves can be manually operated or by electrical means. They are used to control the operations condition of most equipment during operation 43 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.5: servicing valves 4.4.4 BOILER: Boiler is used to heat water (liquid) and required steam or hot water. Boiler is used in LAB department to heat the stripping steam and the fluids that will pre wash the equipment in restarting the plant during shut down. 4.4.5 TRIM COOLER: Trim cooler is a fixed-tube plate exchanger where water is used as temperature stabiliser medium. Trim coolers are normally placed downstream air coolers so that the product passed through them reaches a stable temperature. The reason is that air cooler are affected by weather conditions changes, while the trim cooler are not. 44 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 4.4.6 AIR FIN COOLER: The air cooler is an exchanger where forced air constitutes the cooling medium which passes externally through a bank of finned tubes in which hot fluid is being cold. Air coolers are widely used in refinery operations to cool products whose heat content cannot be economically recovered with heat exchangers, but must be removed for handling reasons. Fig4.6: air fin cooler. 4.4.7 CONDENSER: Condenser like trim cooler is a fixed-tube plate exchanger. Its main function is to condense condensable vapours by removing their latent heat. This type of exchanger is mainly used for top columns vapours which contains light hydrocarbons and in steam turbines for exhaust steam condensing 45 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.7: A condenser 4.4.8 DRUM: A drum is equipment used basically in petrochemical section of KRPC to separate products and store them temporarily. They are high pressure and low pressure drums. The high pressure drum uses high pressure to separate fluids and the low pressure drum uses low pressure to separate. Most of the drums have boot. A boot is capable of separated unwanted particles from the fluid and making more pure and less contaminated, it is usually situated at the bottom of the drum so the particles can easily be drained. 46 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.8: high pressure separator drum. 4.4.9 Compressor: a compressor is a device use to transport gases only; it compresses gases by decreasing their volumes and increasing their pressure, it motor transmit electrical signals to mechanical signals by the action of the piston in the motor of the compressor. In KRPC the compressors use are reciprocating compressors which operates using forward and backward action and has higher compressing ability, it has parts for compressing both makeup and recycled gases from a process It is made up of a suction side where gases enters and a discharge side where gases leave the compressor, it is designed such that the suction is larger than the discharge to create a differential pressure across the compressor, the compressor used has the capacity to compress hydrogen from 20kg/cm2 to 50kg/cm2 It operates under the following principles: 47 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Compressor ratio: ratio of suction to discharge. Charles law: pressure increases with increase in temperature as volume remains constant. Boyle’s law: as pressure increases, volume decreases at constant temperature. It follows the general gas law pv/c=constant. Compressor displacement. Compressors normally have four (4) parts: Distance peace Cylinder The crank shaft assembly Cross head Compressors usually have demisters that separate gases from liquids. 48 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Fig4.9: A typical compressor motor used in KRPC, LAB. 4.5.0 CALCULATIONS AND ANALYSIS OF EXPERIMENTAL AND RECORDED VALUES. 