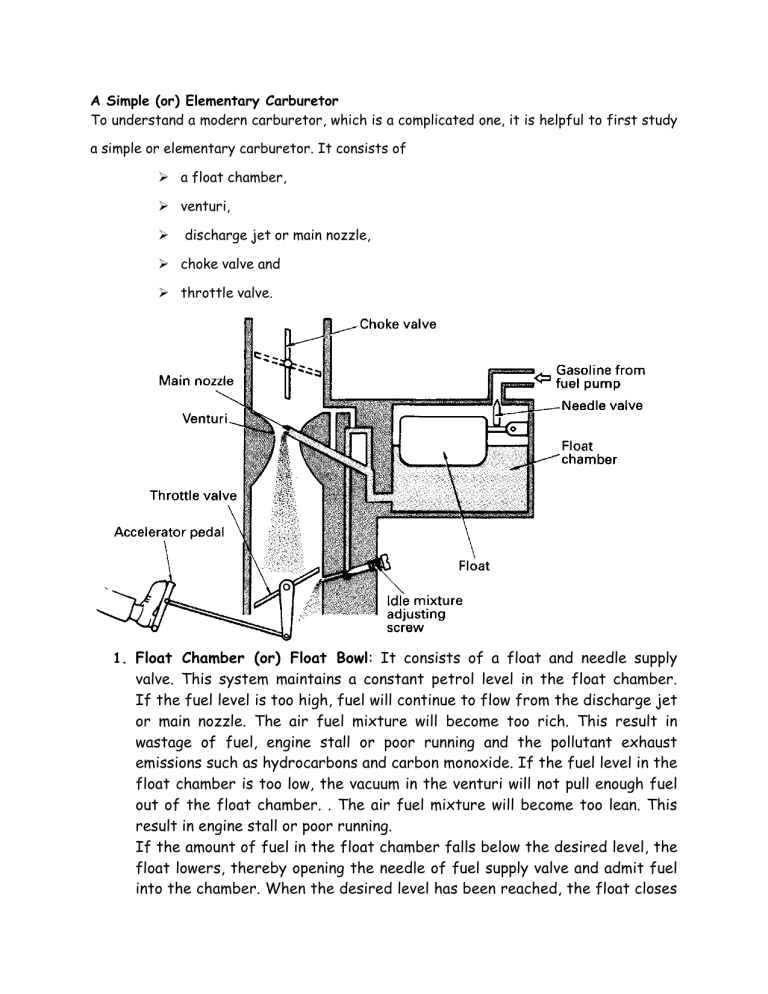

A Simple (or) Elementary Carburetor To understand a modern carburetor, which is a complicated one, it is helpful to first study a simple or elementary carburetor. It consists of a float chamber, venturi, discharge jet or main nozzle, choke valve and throttle valve. 1. Float Chamber (or) Float Bowl: It consists of a float and needle supply valve. This system maintains a constant petrol level in the float chamber. If the fuel level is too high, fuel will continue to flow from the discharge jet or main nozzle. The air fuel mixture will become too rich. This result in wastage of fuel, engine stall or poor running and the pollutant exhaust emissions such as hydrocarbons and carbon monoxide. If the fuel level in the float chamber is too low, the vacuum in the venturi will not pull enough fuel out of the float chamber. . The air fuel mixture will become too lean. This result in engine stall or poor running. If the amount of fuel in the float chamber falls below the desired level, the float lowers, thereby opening the needle of fuel supply valve and admit fuel into the chamber. When the desired level has been reached, the float closes the needle valve, thus stopping additional fuel flow from the supply system. Float chamber is vented to the atmosphere. 2. Venturi (or) Choke Tube: Venturi is a tube of decreasing cross section which reaches a minimum at the throat. During suction stroke air is drawn through the venturi. The air passing through the venturi increasing in velocity and the pressure in the venturi throat decreases. 3. Main Nozzle (or) Discharge Jet: From the float chamber, the fuel is fed to a main nozzle. The tip of the discharge jet is located in the throat of the venturi. 4. Throttle Valve: The throttle valve is a round disc located between the venturi and the engine inlet of the induction system. The throttle is connected to the accelerator pedal by a flexible cable. Depressing the accelerator pedal opens the throttle valve and permits an increased amount of air fuel mixture to reach the engine cylinders. This will increase the power output of the engine and hence the vehicles speed. 5. Choke Valve: It is a valve which is used for controlling the amount of air passing to the venturi and is used when starting a cold engine. Principle As the air flows through the venturi, its velocity increases and hence pressure decreases. Now the pressure in the float chamber is atmospheric pressure and at the venture throat is below the atmospheric pressure. Because of the pressure difference (called carburetor depression) the fuel is discharged through the main nozzle or discharge jet into the air stream of the venturi. Now the fuel particles get mixed with air and the mixture is supplied to the engine cylinder. 1. Types of Carburetors Based on the direction of air flow Up Draught Side Draught Down Draugh 1 Carburetor Systems The fixed venturi carburetor has six systems and several devices that provide the correct air-fuel mixture for different operating conditions. These include: 1. Float System 2. Idle and Low speed System 3. Main-Metering System 4. Power System 5. Accelerator Pump System 6. Choke System 1 Float System 2. Idle System When the throttle valve is closed or only slightly open, only a small amount of air can pass through the air horn. With low air speed, there is very little vacuum in the venture. No fuel will feed from the fuel nozzle. To supply fuel during idle, an idling system is built into the carburetor. This system has an opening in the side of the carburetor below the throttle valve. This hole is called idle port. The port is connected by a passage to the float bowl or float chamber. In addition to the idle port, there is an idle-mixture screw located behind the idle port to control the amount of mixture discharge through it. When the throttle valve is closed and the engine is running, a high vacuum develops in the intake manifold. The pistons are repeatedly moving down on their intake strokes, which mean they are demanding air-fuel mixture. If the pistons do not get enough air-fuel mixture, then a vacuum develops. This vacuum is great enough, when the throttle valve is closed, to cause fuel to flow through the fuel passage from the float bowl to the idle port. Air flows down through a passage in the side of the air horn. The air mixes with the gasoline flowing out of a connecting passage from the float bowl. This mixture moves down to the idle port and discharges in the lower part of the carburetor (i.e. below the throttle valve). This mixture going to the cylinders. 