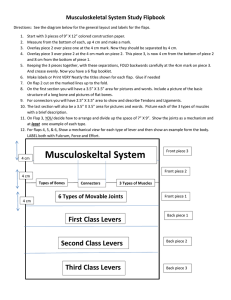

FLIGHT CONTROLS CH 27 B767-3S2F Page - 1 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 2 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY ATA 27 FLIGHT CONTROLS TABLE OF CONTENTS INTRODUCTION ................................................................................... 4 ACTUATORS AND SERVOS ................................................................ 6 HYDRAULIC SHUTOFF VALVES - CONTROL AND INDICATION........8 HYDRAULIC SHUTOFF VALVES ...................................................... 10 CONTROL SYSTEM ELECTRONIC UNITS - (CSEU)........................ 12 CSEU BLOCK DIAGRAM.................................................................... 14 CONTROL SYSTEM ELECTRONIC UNITS POWER DISTRIBUTION 16 AILERON CONTROLS AND INDICATIONS ....................................... 18 AILERON COMPONENT LOCATIONS............................................... 20 AILERON MANUAL CONTROL .......................................................... 22 AILERON TRIM CONTROL................................................................. 24 AILERON DROOP MECHANISM........................................................ 26 AILERON OUTBOARD LOCKOUT ..................................................... 28 AILERON POSITION INDICATING SYSTEM ..................................... 30 SPOILER CONTROLS AND INDICATORS...........................................32 SPEEDBRAKE MECHANISM AND LVDT UNITS............................... 34 SPOILERS AND SPEEDBRAKES - OVERVIEW................................ 36 AUTO SPEEDBRAKE ACTUATOR..................................................... 38 AUTO SPEEDBRAKE SYSTEM.......................................................... 40 AUTO SPEEDBRAKE ELECTRICAL SCHEMATIC ............................ 42 RUDDER CONTROLS AND INDICATORS......................................... 44 RUDDER YAW CONTROL.................................................................. 46 RUDDER SYSTEM.............................................................................. 48 RUDDER TRIM SYSTEM.................................................................... 50 RATIO CHANGER OPERATION......................................................... 52 RUDDER RATIO CHANGER MECHANISM..........................................54 YAW DAMPER SYSTEM .................................................................... 56 ELEVATOR GENERAL DESCRIPTION................................................58 ELEVATOR CONTROL SCHEMATIC................................................. 60 ELEVATOR FEEL FORCE SYSTEM .................................................. 62 STALL WARNING SYSTEM COMPONENTS..................................... 64 STALL WARNING COMPUTER............................................................66 STALL WARNING BITE.........................................................................68 STABILIZER CONTROLS AND INDICATORS ................................... 70 STABILIZER TRIM BLOCK DIAGRAM ............................................... 72 STABILIZER TRIM CONTROL MODULE (STCM).............................. 74 STABILIZER HYDRAULIC CUTOUT SWITCHES .............................. 76 STAB TRIM LIMIT SWITCH AND POS. TRANSMITTER MODULES. 78 HIGH LIFT DEVICES........................................................................... 80 FLAP CONTROL AND INDICATION ................................................... 82 FLAPS GENERAL DESCRIPTION........................................................84 FLAP PRIMARY DRIVE CONTROL .................................................... 86 FLAP POWER DRIVE UNIT (PDU) ..................................................... 88 FLAP PDU COMPONENTS................................................................. 90 FLAP/SLAT SHUTOFF VALVE MODULE ........................................... 92 FLAP ROTARY ACTUATOR ............................................................... 94 INBOARD FLAPS ................................................................................. 96 OUTBOARD FLAPS ............................................................................. 98 FLAP / SLAT ELECTRONIC UNIT (FSEU) ........................................ 100 FLAP SYSTEM INTERFACE.............................................................. 102 FLAP HYDRAULIC OPERATION ....................................................... 104 FLAP LOAD RELIEF MECHANISM.................................................... 106 FLAP LOAD RELIEF SYSTEM........................................................... 108 FLAP ALTERNATE DRIVE CONTROL .............................................. 110 FLAP POSITION TRANSMITTER ..................................................... 112 FLAP POSITION TRANSMITTER ASSEMBLIES .............................. 114 FLAP POSITION INDICATION ........................................................... 116 FLAP/STAB POSITION MODULES (FSPM) ...................................... 118 FLAP ASYMMETRY PROTECTION SYSTEM....................................120 LEADING EDGE SLATS.................................................................... 122 SLAT POWER DRIVE UNITS (PDU)................................................. 124 KRUEGER SEAL FLAP DRIVE SYSTEM (INBD SLATS)................. 126 INBOARD SLAT DRIVE AND TRACKS ............................................ 128 OUTBOARD SLAT DRIVE AND TRACKS ........................................ 130 SLAT FSEU/PSEU INTERFACE ....................................................... 132 SLAT SYSTEM INTERFACE............................................................. 134 SLAT HYDRAULIC OPERATION ...................................................... 136 SLAT ALTERNATE DRIVE CONTROL ............................................. 138 SLAT SENSOR/TARGET POSITIONS.............................................. 140 SLAT PDU TRANSMITTERS ............................................................ 142 SLAT PSEU BITE .............................................................................. 144 STUDENT NOTES: B767-3S2F Page - 3 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 4 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLIGHT CONTROL INTRODUCTION General Flight control systems can be grouped as primary or secondary control systems. Primary flight controls are those which are used to provide continuous control of the airplane about the pitch, roll and yaw axes, and include the aileron, rudder, elevator and spoiler systems. Secondary flight controls are those used intermittently, to modify the basic aerodynamic configuration of the airplane to improve its performance at a particular flight condition, and include the leading edge slat, trailing edge flap, spoilers (when used as air or ground speedbrakes) and stabilizer trim systems. Wing Systems The aileron and spoiler systems provide control about the roll axis through differential operation (up on one wing and down on the other). The leading edge slat, trailing edge flap and spoiler (when raised symmetrically on both wings) systems modify wing lift characteristics. Tail Systems The elevator system provides control about the pitch axis and stabilizer position is varied to trim the airplane about the pitch axis. The rudder provides control about the yaw axis. RUDDER ROLL AXIS YAW AXIS OUTBD AILERON PITCH AXIS ELEVATOR INBD AILERON SPOILERS (6 EACH SIDE) STABILIZER INBOARD FLAP OUTBOARD FLAP LEADING EDGE SLATS (6 EACH SIDE) FLIGHT CONTROL INTRODUCTION B767-3S2F Page - 5 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 6 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLIGHT CONTROL ACTUATORS AND SERVOS General All primary flight controls are driven by hydraulically operated Power Control Actuators (PCA) with no manual reversion capability. A total of twenty nine actuators are employed with eight in the aileron system, twelve in the spoiler system, six in the elevator system and three in the rudder system. In addition the aileron system has three additional Lateral Central Control Actuators (LCCA) to power the wing cable systems to the PCA located at the aileron. Nine autopilot servos, three on each axis, provide triple redundancy required for category three autoland capability. The aileron servos are part of the LCCA with the three elevator and three rudder servos as individual units. Two Yaw Damper Servos (YDS) provide rudder inputs independent of pilot or autoflight control inputs. The trailing edge flaps and leading edge slats, which are secondary flight controls, are operated by power drive units (PDU). The PDU will rotate torque tubes to power two rotary actuators (mechanical) at each control surface. Hydraulic Distribution Three hydraulic systems operate power control actuators in the primary flight control systems which include the aileron, elevator, rudder and spoiler systems. The secondary flight control systems are powered by a combination of one, two, or three hydraulic systems. Roll (LCCA), pitch (elevator) and yaw (rollout guidance) autopilot actuators are powered by each of the three hydraulic systems. The ram air turbine pump in the center hydraulic system can power all center hydraulic system flight controls except the flap and slat systems. The stabilizer trim system is normally powered by the left and center hydraulic systems. A Power Transfer Unit (PTU) can provide right hydraulic system power to operate the left stabilizer trim system. An elevator feel computer and yaw damper servo are powered by the left hydraulic system with identical components powered by the center hydraulic system. The rudder ratio changer, the leading edge slats and trailing edge flap systems are each powered by one hydraulic system. FLIGHT CONTROL ACTUATORS AND SERVOS B767-3S2F Page - 7 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 8 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY HYDRAULIC SHUTOFF VALVES - CONTROL AND INDICATION General Six control switches located on the HYD/GEN FIELD CONT panel (P61). The switches are intended for ground use only and are normally on. These alternate action switches contain white ON lights that are illuminated whenever the switch is in the open position. Each control switch is guarded by a cover, which will not close, in the switch off position (switch protruding). The shutoff valve position is monitored by switch lights and EICAS messages. An amber light in the lower half of the control switch illuminates as soon as the valve moves from the fully open position. An amber EICAS advisory message appears on the upper display when a shutoff valve is not open (i.e. L WING HYD VAL). If more than one valve is not open, EICAS will display a single FLT. CONT VALS message. HYDRAULIC SHUTOFF VALVES - CONTROL AND INDICATION B767-3S2F Page - 9 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 10 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLIGHT CONTROL HYDRAULIC SHUTOFF VALVES Description Six identical shutoff valves are used to isolate flight control components from their hydraulic source during ground maintenance. Hydraulic shutoff valves control pressure to all flight control systems except the flaps, slats and stabilizer systems. An electrical actuator and a rotary selector valve are joined together to form a single LRU. The actuator has a single electrical connector, and position decals to show the actual valve position. The rotary selector valve has three fluid ports and an override handle. The override permits power-off manual operation, and it also functions as a visual indicator. The two-position shutoff valve (open - position 1; closed - position 2) is normally open. Shutoff Valve Locations Left and right wing shutoff valves are mounted on a bracket between the rear wing spar and the spoiler beam adjacent to the inboard corner of the inboard ailerons. The center wing shutoff valve is located on the aft bulkhead in the left wheel well. Tail shutoff valves are located in the stabilizer compartment. Access is through a service door in the bottom of the compartment, just forward of the stabilizer jackscrew. Dispatch Deviation • Flight Control Shutoff Valves INOP Lights: Verify that the related flight control shutoff valve is open. • Pressurize the hydraulic system related to inop valve/light and operate the flight control surface, while observing the flight control deflections on EICAS. Note: It is possible for valve to fail closed with override and position lever indicating open. Visual and flight control operational checks must be accomplished. FLIGHT CONTROL HYDRAULIC SHUTOFF VALVES B767-3S2F Page - 11 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 12 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY CONTROL SYSTEM ELECTRONIC UNITS - (CSEU) General Two identical, left (E1-1) and right (E2-1), CSEU are located in the main equipment center. Each CSEU contains six modules: • Power Supply Modules (PSM) (2) • Spoiler Control Modules (SCM) (3) • Yaw Damper/Stabilizer Module (YSM) (2) CONTROL SYSTEM ELECTRONIC UNITS - (CSEU) B767-3S2F Page - 13 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 14 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY CSEU BLOCK DIAGRAM Components Each CSEU has four flight control modules and two power supply modules. The CSEU interfaces with other primary airplane systems to provide the calculation and control functions for these functions: • • • • • Yaw damping Stabilizer trim Aileron lockout Rudder ratio changer Spoiler deployment Inputs Three air/ground systems discrete inputs allow the CSEU to perform control functions and ground test function. Three ADIRU provide airspeed inputs for aileron lock-out and rudder ratio changer control. Each CSEU module receives hydraulic pressure switch signals from the hydraulic systems. These inputs are used for control of fault annunciation and reset fault latches. The CSEU receives flaps position inputs from three Flap Stabilizer Position Modules (FSPM), located in the P50 card file. Flaps positions are used for spoiler scheduling and stabilizer trim control. Auto pilot system(s) controls the stabilizer trim function via the CSEU. Speed brake lever and control wheel positions allow the CSEU to control spoiler panels. Manual electric stabilizer trim switches send electrical signals through the CSEU for control and indication. CSEU Two PSMs supply power to these components: • Three Spoiler Control Modules (SCM) • Yaw Damper/Stabilizer Trim Module (YSM) • Excitation for LVDT and RVDT for the above LRUs Outputs The following items are controlled by the CSEU: • • • • • Twelve spoiler PCA Two stabilizer trim control modules Two aileron lock-out actuators Two yaw damper servos The rudder ratio changer actuator AIR GND AIR GROUND SYSTEMS (3) SPOILER PCA AIR SPEED ADIRU (3) PSM (2) (P50) HYD PRESS SWITCHES FLAP POSITIONS STAB TRIM CONTROL MODULE FSPM (3) 200 270 +2300 17000 AUTO PILOT SYSTEMS (3) AILERON LOCKOUT ACTUATOR SCM (3) YAW DAMPER SERVOS SPEED BRAKE LEVER YSM CONTROL WHEEL CSEU (2) CSEU BLOCK DIAGRAM B767-3S2F Page - 15 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RATIO CHANGER ACTUATOR RUDDER MECHANISM B767-3S2F Page - 16 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY CONTROL SYSTEM ELECTRONIC UNITS POWER DISTRIBUTION Description The left CSEU power supply modules (PSM) get power from the standby ac/dc buses. The right CSEU PSM get power from the left and right buses. The dual PSM in each CSEU send out 26v ac, +5 vdc and +/-15 vdc to the four operating modules. 26v ac goes to the yaw damper/stabilizer trim module (YSM), and spoiler control modules (SCM) for reference power and for excitation power for the control wheel and speedbrake lever RVDT and LVDT. The spoiler actuator LVDT receive excitation power from the PSM through the SCM. PSM 1 in each CSEU supplies 26v ac power with automatic failure changeover to PSM 2. +/- 15v dc goes to all the modules for card and electrohydraulic servo valve operation. 28v dc goes to all the modules for solenoid valve, actuator, relay, fault monitor and fault ball control. 115V AC STBY BUS POWER SUPPLY MODULE 1L 28V DC STBY BUS 26V AC |15V DC +5V DC CAPT WHL RVDTS (3) 28V DC STBY BUS 26V AC L YAW DAMP/ STAB TRIM MODULE SCM 3L RUDDER RATIO CHANGER LVDT CSEU (E1-1 SHELF) 28V DC LEFT BUS SPD BRK LVDTS (3) SCM 2L POWER |15V DC SUPPLY MODULE 2L +5V DC 28V DC STBY BUS SPOIL CONT MODULE 1L SPOILER PWR CONT ACT LVDTS POWER SUPPLY INTERNAL WIRING SAME AS E1-1 SHELF MODULE 1R 28V DC RIGHT BUS 28V DC LEFT BUS 115V AC RIGHT BUS 26V AC 28V DC POWER SUPPLY MODULE 2R 26V AC CSEU (E2-1 SHELF) P11 SPOILER PWR CONT UNIT LVDTS CONTROL SYSTEM ELECTRONIC UNITS POWER DISTRIBUTION B767-3S2F Page - 17 ATA 27-00 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY YAW DMPR SERVO LVDT (2) B767-3S2F Page - 18 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AILERON CONTROLS AND INDICATIONS Control Dual control wheels provide manual control of the aileron system. The wheels are mechanically connected by overrides and normally operate together. The ailerons are controlled during autoflight by switches on the mode control panel. Trim switches on the control stand control an electric actuator which operates the aileron system. Indication Aileron position is shown by pointers on the EICAS Status page. There is a trim indicator placard on top of each control column. Aileron lockout system faults are shown by an EICAS advisory message, an amber light and an EICAS maintenance message. AILERON CONTROLS AND INDICATION B767-3S2F Page - 19 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 20 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AILERON COMPONENT LOCATIONS Ailerons Forward Quadrants Inboard aileron located on trailing edge of both wings behind engine struts. Outboard aileron located on both wings outboard section, trailing edge. Located under the flight compartment floor just aft of the base of the control columns. They incorporate bus rod, drum position transducers (spoiler lateral control RVDT’s), override and lost motion assemblies, and a control wheel force transducer (autopilot). Primary And Backup Cable System Located under passenger cabin floor along side of the fuselage. Primary along left side to wheel well and backup along right side to right wheel well. Droop Mechanism Located on left and right wing spar, inboard corner inboard ailerons (2 total). Provides inboard aileron droop with first 15 degrees of flap extension for increased lift during take-off and approach. Outboard Aileron Lockout Mechanism Left Wheel Well Components Located on left and right wing rear spar, inboard corner outboard aileron (2 total). Locks-out outboard ailerons at cruise speeds. Locks-out as a function of airspeed and altitude (Mach Number). Consist of feel-centering and trim mechanism, left LCCA torque tube, two LCCA’s (one above the other), and the left LCCA output quadrant. Position Transmitters Right Wheel Well Components Located on the outboard corner of the Inboard ailerons and on outboard section of each outboard aileron (four total). Input is to EICAS status page only. Consists of right wheel well quadrant, right LCCA torque tube/aileron control override mechanism, right LCCA, the right LCCA output quadrant and right aileron control output quadrant. Aileron and Spoiler Hydraulic Shutoff Valves Wing Cable System Routed along left and right wing rear spars from LCCA output quadrants to outboard aileron lockout mechanism. Power Control Actuators (PCA) Consists of two PCA located in the mid-section, leading edge of each aileron (eight total). Each PCA is powered by one hydraulic system and has NO electronic input. Located adjacent to inboard edge of left and right inboard ailerons, (L & R HYD), and on aft bulkhead left wheel well (C HYD). Three shutoff valves total for lateral control. These are designed for ground/maintenance use only. AILERON COMPONENT LOCATIONS B767-3S2F Page - 21 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 22 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AILERON MANUAL CONTROL Control Wheels Outboard Aileron Lockout Mechanism The captain and first officer's yokes each drive respective control column cables. Rotation of either control wheel drives the primary (left) cable system. The outboard aileron lockout mechanism disables (fairs) the outboard ailerons at cruise speeds; controlled by YSM. The electric actuator re-positions linkage which mechanically nulls the outboard aileron PCA inputs. Forward/Aft Quadrants Override The forward quadrants control operation of the primary (left) and backup (right) cable systems. They contain input and drive drums, bus cranks, position transducers (lateral control spoiler RVDT’s), force transducer (control wheel steering), and lost motion and load limiter assemblies. There are seven override mechanisms in the aileron control system. Three overrides function to separate the primary and backup control systems in event of a jam in either system. Four