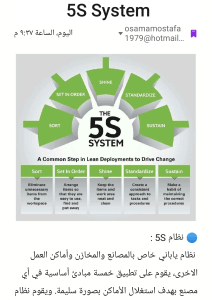

5S In-Depth 5S is a workplace organization technique composed of five steps. 1 2 3 Set In Order Sort Shine Standardize Sustain Sort Keep only necessary items in the workplace. Principles Examples Review tools, parts, & instructions Obsolete/expired procedures Keep only what is essential Defunct/old equipment Damaged/expired inventory Eliminate anything that is non-essential 1 Set In Order 2 3 Arrange items to promote efficient work flow. Principles Examples Arrange items in a logical order Excess movement Indicate places for each item clearly Excess transportation Keep each item close to where it will be used Over production Over processing Excess inventory Excess delays Defects Shine Clean the work area so it is neat and tidy. Principles Examples Make cleaning a part of daily work Dirty tools & equipment Assign areas of responsibility Clutter & mess Spills & leaks Return all items or files to their assigned place Standardize Set standards for a consistently organized workplace. Principles Examples Create standards for Sort, Set In Order, and Shine Work instructions Make standards easy to understand with Visual Controls Equipment/tool labels Assign and educate on individual responsibilities Hazard warnings Process diagrams Sustain Maintain and review standards. Principles Examples Measure and monitor process Emphasize cooperation Address root causes and avoid reversion to the “old ways” Communicate clearly Promote individual feedback and response for improvements Support innovation © Copyright 2016 GoLeanSixSigma.com. All Rights Reserved.