3. Low Speed System If the throttle valve is open just a little for low speed, the edge of the throttle valve moves past the idle port. More air can flow past the throttle valve now, reducing the vacuum in the intake manifold. So less fuel flows from the idle port. However, the low speed port now comes into action. The throttle valve has moved past and above the low speed port. The vacuum in the intake manifold can act on the low speed port as well as on the idle port. Both ports discharge fuel to maintain required amount of air-fuel mixture for low speed. 6.1.3 Main-Metering System If the throttle valve is opened farther, more air will flow through. This means that there will be less vacuum in the intake manifold. As a result, the idle and low speed ports stop discharging fuel. However, with more air flow, there is a vacuum in the venturi. This causes the main nozzle or discharge jet to discharge fuel. Therefore, fuel gets mixed with the air passing through. 4. Power System When a driver wants full power, the accelerator pedal is pushed to the floor (i.e. to the maximum position). This causes the throttle valve to open wide. Another system in the carburetor comes into action to additional fuel. This system is called power system. It includes a metering rod and a hole, called the metering rod jet, in which the rod hangs. The metering rod either has two or more steps of different diameters or is tapered at its lower end. This restricts the fuel flow by partly blocking the jet. However, enough fuel flows to provide the proper air-fuel mixture ratio during part-throttle operation (normal running condition). In piston type a vacuum piston or diaphragm is used to lift the metering rod. The space above the piston is connected to the inlet manifold vacuum. When there is vacuum in the inlet manifold, the vacuum holds the piston up. In this position the metering rod is up and the additional fuel flow is restricted. However, when the throttle is opened wide, the vacuum is lost and can no longer hold the piston up. A spring pushes the piston down. This lowers the metering rod so that additional fuel can flow into the carburetor. So that a rich mixture is formed and is delivered to the engine for full power operation. 5. Acceleration Pump System There is another operating condition that needs a rich mixture. This condition occurs when the accelerator pedal is pushed down suddenly to increase the speed. To get the power needed, the engine has to be supplied rich mixture immediately. This is done by the accelerator pump system. The system includes a pump that is operated when the accelerator pedal is depressed. The movement causes the pump plunger to be pushed down. Pushing the pump plunger down, forces the fuel to flow out through the pump jet. The fuel discharges into the air-fuel mixture that is moving through the carburetor. This further enriches the air-fuel mixture. 6. Choke System When a cold engine is being cranked for starting, extra fuel must be delivered to the engine. The choke valve does this job. When the choke valve is turned to the closed position, very little air can pass through choke into the air horn. Intake manifold vacuum reaches the main nozzle or discharge jet. During cranking, this vacuum is great enough to cause the main nozzle or discharge jet to deliver fuel. This fuel mixes with the air passing through the carburetor to get the engine started. Automatic Choke System Some vehicles use an electronic automatic choke to allow a richer air-fuel mixture to be delivered to the cylinders when the engine is cold. a. When the engine is started The choke valve has been set so that it will