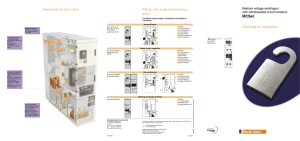

MCset 1-2-3 Medium Voltage Switchgear Withdrawable circuit breaker 17.5 kV User manual MCset Contents General 2 General description 4 Instructions for access to the inside of a cubicle 11 Glossary Symbols Recommendations Standard tightening torques 2 2 3 3 Warning for readers AD cubicle TT1, TT2 cubicles CL-GL cubicles RHB, RHC cubicles Withdrawable mobile part Identification Read the inscriptions on the front panel 4 4 5 5 6 6 9 9 AD cubicle Removing front protection cover plates Removing the MV compartment separation sheet Removing the manhole sheet Removing and inserting fixed or withdrawable VTs Access to lower compartment (cables, CT, earthing switch, surge arresters) Accessing busbars Accessing plug-in pins 15 15 16 Installation and operation recommendation 17 Steps for the tests 18 Operating Instructions 20 Corrective maintenance 36 Voltage presence on MV cables MV cable tests 18 18 Extracting or inserting the mobile part Plugging in the mobile part Withdrawing the mobile part Closing the earthing switch Opening the earthing switch Plugging in VT fuses Withdrawing VT fuses Padlocking and preventing access using padlocks Locking using locks (option) Locking using an electromagnet (option) Forward Summary table Replacement of VT compartment fuses Replacing of a voltage indicator box Replacing the fans on 3600 A/ 4000 A cubicles Replacing the capacitor Putting back the new capacitor Schneider Electric 11 12 13 14 14 20 24 25 26 28 30 31 32 34 35 36 36 37 40 41 41 42 07897302EN indice: C0 - General Glossary Note: this document is available for all the MCset 1-2-3 units ordered from the 1st of March 2006. UF Functionnal Unit (cubicle + mobile part + Sepam) AD Incomming / outgoing cubicle CL-GL Withdrawable line coupling cubicle TT Measurement and busbar earthing cubicle RHB Bus riser cubicle through the top RHC Cable riser cubicle through the top MTP transition panel between an MCset cubicle and a MOTORPACT cubicle DI Fuse switch outgoing cubicle TT Voltage transformer TC Current transformer or current sensor VPIS Voltage Presence Indicating System LV Low voltage MV Voltage class, including levels 7.2 - 12 and 17.5 kV SMALT Earthing switch Mobile part Symbols SMALT operation LF Withdrawable circuit-breaker with SF6 breaking which is used in AD and CL cubicles Rollarc 400 SF6 breaking withdrawable contactor equipping the AD1 cubicle EVOLIS Withdrawable circuit-breaker with vacuum breaking which is used in AD and CL cubicles CTV1 Vacuum breaking withdrawable contactor equipping the AD1 cubicle ERT Rack-in or rack-out and removal tool of the mobile parts on the ground Extraction table Extraction or insertion table without the removal tool of the mobile parts on the ground Plug-in prevention position. Locking possible. Plug-in or withdrawal position. Operation position. Open earthing switch mechanical indicator light. - 07897302EN indice: C0 Schneider Electric General Closed earthing switch mechanical indicator light. Position can be locked using paslocks. Operation position. Mobile part operation “Plugged-in” position. “Withdrawn” position. Insertion / extraction position. Recommendations It is necessary to have a height of ceiling H u 2.80 m to install a tunnel. Height (H) of ceiling for installation of an anti-arc or IPX1 tunnel Installation above the switchboard All type of equipment installation such as lamp or light are forbidden. It is compulsory forbidden to walk on the parts bearing this marking. Marking It is compulsory forbidden to remove the parts bearing this marking when the equipment is energised. Standard tightening torques (non greased screws and bolts) Schneider Electric Screw Torque in Nm Application methods: Ø 6 13 Ø 8 28 Ø 10 50 The elastic washers placed on the external sides of the pads and busbars ensure better distribution of stress regarding screws tightened to the recommended torques. Ø 12 75 Ø 14 120 07897302EN indice: C0 - General description Warning for readers As the MCset range is very extensive and presents a vast number of front panel options, we have decided to present a Functional Unit presentation equipped with the maximum switchgear. AD cubicle AD1 630/1250 A AD2 630/1250 A AD3 2500/3150/3600/4000 A Incomer/outgoer without VT or with fixed VT Incomer/outgoer with withdrawable VT fuses A: LV compartment door B: protection, monitoring, control by Sepam C: compartment door mobile part D: position inspection windows of the mobile part E: operation and locking plate of the