overrides, two in each wing, function to separate inboard and outboard aileron control inputs. The aft quadrants provide an interface between the primary and backup cable system and the wing cable system. The left aft quadrant incorporates a "feel and centering" mechanism for cable system feel force and an electric trim actuator. Both quadrants have control input rods to Lateral Central Control Actuators (LCCA). Inputs are provided through each override by a cam and roller (cam follower) which are held together by spring force. Inputs are from the cam to the roller or the roller to the cam, depending on the installation, and normal or non-normal operation. Normally the cam and roller operate as a unit and move together. Lateral Central Control Actuators (LCCA) The LCCA’s hydraulically power the wing cable system which controls the Power Control Actuators (PCA). LCCA can also be controlled electrically by signals from the Flight Control Computers (FCC) in autopilot operation. Power Control Actuators (PCA) The PCA's position the ailerons hydraulically and are controlled mechanically. There are two PCA's on each aileron (8 total). Each PCA has a single hydraulic system source. Droop Mechanism The droop mechanism positions the inboard ailerons 10 degrees down with the trailing edge flaps equal to or greater than 15 degrees. The flap drive-angle gearbox mechanically positions input rods to the inboard PCA's. If a jam occurs on either side of the override, and sufficient force is applied on the side that is not jammed, the roller is forced up on the cam face. This separates the aileron control system allowing partial system operation. Lost Motion Two lost motion devices are installed between the primary and backup control systems. These devices permit operation of the primary control system during normal operation by preventing contact with the backup control system. The lost motion devices engage during jams or disconnects in the primary control system. This enables full or partial backup cable system operation of the ailerons and spoilers. The devices consist of an arm in a slot with gaps between the arm and slot. Primary control inputs move the arm or slot with the other side of the device moved by aileron system response. Normally there is no contact between the arm and slot. When a jam or disconnect occurs in the primary control system, the lost motion devices are engaged by operation of the backup cable system. AILERON MANUAL CONTROL B767-3S2F Page - 23 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 24 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AILERON TRIM CONTROL The aileron trim arm and control switches are located on the aft end of the control stand. Both switches must be operated to power the trim actuator on the feel, centering and trim mechanism. Maximum aileron trim is 30 degrees of control wheel rotation. Aileron trim indicator placards are located on top of each control column. Each unit of trim represents five degrees of control wheel rotation. AILERON TRIM CONTROL B767-3S2F Page - 25 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 26 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AILERON DROOP MECHANISM Description Both inboard ailerons are lowered (drooped) to improve lift when the trailing edge flaps are extended. The droop mechanism is mechanically operated by the aileron droop angle gearbox as the flaps extend between up and 5 units causing the inboard ailerons to lower 10 degrees. As the flaps are raised, the ailerons return to the neutral position. Extending the flaps from 25 to 30 units causes the inboard ailerons to retract approximately 5 degrees. A droop mechanism for each inboard aileron is located on the left and right wing rear spars inboard of the inboard ailerons. The droop mechanism inboard and outboard quadrants have override mechanisms to separate a jammed inboard or outboard aileron control input from the aileron system. Because the droop mechanism does not operate the body cable systems the only flight deck indication of aileron droop is the position pointers on the EICAS Status page. The aileron droop angle gearbox output crank rotates the droop summing lever as flaps extend from up to 5 units, operating the control rod to the inboard aileron Power Control Actuator (PCA) causing the inboard ailerons to lower (droop) 10 . The output crank cam follower is moved by a cam, operated by a drive shaft, which has a shear out to permit flap operation with a jam in the inboard aileron PCA input mechanism. The droop summing lever pivots on the control rod from the inboard quadrant during droop operation, thus the only input is to the inboard aileron PCAs. When the flaps move from 25 to 30 units, the inboard ailerons move up to approximately five degrees drooped due to the shape of the cam. AILERON DROOP MECHANISM B767-3S2F Page - 27 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 28 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY OUTBOARD AILERON LOCKOUT An airspeeds schedule has been established (YSM software) to permit the outboard ailerons to be locked out (faired) at cruise airspeeds. Aileron lockout prevents over-control and control reversal at high airspeeds. Airspeed is continuously monitored, compared to a lockout schedule in the YSM, and appropriate signals are sent to the lockout actuator. The schedule is a function of calibrated airspeeds and pressure altitude (Mach Number). S.L. to 10,000 ft = 275 + 5 kts 10,000 ft to 18,000 ft = m 0.50 + 0.02 18,000 ft to 27,000 ft = 235 + 5 kts 27,000 ft to ceiling = m 0.58 + 0.02 The schedule includes a transition band to insure gradual, controllable changes. Lockout commences when the airspeed exceeds the high side of the bank for increasing speeds (i.e. m 0.60 at cruise altitude). Unlock begins when the airspeeds slows to the low side of the bank for decreasing airspeeds (i.e. m0.56 at cruise altitude). Lockout extension/retraction time is 15 seconds in either direction. The aileron is faired/unfaired gradually to avoid abrupt control responses. The outboard ailerons are locked out at high speed to reduce roll control sensitivity about the longitudinal axis of the airplane. An aileron lockout mechanism is mounted on the wing rear spar, inboard of each outboard aileron. The mechanism is operated by an electric actuator which positions linkages to prevent quadrant rotation from operating the control rod to the PCA's. The lockout actuators are electronically controlled by stabilizer trim aileron lockout modules (YSM) using speed inputs from the Air Data Inertial Reference Units (ADIRU). OUTBOARD AILERON LOCKOUT B767-3S2F Page - 29 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 30 ATA 27-10 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AILERON POSITION INDICATING SYSTEM Aileron Position Transmitters Each of the four ailerons has a transmitter located near its outboard ends. The transmitter case is mounted on the rear wing spar. A crank with an adjustable rod is attached to the aileron. Aileron motion rotates the crank and generates an output signal to the EICAS computers. The adjustable control rod is used to rig the transmitter to electrical zero (minimum voltage) with the aileron faired to structure. Access is by panels on the lower wing surface just forward of the aileron leading edge. Aileron Position Indicator Aileron position is displayed on the lower EICAS display on the status page only. Triangular pointers arranged on vertical scales indicate each aileron position on a vertical scale. Dispatch Deviation If the Flight Control Surface Indication is INOP it is necessary to provide a visual flight control check prior to each departure. 28V AC R BUS R AILERON POSITION P11 CB PANEL CX LC FILTER RIGHT OUTBD AILERON POSITION XMTR LC FILTER INTERNALS SAME AS RIGHT OUTBD POS XMTR RIGHT INBD AILERON POSITION XMTR 28V AC L BUS L AILERON POSITION P11 CB PANEL 1 OUTBD AIL INBD AIL INBD AIL OUTBD AIL LOWER EICAS DISPLAY INTERNALS SAME AS RIGHT OUTBD POS XMTR LEFT INBD AILERON POSITION XMTR INTERNALS SAME AS RIGHT OUTBD POS XMTR LEFT OUTBD AILERON POSITION XMTR EICAS 28V AC REFERENCE POWER: LEFT AIL POSN - LEFT ENG OIL PRESS (L9) RIGHT AIL POSN - RIGHT ENG OIL PRESS (L36) L/R EICAS CMPTR RUD LC FILTER AIL LC FILTER POSITION POINTERS AILERON POSITION INDICATING SYSTEM B767-3S2F Page - 31 ATA 27-10 11/11/13 EFF - ALL AILERON POSITION INDICATION TRAINING MANUAL FOR TRAINING PURPOSES ONLY ELEV AIL 1 STATUS PAGE B767-3S2F Page - 32 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SPOILER CONTROL AND INDICATION SPEEDBRAKES Light Control Electronic control of hydraulic Power Control Actuators (PCA) is by control wheel Rotary Variable Differential Transformers (RVDT) and speedbrake lever Linear Variable Differential Transformer (LVDT) inputs to Spoiler Control Modules (SCM). Each SCM outputs control signals to an Electro-Hydraulic Servo Valve (EHSV) on two PCA’s. Spoiler panel position signals from a piston operated internal PCA LVDT provide a feedback signal to the SCM for panel control and fault detection. RVDT lateral control inputs are from aileron system operation. LVDT speedbrake control inputs are from speedbrake lever operation. Indication Spoiler system faults cause a maintenance message to be displayed. Faults causing auto shutdown of a panel pair cause display of the amber SPOILERS light and an advisory message. Additional fault information is available from the built in test function of the SCM. Speedbrake Lever Positions DOWN - Is a detent position that signals all spoiler panels to retract. ARMED - Allows automatic deployment of speedbrake upon landing. UP - Speedbrake lever moves to the UP position after both trucks in a no-tilt position. AUTO SPDBRK Light This light illuminates to indicate a fault in the auto speedbrake system. For aircraft equipped with winglets, the AUTO SPDBRK light will indicate a fault in the autostow system. SPOILERS Light This light iIlluminates when one or more spoiler panels are not in the commanded positioned. A failed spoiler PCA could cause this light. This light illuminates to indicate the speedbrake lever is beyond the ARMED detent with radio altitude between 15’ to 800' or radio altitude above 15' with flaps extended beyond 20 degrees. SPOILER CONTROL AND INDICATION B767-3S2F Page - 33 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 34 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SPEEDBRAKE MECHANISM AND LVDT UNITS Location The Speedbrake Lever is connected to the Speedbrake Mechanism in the control stand by a rod. The Linear Variable Differential Transformers (LVDT) are connected to the speedbrake mechanism. The LVDTs are accessed by opening the left side panel of the control stand. Description Three LVDT units are attached to the speedbrake mechanism inner shaft. Rotation of the speedbrake lever moves the connecting rod attached to the inner shaft of the speedbrake mechanism. An auto speedbrake actuator can also operate the inner shaft and LVDT's through an outer shaft and no-back clutch. The inner shaft then operates both the LVDT moveable core rods. The LVDT’s output a variable voltage to the Spoiler Control Modules (SCM’s). LVDT 1 of each LVDT pair outputs to the SCM’s in the left Control System Electronic Unit (CSEU). LVDT 2 outputs to the SCM’s in the right CSEU. Maintenance Practices The LVDT’s are removed and installed in pairs as they have a common rod end. To adjust the LVDT unit, the speedbrake lever is placed in the arm detent, the jam nut is loosened, and the wrench flat is rotated until a voltage of not more than 50 mv is attained on both LVDT's (Null Position). ARM (8.5 DEGREES) DOWN (DETENT) FROM REVERSE THRUST CAM UP (78 DEGREES) SPEEDBRAKE LEVER (LIFT TO MOVE AFT) REVERSE THRUST AUTO SPEEDBRAKE DEPLOY MECHANISM PIVOT SHAFT NO-BACK CLUTCH FLIGHT COMPARTMENT FLOOR AUTO-SPEEDBRAKE ACTUATOR SPEEDBRAKE LVDT (3 PAIRS) SPEEDBRAKE MECHANISM AND LVDT UNITS B767-3S2F Page - 35 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 36 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SPOILERS AND SPEEDBRAKES - OVERVIEW Spoiler/Speedbrake Operation Spoilers deploy as a function of control wheel deflection, speedbrake lever position, flap position, and air/ground logic. All twelve spoilers are programmed to provide roll control, in-flight speedbrakes, and ground spoiler speedbrakes. Each symmetrical pair of spoilers is controlled by a Spoiler Control Module (SCM). Each spoiler is driven by a Power Control Actuator (PCA). The output of each SCM and the feedback from the pair of PCA's being controlled by that SCM form a closed loop electro-hydraulic servo control system. Lateral control inputs to each SCM is by control wheel Rotary Variable Displacement Transducers (RVDT). Speedbrake inputs are by speedbrake lever Linear Variable Displacement Transducers (LVDT). RVDT and LVDT control inputs are demodulated, amplified, and modified by SCM programs. The lateral control and speedbrake commands are mixed to provide approximately the same roll-rates with or without speedbrakes. Each SCM has two output signals - one to the left wing and one to the right wing. The two outputs will cause the spoiler pair to deploy asymmetrically during roll-control and symmetrically during speedbrake operation. These modes are modified within the SCM if a roll is initiated while speedbrakes are deployed. Spoiler panel limits are determined for each Spoiler Control Module by pin programming. Spoilers 4 and 9 are INHIBITED as in-flight speedbrakes. Spoilers 4, 5, 8, and 9 are INHIBITED as lateral control spoilers at cruise speeds (flaps 20 degrees or less). LEFT CONTROL WHEEL SPEEDBRAKE LEVER SPEED BRAKE LEVER LVDT UNITS (3 PLCS) RIGHT CONTROL WHEEL DEPLOY SPOILER RVDT UNIT 2 SPOILERS ANNUNCIATOR PANEL (P5) 3L 3R 1L 1R CSEU DC PWR 1 RIGHT FWD QUADRANT 3 LEFT FWD QUADRANT 2L 2R 2 1 3 SPOILER RVDT UNIT SPOILERS (W) POWER POWER FAULTS ACTIVE CHAN (A) STBY CHAN (B) MODEL CHAN (C) FAULT MON CSEU AC PWR FLAP POSITION FSPM AIR/GND & HYD DISCRETES LOCK/UNLOCK 2L (E1-1) L CSEU POWER FAULTS SPDBK HANDLE POS FLAP DISCRETES INTLK 3L (E1-1) FAULTS FLAP DISCRETES INTLK 1L (E1-1) POWER POWER FAULTS POWER DISCRETES FLAP INTLK FLAP DISCRETES 1R (E2-1) INTERNALS SAME AS 1L FLAP INTLK DISCRETES 2R (E2-1) R CSEU SPOILERS (Y) FAULTS FAULTS L & R EICAS COMPUTER (E8) 3R (E2-1) 1 60 45 OUTBD 1 45 45 PANELS 4, 5, 8 & 9 DO NOT OPERATE FOR LATERAL CONTROL WITH OUBOARD AILERONS LOCKED OUT 2 45 45 45 45 0 0 GROUND SPEED BRAKE MAX LIMIT (DEG) LOW SPEED LATERAL CONTROL MAX LIMIT (DEG) 17 17 XX XX XX 17 60 OUTBD 45 HIGH SPEED LATERAL CONTROL MAX LIMIT (DEG) 1 SPOILER SPEEDBRAKES - OVERVIEW B767-3S2F Page - 37 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY LVDT PCA 0 0 PCA 60 9 INFLIGHT SPEED BRAKE MAX LIMIT (DEG) SPOILER PANEL NO. EHSV LVDT PCA 17 8 0 EHSV LVDT 60 INBD 17 X XX EHSV LVDT 17 7 45 60 OUTBD 45 LVDT 6 17 10 45 LVDT 17 INBD INBD INBD PCA 60 EHSV 17 5 OUTBD 4 OUTBD 45 0 17 60 C HYD PWR OUTBD 45 11 45 45 PCA 60 OUTBD 45 PANELS 4 AND 9 LOCKED OUT DURING IN-FLIGHT SPEED BRAKES EHSV 45 3 OUTBD LVDT EHSV EHSV 60 1 LVDT EHSV EHSV EHSV PCA 60 45 60 60 PCA FWD PCA PCA PCA LVDT PRESSURE PCA LVDT R HYD PWR PCA LVDT C HYD PWR R HYD PWR EHSV EHSV L HYD PWR LVDT YSM 12 45 45 L HYD PWR B767-3S2F Page - 38 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AUTO SPEEDBRAKE ACTUATOR Auto Speedbrake Actuator The Auto Speedbrake Actuator drives the speedbrake lever and the speedbrake LVDT's through a no-back clutch. The clutch allows the flight crew to move the speedbrake lever without moving the actuator output shaft. Access to the actuator is through a side panel in the captain's side of the control stand. REVERSE THRUST LEVER ACCESS PANEL THRUST LEVER DOWN ARMED SPEEDBRAKE LEVER (LIFT TO MOVE) REVERSE THRUST LEVER POSITION SWITCH (S374) NO BACK CLUTCH ASSEMBLY P10 CONTROL STAND UP INNER SHAFT AUTOSPEEDBRAKE ACTUATOR SWITCH CAM SPEEDBRAKE SWITCHES (S371 & S493) LVDT (3) AUTO SPEEDBRAKE ACTUATOR B767-3S2F Page - 39 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 40 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AUTO SPEEDBRAKE SYSTEM Purpose The auto speedbrake system operates the speedbrake lever mechanism to extend the spoilers at touchdown or during a refused takeoff and to retract the spoilers when a go-around starts after touchdown. System Description Auto speedbrake relays control operation of the autospeedbrake electric motor-operated actuator that moves the speedbrake lever mechanism. These inputs control the relays: - Thrust lever position switches (two thrust levers) - Arm switch (speedbrake lever) - Thrust reverse switch (a reverse thrust lever) - Air-ground (YSM). Indication Operation of the auto speedbrake system shows by the position of the speedbrake lever on the P10 control stand. Fault indication shows by the advisory AUTO SPEEDBRAKE on EICAS and the amber AUTO SPDBRK light on P5. AUTO SPEEDBRAKE SYSTEM B767-3S2F Page - 41 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 42 ATA 27-60 11/11/13 EFF - ALL AUTO SPEEDBRAKE ELECTRICAL SCHEMATIC Operation A 28v dc motor-driven actuator extends and retracts the speedbrakes. Extend The auto-speedbrake actuator moves to the full extend position when the auto-speedbrake extend relay energizes. The extend relay energizes when the auto-speedbrake air/gnd system 1 and 2 relays energize. The auto-speedbrake air/gnd system 1 and 2 relays energize when all of these conditions are correct: - YSM shows the airplane is on the ground - Thrust levers are < 8.5 degrees - Speedbrake lever is armed or a reverse thrust lever is at idle. The YSM shows the airplane is on the ground when at least two air/ground inputs show on ground and at least one radio altimeter shows less than ten feet. Retract The auto-speedbrake actuator moves to the full retract position when the retract relay energizes. The retract relay energizes for one or more of these conditions: - A thrust lever moves forward - An auto-speedbrake air/gnd sys relay deenergizes - Speedbrake lever is less than the arm position, and the reverse thrust levers are in the stowed position. TRAINING MANUAL FOR TRAINING PURPOSES ONLY Speedbrake Faults These conditions cause the amber AUTO SPDBRK light on P5 and AUTO SPEEDBRAKE EICAS (level C alert) message when the speedbrake lever is in the arm position: - Disagreement between system 1 and system 2 auto speedbrake air/ground relays - Left and right YSM auto-speedbrake invalid signals are correct - Auto-speedbrake extend and retract relays energize or deenergize at the same time. The auto-speedbrake light and message also show when the actuator is not fully retracted, and the speedbrake handle is in the down detent. AUTO SPEEDBRAKE ELECTRICAL SCHEMATIC B767-3S2F Page - 43 ATA 27-60 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 44 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER CONTROLS AND INDICATORS Trim Control and Indication A trim control knob on the control stand operates the electric trim actuator on the aft quadrant assembly. A trim indicator shows the trim actuator position in units of trim. Rudder Position Indication The rudder position is displayed on the EICAS status page. Yaw Damper Controls The Yaw Damper system is controlled by two switches on the P5 overhead panel. An ON light shows the switch position. An amber INOP light indicates the yaw damper function is inoperative. A three position yaw damper test switch on the P61 panel tests both Yaw Damper systems. EICAS Indications A RUDDER RATIO amber light on the P5 overhead panel indicates the loss of rudder ratio changer function. EICAS advisory and maintenance messages indicate various levels of ratio changer and yaw damper faults. Advisory messages indicate loss of function. Maintenance messages indicate faults in the associated system. TEST L YAW DAMPER R ON ON INOP INOP OVERHEAD PANEL (P5) GND RPROX L C L C INERTIAL REFERENCE INOP INOP R DUCT LEAK RUDDER RATIO OVERHEAD PANEL (P5) TEST PANEL MODULE (P61) RUDDER RATIO R YAW DAMPER L YAW DAMPER PRIMARY DISPLAY 15 10 5 NOSE LEFT AILERON LEFT WING DOWN 0 UNITS 5 10 15 NOSE LEFT RIGHT WING DOWN RUDDER RATIO YAW DAMPER NOSE RIGHT NOSE RIGHT ECS/MSG PAGE R U D D E R RUD AIL/RUD TRIM CONTROL (P8) AIL ELEV AIL STATUS PAGE EICAS DISPLAY UNIT (P2) RUDDER CONTROLS AND INDICATORS B767-3S2F Page - 45 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 46 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER YAW CONTROL Yaw Control The function of the rudder system is to provide directional control and stability around the vertical axis. Pilot inputs via the rudder pedals drive a single cable run from the forward quadrants located beneath the flight compartment floor to the aft quadrant at the base of the vertical stabilizer. Electrical control inputs at the aft quadrant are: • Rudder trim actuation by the flight compartment trim switch • Auto Pilot inputs from