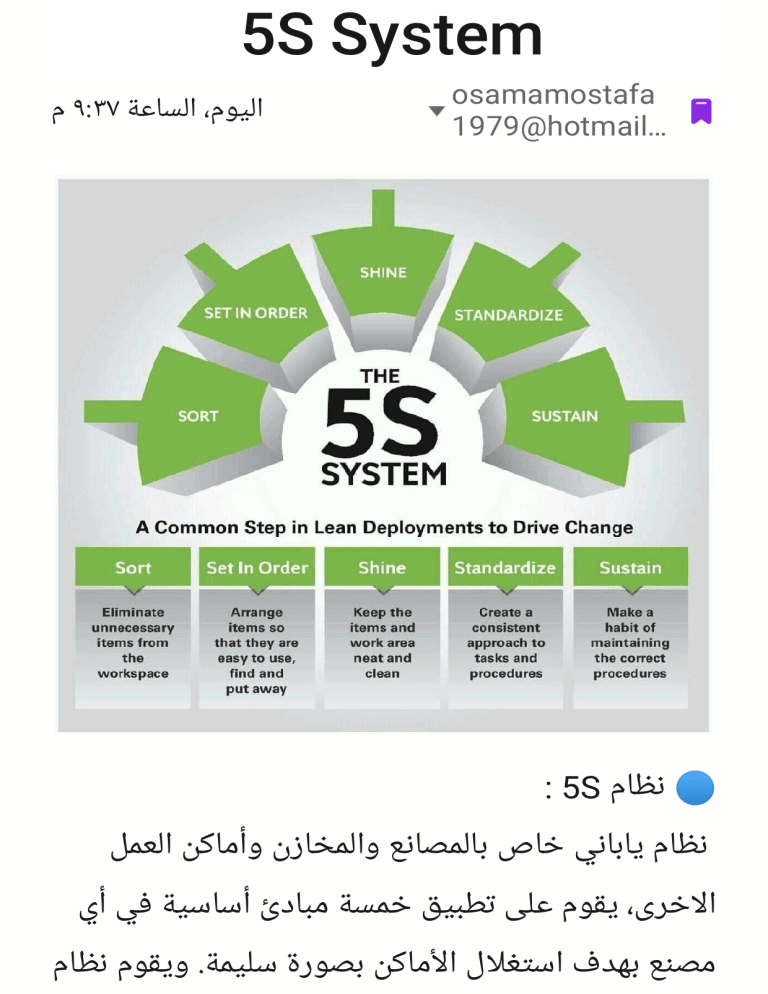

5S System: Lean Manufacturing Principles

advertisement

5S System osamamostafa …1979@hotmail 🔵 اﻟﻴﻮم ،اﻟﺴﺎﻋﺔ ٩:٣٧م ﻧﻈﺎم : 5S ﻧﻈﺎم ﻳﺎﺑﺎﻧﻲ ﺧﺎص ﺑﺎﻟﻤﺼﺎﻧﻊ واﻟﻤﺨﺎزن وأﻣﺎﻛﻦ اﻟﻌﻤﻞ اﻻﺧﺮى ،ﻳﻘﻮم ﻋﻠﻰ ﺗﻄﺒﻴﻖ ﺧﻤﺴﺔ ﻣﺒﺎدئ أﺳﺎﺳﻴﺔ ﻓﻲ أي ﻣﺼﻨﻊ ﺑﻬﺪف اﺳﺘﻐﻼل اﻷﻣﺎﻛﻦ ﺑﺼﻮرة ﺳﻠﻴﻤﺔ .وﻳﻘﻮم ﻧﻈﺎم 5Sﻋﻠﻰ ﻣﺒﺎدئ ﺧﻤﺴﺔ وﺗﺒﺪأ ﻛﻠﻤﺎﺗﻬﺎ ﺑﺤﺮف ) (Sوﺑﻠﻐﺔ اﻟﻌﺮﺑﻴﺔ ﺗﻌﺮف اﻟﻤﺒﺎديء ﺑﺎﻟﺘﺎءات اﻟﺨﻤﺲ وﻫﻲ : .١اﻟﺘﺼﻨﻴﻒ )🚥 (Sorting : ﻳﻬﺪف اﻟﺤﺪ ﻣﻦ اﻟﻤﻮاد اﻟﺘﻲ ﻻ ﺗﻨﺘﻤﻲ اﻟﻰ ﻣﻜﺎن اﻟﻌﻤﻞ اﻟﻤﺄﺧﻮذة ﻣﻦ اﻟﻤﻮاد اﻟﻐﻴﺮ ﺿﺮورﻳﺔ وﻟﻠﺤﺪ ﻣﻨﻬﺎ ﻛﺎﻻدوات اﻟﻤﻜﺴﻮرة واﻟﻐﻴﺮ ﻣﺴﺘﺨﺪﻣﺔ. .٢اﻟﺘﺮﺗﻴﺐ) 🗃 (Set in order : ﻳﻮﻓﺮ ﻣﻦ اﻟﻮﻗﺖ اﻟﻼزم ﻟﻠﺒﺤﺚ ﻋﻦ اﻷﺷﻴﺎء ،ﺑﺘﺤﺪﻳﺪ إﺳﺘﺮاﺗﻴﺠﻴﺔ ﺗﺨﺰﻳﻦ ﻣﻨﻄﻘﻴﺔ رﻓﻮف اﻟﺘﺨﺰﻳﻦ واﻟﻜﺒﺎﺋﻦ )ﻣﻜﺎن ﻟﻜﻞ ﺷﺊ وﻛﻞ ﺷﺊ ﻓﻲ ﻣﻜﺎﻧﻪ(. .٣اﻟﺘﻠﻤﻴﻊ )🌟 (Shining : وذﻟﻚ ﺑﺘﻨﻈﻴﻒ اﻷوﺳﺎخ ﺑﺼﻮرة ﻣﺴﺘﻤﺮة واﻟﻔﺤﺺ ﺧﻼل اﻟﺘﻨﻈﻴﻒ اﻟﻤﺴﺘﻤﺮ واﻟﻤﺘﺎﺑﻌﺔ اﻟﻴﻮﻣﻴﺔ ﻣﻦ أﺟﻞ ﺑﻴﺌﺔ ﻋﻤﻞ ﻧﻈﻴﻔﺔ ﺗﺠﻌﻞ اﻟﻌﻤﺎل ﻳﺸﻌﺮون ﺑﺎﻟﻔﺨﺮ ﻓﻲ اﻟﻌﻤﻞ ﻓﻴﻬﺎ. .٤اﻟﺘﻨﻤﻴﻂ) 📝 (Standardizing : وذﻟﻚ ﺑﺠﻌﻞ ﻛﻞ أﻣﺎﻛﻦ اﻟﻌﻤﻞ ﻣﻮﺣﺪة ﻟﻜﻲ ﺗﺠﻌﻞ ﺧﻄﻮات اﻟﻌﻤﻞ اﻷﺳﺎﺳﻴﺔ واﻟﻌﻤﻠﻴﺎت اﻟﻐﻴﺮ ﻃﺒﻴﻌﻴﺔ واﺿﺤﺔ .ﻓﺒﻌﺪ أن ﻗﻤﺖ ﺑﺘﻄﺒﻴﻖ اﻟﺨﻄﻮات اﻟﺜﻼث اﻟﺴﺎﺑﻘﺔ ﻓﺈﻧﻪ ﻳﺠﺐ ﻋﻠﻴﻚ اﻵن أن ﺗﺮﻛﺰ ﻋﻠﻰ ﺗﻮﺣﻴﺪ ﺻﻮرة اﻟﻌﻤﻞ وﺗﻄﺒﻴﻖ أﻓﻀﻞ اﻟﻤﻤﺎرﺳﺎت ﻓﻲ ﻣﻜﺎن اﻟﻌﻤﻞ. .٥اﻟﺘﻌﺰﻳﺰ )⚙ (Sustaining : ﻓﻲ ﻫﺬه اﻟﺨﻄﻮة ﺗﻄﺒﻖ اﻟﻘﻮاﻧﻴﻦ وﺗﺪﻣﺞ ﻓﻲ ﻋﻤﻞ اﻟﺸﺮﻛﺔ ﺣﺘﻰ ﺗﺼﺒﺢ ﻋﺎدات ،وﻳﻤﻜﻨﻨﺎ اﻟﻘﻮل ﺑﺄن ﻫﺬه اﻟﺨﻄﻮة ﺗﻌﺘﺒﺮ اﻷﺻﻌﺐ ﻓﻲ اﻟﺘﻄﺒﻴﻖ واﻟﻮﺻﻮل إﻟﻰ ﻧﺘﻴﺠﺘﻬﺎ اﻟﻤﺮﺟﻮة ﺗﺮﻛﺰ ﻫﺬه اﻟﺨﻄﻮة ﻋﻠﻰ ﺗﻌﺮﻳﻒ ﺑﻴﺌﺔ اﻟﻌﻤﻞ اﻟﺠﺪﻳﺪة وﺗﻮﺣﻴﺪ اﻟﻌﻤﻠﻴﺎت. 5S is a lean manufacturing approach which is easiest to understand and most difficult to implement based on the Toyota Production System 5S is one of the first tools that can be applied in a company that is starting down the path of the continuous improvement culture. A 5S implementation helps to define the first rules to eliminate waste and maintain an efficient, safe, and clean work environment. 5S is a lean manufacturing approach which is easiest to understand and most difficult to implement Sort, set in order, shine, standardize sustain: aworkplace discipline used to ensure reliable work practices and a clean working environment 1S:Sort The first step requires staff to remove all unnecessary items from the