4.5.1 Calculation of volumes and other parameters of a reactor. To calculate the volumes of reactors (33R01A&B) and other parameters, having the following data for treated kerosene. Molar flow rate of kerosene Fk = 172.3 mol/hr Pressure at reactor P=70kg/cm2 = 70×98.07=6864.9N/m2 Temperature at reactor T= 3150c = 315+273=588k Expected conversion in reactor A, Xk=0.9 Expected conversion in reactor B, Xk1=0.1 49 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Equation of reaction C12H24S +2H2 = C12H26 + H2S with reaction rate -rk = 1.4C2k Implies reaction constant K=1.4. SOLUTION Fk0, Xk0 Fk0 -rk1, Ck0 XK1 Ck1 From material balance equation Input= output + disappearance + accumulation…………………………….. (1) For a continuous stir tank reactor (CSTR), accumulation = Input = F k 0 Output ¿ F k 0(1−X k ) Disappearance = (−r k )V So that F ko=F ko(1− X k )+(−r k )V ………………………… (2) Rearranging and equating, I have that X V = k F k 0 −r k ……………………………………………. (3) Similarly, X τ V = k= Ck0 rk F K0 …………………………………… (4) V c k 0 × Xk Ck 0− Kk τ= = = υ −r k −r k …………………………. (5) From the equation of reaction, 50 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) dNA =0 dt lOMoARcPSD|13198428 εk= 2−3 =-0.333 3 Since εk≠0, it is a varying volume case, so that Ck= Ck 0 (1−Xk ) (1+ εkXk) ……………………………….. (6) Since -rk = KC2k −r k=KC 2 k 0(1−x k ) 2 (1+εkXk )2 ……………………………… (7) From the ideal gas equation PV= n RT CKO= Pk 0 6864.9 mol = 8.314 ×588 =1.4 3 RT m Cko=1.4 J where R=8.314 mol/k mol 3 m Substituting equation 7 into equation 3 for -rk Xk V = F k 0 KC 2 k 0(1− x k ) 2 (1+εkXk )2 (1+ (−0.333 × 0.9 )) ¿ ¿2 ¿ ¿ 1.4 × 1.42 (1−0.9)2 ¿ V 0.9 = ¿ 172.3 V1=281.65 m3 Since the reactors are connected in series, the volume of the second reactor V2 can b calculated as shown below. Fk0, Xk0 Fk1, XK1 Fk2 51 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 -rk1, Ck0 -rk1 Xk2 Ck1 Ck2 Knowing that V 2 Xk 1 = F k 1 rk 1 …………………………………. (8) So that Ck 02 (1+ Xk )2 Ck1= (1+εk × Xk )2 ………………………… (9) Where Xk1=0.1 (1 ± (−0.333 × 0.1 )) ¿ ¿ Ck1= ¿ 1.4 2( 1−0.1)2 ¿ Ck1=1.7 mol m3 Also F k1=F k 0 (1−X k 1) …………………………… (10) And -rk1= KC 2 k 0(1−x k ) 2 (1+ εkXk )2 ………………………………... (11) =172.3(1-0.1) mol =155.07 hr From equation 8, making V2 the subject and substituting kX k 1 1+ε ¿ ¿ V2= ¿2 ¿ F k1 X K 1 ¿ ¿ ……………………. (12) 52 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 (1+ (−0.333 ×0.1 ) ) ¿ ¿ 2 V2= 155.07 ×0.1 ¿ ¿ ¿ V2=39.8 m3 Calculation of how temperature affects equilibrium conversion in the reactor and point maximum yield. Given the reaction between 00c to 3150c Assuming a homogeneous irreversible reaction A J ∆G0=-10280 mol B J ∆H 0=-24149 mol kJ Heat capacity of thiophene A, =1.01 K kJ Heat capacity of kerosene B, =2.01 K Solution Given the formula ∆ H r =∆ H r 1 + ∆C p (T 2−T 1) …………………….. (13) Where T 1 = 00c= 0 + 298 = 298K T 2 = 3150c = 315 + 298 = 613K ∆ H r = -24149 + (1.01-2.01)(631-298) ∆ H r = -24438 J mol Similarly ∆ G0=−RTIn K 298 …………………. (14) 53 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 ∆G 0 K 298 = е RT K 298 = е 10280/ 8.314 ×298 K 298 = 63.4 And 1 1 − T T 298 )………………………………… (15) InK −∆ H r ¿ = K 298 R 24439 24439 −¿ 8.314 T 8.314 ×298 K= 63.4 ¿¿ е¿ ¿ K= 63.4 е (¿ 2939.5 T −9.86) ……………………………… (16) ¿ From equilibrium conversion 1−X ¿ Ae ¿¿ ¿ ¿ K= ………………………….. (17) A 0¿ C¿ C R C A 0 X Ae = ¿ CA It implies that X Ae = K ………………………………………………….. (18) K +1 Table of value for the above formulas as temperature increases T(0c) T(K) K= 2939.5 — T X Ae = 9.86 25 298 63.4 54 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) 0.9845 K K +1 lOMoARcPSD|13198428 45 65 85 105 125 145 165 185 205 225 245 265 285 305 325 318 338 358 378 398 418 438 458 478 498 518 538 558 578 598 39.7 29.7 17.5 10.9 7.1 4.5 3.3 2.3 1.8 1.4 1.1 0.9 0.7 0.6 0.5 Table4.0 table of equilibrium conversion and rate constant 55 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) 0.9754 0.9674 0.9458 0.9158 0.8770 0.8167 0.7609 0.7007 0.6389 0.5776 0.5190 0.4652 0.4142 0.3693 0.3289 lOMoARcPSD|13198428 1.2 1 Temperature (K) 0.8 0.6 X 0.4 0.2 0 250 300 350 400 450 500 550 Equilibrium Conversion X Fig4.10: graph of temperature against conversion. 