the flight control computers Rudder control authority is varied in response to airspeed by the ratio changer mechanism and actuator. Two yaw damper servos each driven by a control module provide turn coordination and protection against uncommanded yaw inputs. The rudder is powered by three actuators, each served by a separate hydraulic system. A surface position signal is developed by a transmitter which provides position indication through the EICAS system to the flight compartment for display on the status page only. RUDDER YAW CONTROL B767-3S2F Page - 47 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 48 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER SYSTEM Description Two sets of adjustable rudder pedals mechanically drive a pair of forward half quadrants. The quadrants are tied together by a bus rod to enable rudder control by either set of pedals. The quadrants and linkages are located beneath the flight compartment floor and accessed through the forward access door, forward of the nose wheel well. A single pair of rudder control cables from the forward quadrants run under the flight compartment floor, up the aft bulkhead of the flight compartment, along the ceiling of the passenger compartment and terminates at the aft quadrant in the base of the vertical stabilizer. The aft quadrant assembly receives control inputs from the pilots' rudder pedals through the cables, from the directional autopilot servos and from the electric trim system. Output is through two control rods to the ratio changer assembly. Yaw Damper Summing Lever Assembly Sums ratio changer and yaw damper inputs to provide control input to rudder actuators. Incorporates a pogo assembly, and a secondary control path override. The assembly is mounted above the ratio changer and receives inputs from the primary and secondary control path linkages, and from the yaw damper servos. Two yaw damper servos receive inputs from control modules and provide turn coordination and protection against uncommanded yaw inputs. Position Transmitter The rudder position transmitter is mounted just below the lower PCA. Rudder surface movement drives a synchro-transmitter which provides a position signal through the EICAS computers and is displayed on the status page. Directional Autopilot Servos Dispatch Deviation Three directional autopilot servos receive control inputs from the flight control computers and provide directional control in autoland mode only on final approach and during runway rollout. Flight Control Surface Indication INOP: Trim Actuator/Feel And Centering Unit One Trim Actuator mounted directly above the aft quadrant drives the rudder to selected trim position by positioning the trim, feel and centering unit. The trim actuator is driven by electrical trim signals from the flight compartment. A cam and roller and springs provide feel force to rudder pedal input and the centering force to return pedals to neutral when input is removed. Rudder Ratio Changer The rudder ratio changer is located directly above the aft quadrant and driven by the aft quadrant output rods. The purpose is to vary the rudder control authority as a function of airplane speed. An electro hydraulic actuator, controlled by signals from control modules, drives the ratio changer mechanism. Ratio changer output is through the primary and secondary control paths. • Flight control surface indication may be INOP provided a visual flight control check is accomplished prior to each departure. Power Control Actuators Three PCAs receive control valve inputs from the primary and secondary control paths. Each actuator is powered by a separate single hydraulic system. UPPER RUDDER PCA C HYD SYS MIDDLE RUDDER PCA L HYD SYS RUD A ELEV AIL LOWER RUDDER PCA R HYD SYS YAW DAMPER SUMMING MECHANISM AIL LOWER EICAS DISPLAY (P2) 15 10 NOSE LEFT AILERON LEFT WING DOWN 5 0 5 UNITS 10 NOSE RIGHT NOSE LEFT RIGHT WING DOWN TEMPERATURE COMPENSATION LINKAGE 15 MAIN EQUIPMENT CENTER NOSE RIGHT R U D D E R LT YSM SINGLE FCC AIL/RUD CONTROL (P8) PEDAL ADJUSTMENT CRANKS RT YSM CAPTAIN'S RUDDER PEDALS YAW DAMPER SERVOS RT YSM RUDDER POSITION TRANSMITTER RATIO CHANGER ACTUATOR LT YSM PRIMARY CONTROL ROD SECONDARY CONTROL ROD TRIM ACTUATOR RUDDER RATIO CHANGER MECHANISM FIRST OFFICER'S RUDDER PEDALS FWD FORWARD QUADRANT FWD TO NOSEWHEEL STEERING AFT QUADRANT ASSEMBLY DIRECTIONAL ROLLOUT AUTOPILOT SERVOS (3) RUDDER SYSTEM B767-3S2F Page - 49 A ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FEEL CENTERING AND TRIM MECHANISM AUTO LAND ONLY FCC (3) B767-3S2F Page - 50 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER TRIM SYSTEM Trim Switch Trim control is by a pilot operated trim switch located on the aft edge of the center console (P8). The rotary switch is spring loaded to the neutral position. The switch is part of the aileron/rudder trim control module and is powered by 28 volt dc from the left dc bus through a circuit breaker located on the p-11 panel. Rotation of the trim switch through the 5 degree position removes the system ground. Rotation through the 15 degree position arms the trim motor circuit. Rotation through the 25 degree position closes the control switch and selects the extend (left rudder trim) or retract (right rudder trim) mode of operation. There is a mechanical stop at the 30 degree position. Only one trim rate exists and is not a function of the trim switch operation. Trim Actuator The rudder trim actuator is a linear actuator powered by a self contained dc motor. The unit contains an electromagnetic brake to limit overrun. Internal limit switches control actuator stroke. Positive mechanical stops prevent over travel in the event of limit switch malfunction. Power is applied by the trim switch and energizes the motor until the switch is released or the limit switch is activated. The brake releases during motor operation and resets by spring force when power is interrupted. Trim Position Indicator The rudder trim position indicator is powered by 28 volt ac from left AC bus and controlled by a circuit breaker on the P-11 panel. The signal to drive the trim indicator is generated by a gear driven RVDT integral to the trim actuator. The transmitter signal drives a DC motor in the receiver unit in the aileron/rudder trim control module to position the trim indicator. The indicator registers 17 units of left or right rudder trim. Nulling of the indicator is done with hydraulic power off and rudder trim to neutral (rudder trailing edge within index groove and cam centered in detent). If the indicator is not at zero, remove the aileron/rudder trim control module and adjust it by rotating the adjusting screw on the aft face of the until the indicator reads zero. Note: An inoperative rudder trim indicator does not affect the ability of the rudder trim actuator to provide trim inputs to the rudder system. 15 10 NOSE LEFT AILERON RUDDER TRIM POSITION (K17) 0 5 UNITS 10 15 NOSE RIGHT NOSE LEFT NOSE RIGHT R U D D E R RIGHT WING DOWN LEFT WING DOWN 28V AC BUS L 5 POWER SUPPLY ZERO ADJUST FWD INDICATOR ADJUSTMENT PANEL 324 BL TAPE DRIVE A N83 RUDDER TRIM INDICATOR TRIM ACTUATOR NOSE LEFT 25L° 28V DC BUS L 15L° RUDDER TRIM CONTROL (K18) P11 OVHD CB PANEL A LEFT (EXT) 5L° 5R° 15R° RIGHT (RET) 25R° NOSE RIGHT M515 RUDDER TRIM ACTR RUDDER TRIM SW (S3) M74 AIL/RUD TRIM CONTROL MODULE (P8) RUDDER TRIM SYSTEMS B767-3S2F Page - 51 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FWD B767-3S2F Page - 52 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER CHANGER OPERATION General The Ratio Changer System varies the amount of maximum rudder travel as a function of airspeed. The system provides for constant rudder pedal response over the entire airplane operating speed range. The Rudder Ratio Changer Actuator (RRCA) is electro-hydraulic and is driven by two separate analog channels. Description The ratio changer actuator, on the ratio changer mechanism, consists of an unbalanced actuator with a solenoid valve, a bypass valve and an Electro-Hydraulic Servo Valve (EHSV). The bypass valve, operated by the solenoid valve, and the EHSV control left hydraulic system pressure to the ratio changer actuator. Ratio Changer Actuator Operation When the ratio changer is inoperative, the solenoid valve is de-energized and the bypass valve is spring loaded closed. In the closed position, the bypass valve shuts off hydraulic pressure to the EHSV and the middle PCA. Left hydraulic system pressure, if available, fully retracts the actuator to the low speed position. When the ratio changer system is in operation, the solenoid valve is energized and opens the bypass valve providing pressure to the EHSV and the middle PCA. As airspeed increases, signals are sent to the EHSV to increase pressure to the extend side of the unbalanced actuator. As the actuator extends, it positions the ratio changer mechanism to a high speed position. Failure Conditions Actuator faults, or ratio changer system failures causing loss of control, de-energize the solenoid valve which closes the bypass valve. Left hydraulic pressure moves the mechanism to the low speed position. SER -CAUTIONREMOVE THE FRONT PANEL SLOWLY TO PREVENT DAMAGE TO INTERNAL CABLE MFR A/S MENU YES ON/OFF TO MIDDLE POWER CONTROL ACTUATOR NO YAW DAMPER/STABILIZER TRIM MODULE (YSM) P/N 285T1122SERIAL NUMBER MOD A B C D LEVEL E F G H L ADIRU BYPASS VALVE LOGIC CROSSFEED LEFT HYD SYS PRESS SW PRIMARY & SECONDARY CONTROL PATHS LEFT YSM SOLENOID VALVE EHSV RATIO CHANGER MECHANISM LVDT A/G SYS 1&2 RATIO CHANGER ACTUATOR SER -CAUTIONREMOVE THE FRONT PANEL SLOWLY TO PREVENT DAMAGE TO INTERNAL CABLE MFR L HYD SYSTEM MENU YES A/S R ADIRU ON/OFF NO YAW DAMPER/STABILIZER TRIM MODULE (YSM) P/N 285T1122SERIAL NUMBER MOD A B C D LEVEL E F G H LEGEND RIGHT YSM ELECTRICAL MECHANICAL HYDRAULIC RATIO CHANGER OPERATION B767-3S2F Page - 53 ATA 27-20 11/11/13 AFT QUADRANT MECHANISM EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 54 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER RATIO CHANGER MECHANISM General Description The purpose of the rudder ratio changer mechanism is to vary the rudder authority (amount of control surface displaced into the airstream) from commands by the rudder pedals, autopilot servos or rudder trim as a function of airspeed. At low airspeed, the mechanism provides high authority to the rudder, at high airspeed, the mechanism provides low authority to the rudder. The ratio changer mechanism is located on the aft spar of the vertical stabilizer. It is connected to the aft quadrant mechanism and the yaw damper summing mechanism. primary and secondary control rods. Maximum rudder authority is approximately 26 degrees. High Speed Position Operation As the actuator extends, the bellcranks are rotated towards the torque tube decreasing the radius of the primary and secondary control rods from the rotational axis of the torque tube. This reduces the output from the aft quadrant mechanism to the primary and secondary control rods. Maximum rudder authority in the high speed position is approximately 2 degrees. Authority is reduced incrementally as speed increases. Ground Test The ratio changer mechanism consists of an offset torque tube containing two bearing mounted bellcranks. The end of the bellcranks are attached to the primary and secondary control rods. The bellcranks are rotated on the torque tube by the ratio changer actuator. The actuator is connected to the left bellcrank and a bus rod interconnects the two bellcranks. A cartridge containing two Linear Variable Differential Transformers (LVDT) is mounted on the ratio changer mechanism structure at one end and connected to the right bellcrank at the other end. A rig pin hole in each bell crank aligns with a rig pin hole in the torque tube to allow adjustments. Ratio Changer Operation When the actuator is retracted, the bellcranks are rotated away from the torque tube. Movement of the torque tube by the aft quadrant provides a maximum input to the primary and secondary control rods. As the actuator extends, the bellcranks are rotated towards the torque tube which decreases the movement of the control rods. If the ratio changer control system fails three springs drive the bellcranks away from the torque tube ensuring full authority of the rudder control system. Low Speed Position Operation When the actuator is retracted the bellcranks are moved away from the torque tube. This is the low speed position. In this position the ratio changer mechanism can transmit a full input from the aft quadrant mechanism to the A ground test positions the actuator to a 360 knots position for system adjustment. In the test position, rig pin 6 can be inserted when the ratio changer mechanism is properly rigged. The LVDT is adjusted to position the mechanism for rig pin fit. RIGHT BELLCRANK RIG PINS ACTUATOR LUG LEFT BELLCRANK YAW DAMPER SUMMING MECHANISM TEMPERATURE COMPENSATION LINKAGE LVDT PCA'S CENTERING AND BIAS SPRING OFFSET TORQUE TUBE YAW DAMPER SERVOS (2) SUPPORT BEARING CRANK ADJUSTING NUT FWD BUS ROD (ADJUSTABLE) RETURN SPRINGS(3) RATIO CHANGER ACTUATOR SECONDARY CONTROL PATH ACTUATOR EXTENDED PRIMARY CONTROL ROD RATIO CHANGER ACTUATOR ROTATIONAL AXIS LOAD LIMITER WITH CRUSH CORE RUDDER RATIO CHANGER LVDT AFT QUADRANT MECHANISM TORQUE TUBE SECONDARY CONTROL ROD ACTUATOR RETRACTED AFT QUADRANT MECHANISM RATIO CHANGER MECHANISM B767-3S2F Page - 55 PRIMARY CONTROL PATH ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER RATIO CHANGER MECHANISM B767-3S2F Page - 56 ATA 27-20 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RUDDER YAW DAMPER SYSTEM System Description The yaw damper system provides automatic rudder control to improve airplane ride quality, dampen gust loads on the vertical stabilizer, dampen undesirable sideslip and roll (Dutch roll), and with any one autopilot engaged provide coordinate turns. The yaw damper system includes two Yaw Damper Stab Trim Modules (YSM) each controlling a yaw damper servo actuator. The system uses inputs from the Air Data Inertial Reference Computers (ADIRU), servo actuator LVDT’s, modal suppression accelerometers, and air/ground relays to command rudder movement. Pressure switches in the left and center hydraulic systems input for fault detection and indication. Movements of the yaw damper servos are summed by a summing lever before transfer to the yaw summing mechanism which commands the rudder. When both yaw damper servos are operative in flight, maximum yaw damper input to the rudder is approximately 6 degrees in each direction. When one servo is operative, maximum rudder movement is approximately 3 degrees. The maximum amount of rudder command available for yaw damping depends on airspeed and the number of ADIRU supplying data. Controls and Indications Two yaw damper control switches are located on the yaw damper control panel. The switches control engage power to the YSMs and to the yaw damper servo actuators. When a system is inoperative or during test, an INOP amber light illuminates in the switch and an advisory L (R) YAW DAMPER message appears on EICAS. CAUTION: WITH ANY HYDRAULIC SYSTEM POWERED THE RUDDER WILL MOVE DURING THE TEST YSM The YSM’s command rudder movement and monitor yaw damper for faults. Failures are detected by automatic BITE and are stored in the module memory for ground recall. Faults are recalled with YSM 6 button front face BITE. YAW DAMPER L R ON INOP ON w INOP a w a YAW DAMPER CONT PANEL (P5) YAW DAMPER TEST SWITCH (P61) YAWDMPR L R SER CSEU PWR SUPPLIES 1L AND 2L S29 ADU CONTROL PRESS SWITCH (C HYD) 28V DC STBY BUS MENU YES TO PCA(S) -CAUTION- REMOVETHEFRONTPANEL SLOWLYTOPREVENTDAMAGE TOINTERNALCABLE MFR ON/OFF NO A YAWDAMPER/STABILIZERTRIM MODULE(YSM) P/N285T1122SERIALNUMBER MOD LEVEL A E B F C G D H L YSM SER 28V DC R DC BUS -CAUTION- INTERNAL LVDT MENU YES AIR/GND SYS S27 ACMP CONTROL PRESS SWITCH (L HYD) ON/OFF NO P/N285T1122SERIALNUMBER MOD LEVEL A E B F C G D H R YSM Page - 57 ATA 27-20 11/11/13 EFF - ALL EHSV FWD L HYD RUDDER YAW DAMPER SYSTEM B767-3S2F TO RUDDER RATIO CHANGER B YAWDAMPER/STABILIZERTRIM MODULE(YSM) CSEU PWR SUPPLIES 1R AND 2R RUDDER SUMMING LINKAGE ASSY YAW DAMPER SERVOS SUMMING LEVER REMOVETHEFRONTPANEL SLOWLYTOPREVENTDAMAGE TOINTERNALCABLE MFR ADIRU L, C, R MODAL SUPPRESSION ACCELEROMETERS (AFT OF CARGO COMP) TRAINING MANUAL FOR TRAINING PURPOSES ONLY C HYD B767-3S2F Page - 58 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY ELEVATOR GENERAL DESCRIPTION General Description The elevator control system gives primary control of the airplane around its pitch axis. The elevators change pitch attitude for climb, descend, and altitude hold. Control The elevator control system has two equivalent systems in parallel. The captains control column supplies inputs to the left elevator PCA through the left aft quadrant. The first officers control column supplies inputs to the right elevator PCA through the right aft quadrant. The two control systems connect through override mechanisms at the control columns and aft quadrants. The autopilot system gives automatic elevator control. The autopilot servos move the aft quadrant assemblies through rods and cranks. The left and center autopilot servos move the left aft quadrant. The right autopilot servo moves the right aft quadrant. The feel and centering unit gives control column feel. The elevator feel computer changes the feel at the column as a function of airspeed. The airspeed is from the pitot system. A stick nudger command from the stall warning computers moves the elevators and the control columns to cause a nose down attitude of the airplane. The slave cable system lets the movement of one elevator make a control input into the opposite elevator PCA. This gives elevator asymmetry protection if the PCA on one side disconnect from the aft quadrant. Forward Controls The two control column torque tubes connect together by a control column override mechanism. A stick shaker is on each torque tube. The torque tubes connect to the tension regulator quadrants. Two pairs of cables connect the tension regulator quadrants to the aft quadrants. The left cables (captain control column) go between the cabin floor beams and connect to the left aft quadrant. The right cables (first officer control column) go up in the flight compartment bulkhead and then in the cabin ceiling and connect to the right aft quadrant. The aft quadrant torque tubes are aft of the horizontal stabilizer. An interconnect rod connects the two aft torque tubes at the override mechanisms. Three elevator autopilot servos are on the aft fuselage structure and connect to the two aft quadrants by rods. Two servos connect to the left aft quadrant and one servo connects to the right aft quadrant. A feel computer, in the stabilizer compartment, makes dual hydraulic pressures that change as a function of airspeed and stabilizer position. This variable hydraulic pressure goes to the feel actuator on the feel and centering unit and also to the stabilizer trim control modules (STCM). A feel and centering unit connects by rods to the two aft quadrant torque tubes. The feel and centering unit has a dual hydraulic actuator supplied with variable pressure from the elevator feel computer. A cam roller spring mechanism and hydraulic feel pressure move the elevator system to center. A stick nudger is on the feel and centering unit. An override mechanism is on the upper aft fuselage structure. The override mechanism gives a neutral position for the feel and centering unit. The aft quadrants output connect by rods to all three PCAs on each outboard elevator. The movement of the elevators moves a slave cable through lost motions and overrides. Position transmitters connect by cranks and linkages to each inboard elevator to give elevator position to the EICAS computers. Operation The elevator control system has two equal systems that operate in parallel. Usually, the two systems operate together. A break-out of the override mechanisms lets the captain column operate the left elevator and the first officer column operate the right elevator independently. In the command mode of the autopilot, the FCC give commands for elevator movement and cause a backdrive of the control columns. Feel force at the control columns changes by the feel computer as a function of airspeed and stabilizer position. The override mechanism lets the elevator system operate if there is a jam in the feel and centering mechanism. The slave cable system gives an alternate means to control one elevator if the linkage disconnects between the aft quadrant torque tube and the PCA. Dual stick shakers give stall warning. A stick nudger on the feel and centering unit gives a forward force to the control columns for stall recovery. Two stall warning computers control the shakers and nudger. FLIGHT CONTROL COMPUTERS CONTROL COLUMN (2) FLIGHT DECK INDICATION AUTOPILOT SERVO AUTOPILOT SERVO AUTOPILOT