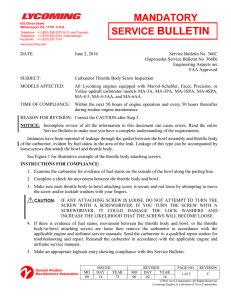

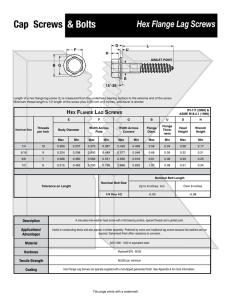

Technische Information 26.2001 Model HS 45 Hedge Trimmers – Series 4228 Contents 1. Gearbox (Gasket) 2. Handlebar with Hand Guard 3. Carburetor with LD Screw (Flange and End Cover Mounting) 4. Model Update Package 4.1 Carburetor with 3 Adjusting Screws 4.2 Spacer Flange, Tensioner 4.3 Filter Housing (Choke Shutter), Filter Cover 4.4 Ignition Module, Crankshaft 4.5 Summary 1. Gearbox (Gasket) The previous gasket 4228 649 0300 (0.5 mm thick) installed between the gearbox cover und gearbox will be replaced by the new gasket 4228 649 0302 (0.75 mm thick). 253TI000 KN Modification to be introduced – see Summary. Summary Item 1 1 Part Name Previous New Remarks Gasket (0.5 mm) Gasket (0.75 mm) 4228 649 0300 --- --4228 649 0302 1) Modification to be introduced – USA production: from serial number 2 51 134 557 Remarks 1) Previous version of part is no longer available from factory TI_26_2001_02_01_01.fm deutsch Seite 2 2. Technische Information 26.2001 Handlebar with Hand Guard The previous handlebar (front handle) with hand guard 4228 791 0100 will be replaced by a fully interchangeable version 4228 791 0101 in order to further optimize component strength. Summary Item 1 Part Name Previous New Remarks Handlebar with hand guard 4228 791 0100 4228 791 0101 1) Remarks 1) Previous version of part is no longer available from factory 3. Carburetor with LD Screw (Flange and End Cover Mounting) 1 2 A new C1Q-S54 carburetor 4228 120 0601 is now available. Four identical screws are now used to secure the end cover and flange as an assembly – instead of the previous separate arrangement with 2 short and 2 long screws. 1 2 The previous carburetor 4228 120 0600 has been deleted. 3 4 5 6 6 7 7 Parts availability 253TI001 KN 3 Left: Carburetor 4228 120 0600 Right: Carburetor 4228 120 0601 The new versions of the end cover and flange can only be used together. Use the new flange 4140 120 2250 for repairs to previous carburetors. This replacement flange comes with the end cover, gasket, metering diaphragm, 4 new mounting screws and illustrated instructions. The new flange and end cover are available as separate items for repairs to the new version of the carburetor. TI_26_2001_02_01_01.fm Technische Information 26.2001 Seite 3 Summary Item 1 2 3 4 5 6 7 8 Part Name Previous New Remarks Carburetor C1Q-S49B; including items 1 to 4, 6, 7: Carburetor C1Q-S54; including items 1, 2, 5 to 7: Screw End cover Screw (2x) Flange Flange Metering diaphragm Gasket Flange; including items 1, 2, 5 to 7 4228 120 0600 --- 1) --- 4228 120 0601 4226 122 7100 4226 121 0800 1128 122 7100 4226 120 2200 --4129 121 4700 1129 129 0900 --- 4226 122 7100 4140 121 0800 ----4140 120 2200 4129 121 4700 4129 129 0902 4140 120 2250 2) 3) 3) 3) 3) 4) Remarks 1) Previous version of part is no longer available from factory 2) Quantity changed from 2 to 4 3) Previous version of part remains available for other models 4) Replacement part for carburetor 4228 120 0600 4. Model Update Package Modifications will come on line in the near future to further optimize functionality. The parts and assemblies affected (carburetor with 3 adjusting screws, spacer flange, tensioner, filter housing, filter cover, ignition module, crankshaft) are described in chapters 4.1. to 4.5. 4.1 Carburetor with 3 Adjusting Screws The carburetor 4228 120 0601 discussed in chapter 3 (BIS* carburetor with LD screw) will be replaced by the new version 4228 120 0603 (with H, L and LA screws). The new carburetor’s high speed screw is equipped with a cap to limit its range of adjustment. The low speed screw and idle speed screw are also equipped with funnel-shaped caps to ease access to the adjustment screws. 392TI033 KN *BIS = Balanced Idle System Left: Previous carburetor with LD screw Right: New carburetor with H, L and LA screws 4.1.1 Construction TI_26_2001_02_01_01.fm Seite 4 Technische Information 26.2001 4.1.3 Repairs / servicing 1 4 2 . Low speed screw (1) . High speed screw (2) . Limiter cap for high speed screw (3) . Stop pin (4) 392TI036 KN 392TI034 KN 3 The limiter cap has to be removed from the high speed screw to replace a damaged high speed screw or clean the carburetor. . Use suitable pliers to pull off the cap. Do not re-use caps because they may be damaged during removal. 4.1.4 Adjustment after repairs / servicing Check the air filter and clean or replace as necessary. . Check spark arresting screen and clean or replace as necessary. 295TI012 KN . The cap is pushed over the knurled head of the adjusting screw. The stop pin (see arrow) in the carburetor body serves to limit adjustment. 