56 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) 600 650 lOMoARcPSD|13198428 4.5.2 Designing a mathematical model for the flow description To design a mathematical model equation for the description of kerosene and sour water in the reactor, since the reaction is irreversible and the some of the parameters were experimented and calculated to be as written below C K 0 =1 mol m3 C K 1 =1.4 mol m3 C K 2 =1.7 mol m3 τ 1 =12min τ r =3min equation of reaction K=1.4 K k R Where K = kerosene and k = rate constant SOLUTION Assumptions density of the fluid are constant the heat capacities of the fluid are constant V1 F+ F R V2 FR F CK 0 CK1 F CK2 Taking total material balance for component K. For reactor one F+ F R =F+ F R …………………………………… (19) For reactor two 57 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) CK2 lOMoARcPSD|13198428 F+ F R =F+ F R …………………………………… (20) Component balance for component k, in reactor one Accumulation = input – output – disappearance……………………. (21) V1 d CK1 dt = FC K 0 + (F+ F R ) C K 1 + F R C K 2 - V 1−r k 1 ……………………….. (22) Since it a first order irreversible reaction, −r k 1 = k 1 C K 1 ………… (23) Also if V F F = τ implies V 1 = τ ………………………. (24) Substituting equations (23) and (24) into equation (22) after dividing through by V 1 , the equation becomes d CK 1 dt 1 1 1 1 = τ C K 0 - τ C K 1 - τ C K 1 + τ C K 2 - K 1 C K 1 …………………… 1 1 R1 R1 (25) Collecting like terms and rearranging the equation and taking initial conditions 1 CK 0 i.e. τ 1 d CK 1 dt = constant, then 1 1 1 = -( τ + τ + K 1 ) + τ C K 2 ………………………………. (26) 1 R1 R1 Component balance for K, in reactor two V2 d CK2 dt = ( F+F R ) C K 1 - F R C K 2 - FC K 2 - V 2 K 2 C K 2 ……………. (27) Applying equation (24), dividing through by V 2 and rearranging the equation d CK 2 dt 1 1 1 1 = ( τ + τ ) CK1 - ( τ + τ ) CK2 2 R2 R2 2 ……………………………………… (28) Therefore equations (26) and (28) are the mathematical description for the above reaction. 58 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 4.5.3 Calculation of utilities around heat exchangers To calculate the heating and cooling utilities for the heat exchanger (33E01A&B) Using problem table method. Warm feed 3150c 1100c 1500c Hot product cold product 600c Cold feed Fig4.5.4 heat exchanger (33E01A) Hot feed 2800c 220 0c 40 0c Hot oil cold oil 1100c Warm feed Fig4.5.5 heat exchanger (33E01B) Streams items nature Ts (0C) Tt (0C) ∆H (KJ) Cp (KJ/0C) 1 kero/H2S Hot 315 150 66.3 0.4 2 hot oil hot 280 40 146 0.6 3 thiophene cold 110 220 63.7 0.6 4 thiophene/H cold 60 220 66.7 1.3 Using problem table method with ∆ T min = 100C 59 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 IF T*hot = T hot - ∆ T min ………………………….. (29) 2 And T*hot = T cold + ∆ T min …………………………….. (30) 2 The cascade of temperatures will be as shown below 310……………………………………… heat surplus QH =47kJ 275…………………………-14kJ…………..14 61 225…………………………-50kJ…………..64 111 145…………………………..72kJ…………..-8 41 115……………………………39kJ………..-47 0 65………………………………-10kJ…………-37 10 35…………………………………-18kJ……..