SERVO LEFT AFT QUADRANT A RIGHT AFT QUADRANT POSITION XMTR (2) B PCA (3) RIGHT ELEVATOR SLAVE CABLE INTERCONNECT STALL WARNING STABILIZER STICK NUDGER NEUTRAL SHIFT FEEL AND CENTERING UNIT SLAVE CABLES DUAL FEEL ACTUATOR SLAVE CABLE INTERCONNECT ELEVATOR FEEL COMPUTER PNEUMATIC HYDRAULIC MECHANICAL ELECTRICAL HYDRAULIC SYSTEM L A PITOT TUBE (2) ELEVATOR GENERAL DESCRIPTION B767-3S2F Page - 59 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B PCA (3) LEFT ELEVATOR HYDRAULIC SYSTEM C B767-3S2F Page - 60 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY ELEVATOR CONTROL SCHEMATIC Dual Path Controls The elevator control system consists of two equal systems in parallel. The captain control column is hard connected to power control actuator (PCA) input levers to the left outboard elevator. The first officers control column is hard connected to PCA input levers to the right outboard elevator. The left and right elevator control systems are interconnected through override mechanisms at the control columns and the elevator aft quadrants in the tail compartment just forward of the APU. The outboard elevators are connected to each other by slave cable interconnects. The captain's and first officers' elevator systems have equal authority. The two systems will normally act together as one system because of interconnection through override mechanisms. One system will control independent of the other (after override) if one system is immobilized. One system is sufficient to control the airplane. The inboard and outboard elevators are even (faired) and a mach trim system is provided and used. CONTROL COLUMNS OVERRIDE MECHANISM CAPTAIN CONTROL COLUMN FIRST OFFICER CONTROL COLUMN TENSION REGULATOR QUADRANT (2) ELEVATOR FEEL COMPUTER FEEL AND CENTERING UNIT OVERRIDE MECHANISM STICK NUDGER HORIZONTAL STABILIZER ELEVATOR A/P SERVO (3) AFT QUADRANT INTERCONNECT ROD SLAVE CABLE INTERCONNECT STICK SHAKER (2) SLAVE CABLE CENTER LINE OF QUADRANT STABILIZER REAR (2) SPAR HINGES LEFT AFT QUADRANT OUTPUT ARM CONTROL ROD LOST MOTION AND OVERRIDE DEVICE (2) PCA (3 ON EACH OUTBOARD ELEVATOR) FWD LEFT OUTBOARD ELEVATOR (RIGHT SIDE SIMILAR) LEFT INBOARD ELEVATOR (RIGHT SIDE SIMILAR) OUTBD ELEVATOR CONTROL SCHEMATIC B767-3S2F Page - 61 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY AFT QUADRANTS OVERRIDE MECHANISM LEFT AFT QUADRANT TORQUE TUBE POSITION TRANSMITTER (2) RIGHT AFT QUADRANT OUTPUT ARM CONTROL ROD RIGHT AFT QUADRANT TORQUE TUBE B767-3S2F Page - 62 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY ELEVATOR FEEL FORCE SYSTEM General Description The two control columns have their torque tubes connected together by a control column override mechanism. A stick shaker is installed on each torque tube. The torque tubes output to the tension regulator quadrants. Two pairs of cables are connected to the tension regulator quadrants. The left cables (captain's control column) are routed between the cabin floor beams to the aft fuselage; the right cables (first officer's control column) are routed up in the flight deck bulkhead and then in the cabin ceiling. The left cables are connected to the left aft quadrant (captain's) and the right cables to the right aft quadrant (first officer's). The aft quadrant torque tubes pivot on the airplane structure. They are located directly aft of the horizontal stabilizer. The two aft quadrants are interconnected by a rod and an override mechanism. Three autopilot servos are mounted on the aft fuselage structure and input to the two aft quadrants by connecting rods. Two servos input to the left aft quadrant and one to the right aft quadrant. Feel and Centering Unit A feel and centering unit, pivoted on the aft fuselage structure, is connected by rods to both aft quadrant torque tubes. The feel and centering unit contains a dual hydraulic actuator supplied with variable pressure from the elevator feel computer. A cam roller spring mechanism and hydraulic pressure provide for centering of the elevator system. A stick nudger is installed on the feel and centering unit. Elevator Feel Computer A feel computer, installed in the stabilizer compartment, generates dual hydraulic pressures which vary as a function of airspeed and stabilizer position. This variable hydraulic pressure is supplied to the feel cylinder of the feel and centering unit and to the stabilizer trim control modules Override Mechanism An override mechanism is installed on the upper aft fuselage structure. Elevator Controls The aft quadrants output by connecting rods to all three power control actuators (PCAs) on each outboard elevator. Slave Cable Interconnect The movement of the elevators drives a slave cable interconnect through lost motions and overrides. Position Transmitters Position transmitters are connected by cranks and linkages to each inboard elevator to provide elevator position signals to the EICAS computers. 1 2 CONNECTIONS ON THIS SCHEMATIC A B CONNECTIONS TO STABILIZER TRIM CONTROL MODULE (STCM) ELEVATOR FEEL COMPUTER STABILIZER FWD PITOT SYSTEM FLT CONTROLS HYD DISTR LFT RELIEF VALVE ELEV FEEL (S,M) PITOT PRESSURE BELLOWS BELLOWS STATIC RELIEF VALVE STATIC SOURCE SOURCE RUD FLT CONTROLS HYD DISTR CTR PITOT SYSTEM APL APL NOSE UP NOSE UP BIAS SPRING AIL ELEV AIL 1 EICAS DISPLAY (P2) STATUS AND MAINTENANCE PAGES) CENTERING SPRING F/O INPUT 2 A S1 S2 1 1 LEGEND PRESSURE L/R EICAS COMPTR (E8) RETURN METERED PRESSURE 1 2 ELEVATOR FEEL COMPUTER - PRESSURE DIFF (>25%) - L, C, R HYD SYS PRESSURIZED - 30 SEC TD ELEVATOR FEEL FORCE SYSTEM B767-3S2F Page - 63 ATA 27-30 11/11/13 CAPT INPUT B EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FEEL ACTUATOR ELEV FEEL AND CENTERING UNIT TIES AND LINKS B767-3S2F Page - 64 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STALL WARNING SYSTEM COMPONENTS Stick Shakers Captain's and first officer's stick shakers are located on the elevator torque tube sections under the flight compartment floor. Shakers are accessible from the access door forward of the nose wheel well. Stick Nudger A single stick nudger actuator, located on the elevator feel and centering unit provides a column forward force by repositioning the feel and centering unit input levers. Stall Warning Computers The left and right stall warning computers are located in the warning electronics unit (P51 panel) accessible from the main equipment area. Test Panel Left and right stall warning test switches are located on the P61 side panel. Each switch is a momentary toggle switch for testing a stall warning system. Interfacing System Components: • • • • • • Center and right Flap/Stabilizer Position Modules (P50) Proximity Switch Electronic Unit (E1-2) Flap/Slat Electronic Unit (E2-4) Air Data Inertial Reference Units (E2-6) Spoiler Control Modules 2L and 1R (E1-1), (E2-1) Air ground relays (controlled by the PSEU) (P36/P37 panels) L STALL R MISC TEST PANEL ELEVATOR TORQUE TUBES P61 RIGHT SIDE PANEL P50 FLAP/STAB POSITION MODULES (FSPM) COLUMN SHAKER (2) STALL WARNING COMPUTERS ELECTRICAL SYSTEM CARD FILE (P50) STICK NUDGER ACTUATOR WEU BITE MODULE WARNING ELECTRONIC UNIT (WEU) (P51) AFT ELEVATOR CONTROL CENTER STALL WARNING SYSTEM COMPONENTS B767-3S2F Page - 65 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 66 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STALL WARNING COMPUTER Purpose Each of the dual digital stall warning computers (SWC) is powered by dual power supplies in the warning electronic unit (WEU). The SWC's calculate data required for stick shaker and stick nudger operation and provide inputs to the electronic flight instrument system (EFIS) and enhanced ground proximity warning computer (EGPWC) for operation of the windshear detection and guidance system. Input/Output Stick shaker: Each SWC computes two angle of attacks (AOA) to compare for activation of the stick shaker discrete. The indicated AOA from the air data computer (ADC) is modified by pitch rate from the inertial reference system (IRS) and true airspeed (TAS) from the ADC to compute a corrected AOA. A shaker AOA, calculated from static flap and slat position (slat motion uses the most retracted position), is modified by mach and computed air speed (CAS) inputs to determine an upper limit for the shaker AOA. If shaker AOA is exceeded by the corrected AOA the SWC will activate the stick shaker output discrete. Each stick shaker is operated by a 28 volt dc motor. The left shaker is operated by the left SWC and the right shaker is operated by the right SWC to provide redundant stall warning indications. The shakers are automatically activated only in the air mode. Test switches (P61) provide for individual testing of each shaker motor on the ground. Stick nudger: A 28 volt dc motor operated actuator, mounted on the elevator feel unit, is controlled by two relays each operated by one of the SWC's. Actuator extension will result in forward pressure on the control columns to reduce the AOA. Each SWC compares the corrected AOA (also used for shaker operation) with a trip value based on current mach (M) input. Nudger operation also requires air mode with both the flaps and slats retracted. The control column will remain in a pushed forward position for the duration of the nudger output discrete. The stick nudger system can be tested by simultaneously activating both the left and right stall warning test switches with the airplane in the ground mode and flaps and slats retracted. The control columns should move forward and remain until either switch is released. Windshear Guidance and Detection System The SWC's provide inputs to the electronic flight indication system (EFIS) and ground proximity warning computer (GPWC) for windshear detection and guidance indications. The use of dynamic inputs such as pitch rate, mach and airspeed as well as static flap/slat configuration enables the SWC to compute an upper limit for the shaker AOA which permits an increased maneuver margin for the airplane to recover from windshear conditions without encountering premature stick shaker warnings. Data words are provided to the EFIS for display of the shaker AOA as a pitch limit indication and for a speed tape display indicating stall speed for the wing configuration. (Additional operating and limit speeds not associated with windshear detection are also provided EFIS by the SWC's.) Shaker AOA, corrected AOA and flap position are input by the SWC's to the GPWC for use in computation of windshear detection and annunciation. (GPWC also uses self generated pitch rate/angle, roll attitude and vertical speed and ADC input true airspeed and computed airspeed in the windshear computation.) Windshear warning is red lights, red message on EFIS, siren and voice annunciation. BITE A warning electronics unit (WEU) built-in-test (BITE) module provides continuous monitoring of the SWC's, WEU power supplies and interfacing component inputs. Faults are annunciated by a WARN ELEX status/ maintenance message. 28V DC STBY BUS STICK SHAKER STALL TEST SW FLAP/STAB POSITION MODULE (FSPM) FLAPS/SLATS ELECTRONIC UNIT (FSEU) STICK SHAKER PROXIMITY SW ELECTRONICS UNIT (PSEU) STALL WARNING COMPUTER (SWC) SPOILER CONT MODULE (SCM) GND PROXIMITY WARN COMPUTER (GPWC) INERTIAL DATA (ADIRU) Large Display System POWER SUPPLY MODULES (PSM) AIR DATA (ADIRU) AIR/GND RELAYS WEU BITE DISPLAY MODULE STALL WARNING COMPUTERS B767-3S2F Page - 67 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 68 ATA 27-30 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STALL WARNING COMPUTER BITE Purpose The warning electronic unit (WEU) built-in-test (BITE) module is located in the P51 panel below the stall warning computers (SWC). It is a printed circuit board equipped with faultballs for WEU power supplies A and B, a power reset switch and two pairs of indicators to display fault codes. Alphanumeric codes are displayed for SWC circuit board faults (on board fault), stall warning system interface anomalies, airplane configuration/options, and software version. Power-Up On power up the SWC's initiate a self test of output drivers, input discrete components, decoders and BITE memories. If a fault or anomaly is detected WARN ELEX status/maintenance messages will be displayed on EICAS, and the appropriate alphanumeric fault code will be displayed on the BITE module. The fault code will be cleared only by a good power up test. If no faults are detected ON power-up, no messages will appear, and the BITE will contain the airplane configuration and option code. Continuous Monitoring Continuous monitoring tests determine circuit board operational capability on a non-operational interference basis. Any on board faults preventing stick shaker, stick nudger and angle of attack (AOA) outputs or interface anomalies such as loss of voltage at the stick shaker and air data inertial reference unit (ADIRU) AOA input will cause the status/maintenance messages WARN ELEX to annunciate. Faults detected during continuous monitoring are not latched and will clear with the fault. An opposite channel (other SWC) failure can also cause a failure code to appear on the good SWC. BITE Test Activation of the appropriate STALL test switch on the miscellaneous test panel (P61), in the ground mode only, will cause the associated SWC to verify the air/ ground discrete and the ADIRU AOA input and then conduct the stall warning BITE test. During this test (approximately 10 seconds), the WARN ELEX messages will be displayed and all segments of the BITE indicators will illuminate. All computer functions, except RAM/ROM memories and all interface components are tested. In addition the associated column shaker will operate and the pitch limit indicator (PLI) will position at ten degrees on the EADI. If installed the stall speed portion of the speed tape will display. If no faults or anomalies are detected a software code will display for one second then the configuration and option code will be displayed and the associated stick shaker will operate until the test switch is released. The other SWC will display code D9 during the test. If faults exist the BITE will display the software code, then each fault code for 1 to 3 seconds in order of priority, with the highest priority fault remaining. Interface anomaly faults will not be displayed if an on board (SWC) fault exists. When a fault is detected the WARN ELEX messages remains after test switch release. The stick shaker will not be activated. CAUTION: IF BOTH TEST SWITCHES ARE ACTIVATED, WITH NO FAULTS, ANY HYDRAULIC SYSTEM PRESSURIZED AND THE FLAPS/ SLATS RETRACTED, THE STICK NUDGER WILL CAUSE THE ELEVATORS TO MOVE. PITCH LIMIT INDICATOR SPD A/T SPEED TAPE DISPLAY 180 G/S FLARE LOC ROLLOUT CMD F 160 140 SHAKER SPEED 120 DH100 .730 150 GS 170 TEST EADI DISPLAY (TYPICAL) L POWER SUPPLY B FAULTBALL RESET SWITCH B A LEFT STALL RIGHT STALL MISC TEST PANEL (P61) RIGHT STALL WARNING COMPUTER LEFT SWC FAULT RIGHT SWC FAULT INDICATORS INDICATORS WARNING ELECTRONICS UNIT (WEU) (P51) STALL WARNING COMPUTER BITE Page - 69 ATA 27-30 11/11/13 EFF - ALL R LEFT STALL WARNING COMPUTER POWER SUPPLY STATUS B767-3S2F STALL POWER SUPPLY A FAULTBALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 70 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STABILIZER CONTROLS AND INDICATORS Stabilizer Trim Switches Electrically signals the stabilizer to trim in the desired direction when simultaneously pushed. Alternate Stabilizer Trim Switches Electrically signals the stabilizer to trim in the desired direction when simultaneously pushed. Stabilizer Trim Indicator Indicates stabilizer position in UNITS of trim. Green band indicates allowable TAKEOFF setting. OFF FLAG appears if trim indicator is INOP. Stabilizer Trim Cutout Switches NORM position allows hydraulic power to the stabilizer trim. CUTOUT position shuts off respective hydraulic system power to the stabilizer trim. STAB TRIM Light Illuminates when stabilizer is trimming at half the signaled rate. UNSCHED STAB TRIM Light Illuminates if the stabilizer moves opposite to elevator during autopilot operations or during uncommanded stabilizer movement when autopilot is disconnected. MANUAL ELECTRIC TRIM SWITCHES STAB TRIM P5 OVERHEAD PANEL - ANNUNCIATOR PANEL UNSCHED STAB TRIM (B) STAB TRIM (C) UNSCHED STAB TRIM FCC SWITCHES UPPER EICAS DISPLAY STAB TRIM (M) CONTROL COLUMN CUTOUT SWITCHES LOWER EICAS DISPLAY ALTERNATE ELECTRIC TRIM SWITCHES APL NOSE DN S T A B T R I M APL NOSE UP HYDRAULIC CUTOUT SWITCHES POSITION INDICATOR CONTROL STAND P10 POSITION INDICATOR SER 0 -CAUTION- REMOVE THE FRONT PANEL SLOWLY TO PREVENT DAMAGE TO INTERNAL CABLE MFR 2 4 6 8 10 12 MENU ON/OFF 14 STABILIZER POSITION INDICATOR (2) (P10) YES NO YAW DAMPER/STABILIZER TRIM MODULE (YSM) P/N 285T1122SERIAL NUMBER MOD LEVEL A E B F C D G H YSM (2) STABILIZER CONTROLS AND INDICATORS B767-3S2F Page - 71 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 72 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STABILIZER TRIM BLOCK DIAGRAM Manual Electric Trim System The control wheel stabilizer trim control switches provide up or down ARM and CONTROL signals to the two yaw damp / stabilizer trim modules (YSM). The YSMs provide up or down ARM and CONTROL signals to solenoids on the stabilizer trim control modules (STCM). ARM AND CONTROL hydraulic valves function in series and allow hydraulic flow to the two hydraulic motors and two hydraulically released brakes on the stabilizer trim ball screw actuator assembly. Two hydraulic cutout switches provide electrical power to the STCM shutoff valve motors, isolating hydraulic power from the control modules. Hydraulic inputs from the elevator feel computers control the rate of stabilizer trim. The left and right limit switch and position transmitter modules provide position feedback through Flap/Stabilizer Position Modules (FSPM) in the P50, to the Flight Control Computers (FCC). The Position and Limit Switch Modules also drive the flight compartment position indicators, and limit stabilizer travel by cam actuated micro-switches which break the ARM electrical paths from the YSM to the STCM. Column operated cutout switches also break the electrical ARM paths from the YSM to the STCM when the control columns are moved in a direction opposing stabilizer trim. Autopilot Trim System (Autotrim) One of three Flight Control Computers ( FCC ) provide autopilot input signals to the YSM to trim the stabilizer based on elevator out of neutral position, using only 1 motor (half speed). The function of the YSM, the STCM, the stabilizer trim ballscrew actuator assembly and the limit switch and position transmitter modules is identical to the manual electric system described above. Alternate Electric Trim System Two alternate trim switches provide ARM and CONTROL commands directly to solenoids inside the STCM. The SCTM'S provide hydraulic pressure to release the hydraulic brakes and drive the hydraulic motors to trim the stabilizer. Mach Trim System One of two YSM will automatically trim the stabilizer according to airspeed signals from the Air Data Inertial Reference Units (ADIRU), located on shelves E1-3 and E2-3 in the main electronic compartment. The flap/stabilizer position modules, located in the P-50 card file, signal the YSM for mach (flaps retracted) trim selection. Air/ground logic from the air/ground relays inhibits mach trim on the ground. Any autopilot engagement also inhibits mach trim. Stabilizer Trim Fault Indication System The YSM control the logic associated with flight compartment amber annunciation the P5 pilot's overhead panel and the readout on EICAS. The YSM can record Existing Faults on the status of various system LRUS. HYDRAULICS (L/C) A POSITION INDICATORS STAB TRIM UNSCHED STAB TRIM ELEV FEEL COMPUTER P5 PANEL MANUAL ELECTRIC TRIM COMMANDS HYDRAULIC RELEASED BRAKE (2) BALL SCREW ACTUATOR ASSY EICAS COMPUTERS STABILIZER HYDRAULIC MOTOR (2) ADIRU (2) COLUMN CUTOUT SWITCHES A STCM (2) FCC (3) YSM (2) FSPM (3) LIMIT SWITCH AND POSITION TRANSMITTER MODULE (3) STABILIZER TRIM BLOCK DIAGRAM B767-3S2F Page - 73 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 74 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STABILIZER TRIM CONTROL MODULE (STCM) Operation The STCM receive electric command inputs to control the porting of hydraulic fluid to the stabilizer trim ballscrew actuator assembly hydraulic motors and hydraulically released brakes. Location And Access There are two interchangeable STCM (right and left) mounted on the bulkhead above the stabilizer ballscrew actuator assembly. Access to the STCM is through the stabilizer service access door. Components There are seven hydraulic ports and four electrical connectors on each STCM. There is a cleanable 100 micron in-line filter screen in the system pressure port. There are four dual coil solenoid valve assemblies for nose up and nose down ARM and CONTROL electrical inputs on each STCM. A pressure switch set at 750 to 1000 