mobile part F: voltage indicators G: earthing switch operation and locking plate and padlocking of the mobile part H: access panel to connection compartment of MV cables or withdrawable VT fuses J: visualisation windows of cables or of VT fuse position K: operation and padlocking plate of withdrawable VT fuses L: fan compartment (on 3600 A / 4000 A) M: cable compartment (on 3600 A / 4000 A) - 07897302EN indice: C0 Schneider Electric General description TT1, TT2 cubicles A: B: D: F: G: H: J: K: L: Voltage transformers with withdrawable fuses Voltage transformers without VT or with fixed VT LV compartment door protection, monitoring, control by Sepam visualisation windows voltage indicators earthing switch operation and locking plate and padlocking of the mobile part access panel to connection compartment of MV cables or withdrawable VT fuses visualisation windows of cables or of VT fuse position operation and padlocking plate of withdrawable VT fuses compartment door fixed busbar bridge. CL-GL cubicles Circuit-breaker coupling cubicle Bus riser cubicle With upstream and downstream VT with withdrawable fuses A: B: C: D: E: F: G: J: L: M: N: P: LV compartment door protection, monitoring, control by Sepam compartment door mobile part position inspection windows of the mobile part operation and locking plate of the mobile part voltage indicators earthing switch operation and locking plate and padlocking of the mobile part visualisation windows of cables or of VT fuse position access panel to withdrawable VT fuses and to the lower busbar compartments operation and padlocking plate of withdrawable VT fuses compartment door fixed busbar bridge fan compartment (on 3600 A / 4000 A) Schneider Electric 07897302EN indice: C0 - General description RHB, RHC cubicles RHB1, RHC1 630/1250 A RHB2, RHC2 630/1250 A RHB3, 2500/3150/3600/4000 A RHC3, 2500/3150 A A: B: C: D: E: F: G: H: J: K: L: M: LV compartment door protection, monitoring, control by Sepam compartment door mobile part position inspection windows of the mobile part operation and locking plate of the mobile part voltage indicators earthing switch operation and locking plate and padlocking of the mobile part acces panel to the busbars or to the withdrawable VT fuses visualisation windows of cables or of VT fuse position operation and padlocking plate of withdrawable VT fuses connection through the top using busbars (RHB) or cables (RHC) fan compartment (on 3600 A / 4000 A) Withdrawable mobile part LF1 - 07897302EN indice: C0 Schneider Electric General description LF2 LF3 Disconnector carriage Note: available in 3 widths. Busbar earthing carriage on circuit-breaker base Note: option available in 3 widths. Schneider Electric 07897302EN indice: C0 - General description ROLLARC 400 CTV1 Evolis Note: available in 3 widths. Busbar earthing carriage on Evolis base Note: available in 3 widths. - 07897302EN indice: C0 Schneider Electric General description Identification Ex : AD functional unit A: name of the cubicle B: manufacturer’s label C: characteristics, designations and serial number. LF withdrawable mobile part D: characteristics, designations and serial number. Rollarc or CTV1 withdrawable mobile part E: characteristics, designations and serial number. Evolis withdrawable mobile part F: characteristics, designations and serial number G: location of operating instructions (behind the cover). Read the inscriptions on the front panel A: B: C: D: procedure pictogram withdrawable mobile part earthing switch plate withdrawable fuse voltage transformer plate. Schneider Electric 07897302EN indice: C0 - General description Procedure pictogram 1: mobile part operation 2: earthing switch operation. Mobile part 1: mechanical opening push-button 2: mobile part position selector 3: opening for inserting mobile part operating handle E: mechanical indicator light for indication of the mobile part position F: location for disconnector carriage lock (optional). Cubicle Earthing switch, voltage presence and plug-in prevention 4 : earthing switch position selector 5 : opening for the insertion of the earthing switch operating handle G : voltage presence H : plug-in prevention selector switch L : mechanical indicator of earthing switch status M : location for plug-in prevention lock N : location for earthing switch locks. Withdrawable voltage transformer 6 : position selector switch for voltage transformer withdrawable fuses 7 : opening for the insertion of the voltage transformer withdrawable fuse operating handle. 