-19 28 QC = 28kJ Calculating the amount heat in each cascade using the formula below εCpc ∆ H i=¿ - εCp h ) × ∆T i …………………………… (31) ∆ H 1 = (0 – 0.4) ×35 ∆ H 2 = (0 – 1) ×50 = -14kJ = -50kJ ∆ H 3 = (1.9 – 1) ×80 ∆ H4 = (1.9 – 0.6) ×30 = 39kJ ∆ H 5 = (0.4 – 0.6) ×50 ∆ H6 = 72kJ = -10kJ = (0 – 0.6) ×30 = -18kJ Pinch temperature of the hot stream = 1200C Pinch temperature of the cold stream = 1100C 60 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 The heat exchanger networking will be as shown below 11 3150C 1200C 1500C 2 2800C 1200C 400C 2200C 1100C 2200C 1100C 60 0C Considering the section above the pinch 11 3150C 1200C 2 2800C 1200C 2200C 1100C 2200C 110 Amount of heat in each item is calculated using ∆ H i = Cp × ∆T i ∆ H 1 = 0.4 ×195 = 78kJ ∆ H 2 = 0.6 ×160 = 96kJ ∆ H 3 = 0.6 ×110 = 66kJ ∆ H4 = 1.3 ×110 = 154kJ Interval temperatures will be 78 = 1.3 (T-110) implies T = 1700C 21 = 0.6 (T-110) implies T = 1450C Considering the section below the pinch 61 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 1200C 1500C 1200C 400C 1100C ∆ H 1 = 0.4 ×30 = 12kJ ∆ H 2 = 1.0 ×80 = 80kJ ∆ H 3 = 1.3 ×50 = 64kJ 4 Interval temperature will be 52 = 0.6 (T-40) implies T = 1270C Using the rule CpH ≤Cpc for section above the pinch and CpH ≥Cp c for section below the pinch, the networking using Grid diagram will b as shown below. 11 3150C 1200C 2 2800C 1200C 22 QH =47kJ 2200C 75kJ 21kJ 78kJ 1500C 400C 1100C 12kJ Q C =28kJ 52kJ So that The heating utility required = 47kJ The cooling utility required = 18kJ 62 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) 1100C 600C lOMoARcPSD|13198428 4.5.4 Material balance calculation To take the material balance around the fractionation column (33C01) Feed is kerosene, K Top product is naphtha, N Bottom product is sour water, S Middle product treated kerosene, P Overall material balance K = N + S + P…………………………………….. (32) Component balances 63 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Kx = Ny + Sz + Pl………………………….. (33) 4.6: PROBLEMS UNCOUNTED During my industrial training in KRPC, some problems were encountered which include:i. Limited supply of safety wear to the training students such as helmets, safety boots, overall and hand gloves which are not affordable ii. Another problem encountered was the hazardous environment which one was exposed to, which were dangerous to health iii. Most of the sections in LAB department are not working, so practical knowledge of the sections was limited. iv. Transportation is also difficult since the refinery is far from where I stay and KRPC transportation does not have a particular pickup time. v. CAVITATION: This is a process whereby air is present in the impeller chamber of a pump that is not design to pump air which could result to overheating and malfunctioning, sometime could lead to the burning of the electric motor of the pump this is because of low level of fliud in tank or as a of leakages 4.7 i. POSSIBLE SOLUTIONS Adequate safety wear should be made available in order to avoid accident within the plant. ii. Most skill operator are expected to acquire both physical and chemical knowledge of the entire process, this will create a more secured environment for both industrial trainees and the operators working within the plant. 64 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 iii. Proper housekeeping should be carried out at regular interval to avoid exposure to harmful substances and provide a work free environment. iv. The LAB section should be made working to capacity since it’s a profitable venture and will solve most of Nigeria’s petrochemical problems CHAPTER FIVE 5.0 SUMMARY In KRPC, production department, the petrochemical (LAB) section is charged with the sole aim of producing linear alkyl benzene used in making liquid and powdered detergents of all kind. The basic raw materials are kerosene, reformate and hydrogen all from the refinery. Several processes are involved in producing LAB. elements like sulphur, chlorine, nitrogen, oxygen etc. are removed from the kerosene in the hydro-desulphurization unit(HDS) to produce 65 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 treated kerosene