psi signals pressure to the hydraulically released brakes for use by the digital stabilizer trim and aileron lockout modules (YSM). A 28 volt DC motor operated shutoff valve, with manual override, controlled by the flight compartment hydraulic cutout switches, is located on each STCM. Each STCM has a manually operated bypass valve to test the brake reaction torque. The test is performed by pressing a button protruding from the outside of the module. Maintenance Practices Several of the components mounted on the two STCM are line replaceable units. These include the four dual coil solenoid valves; the motor operated hydraulic shutoff valve; the brake bypass test switch assembly, and the hydraulic pressure switch assembly. APL NOSE DOWN PORT ARM NOSE DOWN SOLENOID ARM NOSE UP SOLENOID CONTROL NOSE DOWN SOLENOID CONTROL NOSE UP SOLENOID APL NOSE UP PORT BRAKE RELEASE PORT STABILIZER AFT COMPONENTS PRESSURE SWITCH RETURN PORT FWD MOTOR-OPERATED SHUTOFF VALVE (MANUAL OVERRIDE NOT SHOWN) STABILIZER TRIM CONTROL MODULE (STCM) B767-3S2F Page - 75 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY BRAKE BYPASS BUTTON B767-3S2F Page - 76 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STABILIZER HYDRAULIC CUTOUT SWITCHES General Description The hydraulic cutout switches control power to the hydraulic shutoff valves on the STCMs. The valves stop hydraulic flow through the STCMs for maintenance or in a runaway trim condition. Cutout Switches and Shutoff Valves Two guarded cutout switches are on the top left side of the control stand. The shutoff valves on the lower side of each STCM operate by 28v dc electric motors. Operation The left switch controls the shutoff valve on the left STCM. The right switch controls the valve on the right STCM. When the guard is down, the switches are in the NORM position, and the shutoff valves are open. You put the cutout switches in the CUTOUT position to close the shutoff valves. Maintenance Practices Access to the switch wiring is by removal of the fuel control panel. The hydraulic cutout switches also do functional tests of the stabilizer trim system. When the two cutout switches are in the CUTOUT position, hydraulic power to the STCMs stops, and the stabilizer operation disables. When only one cutout switch is in the CUTOUT position, the stabilizer operates at half speed because only one hydraulic motor can move. STABILIZER HYDRAULIC CUTOUT SWITCHES HYD SHUTOFF VALVE (SOV) CUT OUT 28V DC STBY CLOSE NORM C STAB TRIM OPEN CUT OUT 28V DC STBY SOV R STAB TRIM CONTROL MODULE NORM L STAB TRIM CLOSE NORM CUT OUT L OPEN C STAB TRIM SOV L STAB TRIM CONTROL MODULE STABILIZER HYDRAULIC CUTOUT SWITCHES B767-3S2F Page - 77 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 78 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY STAB TRIM LIMIT SWITCH AND POSITION TRANSMITTER MODULES General Each module contains four cam actuated micro-switches, one synchro, and one Rotary Variable Displacement Transducer (RVDT). Although all three modules are identical and interchangeable, each services different functions as determined by the wiring of the electrical connectors. Limit Switches Operation A drum connected by a cable to the stabilizer drives each stabilizer trim limit switch and position transmitter module. As the stabilizer moves, the cables drive the drum which rotate the module input shaft. Maintenance Practices Access to the stabilizer trim and position transmitter modules is by opening the access door to the stabilizer compartment. These switches will interrupt the electrical trim signal to the hydraulic Stabilizer Trim Control Modules (STCM) solenoids, providing the limits for electrical stabilizer trim. The three modules are line replaceable units and are interchangeable. No field adjustment is required on the modules. Each module is replaced without disturbing the cable drive system. The module spline shaft has a missing tooth which is aligned with the missing tooth of the splined drum. • The up limit switch will open at 1.5 units (flaps down) or 0.5 units (flaps up) of trim. • The down limit switch will open at 13 units (300) of trim. The cables are rigged with the stabilizer set to a specific position and the drums positioned by rig pins. Greenband Switch The switch provides a signal (switch closed) to the configuration warning card when the stabilizer is within the takeoff trim limits. Outside of these limits, the switch will open and the appropriate configuration warning will be annunciated if the plane is in a Takeoff configuration. 0.25 to 7.0 units of trim is available. RVDT The RVDT sends an AC voltage signal, corresponding to stabilizer position, to the flap/stabilizer position module (FSPM) in the P-50 card file for conversion to a usable DC signal for various digital user systems. Synchro The synchro signals stabilizer position to the flight compartment position indicators and the Flight Data Recorder. STABILIZER PIVOT POINT STABILIZER CENTER SECTION STABILIZER TRIM CONTROL MODULES HYDRAULIC BRAKES (2) STABILIZER TRIM CONTROL MODULES STABILIZER TRIM BALLSCREW ACTUATOR ASSEMBLY HYDRAULIC MOTORS (2) LIMIT SWITCH AND POSITION TRANSMITTER MODULES (3) STABILIZER TRIM BALLSCREW ACTUATOR ASSEMBLY L COMPONENT C FUNCTION R COMPONENT FUNCTION COMPONENT FUNCTION SWITCH 1 UP LIMIT SWITCH 1 NOT USED SWITCH 1 UP LIMIT SWITCH 2 UP LIMIT SWITCH 2 NOT USED SWITCH 2 UP LIMIT SWITCH 3 NOT USED SWITCH 3 DOWN LIMIT SWITCH 4 GREEN BAND SWITCH 4 NOT USED SWITCH 3 DOWN LIMIT NOT USED SWITCH 4 RVDT FSPM ( L) SYNCHRO CAPT IND & FLT DATA REC RVDT SYNCHRO ELECTRICAL CONNECTOR STABILIZER TORQUE BOX FSPM (C) NOT USED ELECTRICAL CONNECTOR RVDT FSPM (R) SYNCHRO F/O INDICATOR FWD ELECTRICAL CONNECTOR LIMIT SWITCH AND POSITION TRANSMITTER MODULE (3) (VIEW LOOKING FORWARD) STAB TRIM LIMIT SWITCH AND POSITION TRANSMITTER MODULES B767-3S2F Page - 79 ATA 27-40 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY LIMIT SWITCH AND POSITION TRANSMITTER MODULES (3) B767-3S2F Page - 80 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY HIGH LIFT DEVICES Introduction The high lift devices include the trailing edge flaps and leading edge slats systems. The high lift devices are extended to improve wing lift and drag characteristics for takeoff and landing operations and to provide increased stall operating margins. There are four trailing edge flaps which have six operating positions. The inboard flaps have main and aft sections and are double slotted when fully extended. The outboard flaps have one section and are always single slotted when extended. There are twelve leading edge slats which have three operating positions. A krueger flap, extending from the bottom of the wing, operates with the inboard leading edge slats. Operation The leading edge slat and trailing edge flap systems are usually operated together by the flap control lever. The trailing edge flaps are operated by one drive system and power drive unit (PDU) with two rotary actuators at each flap. The leading edge slat system has separate drives for the inboard and outboard devices with the two inboard slats operated by one drive and PDU, and the ten outboard slats operated by another drive and PDU. There are two rotary actuators at each slat. A flap/slat electronic unit (FSEU) provides position indication, failure protection and control functions. A flap/slat shutoff valve module is controlled by the FSEU to sequence flap and slat operation. The FSEU also provides separate flap and slat alternate operation for non-normal high lift systems operation. High Lift Configurations The flaps and slats are controlled by the flap control lever during primary (hydraulic motor) operation and by the alternate flap selector and arm switches during alternate (electric motor) operation. Alternate operation is about six times slower than normal operation. The flap lever and alternate position selector switch have positions showing units of trailing edge flap extension. The trailing edge flaps are retracted at both the up and one positions of the lever or switch. The leading edge slats have three positions of retracted (up), intermediate (takeoff/sealed), extended (landing/gapped) and operate between lever, or switch, positions of up to one and 20 to 25. The inboard and outboard flaps and inboard and outboard slats have different degrees of extension at each position. The inboard and outboard slats have different operating times due to large differences in the amount of extension at the intermediate and full extension positions. The alternate position selector switch has a NORM (normal) position which does not provide an output command. This is a safety position to prevent inadvertent alternate drive operation in event either arm switch is actuated and flap or slat position disagrees with the selector switch. The Flap/Slat Electronics Unit controls the Interlock/Sequencing between the Flaps and Slats as follows: • Initial Hydraulic Extension: slats extend to take-off position then flaps extend • Last Hydraulic Retraction: flaps must fully retract then slats will Retract from take-off to up position • Initial Electric Extension: no interlock • Last Electric Retraction: flaps must fully retract then Slats will retract from take-off to up position KRUEGER SEAL FLAP INBOARD DOUBLE SLOTTED FLAP OUTBOARD SINGLE SLOTTED FLAP INBOARD LEADING EDGE SLAT OUTBOARD LEADING EDGE SLAT HIGH LIFT DEVICES B767-3S2F Page - 81 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 82 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAPS CONTROL AND INDICATION TE Flap Control And Indication The flap control lever provides control during primary (hydraulic motor) operation of the flap system. Alternate (electric motor) operation is controlled by the ALTN FLAPS position selector and arm switches. Two needles on the flap position indicator show left and right wing flap drive positions. Flap drive position is shown in units with indicated airspeed (IAS) limits shown for each extended position. A TRAILING EDGE amber light, master CAUTION lights and EICAS caution alert, advisory alert, status and maintenance messages show flap system faults. LE Slat Control And Indication The flap lever provides control during primary (hydraulic motor) operation of the slat system. Alternate (electric motor) operation is controlled by the ALTN FLAPS position selector and LE arm switches. Two needles on the flap position indicator show slat position at the up and one unit positions. A LEADING EDGE amber light, master CAUTION lights and EICAS caution, and status and maintenance messages show slat system faults. TRAILING EDGE LEADING EDGE TE FLAP ASYM (B) TE FLAP DISAGREE (B) FLAP LOAD RELIEF (C) FLAP LIMIT (IAS) 220K 240K 210K 5 1 15 UP FLAPS 20 FLAP/SLAT ELEC (S,M) 195K 25 TE FLAP SHUTDOWN (S,M) 30 190K 162K ALTN FLAPS 5 1 15 EICAS DISPLAY UNITS (P2) 1 UNIT (GATE) 5 UNIT 15 UNIT 20 UNIT (GATE) FLAP LEVER 0 (FLAPS UP) 25 UNIT 30 UNIT (FLAPS AND SLATS FULLY EXTENDED) FWD Page - 83 ATA 27-50 11/11/13 POSITION SELECTOR 20 NORM 25 30 LE ALTN TE FLAP ARM SW FLAPS CONTROL AND INDICATION B767-3S2F UP EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY TE ALTN B767-3S2F Page - 84 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAPS GENERAL DESCRIPTION Introduction Two trailing edge flaps are mounted on each wing. The inboard flaps are double slotted and the outboard are single slotted. A single power drive unit (PDU) powers eight rotary drive actuators (two on each flap assembly) through gearboxes and drive shafts. Control of primary (hydraulic) flap operation is by a flap control lever connected by cables to the flap aft quadrant. A load relief (alleviation) actuator is connected to the PDU input linkage to limit extension if airspeed limits are exceeded at landing flap settings. A flap slat electronic unit (FSEU) controls position indicating, failure protection and alternate (electric) operations. Position transmitters on the flap drive actuators and flap control lever are used by the FSEU for its control functions. The FSEU controls the flap/slat shutoff valve module to sequence flap and slat drive operation and to remove hydraulic pressure to the PDU during cruise flight operations. FLAP INDICATION FLIGHT DECK OUTBD FLAP ALT POS SELECT SW EICAS FLAP LEVER INBD FLAP FSPM (3) ALT ARM SW MEC FLAP LEVER POSITION TRANSMITTERS (2) SLAT AFT QUADRANT (REF) DRIVE SHAFT FLAP LOAD RELIEF ACTUATOR FSEU FLAP AFT QUADRANT OUTBOARD MAIN FLAP FLAP/SLAT SHUTOFF VALVE MODULE INBOARD MAIN FLAP SECTION GEARBOX FLAP POWER DRIVE UNIT INBOARD AFT FLAP SECTION ROTARY ACTUATOR (8) FLAP POSITION TRANSMITTERS (8) FLAPS GENERAL DESCRIPTION B767-3S2F Page - 85 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 86 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP PRIMARY DRIVE CONTROL Operation The hydraulic motor on the flap power drive unit (PDU) is the primary power source for the flap drive. Inputs to the PDU control unit for hydraulic motor operation are from cables and control rods operated by the flap control lever or by operation of the control rods by the flap load relief actuator. Drive shaft operation of the control unit provides hydraulic motor shutdown at the commanded position (closed loop). Cables from the flap control lever are routed through the forward cargo compartment to a flap aft quadrant in the aft cargo compartment. A control rod from the quadrant extends through the right wheel well aft wall. Controls shafts connect the control rod to the PDU. Turnbuckles are provided at two locations for cable rigging. Flap Control Lever The spring loaded flap lever has seven detent positions. The detents show units of primary drive command input. Gates at the 1 and 20 unit positions prevent lever movement directly through these positions. These gates show lever positions for critical flap and slat configuration changes during flight operations. Two rotary variable differential transformers (RVDT) are operated by a flap lever gearbox in the control stand. RVDT number 1 inputs flap lever position to flap slat electronic unit (FSEU) section 2 and RVDT number 2 to inputs FSEU section 1. Flap Detent Degrees 1 0 5 13.8 15 20.0 20 25.4 25 35.0 30 41.4 CABLES (RIGHT SIDE UNDER FLOOR) LOAD RELIEF ACTUATOR PDU TURNBUCKLES (2 LOCATIONS) (AFT CARGO COMPT) FLAP LEVER FLAP AFT QUADRANT SLAT AFT QUADRANT (REF) FLAP LOAD RELIEF ACTUATOR ND TE X E FLAP LEVER FWD WALL OF AFT CARGO COMPT CONTROL RODS CABLES FWD FLAP LEVER QUADRANT CABLES POWER DRIVE UNIT (RIGHT WHEEL WELL - AFT BULKHEAD) FLAP PRIMARY DRIVE CONTROL B767-3S2F Page - 87 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 88 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP POWER DRIVE UNIT (PDU) General The trailing edge flap power drive unit (PDU) is on the aft bulkhead of the right main gear wheel well. Hydraulic and electric motors are installed on a gearbox which operates the left and right wing drive shafts. Primary operation is by the hydraulic motor, alternate operation is by the electric motor. A control unit and control valve module with bypass valve, control pressure to the hydraulic motor. Maintenance Practices A tool can be installed on the PDU to lock the gearbox so the flap drive cannot be operated with either the hydraulic or the electric motor. LOAD RELIEF MECHANISM (REF) HYDRAULIC MOTOR GEARBOX ASSEMBLY CONTROL RODS GEARBOX ASSEMBLY ELECTRIC MOTOR UP POSITION HYDRAULIC MOTOR PILOT INPUT ARM PDU GEARBOX ASSEMBLY DRIVE SHAFT CONTROL UNIT OUTPUT ARM UP POSITION CONTROL UNIT CONTROL UNIT CONTROL VALVE MODULE UP POSITION CONTROL VALVE MODULE CONTROL VALVE INPUT ARM INBD TE FLAP PDU (LOOKING AFT) PDU LOCK OUTBD Page - 89 ATA 27-50 11/11/13 EFF - ALL FWD TE FLAP PDU (RIGHT WHEEL WELL, AFT BULKHEAD) FLAP POWER DRIVE UNIT (PDU) B767-3S2F BALL LOCKPIN TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 90 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP PDU COMPONENTS PDU General The major components of the flap power drive unit (PDU) are hydraulic and electric motors; gearbox; control unit; and control valve module with control and bypass valves. Control Unit The control unit input cam is operated by an internal input crank connected to the pilot input arm. The follow up cam is operated by a quill shaft driven by the PDU gearbox. A summing lever, operated by both cams through cam followers, operates a control unit output arm and input rod to the control valve module. Operation of the primary control system moves the input cam, with the follow-up cam held by the gearbox, causing the summing lever to input to the control valve. Operation of the gearbox drives the follow-up cam with the input cam held by the flap control lever in detent, with the summing lever nulling the control valve when the drive reaches the commanded position. There is a rig pin hole for each cam defining their neutral positions. Control Valve Module The control valve module has control and bypass valves. The control valve provides center hydraulic system pressure to a reversible hydraulic motor through the bypass valve. The bypass valve has a manual override lever which also shows the valve position. The bypass valve shuts off pressure to the hydraulic motor and opens both ports of the motor to center hydraulic system return. The valve is moved from the normal position "two" to bypass position "one" during electric motor operation, to remove the hydraulic motor lock on the gearbox, and during flap system faults to shut down primary control operation. CONTROL VALVE MODULE CONTROL UNIT INPUT CAM PRESS SUMMING LEVER UP PILOT INPUT ARM RETURN DN NUL FOLLOW-UP CAM FSEU/ ALT ARM SW CONT VALVE ELECTRIC HYDRAULIC MOTOR MOTOR BYPASS NORM BYPASS VLV UP GEARBOX DN C1 C2 CD DRIVE SHAFT CONTROL UNIT CD NORM CLOSED HYDRAULIC MOTOR ALTERNATE DRIVE ELECTRIC MOTOR (ARROWS = EXTEND) GEARBOX DRIVE SHAFT CONNECTION CONTROL UNIT OUTPUT ARM OPEN BYPASS C SYS HYDRAULIC RETURN PORT BYPASS VALVE C SYS HYDRAULIC PRESSURE PORT CONTROL VALVE MODULE INPUT ROD MANUAL OVERRIDE LEVER BYPASS VALVE HYDRAULIC MOTOR CASE DRAIN HYDRAULIC MOTOR RETURN HYDRAULIC MOTOR PRESSURE CONTROL VALVE MODULE INBD TE FLAP PDU (LOOKING AFT) CONTROL VALVE MODULE FLAP PDU COMPONENTS B767-3S2F Page - 91 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 92 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP/SLAT SHUTOFF VALVE MODULE Description The flap/slat shutoff valve module provides center hydraulic system pressure to the flap and slat power drive units (PDU). The module has a priority valve, a flow regulator, and flap and slat solenoid-operated shutoff valves. The module is installed on the aft bulkhead in the right main gear wheel well, outboard of the PDU. The priority valve permits flow only when center hydraulic pressure exceeds 1200 psi. The flow regulator, installed downstream of the priority valve, limits hydraulic flow to the flap and slat hydraulic motors to regulate maximum motor speed to control the rate of flap and slat extension or retraction. The flow regulator provides a maximum flow of 24 gpm. The flap solenoid-operated shutoff valve depressurizes the hydraulic motor when the flaps are retracted and for flap/slat interlock (sequencing). The valve is spring-loaded open and electrically closed by flap/slat electronic unit (FSEU) control signals. The slat solenoid-operated shutoff valve depressurizes both PDU hydraulic motors when the slats are in the commanded position and on retraction until the trailing edge flaps are retracted (interlock). The valve is spring-loaded open and electrically closed by flap/slat electronic unit (FSEU) control signals. C HYDRAULIC SYSTEM FLOW REGULATOR FROM FLAP POWER DRIVE UNIT RTN PRESS FLAP LOAD RELIEF ACTUATOR (REF) PRIORITY VALVE FSEU TE FLAP PDU (REF) SLAT SOLENOID VALVE RIGHT WHEEL WELL AFT BULKHEAD SLAT SHUTOFF VALVE FLAP SOLENOID VALVE SLAT SOLENOID VALVE (REF) FSEU FLAP SOLENOID VALVE C2 TO SLAT POWER DRIVE UNITS C1 FLAP SHUTOFF VALVE TO FLAP POWER DRIVE UNIT RETURN PRESSURE FLAP SHUTOFF VALVE SLAT SHUTOFF VALVE (REF) C HYD SYSTEM PRESSURE PORT VALVE PRIORITY FLAP PRESSURE FLOW REGULATOR FLAP/SLAT SHUTOFF VALVE MODULE C HYD SYS RETURN PORT FLAP / SLAT SHUTOFF VALVE MODULE B767-3S2F Page - 93 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY TOP VIEW SLAT PRESSURE B767-3S2F Page - 94 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP ROTARY ACTUATOR General Description The wing rotary actuators are installed in two support ribs mounted in the spoiler beam or wing rear spar. Three mounting brackets hold the actuator which is installed using a missing tooth reference on a reaction ring on a support rib. The actuator output shaft is splined into a drive shaft installed in the support ribs. The drive shaft is connected to a flap drive arm. A flap position transmitter is mounted on the opposite side of the support ribs. The flap transmitter drive frame tangs fit in channels in the splined drive