10 - 07897302EN indice: C0 Schneider Electric Instructions for access to the inside of a cubicle AD cubicle Schneider Electric Markings Access 1 To the lower compartment via the maintenance space or duct (access same as for CT)). 2 Rear (dismantling is optional and has not been secured). 3 Facilitates access to cables (AD cubicle ), through the front (access same as for CT). 4 To the busbars (not possible for VT cubicle). 4 and 5 To the rear inter cubicle fastening screws. This sheet must be reassembled before installation of busbars. 6 To the lower compartment through the front (analogue access for VT and CT). 7 To the mobile part. 8 To low voltage compartment. 07897302EN indice: C0 - 11 Instructions for access to the inside of a cubicle Removing front protection cover plates Cubicle with or without fixed voltage transformer (VT) Close earthing switch (see chapter “Closing the earthing switch”). In the case of a cubicle equipped with a fixed VT. It is recommended to padlock it in this position (see chapter “Padlocking and preventing access using padlocks”). Open the protection switch of the VT secondaries which is located in the regrouping sleeve or in the LV compartment. Closure To place back into operation, carry out operations in the reverse order of removal (closed earthing switch). Dismantle the panel (10 screws). Cubicle equipped with a withdrawable fusevoltage transformer Withdraw VT fuses (see chapter “Withdrawing VT fuses”). Close earthing switch (see chapter “Closing the earthing switch”). It is recommended to padlock it in this position (see chapter “Padlocking and preventing access with padlocks”). 12 - 07897302EN indice: C0 Schneider Electric Instructions for access to the inside of a cubicle Open the protection switch of the VT secondaries which is located in the regrouping sleeve or in the LV compartment. Remove the access panel to VT mobile fuses (6 screws),as well as the U A angle bar ( 4 screws and 2 nuts ). Closure To place back into operation, carry out operations in the reverse order of removal (closed earthing switch). Remove the access panel to the connection compartment of MV cables (4 screws). Removing the MV compartment separation sheet Remove the circuit-breaker (see chapter “Removing and inserting the mobile part”). Remove screws A and remove the separation sheet from the MV compartment. . Closure Schneider Electric To place back into operation, carry out operations in the reverse order of the removal. 07897302EN indice: C0 - 13 Instructions for access to the inside of a cubicle Removing the manhole sheet On a cubicle equipped with VTs, remove them. Remove the screws and remove manhole sheet. Access to the connection compartment of MV cables is possible via the maintenance space at the cubicle manhole level. Likewise, it is possible to access the maintenance space or duct through the inside of the cubicle. See chapter “Instructions for access to the inside of a cubicle”. Closure To place back into operation, carry out operations in the reverse order of removal. Removing and inserting fixed or withdrawable VTs Fixed VTs On each VT, disconnect the connection rod, by unscrewing the nut, then removing the deflector, and raising the connection rod. Similar operation whatever type of VT Closing the MV connection compartment 14 - 07897302EN indice: C0 Disconnect the VT low voltage connector. Remove the VTs using the handle. To place back into operation, carry out operations in the reverse order of removal. For fixed VTs Tightening torque on VT: 30 Nm. Schneider Electric Instructions for access to the inside of a cubicle Access to lower compartment (cables, CT, earthing switch, surge arresters) During the first VT insertion, cut and remove the connector immobilisation binding. Connect the VT low voltage connector. All operations described hereafter must be carried out in compliance with the safety standards in force, under the responsibility of a competent person. Access to the MV cable connection compartement is possible through the maintenance space by removing the cubicle manhole sheet (see chapter “Removing the manhole sheet”). Safety rules Accessing busbars Safety rules All operations described hereafter must be carried out in compliance with the safety standards in force, under the responsibility of a competent person. Upper For access to busbars, see chapter “Instructions for access to the inside of the cubicle”. Lower Access to lower busbars is possible through the maintenance space by removing the cubicle manhole sheet. See chapter “Instructions for access to the inside of the cubicle”. Schneider Electric 07897302EN indice: C0 - 15 Instructions for access to the inside of a cubicle Accessing plug-in pins Safety rules All operations described hereafter must be carried out in compliance with the safety standards in force, under the responsibility of a competent person. Opening and closing lower flaps Using a screwdriver, raise the vane to release the locking. Push the ball into the link axis. The flaps fall downwards up to locking. To close, pull the flaps upwards up to locking. Using a screwdriver, raise the vane to release the locking. Push the ball into the link axis. Push the flaps upwards up to locking. To close, pull the flaps downwards up to locking. Opening and closing upper flaps Before re-plugging in the mobile part, ensure that the shutters mechanisms have been put back into their initial position (locked closed). Failure to comply with this instruction may result in damage to the equipment. 16 - 07897302EN indice: C0 Schneider Electric Installation and operation recommendation the switchgear’s resistance to ageing in an MV substation depends on 3 main factors: The necessity of correct implementation of connections: New cold retractable or slip-on technology offers ease of installation that favours resistance over time. Their design allows them to used in polluted environments with harsh climatic conditions. Impact of the relative humidity factor: Installing a heating device is essential in climates with high relative humidity levels and major temperature differences. The equipment must be installed in conformity with the relevant IEC standard. Outside of these normal usage conditions, we recommend contacting Schneider Electric to determine the operations to be carried out as well as their frequency according to the actual service conditions. Ventilation control: Grid size must be suited to the power dissipated in the substation. These grids must be placed exclusively in the vicinity of the transformer, in order to avoid air circulation on the LV switchboard. Ensure that draughts and / or thermal shocks are avoided in all cubicle compartments in order to avoid the creation of dew points (sources of partial discharges). Operation and maintenance It is strongly advised to periodically carry out, (minimun every 2 years approximately), a few operation cycles on operating devices. Outside normal conditions of use, (between -5°C and 40°C , absence of dust, corrosive gas, etc.), it is recommended to examine, with our Schneider Electric services centre, the steps to be taken, in order to ensure correct functioning of the installation. After 6 to 12 month operations, we recommend you to check the busbars and MV cable connection tightening. It should be done with a calibrated torque spanner, adjust to lower torque compare to values indicated in page 4. If no problems are detected and if the busbars and cable connections haven’t been modified, it will not necessary to do again this check. In case of dismantling, the elastic washers must be change and replace by new ones supplied by Schneider Electric. Our service centre is at your disposal at any time: - To undergo an installation diagnostic, - To offer you, if need be, suitable maintenance operations, - To offer you maintenance contracts, - to offer you adaptations. b Version 3600 A / 4000 A: We strongly recommend that you clean the ventilation grids regularly (every 2 years): A : standard grids B : grids on RHB version. b A fan monitoring system must be installed with the cubicle control and monitoring devices. Permanent operation of the following must be guaranteed: - 1 fan for version 3600 A - 2 fans for version 4000 A. Schneider Electric 07897302EN indice: C0 - 17 Steps for the tests Voltage presence on MV cables Cubicle equipped with VPIS voltage indicator boxes VPIS : Voltage Presence Indicating System, a box with 3 integrated lamps. Characteristics: The definite “voltage presence” indication is ensured on the voltage range stipulated by IEC 61958. Instruction for use VPIS must not be used as a VDS (Voltage Detecting Systems). The indication of a VPIS alone does not suffice to ensure that the system is deenergised: if the operation rules require this, then suitable voltage detectors in compliance with IEC 61243 must be used for this. A: voltage presence indicator light (1 for each phase) B: connection points enabling a phase concordance unit to be connected. Open earthing switch. Cables connected to injection tools. Check