facility. This step requires eliminating items that are not needed. These unnecessary items create clutter and waste time, because they must be sorted through or moved around to find the tool or piece of equipment that is needed at the moment. In addition, unnecessary equipment creates a sanitation issue because it is difficult to clean a cluttered, full area 2S: Set in Order After the excess items in the facility have been disposed of, the next step requires the establishment of a storage location for all remaining items. Reexamine work areas and consider where to place items to and consider where to place items to decrease wasted motion and travel to utilize and store the item. Searching endlessly for an item is the old way of doing things 3S: Shine This step is about repairing or fixing any tools and equipment, as well as thoroughly cleaning everything. Sometimes this step is called the "Safety step" because it eliminates many potential slips, trips, and falls, which are among the leading causes of injuries in a manufacturing facility. It is essential to review and update master sanitation schedules to accommodate the new work area practices 4S: Standardize This step is about ensuring that the work area stays in tip-top shape. The area stays in tip top shape. The standardization step encourages repeatability, lack of variation, and accountability. Document the best practices so that new standards can be communicated to all affected employees including through training . 5S: Sustain The "Sustain" step can be the most difficult of the 5S. The primary goal in this step is that the new methods have become the habit, and the gains are able to be sustained. It is easier to maintain and keep focus when the 5S project is current and everyone is thinking about it The 5S system has many benefits, including Process and product efficiencies, lessdowntime, and decreased waste Decreased storage and inventory- Increase in safety and decrease in injuries,Increase in morale and job satisfactionwith employees feeling empowered Eng. Osama Mostafa