shaft, causing the drive frame to rotate with the drive shaft/drive arm and operate the transmitter. A torque limit indicator pivots out of spring clips if the actuator torque limit is exceeded. SPOILER BEAM ACTUATOR MOUNTING BRACKET (3) SUPPORT RIBS REACTION RING (SPLINED) DRIVER FRAME TANGS (2) (FIT IN CHANNELS IN SPLINED DRIVE SHAFT) SUPPORT RIBS TRANSMITTER DRIVER FRAME FLAP LINKAGE ATTACH POINTS FLAP DRIVE ARM FLAP TRANSMITTER SPLINED DRIVE SHAFT ACTUATOR OUTPUT SHAFT TRANSMITTER HOUSING MOUNTING FRAME TRANSMITTER SUPPORT BRACKETS ACTUATOR MOUNTING BRACKET ACTUATOR (3) FLAP DRIVE ARM OUTBD REDUCTION GEAR OUTPUT RING GEAR INPUT SHAFT TORQUE LIMITER TRIP GEAR (DISK) OUTPUT SHAFT TORQUE LIMIT INDICATOR FWD ACTUATOR 3 INSTALLATION (ACTUATOR 6 SIMILAR) TORQUE LIMITER TRIP GEAR (DISK) FIRST GEAR INPUT SHAFT NO-BACK BRAKE TORQUE LIMITER TORQUE LIMIT INDICATOR INDICATOR RETAINING CLIP (BOTTOM HALF) (HOLDS TORQUE LIMITER INDICATOR) FLAP ROTARY ACTUATOR B767-3S2F Page - 95 ATA 27-50 11/11/13 STRUCTURALLY MOUNTED REACTION RING (MISSING TOOTH REFERENCE) EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 96 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY INBOARD FLAPS Flap Inboard Drive The inboard flap inboard drive mechanisms are in the aft body fairings with the other six drive mechanisms in fairings on each wing. The flap support tube, extending outboard through the fairing, is attached to a track roller carriage mounted on a support track. Forward, mid and aft fairing doors are operated by drive rods to close the opening in the fairing when the flaps are retracted or fully extended. The door driver rods are connected to bell cranks operated by a door actuation cam track. The forward and aft doors, operated by the upper drive rod, are spring loaded closed. When the flaps are retracted the forward door is held open by the flap support tube with the mid and aft doors closed. All doors are open when the flaps are not fully retracted or extended. When the flaps are fully extended the aft door is held open by the flap support tube with the mid and forward doors closed. The rotary actuator drive arm operates drive arms and linkage to move the flap section. Only the inboard flap drive mechanisms have roller carriages and support tracks, the other drive mechanisms use only the linkage for support. Flap Outboard Drive The inboard flap outboard drive mechanism is in a three section fairing on the wing structure. The rotary actuator in the support structure, operates drive arms and linkage connected to the main flap. A support beam holds the flap sections and drive mechanism. The aft flap is operated by two pushrods, two bell cranks and a cam in the fairing. As the main flap extends, the forward bell crank, attached to support structure, pivots to push on the forward pushrod. This pivots the aft bell crank, mounted on the main flap, which pulls on the aft pushrod to rotate the cam counterclockwise. The cam roller, on the aft flap, then moves on the lower cam lobe which is concentric with the cam pivot point and the aft flap remains faired to the main flap. As the main flap approaches full extension, the forward bell crank pulls on the control rod causing the aft bell crank to push on the aft pushrod and rotate the cam clockwise. The roller then moves up on the non-concentric upper cam lobe pushing the aft flap away from the main flap. This occurs as the flap fully extend from 25 to 30 units. The aft flap drive operates a slave rod assembly in the main flap connected to the other end of the aft flap. This drives both ends of the aft flap evenly to the gapped position. The aft flap is supported by two deflection control tracks, attached to the main flap aft spar, that ride on rollers in recesses in the aft flap. 4 3 6 5 2 1 MID-DOOR OUTLINE RETRACTED (DOOR CLOSED) SUPPORT FWD/AFT DOOR FWD-DOOR OUTLINE TRACK DRIVE ROD FLAP SUPPORT (DOOR CLOSED) TUBE AFT-DOOR OUTLINE 3 (DOOR OPEN) DRIVE ARM 4 TRACK ROLLER CARRIAGE 5 6 MID-DOOR DRIVE ROD 1 MAIN FLAP LINK DOOR ACTUATION CAM TRACK 2 ACTUATOR DRIVE DOOR DRIVE BELL CRANKS FULLY EXTENDED INBOARD FLAP B767-3S2F Page - 97 ATA 27-50 11/11/13 EFF - ALL LOAD ROLLER TRAINING MANUAL FOR TRAINING PURPOSES ONLY AFT FLAP B767-3S2F Page - 98 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY OUTBOARD FLAP The outboard flap is driven by two rotary actuators. Each actuator rotates a drive arm which operates drive arms and links to move the flap. A flap deflection control track and rollers are installed at the outboard end of the flap to prevent flap deflection from the wing. A roller on the inboard end of the flap engages in a fishmouth slot in the wing structure to prevent flap deflection when the flap is retracted. An aerodynamic fairing covers both outboard flap mechanisms. The fairing consists of three sections. DEFLECTION CONTROL CARRIAGE AND TRACK REAR SPAR FISHMOUTH SLOT (IN STRUCTURE) TRACK ROLLERS (ON STRUCTURE) (ON CARRIAGE) FLAP (RETRACTED) OUTBOARD FLAP (EXTENDED) ROLLER (ON FLAP) CARRIAGE (ON FLAP) REAR SPAR INBOARD END ACTUATOR SUPPORT RIB FLAP (EXTENDED) DEFLECTION CONTROL TRACK (ON WING) MAIN FLAP ASSEMBLY ACTUATOR SPOILER FWD FAIRING SECTION CENTER FAIRING SECTION AFT FAIRING SECTION DRIVE ARM FLAP RETRACTED FLAP EXTENDED OUTBOARD FLAP B767-3S2F Page - 99 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 100 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAPS / SLAT ELECTRONIC UNIT (FSEU) General The Flap / Slat Electronics Unit (FSEU) is the primary electronic control unit in the high lift system. It provides sequencing control, failure/asymmetry protection, system annunciation outputs, and flap load relief. During the alternate mode of operation, it does closed loop flap/slat positioning function. The FSEU can help you find and isolate a failure in the TE flap system and the LE flap and slat system. Front panel BITE on the FSEU gives you an interface with the BITE functions in the FSEU. The FSEU has a BITE panel with six switches. These are the functions of each switch: • • • • ON/OFF - starts or stops BITE display MENU - shows the menu YES or NO - response to question Down arrow or up arrow - scrolls through menu or results If you do not push a switch on the FSEU BITE panel in 5 minutes, the FSEU stops the BITE function and puts the display off. These are the items in the main menu of the FSEU BITE: • • • • EXISTING FAULTS? FAULT HISTORY? GROUND TESTS? OTHER FUNCTIONS? EXISTING FAULTS? The EXISTING FAULTS selection shows existing faults in the system and does a check of the interfaces to the FSEU. FAULT HISTORY? The FAULT HISTORY? selection shows past faults by flight leg. This fault data is in the non-volatile memory (NVM) in the FSEU. GROUND TESTS? The GROUND TESTS? selection lets you do these tests: • • • • TE flap load relief actuator test TE flap load relief system test Sensor checks Display test OTHER FUNCTIONS? The OTHER FUNCTIONS? selection lets you do these functions: • • • • LRU configuration Input/output monitor Change FSEU output discretes Erase faults SECTION 1 - FLAP SHUTOFF VALVE CONTROL - BYPASS VALVE CONTROL - FLAP LOAD RELIEF CONTROL - UNCOMMANDED MOTION DETECTION AND SHUTDOWN - ASYMMETRY/SKEW DETECTION AND SHUTDOWN SECTION 2 - FLAP DISAGREE DETECTION - FLAP LOAD RELIEF FAILURE DETECTION - MONITOR/ANNUNCIATION CONTROL - OUTPUT HYDRAULIC DEMAND DISCRETE BITE INSTRUCTIONS: Push ON/OFF to start or end BITE display. Push YES or NO to reply to questions(?). Push to move down in list. Push to move up in list. Push MENU to return to previous menu. BITE MAIN MENU: MENU ON OFF YES NO EXISTING FAULTS-Shows existing faults. FAULT HISTORY-Shows past faults by flight leg. GROUND TESTS-Shows list of ground tests. OTHER FUNCTIONS-Shows other functions. FLAP/SLAT ELECTRONIC UNIT P/N 285T0049SER NO. MOD LEVEL FMG DATE CAGE CODE 81205 MFR SER PMR MOD FSEU FLAP / SLAT ELECTRONIC UNIT (FSEU) B767-3S2F Page - 101 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SECTION 3 - ALTERNATE MODE CONTROL B767-3S2F Page - 102 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP SYSTEM INTERFACE Hydraulic Motor Operation Failure protection shutdown, flap/slat sequencing, long-term pressure shutoff, and load relief during hydraulic motor operation are provided by flap slat electronic unit (FSEU) section 1 through control of the flap shutoff valve, load relief actuator and bypass valve. These control functions require inputs from a flap lever rotary variable differential transformer (RVDT), a flap position transmitter RVDT (from a Flap stabilizer position module (FSPM)), flap position transmitter resolvers and slat power drive unit (PDU) RVDTs. Alternate arm switch input inhibits failure protection shutdown and load relief functions in FSEU 1. Electric Motor Operation FSEU section 3 controls the electric motor using inputs from the alternate flap selector switch and a flap position transmitter RVDT (from a FSPM). The flap alternate arm switch operates the PDU bypass valve and engages the electric motor clutch. Position Indication Flap position transmitter syncros operate the flap indicator syncros. FSEU section 3 controls a flap reference transfer relay using inputs from a flap position transmitter RVDT (from a FSPM) and slat PDU RVDT. Fault Annunciation A fault light and messages are control by FSEU section 2 using inputs from a flap lever RVDT, alternate arm and position selector switches, flap position transmitter RVDT (from a FSPM) and slat position (from FSEU sections 1 and 3). FSEU section 1 controls a single fault message and inputs to section 2 for existing faults. CENTER HYD SYS TRAILING EDGE LEADING EDGE FLAP LIMIT (IAS) 220K 240K 1 FLAP LEVER 210K 5 15 UP FLAPS 20 30 FLAP/SLAT SOV MODULE CONTROL VALVE 195K 25 190K RVDT (2) 162K B ALTN FLAPS 5 1 15 UP LOAD RELIEF ACTUATOR EICAS 20 NORM 30 HYDRAULIC ELECTRICAL MECHANICAL ARINC 429 SHUTOFF VALVE 25 LE TE ALTN ALTN ADIRU - ADP LOGIC BYPASS VALVE A E FLAP DRIVE - ECS A - CNFIG WARN C HYDRAULIC MOTOR FDR TE FLAPS GEAR BOX PSEU D ROTARY ACTUATORS C ELECTRIC MOTOR FLAP REF XFR RLY RVDT (4) INBD/OUTBD SLAT PDU E FLAP PDU FSEU B FLAP SYSTEM INTERFACE B767-3S2F Page - 103 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY CLUTCH FSPM L/C/R FLAP XMTR ASSEMBLY D B767-3S2F Page - 104 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP HYDRAULIC OPERATION Flap control lever, or load relief actuator, operation of the power drive unit (PDU) control unit input cam, moves the control valve module control valve from the null position. Center hydraulic system pressure is then provided to the hydraulic motor through the control valve module bypass valve. Flap drive shaft rotation operates the control unit follow-up cam to return the control valve to null. When the control valve is at null and the bypass valve is at normal, there is a hydraulic lock on the motor to hold the gearbox and flap drive. Hydraulic pressure to the motor can be shutoff by the Flap/Slat Shutoff Valve module flap shutoff valve or by the bypass valve in the PDU control valve module. . Pressure is shutoff to the motor as follows using the Flap/Slat Shutoff Module: • The flap solenoid valve is powered by the flap/slat electronic unit (FSEU) to close the flap shutoff valve when the flaps and flap lever are up or, on extension, until the leading edge slats have moved to their intermediate position. • If pressure is shutoff at the Flap/Slat Shutoff Valve Module the hydraulic lock remains on the motor Pressure is shutoff to the motor as follows using the Bypass valve: • The bypass valve is positioned to bypass when the alternate flap system arm switch is actuated or by the FSEU during flap system failure. • If pressure is shutoff by the bypass valve the motor can be rotated by the gearbox. C HYDRAULIC SYSTEM FSEU SLAT SOLENOID VALVE SLAT SHUTOFF VALVE PRESS FLOW REG PRIORITY VALVE RETURN FSEU FLAP SOLENOID VALVE C1 C2 TO SLAT POWER DRIVE UNITS FLAP SHUTOFF VALVE CONTROL VALVE MODULE INPUT CAM PRESS CONT UNIT ASSY RETURN DN UP PILOT INPUT ARM OPEN BYPASS NUL FSEU/ ALT ARM SW CONT VALVE BYPASS SUMMING LEVER BYPASS VLV UP FOLLOW-UP CAM DN C1 C2 CD QUILL SHAFT (WORM GEAR) GEARBOX LEGEND PRESSURE RETURN B767-3S2F (ARROWS = EXTEND) ATA 27-50 11/11/13 EFF - ALL CD NORM CLOSED HYDRAULIC MOTOR DRIVE SHAFT ALTERNATE DRIVE ELECTRIC MOTOR FLAP HYDRAULIC OPERATION Page - 105 NORM TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 106 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP LOAD RELIEF MECHANISM The flap load relief (alleviation) mechanism is on the aft wall of the right wheel well above the Power Drive Unit (PDU). The mechanism is comprised of a bell crank and electric actuator connected to two control rods which operate the pilot input arm of the PDU control unit. When the actuator is retracted the control rods are aligned between the aft quadrant crank and pilot input arm. When the actuator is extended, the bell crank moves the control rods out of alignment, pulling up on the pilot input arm. This inputs to the control unit and control valve to position the flap drive to 20 units with the lever at 25 or 30 units. The actuator in controlled by the Flap Slat Electronic Unit (FSEU). AFT QUAD CRANK (LEVER 30) LOAD RELIEF ACTUATOR INPUT RODS (FLAPS 30) AFT QUADRANT CRANK (LEVER UP) INPUT SHAFT FROM TE FLAP AFT QUADRANT AFT QUADRANT CRANK UP STOP (FLAP 20) LOAD RELIEF BELLCRANK LOAD RELIEF ACTUATOR CONTROL RODS PILOT INPUT ARM IN LOAD RELIEF LOAD RELIEF MECHANISM FLAP LOAD RELIEF MECHANISM B767-3S2F Page - 107 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 108 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP LOAD RELIEF SYSTEM General Description The load relief (alleviation) system prevents excessive air loads on the flaps by automatically limiting flap extension when airspeed is too high for flaps 25 or 30. The system will limit flap position to a maximum of 20 units when the airspeed equals or exceeds 172.5 knots with the flap lever at 30 units or 182.5 knots with the flap lever at 25 units. Operation requires a valid airspeed input from either Air Data Inertial Reference Unit (ADIRU). Load relief system operation is inhibited when: • • • • Alternate Flap System is ARMED Center Flap Stabilizer Position Module (FSPM) failure Flap lever transmitter (RVDT) failure Loss of 26 volt ac power supply Load relief operation is latched after actuation and is reset by reduction in airspeed to 168.5 knots for flap extension to 30 units and to 178.5 knots for extension to 25 units. Airspeed must be valid from either ADIRU to reset. If both ADIRUs are invalid the latches can be reset by moving the flap lever to 25 or 20 units. The only indication during flap load relief is the position indicator needles indicating flap movement. The trailing edge amber light and the FLAP LOAD RELIEF advisory message will illuminate if the system fails when load relief is required. Disagreement annunciation between flap lever and flap position and the flap failure protection shutdown system are inhibited during load relief operation. Load relief operation is controlled by Section 1 of the FSEU, fault annunciation is controlled by section 2. A FLAP LOAD RELIEF (C) message is displayed, when there is a failure of the flaps to relieve from 30 to 25 units. FSEU section 2 provides the fail input for the EICAS computers, and illuminates the TRAILING EDGE light. If the flaps fail to return to 30 from 25 units when the airspeed decreases below 168.5 knots, FSEU section 2 provides a TE FLAP DISAGREE message and illuminates the TRAILING EDGE light. Load Relief System operation is Inhibited when: • • • • Alternate Flap System is ARMED Center Flap Stabilizer Position Module (FSPM) failure Flap lever transmitter (RVDT) failure Loss of 26 volt ac power supply. 28V DC 115V AC SENSOR PWR TRANSFORMER POWER SUPPLY 28V AC FAIL FLAP LEVER RVDT FAIL FLAP/SLAT ELEC (S,M) LOAD RELIEF INHIBIT EICAS CMPTR(S) FSPM FAIL NOT RETRACT RETRACTED ALTN FLAP ARMED INHIBIT ARM SW POSN ALT FLAP FAIL PROT & FLAP DISAGREE ARM SW (P3-1) XMTR 4 FLAP POSN >20 LOAD RELIEF C FSPM (P50) 25 30 <20 VALID P10 AIRSPEED DATA BUS 4 R ADC INPUT >182.5 >172.5 AIRSPEED DATA BUS 4 L ADIRU (E1-3) ARINC 429 (SECT 1) FSEU (E2-4) L ADC INPUT VALID <168.5 VALID <25 FLAP LOAD RELIEF SYSTEM B767-3S2F Page - 109 ATA 27-50 11/11/13 RESET VALID R ADIRU (E2-3) EFF - ALL EXTENDED FLAP LOAD RELIEF ACTUATOR <178.5 ARINC 429 CONT FLAP LOAD RELIEF (P33) NOT EXTEND EXTENDED FLAP LEVER POSITION FLAP LEVER POSN RVDT 2 RETRACTED BRAKE TRAINING MANUAL FOR TRAINING PURPOSES ONLY LATCH LATCH RESET B767-3S2F Page - 110 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP ALTERNATE DRIVE CONTROL The flap Power Drive Unit (PDU) alternate drive electric motor is controlled by the Flap Slat Electronic Unit (FSEU). The FSEU receives command inputs from the alternate flaps position selector switch. Alternate flap arm switch inputs are also used by the FSEU for relay control as well as for direct control of the PDU bypass valve. The FSEU controls alternate flap relays to provide power to the reversible PDU electric motor. A right wing drive position transmitter inputs to a flap stabilizer position module (FSPM) which provides flap drive position to the FSEU. This provides an FSEU closed loop control system, similar to primary drive, to turn off the electric motor when flap drive and selector switch inputs agree. UP BITE INSTRUCTIONS: TRAILING EDGE LEADING EDGE Push ON/OFF to start or end BITE display. Push YES or NO to reply to questions(?). Push to move down in list. OFF FLAP LIMIT (IAS) ALT FLAPS POSITION SELECTOR SWITCH ALTERNATE FLAP ARM SWITCH RETRACT 270K Push to move up in list. Push MENU to return to previous menu. 220K 240K 210K 5 1 15 UP FLAPS 20 30 195K DN LOCK OVRD UP MENU ON OFF YES NO ALTN GEAR EXTENSION P33 OFF FLAP/SLAT ELECTRONIC UNIT 20 30 EXISTING FAULTS-Shows existing faults. FAULT HISTORY-Shows past faults by flight leg. GROUND TESTS-Shows list of ground tests. OTHER FUNCTIONS-Shows other functions. 