voltage absence. Close the earthing switch. Voltage indicator lights are not lit. See chapter “Closing the earthing switch”. Once the cables are energised, the voltage indicator lights should light up. MV cable tests Test condition Voltage injections on MV cable heads On outgoing cables(without VT) 18 - 07897302EN indice: C0 Schneider Electric Steps for the tests Remove front protective cover plates. See chapter “Instructions for access to the inside of a cubicle”. Connect the voltage injection circuit to cable lugs. Open the earthing switch. See chapter “Opening the earthing switch”, then carry out the tests. At the end of the tests: - Close the earthing switch - Remove the accessories. Schneider Electric 07897302EN indice: C0 - 19 Operating Instructions Extracting or inserting the mobile part Starting status Cubicle + mobile partin a disconnected /test position. Note: the following operations are described using the extraction and insertion tool application and the removal of mobile ERT parts ... ...the operating mode is identical when using the extraction table. These tools can be adjusted in width and height. See the corresponding manuals. Open the access door to the mobile part by pulling then turning the handle towards the right. Disconnect the LV auxiliary cord by pressing on the red button and by pulling the socket lock (circuit-breaker or contactor). Bring the ERT into position (the pins entered into the holes intended for this purpose on the cubicle). Lock the latching mechanism by pushing in, then tipping the 2 OED notching operating mechanism handles to the right (check latching mechanism). Extraction Block the 2 ERT castors. 20 - 07897302EN indice: C0 Schneider Electric Operating Instructions Change the position of selector switch 2 to and then, using handles A, remove the mobile part. Bring it up against to be butted against the ERT. Change the position of selector switch 2 back to . Note: moving the circuit-breaker on the ERT must be done near the ground. Disconnect the ERT by turning the 2 notching operating mechanism handles towards the left then pulling them. Unblock the ERT castors. Remove the ERT then place the mobile part on the ground by activating the handle. Remove the ERT. Before closing the access door to the mobile part, pull down the panel. Close the access door to the mobile part by turning the handle towards the left, then pushing it. Schneider Electric 07897302EN indice: C0 - 21 Operating Instructions insertion Open the access door to the mobile part by pulling then turning the handle towards the right. Bring the ERT into position. (the pins entered into the holes intended for this on the cubicle). Block the 2 ERT castors. Lock the latching mechanism by pushing in, then turning towards the right the 2 ERT notching operating mechanism handles (check latching mechanism). Change the position of selector switch 2 to . Push the mobile part into the cubicle until butted against it then change the position of selector switch 2 back to . Disconnect the ERT by turning then pulling the 2 notching operating mechanism handles to the left. Unblock the 2 ERT castors and remove it. 22 - 07897302EN indice: C0 Plug in the LV socket, to do so, push and keep pressing the red button located under the lock pressed down. Push the lock. Connect the cord and notch it. Schneider Electric Operating Instructions Before closing the access door to the mobile part, lift the panel, and ensure that it is well notched at the top. Schneider Electric Close the access door to the mobile part by turning the handle to the left then pushing it. 07897302EN indice: C0 - 23 Operating Instructions Plugging in the mobile part Starting status Door closed Selector switch 4 to (open earthing switch) Selector switch H in plug-in or drawout position to Operation Lower the protective flap of push-button 1. Press push-button 1, and while keeping it pushed down. Change the position of selector switch 2 to . Insert the crank into opening 3. Plug in the mobile part by turning the crank (45 turns) clockwise until the position indicator changes status. Change the position of selector switch 2 to . In the case of a circuit-breaker or a contactor, the electric operation for charging the downstream part of installation is now possible. The pictogram with a black background on the front plate is a reminder of the operations. 