4.1.5 Standard setting of H screw (without cap) 4.1.2 Function 392TI037 KN H 392TI035 KN 270° . Starting with the screw lightly against its seat: Open high speed screw (H) 1 1/2 turns. The pin limits rotation of the cap and thus the range of adjustment of the high speed screw to 270 degrees (3/4 turn). TI_26_2001_02_01_01.fm Technische Information 26.2001 Seite 5 4.1.9 Setting instructions for users 4.1.6 Installing the cap The user may adjust the carburetor’s high speed screw within a range of 270 degrees. This enables the user to make the mixture leaner if necessary, e.g. for operation at high altitude. H 392TI038 KN The procedure for setting the new carburetor is as described in the owner’s manual (see chapter "Adjusting the Carburetor"). Caps that have been removed once must not be re-used because they might be damaged. . Position new cap for high speed screw (H) so that it is in line with "rich" stop (arrow). . Push cap home as far as stop against carburetor body. 4.2 Spacer Flange, Tensioner The previous spacer flange 4140 121 1600 will be replaced by the new version 4140 121 1605 when the new carburetor is introduced (chapter 4.1). The surface structure of the new spacer flange has been designed for optimized fuel/air intake flow. 253TI002 KN 4.1.7 Adjusting idle speed L Tensioner 4140 182 7600 (with pin and push nut) Right: Tensioner 4140 182 7602 LA 295TI017 KN Left: Starting with the screws lightly against their seats: . Open low speed screw (L) one full turn counterclockwise. . Use idle speed screw (LA) to set engine speed to 2,800 RPM. This adjustment must be checked with a tachometer. 4.1.8 Checking running behavior . Open the throttle several times to check that engine accelerates smoothly. Engine must run smoothly at idle speed. TI_26_2001_02_01_01.fm The previous tensioner 4140 182 7600 will be replaced by tensioner 4140 182 7602. The new tensioner runs on the spacer flange’s integral pivot pin (see arrow). Therefore, the bearing pin 4137 123 8900 and push nut 9417 003 7512 are no longer required and have been deleted. Seite 6 4.3 Technische Information 26.2001 4.4 Filter Housing (Choke Shutter), Filter Cover Ignition Module, Crankshaft Modified versions of the filter housing, choke shutter and the filter cover will be installed at the same time as the new carburetor described in chapter 4.1. L 1 253TI004 KN H 3/4 253TI003 KN LD The positon of the hinge on the filter housing and filter cover has been moved (see arrows) to allow access to the adjusting screws of the new carburetor. The symbols for setting the new carburetor are marked on the new filter cover. In addition, a modified choke shutter has been installed. Parts availability Filter cover 4228 141 0500 remains available as a spare for HS 45 machines with carburetor 4228 120 0600 / 0601 (BIS carburetor with LD screw). Position of slot for flywheel Left: Crankshaft 4228 030 0400 Right: Crankshaft 4228 030 0402 Ignition timing and cut-off speed range have been optimized. For this reason the previous ignition module 4140 400 1300 has been replaced by ignition module 4140 400 1302 and a new crankshaft. Compared with the previous version, the position of the key slot for the flywheel has been changed on the new crankshaft 4228 030 0402 (see arrows). Service note In case of a repair, only the new versions of the parts may be used for HS 45 machines with carburetor 4228 120 0603. The new filter housing 4228 140 2850 must be used as a replacement for all HS 45 machines – irrespective of the carburetor version. The replacement part includes the filter and prefilter as well as the new replacement filter cover 4228 141 0502. Since there are no setting symbols on this filter cover, it can be used as a universal replacement. The modified choke shutter is made from orangecolored plastic so that it can be easily distinguished from the previous choke shutter (black). TI_26_2001_02_01_01.fm Technische Information 26.2001 4.5 Item Seite 7 Summary Part Name Previous New Remarks 1 2 Carburetor C1Q-S54 Carburetor C1Q-S67 4228 120 0601 --- --4228 120 0603 1) 2) 3 4 5 6 7 4140 121 1600 4140 182 7600 4137 123 8900 9417 003 7512 --- 4140 121 1605 4140 182 7602 ----4228 140 2850 1) 3) 1) 1) 4) 4140 140 2800 -*- 5) 6) 9 10 11 12 13 14 Spacer flange Tensioner Pin Push nut Filter housing; including items 8 to 14: Filter housing; including items 9 to 11: Lever Choke shutter Push nut Filter Prefilter Filter cover 4140 141 3700 4140 141 3800 9417 003 7512 4140 124 2800 4228 124 1500 4228 141 0500 4140 141 3700 4140 141 3801 9417 003 7512 4140 124 2800 4228 124 1500 4228 141 0502 15 16 Crankshaft Ignition module 4228 030 0400 4140 400 1300 4228 030 0402 4140 400 1302 8 1) 1) 1) 1) Modification to be introduced: in progress Remarks 1) Previous version of part remains available as spare for older machines 2) For component parts see illustrated parts list 3) Previous version of part will be supplied from factory only as long as existing stocks last 4) Use part as replacement for previous and new versions of filter housing 5) Previous version of part will not be available when modification is introduced 6) New version of part not available as separate item (use item 7 as replacement) Last Technical Information on model HS 45: 44.1999 © 2001 Andreas Stihl AG & Co. Waiblingen TI_26_2001_02_01_01.fm Technical Documentation D1/MTK-sc 7317