through heating(300-3500c) in the presence of a catalyst(molybdenum alumina), the branched chain attached to the kerosene is removed in the molecular extraction unit(MOLEX) to produce linear paraffin(saturated hydrocarbons) and a by-product called kero-solvent through heating(300-4500c), using dehydrogenation process the linear paraffin is converted to linear olefin(unsaturated hydrocarbons) at (170-180 0c) in the presence of platinum based catalyst, in the THDA unit, reformate is converted to benzene at (80-900c) through heating(650-7000c) with by-products like toluene, ethyl benzene and medium pressure steam, the olefin and benzene then combine in the HF-Alkylation unit to yield linear alkyl benzene in the presence of hydrofluoric acid as catalyst, with by-products like hydrofluoric acid, polymers, light and heavy alkylates. All the units produce light and heavy naphtha as by-product too. 5.1 CONCLUSION During my period of attachment at the petrochemical section of KRPC production department I was able to understand most of the unit operations and unit processes in the section, I understood each unit their major importance and the products each unit produces. The major raw materials, processes involved and the final products were also understood. 66 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 Furthermore, the operating conditions such as temperature, pressure, and flow rate for the refining process are also factors that have a great influence on the products yield and quality. V.2 RECOMMENDATION The Kaduna Refining and petrochemical Company is an integrated refinery for the production of a wider variety of petroleum products such as lubricating oil, kerosene, petrol, Automotive Gas Oil (AGO) in the refinery section and linear alkyl benzene, benzene, kero-solvent, alkylate, polymers, naphtha ( etc.) in the petrochemical section. In view of the above, the following recommendations are made. 1. For better productivity, operator of plants should be given proper orientation on the plant and the job in general before they commence work. 2. For proper and accurate identification of faults, the company should make sure they make use of fault detection equipments. 3. There should be adequate staffing that is, scrutanization should be made to actually employ those who know the job and can do it effectively and efficiently. 4. There must be strict adherence to operating conditions for better yield and high quality products. 5. Regular biennial Turnaround Maintenance (TAM), as is the industry standard 6. Provision of adequate PPE esp. to SIWES students to safeguard their health and safety. REFERENCES Chiyoda Corporation (1983). Area1 Operational Manual for hydro-desulphurization. Chiyoda” 1979 LAB Operational Hand Book, on all units of LAB. 67 Downloaded by Fisayo Bami (swordsaint819@gmail.comh) lOMoARcPSD|13198428 John J. McKetta Jr (1992). Petroleum Processing Handbook, CRC Press. James G. Speight, Baki Ozum (2001). Petrochemical Refining Processes, CRC Press Chemical Engineering Coulson Richard Son Volume one 3rd Edition. J. H Hong (1992) Quality Control and Monitoring Manual. “KRPC NEWS” Vol.3, No.4 Chiyoda Chemical Engineering Company Lecture received from my Industrial Supervisor and other operators. Octave Levenspiel (2006). Chemical Reaction Engineering third edition Plant Design and Economics for Chemical Engineers. Max. S. Peters Klaus. D. Timmerhaus. 4th Edition. Process safety by Stanley M. Englund, M.S, Ch. E, Fellow, American Institute of Chemical Engineers page 26-59. Surinder Parkash (2003). Refining Processes Handbook. WWW. Google.com/ unit Operation for Chemical Engineers accessed 18/09/2011. WWW. Google.com siwes in Nigeria accessed 20/08/2011. 68 Downloaded by Fisayo Bami (swordsaint819@gmail.comh)