24 - 07897302EN indice: C0 Schneider Electric Operating Instructions Withdrawing the mobile part The mobile part in the plugged-in position. Starting status Operation Press push-button 1 (which sends an order for the mechanical opening of the circuitbreaker). While keeping it pushed down, change the position of selector switch 2 to . Insert the crank into opening 3. Withdraw the mobile part by turning the crank (45 turns) anti-clockwise until the position indicator changes status. Change the position of selector switch 2 to . The mobile part is withdrawn. The cubicle is in the disconnected position. The pictogram with a black background on the front plate is a reminder of the operations. Schneider Electric 07897302EN indice: C0 - 25 Operating Instructions Closing the earthing switch Starting status The mobile part is in a disconnected position or in an extracted position, that is, absent from the cubicle. Check that the voltage presence lights are not lit. Any potential locks must enable the operation to be carried out. Operation Change the position of selectorswitch 4 to , by pulling it and turning it towards the right. Insert the crank into the pin of operating axis 5, and turn it clockwise until the position indicator changes status. Closing is accompanied by a noise (sudden closing). 26 - 07897302EN indice: C0 Schneider Electric Operating Instructions Change the position of selector switch 4 to , by pulling it and turning it towards the right. The earthing switch is in the closed position. The MV cable heads are short-circuited and earthed. The pictogram with a yellow background on the front plate, is a reminder of the operations. Schneider Electric 07897302EN indice: C0 - 27 Operating Instructions Opening the earthing switch Closed earthing switch Any potential locks must enable the operation to be carried out. Starting status Operation Change the position of selector switch 4 to , by pulling it and turning it towards the left. Insert the crank into operating axis 5, and turn it anti-clockwise until the position indicator changes status. The change of status is accompanied by a sudden closing noise. Change the position of selector switch 4 to by pulling it and turning it towards the left. 28 - 07897302EN indice: C0 Schneider Electric Operating Instructions The earthing switch is in the open position. The pictogram with a yellow background on the front plate, is a reminder of the operations. Schneider Electric 07897302EN indice: C0 - 29 Operating Instructions Plugging in VT fuses Starting status Assembled lower panel Selector switch 6 to Operation Change the position of selector switch 6 to , by pulling it and turning it towards the right. Insert the crank into operating axis 7, and turn it clockwise until it is plugged in. Plug-in is completed when resistance can be felt (stop). Change the position of selector switch 6 to , by pulling it and turning it towards the right. The pictogram with a blue background on the front plate, is a reminder of the operations. 30 - 07897302EN indice: C0 Schneider Electric Operating Instructions Withdrawing VT fuses Starting status Assembled lower pane Selector switch 6 to Operation Change the position of selector switch 6 to , by pulling it and turning it towards the left. Insert the crank into operating axis 7, and turn it anti-clockwise until drawout. Change the position of selector switch 6 to , by pulling it and turning it towards the left (this authorises the removal of the fuse access panel). The pictogram on the front panel, is a reminder of the operations. Schneider Electric 07897302EN indice: C0 - 31 Operating Instructions Padlocking and preventing access using padlocks Number of possible padlocks per cubicle type 3 padlocks on the plug-in prevention selector switch. 3 padlocks on the selector switch of plug-in or drawout VT fuses. Nota : used padlocks Ø 6 to 8 mm. 1 padlock on the protective flap of the mechanical opening push-button of the mobile part. 1 padlock on the operating mechanism of each of the plug-in contact flaps 3 padlocks on the earthing selector switch in the opened or closed position. Preventing the plug-in of a mobile part Place 1 to 3 padlocks on the plug-in prevention selector switch H. Plug-in prevention in Preventing the opening of a compartment flap on the withdrawable part (option) Close with padlock On the operating mechanism of the plug-in contact flaps, when they are closed. The flap operating mechanism is located inside the cubicle, on the right side. Press on the flap guide, and place the slides (1 and 2, 1 or 2) then place the padlocks in the holes. 