be held fully closed by the bimetal element until the ambient temperature reaches 30C (86F). When the engine is cranked with the choke valve held closed, a vacuum is created below the valve. This causes a great amount of gasoline to be delivered causing the air-fuel mixture to become rich. b. After the engine starts When the engine starts, terminal L of the alternator begins outputting current and this current is directly applied to the electric heat coil. When the bimetal element gets warm, it begins to expand, opening the choke valve. The PTC (Positive Temperature Coefficient) thermistor has been provided to prevent more current from flowing to the electric heat coil than the coil needs after the choke valve has opened all the way (and the inside of the spring housing has reached about 100C (212F). Single and Multi Barrel Carburetors Many four-cylinder engines use single-barrel carburetors. For better performance, many six-cylinder and all eight-cylinder engines use two or four barrel carburetors. Adding the extra barrel allows more air-fuel mixture to enter the engine to improve engine DOUBLE-BARREL TYPE volumetric efficiency. This improves engine performance and drivability. One barrel is the primary barrel which takes care of the air-fuel mixture for all cylinders during idle, low speed and normal running operation. When the throttle is opened wide for high-speed operation, the secondary barrel comes into operation. Then it supplies the additional airfuel mixture for full power and hence high speed. Hot-Idle Compensator (HIC) If the vehicle is moving slowly when the ambient temperature is high, the temperature inside the engine compartment will rise. This will cause the gasoline inside the carburetor to become hot and give off vapour. If this vapour is discharged from the main nozzle or the air vent tube and goes into the intake manifold, the air-fuel mixture will become over-rich, causing engine stall or rough idling. Furthermore, if the vapour remains in the carburetor after the engine has stopped, the engine will be difficult to restart. The hot idle compensator, which is a thermostatic valve, has been provided to overcome this problem. As the temperature in the engine compartment rises, the bimetallic element opens the thermostatic valve. As this valve opens, air from the air horn flows into the intake manifold via the air passage in the flange, causing the air-fuel mixture to return to normal. The thermostatic valve is kept closed when the air temperature is low. Note: The hot idle compensator begins to open when the temperature surrounding the bimetallic element is approximately 55C (131F), and is fully open when the temperature reaches approximately 75C (167F). 9. Variable Jet Carburetor In this carburetor, the piston (round or rectangular shape) and throttle body form the variable venturi. The piston moves up and down as the vacuum between it and the throttle valve changes. When the throttle valve is closed so that the engine is idling, there is very little vacuum on the throttle valve side. So the piston spring pushes the piston down to its lowest side. The space between it and the lower floor of the throttle body is small. Only a little air can pass through. At the same time, the tapered needle valve is well down in the fuel jet so only a little gasoline can feed to the passing air. The resulting mixture is for engine idling. When the throttle is opened, the inlet manifold vacuum enters the throttle body. This vacuum draws air from the space above the piston, acting through the vacuum port in the lower part of the piston. The piston raised by the vacuum, partly lifting the needle out of the fuel jet. Now more air can flow through the carburetor and more fuel can feed into it. The amount of fuel delivered increases to match the additional air flowing through. The wider the throttle opens, the greater the vacuum working on the piston. So it moves up still more. It carries the needle up with it so that the air-fuel ratio stays the same throughout the operating range of the engine. Variable jet carburetors are widely used in two wheeler engines.