40 kA/1s internal arc withstand: to get to the shutters mechanism, you must remove the metal sheet closing (2 screws A). The metal sheet must be installed before to insert the circuit-breaker. 32 - 07897302EN indice: C0 Schneider Electric Operating Instructions Preventing the mechanical opening order of a withdrawable part in an operational position Place 1 padlock on the mechanical opening push-button protective flap 1. Can also serve as an additional plug-in and drawout lock out. Padlocking the earthing switch Open earthing switch: place 1 to 3 padlocks on selector switch 4 to prevent closure. Closed earthing switch: place 1 to 3 padlocks on selector switch 4 to prevent opening. This also prevents the plug-in of a mobile part. plugged-in fuses:place 1 to 3 padlocks on selector switch 6 to prevent drawout. This also prevents removalof the front panel. Withdrawn fuses:place 1 to 3 padlocks on selector switch 6 to prevent plug-in. Padlocking the operation of VT fuses Schneider Electric 07897302EN indice: C0 - 33 Operating Instructions Locking using locks (option) Mobile part in a drawn out position: 1 lock on the cubicle (2 O) or (2 C) or (1 O and 1 C) or (1 O) or (1 C): on earthing switch. Disconnector carriage (withdrawable busbar bridges): 1 lock in the plugged-in position (on the disconnector). Number of possible locks Locking on a cubicle The wrench is only released when plug-in prevention is locked. Locking the plug-in prevention of a mobile part. Locking the disconnector carriage in the plug-in position The wrench is only released when the mobile part is in the plug-in and locked position. Closed disconnector Plugged in disconnector carriage Locking the earthing switchwith a lock 1 lock in closed position Locking the earthing switchwith two locks 34 - 07897302EN indice: C0 1 lock in open position (2 O) or (2 F) or (1 O et 1 F) or (1 O) or (1 F). Schneider Electric Operating Instructions Locking using an electromagnet (option) Locking the earthing switch The electromagnet automatically locks the earthing switch in the “open” and “closed” position. A push-button located on the low voltage compartment authorises the operation of selector switch 4, if switchboard configuration is certain. Locking on a cubicle The electromagnet automatically locks plug-in padlocking when it is activated. Electromagnetic locking prevents the plug-in of a mobile part. A push-button located on the low voltage compartment authorises unlocking, if switchboard configuration is certain. Schneider Electric 07897302EN indice: C0 - 35 Corrective maintenance Forward Corrective maintenance operations allow for defective subassemblies to be replaced. For any other intervention,call upon the nearest Schneider group agents. The operations mentioned in the summary table here after can be carried out by the customeror by Schneider Electric After Sales agents. After each operation, carry out electric tests in compliance with the standards in force. Careful: during replacement, all the following accessories must absolutely be replaced by new equipment. - Nylstop (self-locking nut) - Contact washer - Stop rings - Mechanical pin. Summary table Description Execution Comments Replacement on FU (cubicle AD or CL) Busbar rating Earthing switch clamps and capacitive isolators For any intervention, Plug-in pins call the nearest Upper and lower bushing Schneider Electric Increase in the number of cables agents. Flaps and flap operating mechanisms Extraction of a cubicle VT fuse Customer/ See the following page VPIS voltage indicator box Customer/ See the following page CT Customer/ See Kit no. 07897207 instructions Anti-condensation resistor Customer/ Consult us Earthing switch position auxiliary contact block Customer/ See Kit no. 07897324 instructions Surge arrester Customer/ Consult us Locking using plug-in padlocking lock(s) Customer/ See Kit no. 07897330 instructions Plug-in padlocking electromagnetic locking Customer/ See Kit no. 07897326 instructions Locking using earthing switch lock(1) Customer/ See Kit no. 07897328 instructions Locking using earthing switch locks(2) Customer/ See Kit no. 07897329 instructions Earthing switch electromagnetic lockin Customer/ See Kit no. 07897325 instructions Locking using lock(s) for prevention of withdrawal Customer/ Consult us Zero frequence toroid Customer/ See Kit no. 07897216 instructions VT and VT compartment Customer/ See Kit no. 07897218 instructions High voltage contacts on VT fuses Customer/ See Kit no. 07897219 instructions MV handles Customer/ See Kit no. 07897220 instructions Cable connection bar support isolators Customer/ Consult us Circuit-breaker carriage position auxiliary contacts Customer/ See Kit no. 07897222 instructions Withdrawable VT auxiliary contacts Customer/ Consult us Withdrawable VT fuse blowing auxiliary contacts Customer/ See Kit no. 07897223 instructions Printed circuit and relay support (STPI) Replacing the fans on 3600 A / 4000 A cubicles Cleaning ventilation grids on 3600 A / 4000 A cubicles Customer/ Customer/ Customer/ Consult us See page 41 See page 17 36 - 07897302EN indice: C0 Schneider Electric Corrective maintenance Replacement of VT compartment fuses Starting position Withdrawn fuses and disconnected VT low voltage connector (see chapter “Operating instructions”). Remove the protective panel (see chapter “Instructions for access to the inside of a cubicle”). Removing 1: raise vane A 2: disconnect the small vertical rod B 3: pivot the striker pads C into a horizontal position 4: carefully remove the pin from the striker pads D. Schneider Electric 07897302EN indice: C0 - 37 Corrective maintenance 5: push wrench E and turn towards the left and let go. The fuse is unlocked. 6: Remove the wrench and the fuse. Placing Place the spring on the wrench and check that it is butted against the bottom of the wrench and positioned between the two clips indicated by the arrows. Place the fuses, with the strikers on the outside. Fit the wrenches on the fuses (spring towards the bottom). 1: push wrench E 2: turn it towards the right and let go. The fuse is locked, check the wrench latching mechanism. 38 - 07897302EN indice: C0 Schneider Electric Corrective maintenance 3: carefully insert the pin on the striker pads D. 4: raise vane A to place the striker pads C in a vertical position. 5: connect the small vertical rod B to ensure free operation of the small rod. Operation Schneider Electric Connect the VT low voltage connector (see chapter “Operating instructions”). Place protective panel (see chapter “Instructions for access to the inside of a cubicle”). 07897302EN indice: C0 - 39 Corrective maintenance Replacing of a voltage indicator box Removing This operation can be carried out while the equipment is energised. Placing Remove the 2 fastening screws (A) from the voltage indicator box. Remove the voltage indicator box (B) and disconnect the connector. Check on the characteristics label (B) that the new box corresponds to the rated voltage of your network. Place the new voltage indicator box in the reverse order of removal. - 1.7 kV to 3 kV - 3 kV to 7.2 kV - 10 kV to 24 kV. 40 - 07897302EN indice: C0 Tightening torque: 0.1 mdaN. Schneider Electric Corrective maintenance Replacing the fans on 3600 A / 4000 A cubicles With or without capacitor Removing withpower off. 1: disassemble the 10 screws (A) take off the cover. 3: disassemble the 8 screws (C) securing the fan to the cover of compartment (A). 2: disconnect the wires (D) mark the wires when disassembling. Replacing the capacitor With power off. Remove the roof plate on each cubicle (6 screws). Schneider Electric To acc the capacitor. 07897302EN indice: C0 - 41 Corrective maintenance Mark the wiring and disconnect (A). Putting back the new capacitor Disassemble the nut and washer (B). Fit the fan and the capacitor (if necessary) in the opposite order to disassembly. Check on the characteristics label that the new fan and capacitor match the rated voltage indicated. - 5 1237 333FA 220 Vac - 5 1237 333FB 110 Vac - 5 1237 333FC 48 VD. 42 - 07897302EN indice: C0 Schneider Electric Schneider Electric 07897302EN indice: C0 - 43 44 - 07897302EN indice: C0 Schneider Electric Schneider Electric group service centers are there to provide: - engineering and technical assistance, - commissioning, - training, - preventive and corrective maintenance, - adaptation work, - spare parts. 07897302EN - REV. C0 a Schneider Electric Industries SAS – All rights reserved. Call your sales representative who will put you in touch with your nearest Schneider Electric group service center or directly call the following telephone number: +33 (0)4 76 57 60 60 Grenoble France. Schneider Electric Industries SAS 89, boulevard Franklin Roosevelt F-92506 Rueil-Malmaison Cedex Tel: +33 (0)1 41 29 85 00 www.schneider-electric.com As standards, specifications and designs change from time to time, please ask for confirmation of the information given in this publication. This document has been printed on ecological paper. Publishing: Schneider Electric Industries SAS. Design: Profil. Printing: 07897302EN - REV. C0 10/2005