190K 162K NORM BITE MAIN MENU: 25 ALTN FLAPS 5 1 15 INPUT TO FLAP PDU BYPASS VLV EXTENDED 270K-.82M EXTENDED 320K-.82M 25 LE TE ALTN ALTN P/N 285T0049SER NO. DN MOD LEVEL GND PROX FLAP OVRD GND PROX/CONFIG GEAR OVRD OVRD FMG DATE CAGE CODE 81205 MFR SER PMR MOD OVRD ALT FLAP RELAYS ALTERNATE FLAP CONTROL (P3-1) FSEU GEARBOX RIGHT WING DRIVE SHAFT ALTERNATE DRIVE ELECTRIC MOTOR FSPM BYPASS VALVE 1 ELECTRICAL CONNECTOR P50 ELECTRICAL SYSTEMS CARD FILE 1 FLAP POSITION TRANSMITTER, POSITION 5 (OUTBOARD VIEW) CONTROLLED BY ALT FLAP ARM SW FLAP ALTERNATE DRIVE CONTROL B767-3S2F Page - 111 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY OUTBD FWD TE FLAPS POWER DRIVE UNIT (RIGHT WHEEL WELL) B767-3S2F Page - 112 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAPS POSITION TRANSMITTER Flap position transmitters are installed on the support ribs for all eight flap drive mechanisms and connected to the splined drive shaft operated by the rotary actuator. Two types of flap transmitters are used which have different faces to insure correct installation. The two types of transmitters contain different components. The transmitters are rotated internally by a driver frame engaged, by tangs, in the splined drive shaft. The two tangs are different size with one having a rig pin hole to insure correct installation. A cutout in the transmitter assembly face fits around an adjustment fitting on the mounting structure. The adjustment fitting and mounting bolts hold the transmitter in position. There are three rig pin holes in the transmitter with a placard identifying the flaps 30 position. The transmitter is installed with a rig pin through the flaps 30 rig pin hole and the tang with the flaps hydraulically extended to 30 units. With the mounting bolts finger tight in the elongated mounting holes, the adjustment fitting is used to center the tang in the splined drive shaft. TRANSMITTER 4 TRANSMITTER 1 TRANSMITTER 7 TRANSMITTER 2 TRANSMITTER 8 P D U TRANSMITTER 5 TRANSMITTER 6 N TRANSMITTER 3 F L A PS 3 0 S PO TRANSMITTER ASSEMBLY 2, 3, 4, 5, 6 AND 7 TRANSMITTER ASSY 1 AND 8 FLAP POSITION TRANSMITTER (TYPICAL) FLAP POSITION TRANSMITTER B767-3S2F Page - 113 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 114 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP POSITION TRANSMITTER ASSEMBLIES Transmitter Assemblies 1 and 8 Transmitter assemblies at the 1 and 8 flap drive positions contain a resolver and a Syncro. The syncros are powered directly from the 28 VAC buses and drive syncros in the flap indicator. Syncro failures are shown by flap needle operation. The resolvers are powered by 28 VAC from Flap Slat Electronic Unit (FSEU) section 1. Failures are shown by FLAP/SLAT ELEC status/ maintenance messages and by the associated FSEU XMTR fault light during Built-in-test (BITE) operation. Resolver failure causes loss of flap asymmetry shutdown protection by FSEU section 1. Transmitter Assemblies 3, 4 and 5 for Flap Stabilizer Position Modules Transmitter assemblies at the 3, 4 and 5 flap drive positions contain resolvers and rotary variable differential transformers (RVDT). The resolver in the transmitter assembly at drive position number 3 is unpowered. Resolvers 4 and 5 operate the same as 1 and 8. The RVDT's are powered and monitored by Flap Stabilizer Position Modules (FSPM) which input flap drive position to the FSEU. RVDT or FSPM faults are shown by FLAP/SLAT ELEC status/ maintenance messages and by FSPM fault lights on the FSEU during BIT operation. The FSPM's have BITE to identify RVDT or module faults. Flap Lever Transmitters Two rotary variable differential transformers (RVDT) are operated by a flap lever gearbox in the control stand. Access is through the right side of the control stand. RVDT number 1 inputs flap lever position to flap slat electronic unit (FSEU) section 2 and RVDT number 2 to inputs FSEU section 1. The RVDT's are installed in electrical null alignment with the lever at fifteen units plus 4.5 degrees. The RVDT signal voltage is then checked at each lever position and adjusted as required by rotating the RVDT in its clamp. A failure of either transmitter is indicated by FLAP SLAT ELEC status/ maintenance messages. FSEU testing indicates the failed RVDT by a fault light. RVDT number 2 is also monitored for correct rig voltage with the flaps and slats up and the altitude is above 20,000 feet or airspeed is greater than 270 knots. A BIT/verify test will display the faulted flap lever RVDT voltage by displaying the MISRIG light. The flap lever and flaps must be in the UP position when testing for this fault. The RVDT misrig condition will be indicated by the FLAP SLAT ELEC message. A A B C LEFT FSPM CENTER FSPM RIGHT FSPM RVDT NO.3 FLAP LEVER RVDT NO.5 RVDT NO.4 PRESS/ TEST RESOLVER (TE FLAP DISAGREE) RIGHT (SECT 3) M603 FLAP LEVER POSITION XMTR 2 (SECT 1) M492 FLAP POSITION XMTR 5-RIGHT (SECT 1) M604M603 FLAPFLAP LEVERLEVER POSITION XMTR 1 (SECT 2) M473 FLAP POSITION XMTR 1-LEFT (SECT 1) BITE INSTRUCTIONS: M548 OUTBD SLAT PDU RVDT MISRIG (SECT 3) S846 HYD PRESSURE SWITCH (SECT BITE 1) MAIN MENU: TRANSMITTER NO. 3 XMTR NO.1 XMTR NO.2 Push ON/OFF to start or end BITE display. Push YES or NO to reply to questions(?). Push to move down in list. Push to move up in list. Push MENU to return to previous menu. B RVDT (FSPM) EXISTING FAULTS-Shows existing faults. FAULT HISTORY-Shows past faults by flight leg. GROUND TESTS-Shows list of ground tests. OTHER FUNCTIONS-Shows other functions. M476 FLAP POSITION XMTR 4-LEFT (SECT 1) M100 AIR DATA COMPUTER-LEFT (SECT 1) M483 INBD SLAT PDU POSITION XMTR 1 (SECT 1) M544 OUTBD SLAT PDU POSITION XMTR 1 (SECT 1) M545 FLAP/SLAT ELECTRONIC UNIT (SECT 2) FLAP/SLAT ELECTRONIC UNIT P/N 285T0049SER NO. MOD LEVEL RESOLVER (TE ASSYM) (TE SHUTDOWN) CAGE CODE 81205 FMG DATE BIT/ VERIFY (XMTER FAIL) M603 FLAP LEVER RVDT MISRIG (SECT 1) M489 FLAP POSITION XMTR 8-RIGHT (SECT 1) M101 AIR DATA COMPUTER-RIGHT (SECT 1) M549 INBD SLAT PDU MFR POSITION XMTR 2 (SECT 3) SER PMR M548 OUTBD SLAT PDU MOD POSITION XMTR 2 (SECT 3) MENU ON OFF YES NO XMITR NO.3 FLAP SHUTDOWN XMITER NO.4 S/M FLAP/SLAT ELEC EICAS C TEST COMPLETE (SECT 2) FSEU FLAP/SLAT ELECTRONIC UNIT FLAP DISAGREE RESOLVER (TE ASSYM) TESTING (SECT 2) TRANSMITTER NO. 4 TRANSMITTER NO. 5 FLAP LIMIT 230K RESOLVER (TE ASSYM) TRANSMITTER NO. 1 10 15 L R 1 SYNCRO (INDICATION) RESOLVER (TE ASSYM) 210K 250K 210K 20 UP FLAPS 30 25 SYNCRO (INDICATION) 180K 170K FLAP POSITION TRANSMITTER ASSEMBLIES B767-3S2F Page - 115 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY TRANSMITTER NO. 8 B767-3S2F Page - 116 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAPS POSITION INDICATION General The flap position indicator syncro receivers (needles) are driven by the syncro transmitters in the flap position transmitter assemblies at flap drives one and eight. Flap drive transmitter one operates the left needle, flap drive transmitter eight operates the right needle. The syncro transmitters drive the syncro receivers to show flap position whenever the flap/ref. transfer relay is de-energized. This relay is controlled by the FSEU using flap and slat drive position transmitter inputs and is de-energized when the slats or flaps are extended. The flaps are retracted when needles are at up or 1. The Flap position transmitters position the needles at 1 through 30 to show flap positions of up, 5, 15, 20, 25 or 30 units. The flap position indicator up position shows that all the leading edge slats are retracted. Slat Position Indication Left and right needles are operated by synchro receivers in the flap position indicator that are driven by synchro transmitters in flap position transmitters one and eight. Both synchro receivers can also be driven by two fixed reference signal transmitters that position the needles at up and one-half unit. An intermediate/retract relay, controlled by the Proximity Switch Electronic Unit (PSEU), and a flaps/reference transfer relay, controlled by the Flap/Slat Electronic Unit (FSEU), switch the indicator synchro receivers between the flap position synchro transmitters and the reference signal transmitters. Operation With the flaps and slats retracted both relays are energized and both needles are driven by the retracted reference signal transmitter. When any of the 24 slat proximity sensors show a target far the PSEU de-energizes the flap intermediate/retract relay and switches the needles to the intermediate reference signal transmitter. When both slat power drive unit (PDU) position transmitters show the PDU’s at their intermediate, or takeoff position, the FSEU de-energizes the flaps reference transfer relay and the needles are switched to the one and eight flap position transmitters which position the needles to one unit with the flaps retracted. From one to 30 units the needles are driven by their respective flap position transmitter. On retraction the FSEU energizes the transfer relay when the flaps are retracted and either slat PDU is less than takeoff to move the needles to one-half unit. The PSEU energizes the intermediate/retract relay when all slat sensors (24) have near targets to move the needles to up. 28V DC 28V AC P11 FIXED 1/2 XMTR 8 SLATS INTMD REF SIGNAL XMTR (P33) 5 1 XMTR 1 UP FLAPS 30 SLATS RET REF SIGNAL XMTR (P33) FLAPS INTMD/ RETRAC (P33) 28V AC R BUS FLAPS REF TRANSFER (P33) ALL SLAT LE SLATS RETRACTED POSN IND 115V AC R BUS PSEU (E1-2) P11 R FSPM POWER SUPPLY P50 28V AC EXC GOOD = RETRACTED FLAP POSN FSPM GOOD LOGIC INBD SLAT PDU 2 TRANSMITTER REF XMTR SELEC < T/O INBD SLAT POSN LOGIC RVDT GOOD < T/O OUTBD SLAT POSN LOGIC RVDT GOOD OUTBD SLAT PDU 2 TRANSMITTER FSEU (E2-4) FLAP POSITION INDICATION B767-3S2F Page - 117 ATA 27-50 11/11/13 EFF - ALL 20 25 FIXED UP XMTR 5 15 TRAINING MANUAL FOR TRAINING PURPOSES ONLY (SECT 3) B767-3S2F Page - 118 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAP/STAB POSITION MODULES (FSPM) Three identical Flap Stabilizer Position Modules (FSPM) power the flap position transmitter assembly rotary variable differential transformers (RVDT) at flap drive positions 3, 4, and 5. The FSPM receive an analog AC voltage signal from the RVDT and output flap position analog DC voltage signals and flap position discrete signals to various airplane systems. Each Flap Slat Electronic Unit (FSEU) section receives flap position from a different FSPM. The alignment of FSPM to FSEU section is shown on the FSEU with the left FSPM to section 2, center FSPM to section 1 and right FSPM to section 3. The RVDT input is monitored by the FSPM to detect a failed transformer. FSPM primary and monitor channels both generate signals which are compared by an outputs monitor to detect a module failure. Only the primary signal is output from the FSPM. RVDT or module faults shut down the FSPM analog and discrete outputs. A low voltage signal caused by a failed RVDT or FSPM causes the associated FSEU section to initiate a FLAP/SLAT ELEC message. The faulted FSPM input is then identified by the FSEU built-in-test. Testing of the FSPM is done by selecting Existing Faults on the six button front face bite as per the aircraft maintenance manual. MODULE STAB TRIM AFDS TMS FSEU (SECT 2) ENG IGN CNTL EEC SPLR CNTL 28V AC TEST GOOD STAB XMTR FLAP XMTR GND PROX FLAP POS XMTR 3 BIT/VERIFY L FSPM (P50) AFDS STAB TRIM 115V AC AFDS XFMR STAB TRIM 28V AC STALL WARNING STALL WARNING SAME AS L FSPM FSEU (SECT 1) SAME AS L FSPM PACK FLOW CNTL LAND CONF WARN SPLR CNTL Page - 119 11/11/13 EFF - ALL SPLR CNTL R FSPM (P50) FLAP / STAB POSITION MODULES (FSPM) ATA 27-50 EEC FLAP POS XMTR 5 C FSPM (P50) B767-3S2F ENG IGN CNTL PACK FLOW CNTL T/O CONF WARN FLAP POS XMTR 4 FSEU (SECT 3) TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 120 ATA 27-50 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY FLAPS ASYMMETRY PROTECTION SYSTEM The flap asymmetry protection system shuts down (bypasses) the flap primary drive and illuminates the TE FLAP ASYM message and produces the appropriate Existing Fault when a flap drive asymmetry condition is detected. Resolvers in flap position transmitter assemblies one and eight and four and five are compared by the flap slat electronic unit (FSEU) section 1 to detect a disconnect in the flap drive system. A difference in resolver degree input between resolvers one and eight or between four and five equivalent to 43 1/4 drive shaft revolutions causes immediate system shutdown and fault annunciation (approximately 12% of flap drive full travel). If the resolver difference remains for five seconds the fault and annunciation are latched. If the asymmetry no longer exists, the latch can be reset by pushing the flap alternate arm switch on and off, by opening and closing the FSEU 1 control circuit breaker, or by moving the flaps and flap lever to the retracted position. LE TE ALTN CYCLED FLAP LEVER = UP FLAP = UP ALTN FLAP/SLAT ELEC (S,M) 115V AC STBY BUS POWER SUPPLY 28V AC VEXC 28V AC EXC FAIL COMPARE: 1&8, 2&7, 3&6, 4&5 RESET 2 ASYM COMPARE: 1&2, 3&4, 5&6, 7&8 5 SEC TE FLAP ASYM (B) LATCH EICAS COMPUTERS (E8) FLAP SHUTDOWN SKEW (SECTION 1) RS RS XMTR 1 RS RS XMTR 2 XMTR 7 RS RS XMTR 3 5 1 UP FLAPS Page - 121 RS FSEU (E2-4) ATA 27-50 11/11/13 20 XMTR 5 25 1 FLAP DISAGREE/FLAP LIGHT (SECT 2) 2 43.25 DRIVE SHAFT REVOLUTION DIFFERENCE FLAP ASYMMETRY PROTECTION SYSTEM B767-3S2F 15 XMTR 6 RS XMTR 4 TRAILING EDGE LEADING EDGE XMTR 8 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY 30 FLAP INDICATOR 1 B767-3S2F Page - 122 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY LEADING EDGE SLATS General Description Extension of the leading edge slats improves wing stall characteristics enabling higher angles of attack for takeoff and climb and increased maneuvering margins during approach and landing. There are five outboard and one inboard slat surfaces on each wing. The slats are numbered from the left to the right wing tip. The slats extend from the top of the wing and have three positions. A Krueger seal flap extends from the bottom of each wing between the inboard slat and the engine strut to reduce drag with the slats extended. Primary Control The leading edge slats are controlled by inputs from the flap lever. The flap lever operates a cable system to the slat aft quadrant which is connected to the inboard and outboard slat Power Drive Units (PDU). A hydraulic motor powers each PDU gearbox, which operates drive shafts, gearboxes and rotary actuators connected to the slats. There is a separate PDU and drive system for the inboard and outboard slats. Krueger seal flaps, operated by the inboard slat drive system, are fully extended when the inboard slats are in takeoff (sealed) position. Slat Alternate Control The PDU gearbox can also be operated by an electric motor for alternate system operation. The electric motor is controlled by the flap slat electronic unit (FSEU). CAUTION: BEFORE OPERATING FLAPS OR SLATS, ENSURE THAT ENGINE STRUT ACCESS DOORS, INBOARD FAN COWLING, AND THRUST REVERSER COWLING ARE NOT IN THE PATH OF SLATS, TO PREVENT DAMAGE. FLAP INDICATION ALT POS SEL SW ALT ARM SW FLIGHT DECK EICAS MEC FLAP LEVER FLAP LEVER POSITION TRANSMITTERS (2) INBD PDU FSEU PSEU CONTROL SHAFT SLAT AFT QUADRANT ANGLE GEARBOX (4) GEARBOX BEARING SUPPORT OUTBD PDU KRUEGER FLAP DRIVE KRUEGER FLAP DRIVE ACTUATOR (2) INBD SLAT ROTARY ACTUATOR (4) INBD SLAT (2) FSPM (3) DRIVE SHAFT FLAP PDU (REF) ANGLE GEARBOX OUTBD SLAT ROTARY ACTUATOR (20) LEADING EDGE SLATS B767-3S2F Page - 123 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY OUTBOARD SLAT (10) B767-3S2F Page - 124 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT POWER DRIVE UNITS (PDU) General The inboard and outboard slat power drive units (PDU) are located in the forward wing/body fairings. The PDU are mounted on the wing front spar by a support attachment with two fasteners and a support rod. The PDU are similar. The outboard PDU is larger than the inboard with larger hydraulic and electric motors required to drive ten slat surfaces. Maintenance Practices Access to each PDU is through panels on the bottom of the wing below each PDU. A tool (ground lock) can be installed on the gearbox so the PDU cannot be operated with either the electric or hydraulic motor. SUPPORT ROD ELECTRIC MOTOR HYDRAULIC MOTOR DRIVE SHAFT GEARBOX GEARBOX OUTBOARD SLAT PDU (LOOKING INBOARD) DRIVE SHAFT ELECTRIC MOTOR HYDRAULIC MOTOR GEARBOX FWD PDU GROUNDLOCK INBD SLAT POWER DRIVE UNIT (PDU) B767-3S2F Page - 125 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SUPPORT ATTACHMENT DRIVE INBOARD SLAT PDU SHAFT (BOTTOM VIEW) B767-3S2F Page - 126 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY INBOARD SLAT KRUEGER SEAL FLAP DRIVE SYSTEM Krueger Seal Flap Drive A single Krueger seal flap is mounted between the inboard slat and engine strut on each wing. The flap extends down and forward from beneath the wing leading edge to form a seal between the inboard slat and engine strut. The Krueger seal flap rotary actuator is connected to the inboard slat outboard actuator by a drive shaft through two universal joints. The Krueger seal flap extends fully as the leading edge slats extend from the fully retracted to the intermediate (takeoff) position. The drive linkage allows for slat extension to the fully extended position without further Krueger seal flap extension. The Krueger seal flap is a two-section structure. The bull nose is operated by linkage from the seal door. Maintenance Practices The Krueger seal flap rotary actuator can be removed by disconnecting at the flap drive link and the drive shaft input universal joint. An adjustable stop screw on leading edge structure is used to fair the Krueger seal flap with the wing leading edge when retracted INBOARD SLAT (REF) WING LEADING EDGE ROTARY ACTUATOR ROTARY ACTUATOR BULL NOSE DRIVE SHAFT FROM INBD SLAT OUTBD ROTARY ACTUATOR INBD FWD BULL NOSE INBOARD SLAT KRUEGER SEAL FLAP DRIVE SYSTEM B767-3S2F Page - 127 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 128 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY INBOARD SLAT DRIVE AND TRACKS Description Each inboard slat is extended and retracted by two control rods each connected to a rotary actuator arm and a fitting on the aft side of the slat. The main support for the slat is by an "A" frame at the inboard end, a support arm at the center and a main track, with emergency down stop, at the outboard end, all mounted to the wing front spar. The slat is held in position on the main support components and the control rods by three auxiliary track arms. The slat is attached to each auxiliary track arm at two places to prevent slat rotation and provide slat angle positioning by the profiled auxiliary track. The auxiliary tracks position the inboard slats at 12 degrees when extended to the intermediate or takeoff position and at 30.3 degrees when fully extended. PIVOT POINTS (MOUNTED TO FRONT SPAR SUPPORT FITTING) PIVOT POINT (MOUNTED TO FRONT SPAR SUPPORT FITTING) ACTUATOR CONTROL ROD WING LEADING EDGE SLAT SUPPORT STRUCTURE (INSIDE SLAT) MAIN SUPPORT STRUCTURE (A-FRAME) ACTUATOR CONTROL ROD AUXILIARY MAIN SUPPORT TRACK ARM ARM (3) WING LEADING EDGE WING LEADING EDGE MAIN TRACK AUXILIARY TRACK ARM SUPPORT LINK ROTARY ACTUATOR ARM ROLLERS AUXILIARY TRACK SUPPORT BRACKET SLAT EMERGENCY DOWN STOP MAIN TRACK ROLLER SLAT MAIN SUPPORT TRACK (OUTBOARD END) AUXILIARY TRACK ARM AUXILIARY TRACK (3) INBOARD SLAT DRIVE AND TRACKS B767-3S2F Page - 129 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY ACTUATOR CONTROL ROD SLAT CONTROL ROD (2) (OUTBOARD SHOWN) B767-3S2F Page - 130 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY OUTBOARD SLAT DRIVE AND TRACKS Description Each outboard slat is extended and retracted by two control rods each connected to a rotary actuator arm and a fitting on the aft side of the slat. Two main tracks, with emergency down stops, support the slat. These tracks extend into recesses in the wing fuel tanks when the slats are retracted. The slat is held in position on the main tracks and control rods by two auxiliary track arms. The slat is attached to the auxiliary track arms at two places to prevent slat rotation and provide slat angle positioning by the profiled auxiliary track. The auxiliary tracks position the outboard slats at 26 degrees when extended to the intermediate (takeoff) position and at 35 degrees when fully extended. ACTUATOR CONTROL ROD ACTUATOR CONTROL ROD INBD FWD MAIN TRACK MAIN SLAT SUPPORT TRACK AUXILIARY STRUCTURE (TYP) TRACKS (INSIDE SLAT) WING LEADING EDGE VIEW LOOKING UP THROUGH BOTTOM OF WING TYPICAL FOR ALL OUTBOARD SLATS ALIGNMENT FITTING ROLLER ROTARY FRONT SPAR WING LEADING ACTUATOR EDGE FRONT SPAR WING AUXILIARY LEADING EDGE TRACK FWD SLAT ROTARY ACTUATOR ARM ACTUATOR CONTROL ROD (2) FRONT SPAR SLAT SUPPORT BRACKET SUPPORT LINK ROLLERS MAIN TRACK AUXILIARY TRACK ARM AUXILIARY TRACK (2) OUTBOARD SLAT DRIVE AND TRACKS B767-3S2F Page - 131 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY MAIN TRACK (2) EMERGENCY DOWN STOP B767-3S2F Page - 132 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT FSEU / PSEU INTERFACE Operation FSEU: The Flap/Slat Electronic Unit (FSEU) controls the slat shutoff valve during hydraulic motor operation to sequence the flaps and slats and for long-term system depressurization. The FSEU controls the PDU bypass valves for hydraulic motor shutdown for uncommanded motion and asymmetry failures. Inputs to the FSEU for PDU bypass valve operation for uncommanded motion shutdown and for control of the slat shutoff valve are from flap lever and PDU rotary variable differential transformers (RVDT). Inputs to the FSEU for PDU bypass valve operation for asymmetry shutdown are from the proximity switch electronic unit (PSEU) and a flap lever RVDT. The FSEU uses disagree and asymmetry signals from the PSEU to control the leading edge fault light and caution messages. Alternate position selector switch and PDU RVDT inputs are used by the FSEU for electric motor operation. PSEU: The Proximity Switch Electronic Unit (PSEU) monitors proximity sensors on each slat to detect disagree and asymmetry faults. The PSEU receives flap lever and alternate position selector switch inputs from the FSEU for disagree fault detection. The PSEU signals the FSEU when either fault is detected. The flap position indicator is controlled by a transfer relay controlled by the FSEU and an intermediate/retract relay controlled by the PSEU. Maintenance Practices The FSEU and the PSEU have built-in-test equipment to identify faulted components in the slat control and indication system. SECTION 1 - SLAT SHUTOFF VALVE CONTROL - BYPASS VALVE CONTROL - UNCOMMANDED MOTION DETECTION AND SHUTDOWN - ASYMMETRY/SKEW ANNUNCIATION AND SHUTDOWN - SLAT CMD DISCRETE TO PSEU SECTION 2 - FLAP DISAGREE DETECTION - SLAT DISAGREE INDICATION - SLAT COMMAND DISCRETE OUTPUT SECTION 3 - ALTERNATE MODE CONTROL - SLAT DISCRETE TO STALL WARNING BITE INSTRUCTIONS: Push ON/OFF to start or end BITE display. Push YES or NO to reply to questions(?). Push to move down in list. Push to move up in list. Push MENU to return to previous menu. BITE MAIN MENU: EXISTING FAULTS-Shows existing faults. FAULT HISTORY-Shows past faults by flight leg. GROUND TESTS-Shows list of ground tests. OTHER FUNCTIONS-Shows other functions. LE SLAT PROXIMITY SENSORS FLAP LEVER & POSN SEL SW POSITION MENU ON/OFF YES NO FLAP/SLAT ELECTRONIC UNIT P/N 285T0049SER NO. MOD LEVEL CAGE CODE 81205 FMG DATE THE BOEING COMPANY MFR SER PMR MOD PROXIMITY SWITCH SYSTEM FSEU (E2-4) TARGET NEAR TARGET FAR 7 PRESS/TEST 6 7 SLAT DISAGREE SENSOR CHANNEL SELECT SLAT ASYMMETRY SLAT POSITION SENSOR VERIFY BIT CARD TARGET TARGET TEST L/R STALL WARNING RESET PSEU (E1-2) LANDING CONFIG WARNING SLAT FSEU / PSEU INTERFACE B767-3S2F Page - 133 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY ENGINE IGNITION CONTROL B767-3S2F Page - 134 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT SYSTEM INTERFACE Hydraulic Motor Operation Slat failure protection shutdown, flap/slat sequencing and long-term hydraulic pressure shutoff are controlled by Flap Slat Electronic Unit (FSEU) section 1 operation of the slat shutoff valve or the power drive unit (PDU) bypass valves. These control functions require inputs from a flap lever rotary variable differential transformer (RVDT), PDU RVDT, Flap Stabilizer Position Module (FSPM), and the Proximity Switch Electronic Unit (PSEU). An alternate arm switch armed input inhibits failure protection shutdown in FSEU section 1. Electric Motor Operation FSEU section 3 controls the electric motors using inputs from the alternate flap position selector switch and PDU RVDTs. The slat alternate arm switch operates the PDU bypass valves and engages the electric motor clutches. Position Indication The PSEU controls slat position transmitters to position the flap position indicator synchros to the up and one-half unit positions. The PSEU monitors proximity sensors on each slat for flap position indication and fault detection. Fault Annunciation A leading edge fault light and EICAS disagree message are controlled by FSEU section 2 using inputs from a flap lever RVDT, alternate arm and position selector switches, an FSPM, FSEU section 1 and the PSEU. FSEU section 1 controls the asymmetry fault message and inputs to section 2 for illumination of the leading edge fault light. FSEU section 2 provides flap lever/alternate position selector switch position to the PSEU for disagree fault detection. CENTER HYD SYS TRAILING EDGE LEADING EDGE FLAP LEVER FLAP LIMIT (IAS) SHUTOFF VALVE FLAP/SLAT SOV MODULE CONTROL VALVE 5 1 15 UP FLAPS 20 25 RVDT (2) 30 B ALTN FLAPS 5 1 15 UP EICAS A 20 NORM BYPASS VALVE E SLAT DRIVE ROTARY ACTUATORS 25 30 LE TE ALTN ALTN HYDRAULIC MOTOR HYD PRESS LE SLATS GEAR BOX L/C FSPM ELECTRIC MOTOR E A CLUTCH FSEU C PSEU HYDRAULIC ELECTRICAL MECHANICAL B -STALL WARNING -CONFIG WARNING -ENGINE IGNITION SLAT PDU (TYP) SLAT SYSTEM INTERFACE B767-3S2F Page - 135 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY RVDT (2) PROX SENSORS (4 INBD) (20 OUTBD) C B767-3S2F Page - 136 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT HYDRAULIC OPERATION General Flap lever operation of the power drive unit (PDU) pilot input arm operates the control unit input cam, to move the control valve module control valve from the null position. Center hydraulic system pressure is then provided to the hydraulic motor through the control valve module bypass valve. Slat drive shaft rotation operates the control unit follow-up cam to return the control valve to null. When the control valve is at null and the bypass valve is at normal, there is a hydraulic lock on the motor to hold the gearbox and slat drive. Operation Hydraulic pressure to the motor can be shutoff by the flap/slat shutoff valve module slat shutoff valve or by the bypass valve in the PDU control valve module. Pressure is shutoff to the motor as follows using the Flap/slat shutoff valve module: • The slat solenoid valve is powered by the flap/slat electronic unit (FSEU) to close the slat shutoff valve when the slat drive and flap lever are in agreement or, on retraction, until the trailing edge flaps are up. • If pressure is shutoff at the flap/slat shutoff valve module, the hydraulic lock remains on the motor. Pressure is shutoff to the motor as follows using the bypass valve: • The bypass valve is positioned to bypass when the alternate slat system arm switch is armed or by the FSEU during slat system failure. • If pressure is shutoff by the bypass valve, the motor can be rotated by the gearbox. C HYDRAULIC SYSTEM PRESS FSEU SLAT SOLENOID VALVE SLAT SHUTOFF VALVE FLOW REG PRIORITY VALVE RETURN FSEU FLAP SOLENOID VALVE C2 OUTBD SLAT PDU C1 FLAP SHUTOFF VALVE FLAP PDU CONTROL VALVE MODULE CONT UNIT ASSY EICAS INPUT CAM SLAT SOV PRESS SW PRESS SUMMING LEVER PILOT INPUT ARM UP FOLLOW-UP CAM RETURN DN OPEN BYPASS NULL FSEU/ ALT ARM SWITCH CONT VALVE 1 PDU RVDT NOT SHOWN FOR CLARITY REASONS QUILL SHAFT (WORM GEAR) BYPASS NORM BYPASS VLV UP DN LEGEND C1 C2 CD PRESSURE RETURN NOTE: INBOARD PDU SHOWN OUTBOARD IS SIMILAR GEARBOX 1 SLAT HYDRAULIC OPERATION B767-3S2F Page - 137 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY CD NORM CLOSED HYDRAULIC MOTOR DRIVE SHAFT ALTERNATE DRIVE ELECTRIC MOTOR B767-3S2F Page - 138 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT ALTERNATE DRIVE CONTROL General The slat inboard and outboard Power Drive Unit (PDU) alternate drive electric motors are controlled by the Flap Slat Electronic Unit (FSEU). The FSEU receives command inputs from the alternate flaps position selector switch and slat drive position from rotary variable differential transformers (RVDT) on each PDU. Using these inputs, section 3 of the FSEU controls relays to provide power to the reversible electric motors on both PDU. Operation The slat alternate arm switch directly controls the bypass valves on the PDU during alternate drive operation to remove the hydraulic motor lock on the PDU gearbox. The arm switch also controls power to the FSEU for relay control. The FSEU compares the command and slat drive position inputs separately in the inboard and outboard slat systems for individual, closed-loop motor control. Electric motor turn off does not occur simultaneously on the inboard and outboard slat systems due to different degrees of extension at the intermediate (takeoff) and fully extended positions. LEADING TRAILING EDGE EDGE FLAP LIMIT (IAS) 225K 250K ALT FLAPS POSITION SELECTOR SWITCH 215K 5 1 205K 20 UP FLAPS 190K 170K ALTN FLAPS 5 1 15 UP Push to move up in list. Push MENU to return to previous menu. BITE MAIN MENU: 25 30 ALTERNATE SLAT ARM SWITCH P37 BITE INSTRUCTIONS: Push ON/OFF to start or end BITE display. Push YES or NO to reply to questions(?). Push to move down in list. 15 EXISTING FAULTS-Shows existing faults. FAULT HISTORY-Shows past faults by flight leg. GROUND TESTS-Shows list of ground tests. OTHER FUNCTIONS-Shows other functions. MENU ON/OFF YES NO 20 FLAP/SLAT ELECTRONICS UNIT NORM P/N 285T0049SER NO. 25 30 LE MOD LEVEL TE CAGE CODE 81205 FMG DATE THE BOEING COMPANY ALTN MFR SER PMR MOD ALT SLAT RLYS (P37) ALTN ALTERNATE SLAT CONTROL (P3-1) FSEU (SECT 3) (E2-4) TO SLAT PDU BY-PASS VLV PDU BYPASS VALVE 1 PDU BY-PASS VALVE 1 RVDT ALT DRIVE ELECTRIC MOTOR RVDT ALT DRIVE ELECTRIC MOTOR GEARBOX 1 CONTROLLED BY ALT SLAT ARM SW GEARBOX INBOARD SLAT PDU SLAT ALTERNATE DRIVE CONTROL B767-3S2F Page - 139 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY OUTBOARD SLAT PDU B767-3S2F Page - 140 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT SENSOR/TARGET POSITIONS General Each proximity sensor is powered and monitored by the Proximity Switch Electronic Unit (PSEU) to detect a target near or far condition. Sensor Location On the outboard slats the sensor and retract target at the inboard auxiliary track are mounted further aft on structure and the auxiliary track arm, respectively, than the sensor/target on the outboard auxiliary track. On the inboard slats the sensor/targets at the outboard auxiliary track are mounted further aft. Operation When the slat is fully retracted the retract target on the auxiliary track arm is near to the proximity sensor. When the slat is in the intermediate (takeoff) position the auxiliary track roller ball assembly target is near on the inboard auxiliary track on the outboard slats and the outboard auxiliary track on the inboard slats. When the slat is fully extended, the near sensor/targets are reversed, with the roller ball assembly target near on the outboard auxiliary track for the outboard slats and the inboard auxiliary track for the inboard slats. Maintenance Practices A target out of adjustment or a faulted sensor would be detected by the PSEU as a slat asymmetry condition. The PSEU built-in test (BITE) would identify the faulted component by a sensor/target code and sensor or target fault light. Proximity Sensor/Target Installation A proximity sensor is installed on wing leading edge structure near the inboard and outboard auxiliary tracks on each slat. The sensor is actuated by either a retract target, riveted on the auxiliary track arm, or a roller bolt assembly at the aft end of the auxiliary track arm that holds the track arm on the track. On each slat one sensor is installed farther aft on wing structure than the sensor near the other auxiliary track with its retract target installed the same distance aft on the auxiliary track arm. Operation When the slat is retracted both retract targets are near to their sensors due to the offset (staggered) sensors and targets. As the roller bolt assemblies (targets) are in the same position at the aft end of each auxiliary track arm, one sensor/target is near and one far at the intermediate slat position with the near/far target positions reversed at the slat fully extended position. SENSOR (NEAR) SENSOR (NEAR) SLAT 12 T T TAKEOFF SLAT MOTION PS T FWD FULLY RETRACTED POSITION SENSOR (NEAR) SENSOR (FAR) LANDING T PS FULLY RETRACTED POSITION SLAT 1 TABLE 102 SLAT NO. INBD INTERMEDIATE FWD POSITION PROXIMITY SWITCH SYSTEM TARGET NEAR PRESS/TEST 6 7 SENSOR CHANNEL SELECT SENSOR (FAR) VERIFY BIT TARGET FULLY EXTENDED POSITION (OUTBOARD SLAT SHOWN) RESET ATA 27-80 11/11/13 F N1 N1 F 2 N2 N2 F N1 N1 F 3 S278 (OUTBD) S284 (INBD) N2 N2 F N1 N1 F 4 S279 (OUTBD) S285 (INBD) N2 N2 F N1 N1 F 5 S280 (OUTBD) S286 (INBD) N2 N2 F N1 N1 F 6 S281 (INBD) S287 (OUTBD) N2 N2 N1 F F N1 7 S299 (INBD) S305 (OUTBD) N2 N2 N1 F F N1 8 S298 (OUTBD) S304 (INBD) N2 N2 N1 F F N1 9 S297 (OUTBD) S303 (INBD) N2 N2 N1 F F N1 10 S296 (OUTBD) S302 (INBD) N2 N2 N1 F F N1 11 S295 (OUTBD) S301 (INBD) N2 N2 N1 F F N1 12 S294 (OUTBD) S300 (INBD) N2 N2 N1 F F N1 N1 = TARGET NEAR (TARGET ON AUXILIARY TRACK ROLLER BOLT OPPOSITE SWITCH) F = TARGET FAR (TARGET ON AUXILIARY TRACK ROLLER BOLT OFFSET FROM SWITCH) N2 = TARGET NEAR (TARGET ON AUXILIARY TRACK ARM OPPOSITE SWITCH) SLAT SENSOR / TARGET POSITIONS Page - 141 N2 N2 S277 (OUTBD) S283 (INBD) TARGET TEST PSEU B767-3S2F S276 (OUTBD) S282 (INBD) SENSOR (NEAR) SENSOR CARD EFF - ALL A B C SLATS FULLY SLATS SLATS FULLY INTERMEDIATE RETR EXTENDED 1 TARGET FAR 7 SENSOR/ TARGET CODE TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 142 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT SENSORS AND TRANSMITTERS PDU Position Transmitters The slat Power Drive Unit (PDU) rotary variable differential transformers (RVDT) are powered and monitored by the Flap Slat Electronic Unit (FSEU). One RVDT on each PDU is powered by and inputs to FSEU section 1, RVDT two is powered by and inputs to FSEU section 3. A failed RVDT causes display of the FLAP/SLAT ELEC status/maintenance messages. FSEU testing indicates the failed RVDT by a Existing Fault message. RVDT two on the outboard PDU is also monitored for correct rig voltage when the slats are retracted and altitude is above 20,000 feet or airspeed is above 270 knots. A Ground Test will display the RVDT Misrig Existing Fault message.. The flap lever and slats must be in the UP position when testing for this fault. A misrig condition will be indicated by the FLAP SLAT ELEC message. INBOARD SLATS PDU CONTROL UNIT RVDT COVER A RVDTS A CONTROL UNIT RVDT 1 CLAMP CLAMP BOLT (2 ON EACH RVDT) SCREW, WASHER (6) GEARBOX OUTBOARD SLAT PDU (VIEW LOOKING INBOARD) INBD RVDT 2 A-A (RVDT COVER REMOVED) NOTE: INBOARD PDU RVDT(S) ARE SIMILAR TO OUTBOARD PDU RVDT(S) ELECTRICAL NULL ALIGNMENT MARKS RVDT SLAT SENSORS AND TRANSMITTERS B767-3S2F Page - 143 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 144 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT PSEU BITE General Description The Proximity Switch Electronics Unit (PSEU) monitors slat system proximity sensors and targets to detect faults and signal the Flap/Slat Electronic Unit (FSEU) for protective shutdown and display of the slat asymmetry and disagree indications. LE Slat Asymmetry A slat system sensor or target fault causes the slat asymmetry fault indications. The PSEU BITE will show the faulted component when tested. System test code 506 is used to test only the leading edge slat system; target test is used to test single sensor/target inputs. LE Slat Disagree A faulted slat normal or alternate command discrete input to the PSEU from the FSEU can cause the slat disagree fault indications. PSEU BITE will show the faulted input when tested. BITE INSTRUCTIONS (AIRCRAFT MUST BE ON GROUND) NOTE: IF NO BITE RESPONSE, PRESS PRESS/TEST & TARGET TEST SWITCHES SIMULTANEOUSLY TO RESET. A-MEMORY RECALL AND RESET PRESS BIT SWITCH TO DISPLAY FAILED LRU. PRESS BIT SWITCH AGAIN FOR NEXT LRU. PRESS RESET SWITCH TO CLEAR MEMORY. NOTE : LRU(S) ARE DISPLAYED ON A LAST IN - FIRST OUT BASIS. B-SYSTEM TEST SELECT TEST CODE WITH CHANNEL SELECT: CODE 500 CARGO DOOR CONTROL CODE 501* ALL T/R SYSTEMS CODE 502* ENTRY DOOR CONTROL CODE 503 DOOR SYSTEM CODE 504 LG SYSTEM NO. 1 CODE 505 LG SYSTEM NO. 2 CODE 506 LE SLATS CODE 507 ALL SYSTEMS * NOT INSTALLED ON ALL AIRPLANES ALL OTHER CODES = ALL SYSTEMS PLUS MEMORY TEST. CODE BITE INSTRUCTIONS: Push ON/OFF to start or end BITE display. Push YES or NO to reply to questions(?). Push to move down in list. Push to move up in list. Push MENU to return to previous menu. BITE MAIN MENU: EXISTING FAULTS-Shows existing faults. FAULT HISTORY-Shows past faults by flight leg. GROUND TESTS-Shows list of ground tests. OTHER FUNCTIONS-Shows other functions. MENU ON/OFF YES NO FLAP/SLAT ELECTRONICS UNIT P/N 285T0049SER NO. MOD LEVEL MFR SER PMR MOD CAGE CODE 81205 FMG DATE THE BOEING COMPANY PRESS VERIFY SWITCH. FAILED LRU IS DISPLAYED AT END OF TEST. PRESS VERIFY SWITCH AGAIN FOR NEXT LRU. C-TARGET TEST(DISPLAY DELAYED APPROX. 5 SECONDS) SELECT SENSOR CHANNEL WITH CHANNEL SELECT SWITCH. PRESS TARGET TEST SWITCH TO DISPLAY POSITION OF TARGET. FSEU (E2-4) DISPLAY CODE 000 MEMORY RECALL (BIT) COMPLETE. CODE 001-016 FAILED CARD WITH CARD LIGHT. CODE INDICATES CARD SLOT NUMBER (001-007 LEFT SIDE, 008 BITE MODULE, 009-016 RIGHT SIDE). SEE NOTE BELOW FOR CARD 001-004 OR 013-016 FAILURE. CODE 150-305 FAILED SENSOR WITH SENSOR LIGHT OR FAILED TARGET WITH TARGET LIGHT, CODE INDICATES SENSOR ITEM NUMBER EXCEPT FOR RIGHT THRUST REVERSER. CODE 400-409 SUBSYSTEM INPUT POWER FAILURE. CODE 421-428 DISCRETE INPUT FAILURE. CODE 888 LAMP TEST (PRESS/TEST). CODE 999 SYSTEM TEST (VERIFY) COMPLETE. CODE AAA AIRCRAFT IN AIR MODE. CODE CCC SYSTEM TEST (VERIFY) IN PROGRESS. (FLASHING). CODE DDD DEACTIVATED OR NOT INSTALLED ON THIS AIRPLANE. CODE EEE MEMORY CLEARED (RESET). NOTE: PROXIMITY CARD FAULT (CODES 001-004 OR 013-016) DURING VERIFY TEST OR TARGET TEST MAY BE CAUSED BY DAMAGED SENSOR OR TARGET BEING LESS THAN .03 INCHES FROM RECTANGULAR SENSOR. INTERCHANGE CARD WITH GOOD CARD. REPLACE CARD IF FAULT FOLLOWS. IF SAME SLOT IS FAULTED AGAIN, PERFORM TARGET TEST ON EACH SENSOR FOR THAT CARD SLOT (SEE INSIDE TABLE). THE CARD FAULT LIGHT WILL ILLUMINATE WHEN THE MISRIGGED OR DAMAGED SENSOR IS TESTED. TARGET NEAR TARGET FAR PRESS/TEST 7 6 7 SENSOR CHANNEL SELECT Page - 145 ATA 27-80 11/11/13 EFF - ALL L SLAT #1 OUTBD L SLAT #2 OUTBD L SLAT #3 OUTBD L SLAT #4 OUTBD L SLAT #5 OUTBD L SLAT #6 INBD L SLAT #1 INBD L SLAT #2 INBD L SLAT #3 INBD L SLAT #4 INBD L SLAT #5 INBD L SLAT #6 OUTBD R SLAT #12 OUTBD R SLAT #11 OUTBD R SLAT #10 OUTBD R SLAT #9 OUTBD R SLAT #8 OUTBD R SLAT #7 INBD R SLAT #12 INBD R SLAT #11 INBD R SLAT #10 INBD R SLAT #9 INBD R SLAT #8 INBD R SLAT #7 OUTBD 400 401* 402* 403* 404* 405* 406 407 408 409 CARGO DOOR CONTROL T/R IND LEFT T/R IND RIGHT T/R AUTO RESTOW L T/R AUTO RESTOW R ENTRY DOOR CONTROL DOOR SYSTEM LG SYSTEM #1 LG SYSTEM #2 LE SLATS 421 422 423 424 425 426 427 428 LDG GR LVR DOWN 1 LDG GR LVR DOWN 2 SLAT CMD TO RET 1 SLAT CMD TO RET 2 SLAT CMD TO T/O 1 SLAT CMD TO T/O 2 SLAT CMD TO LDG 1 SLAT CMD TO LDG 2 28V DC INPUT POWER DISCRETE INPUTS SENSOR CARD TARGET VERIFY TARGET TEST BIT RESET SLAT PSEU BITE B767-3S2F 276 277 278 279 280 281 282 283 284 285 286 287 294 295 296 297 298 299 300 301 302 303 304 305 PROXIMITY SWITCH SYSTEM PSEU (E1-2) LEFT FRONT DOOR SENSOR (TARGET) LEADING EDGE SLATS TRAINING MANUAL FOR TRAINING PURPOSES ONLY CODES 423-428 FROM FSEU M545 RIGHT FRONT DOOR B767-3S2F Page - 146 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT ASYMMETRY INDICATION General The Proximity Switch Electronic Unit (PSEU) monitors each slat to detect a difference between left and right wing slat positions (asymmetry). Inboard and outboard slat system PSEU proximity card logic signals, based on sensor/target near or far position, input to the PSEU logic card to detect an asymmetry condition in either system. There are two logic position signals from the proximity card to the logic card for each slat. On the logic card the two left inboard and two right inboard position signals are grouped separately. On the outboard slat system the ten left and ten right position signals are grouped separately. The logic card also groups the position signals by slat position retracted, intermediate (takeoff) and fully extended. Operation The PSEU detects an inboard or outboard slat asymmetry condition when the proximity card position signals to the logic card show a difference between the left and right groups for any of the slat positions, e.g. the position signals for the outboard slat system show all sensor/targets near in the left group and one sensor/target far in the right group at the intermediate (takeoff) position. When an asymmetry is detected, a PSEU driver inputs a signal to the flap slat electronic unit (FSEU). The signal is latched until the asymmetry signal from the PSEU is removed. If an asymmetry shutdown is latched, by moving the flap lever, the asymmetry latch can be reset by cycling the alternate slat arm switch if the PSEU has removed the asymmetry signal. If an asymmetry latch is set for longer than four seconds (ten seconds in alternate drive), the slat light and LE SLAT ASYM caution message are displayed. The indication will be displayed until the FSEU asymmetry latch is reset. Maintenance Practices Slat asymmetry indication is caused by an actual asymmetry resulting from a disconnected slat drive system or a slat sensor or target fault. L/R STALL WARNING LANDING CONFIG WARNING ENGINE IGNITION CONTROL 28V AC FAIL LEVER OR SLAT PDU XMTR FAIL FLAP/SLAT ELEC (S,M) LE SLAT ASYM (B) OUTBD SLATS L OUTBD SLAT POSITION R OUTBD SLAT POSITION SHUTDOWN SLAT ASYM LEADING EDGE OUTBD ASYM HYD OPER PSEU LE LIGHT 4S OUTBD ASYM ALT OPER 10 S FSEU (SECT 1) NOTE: OUTBOARD SHOWN INBOARD IS SIMILAR SLAT ASYMMETRY INDICATION B767-3S2F Page - 147 ATA 27-80 11/11/13 EICAS ASYM S/D EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 148 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT DISAGREE INDICATION General The proximity switch electronic unit (PSEU) compares slat position signals from proximity sensors at each slat with flap lever or alternate flap position selector switch position inputs from the flap slat electronic unit (FSEU) to detect a slat disagreement. Operation When the flap lever is moved during primary drive slat system operation or the alternate flap position selector switch is moved during alternate operation, the PSEU sends a disagree signal to the FSEU. When the proximity sensors show agreement with slat command the PSEU removes the disagree signal. A PSEU disagree input is inhibited in the FSEU when any of the following conditions exist. • Either inboard or outboard slat PDU is moving toward the flap lever or alternate flap position selector switch position (command) in primary or alternate operation • The flap drive is moving toward the flap lever position in primary operation • The slats are commanded up in primary or alternate operation and the flaps are not retracted • A slat asymmetry condition exists If the PSEU disagree signal is present after the inhibits are removed, the FSEU causes display of the LEADING EDGE light and LE SLAT DISAGREE caution message after ten seconds. Maintenance Practices Slat disagree indications are displayed when the PSEU detects all sensors in the inboard or outboard group in disagreement with command. This condition is caused by a jammed slat drive, command input without hydraulic or electrical drive power, or a faulted FSEU flap lever or alternate position selector switch position input to the PSEU. SLAT DISAGREE INBD SLAT POSITION SLAT SEQUENCE DURING RETRACT FLAPS MOVING TOWARD CMD POSN INBD SLATS PDU MOVING TOWARD CMD POSN 10 FLAP/SLAT ELEC (S,M) COMMANDED POSITION 28V AC FAIL L FSPM FAIL FLAP LEVER POSN XMTR FAIL PSEU LE SLAT DISAGREE (B) ALTN FLAPS 5 1 FLAP LEVER POSN UP 20 SW = NORM NORM 25 30 LE ALTN FLAP POSN SW EICAS COMPUTERS 15 TE ALTN 7 ARMED LEADING TRAILING EDGE EDGE FLAP LIMIT (IAS) 225K ALTN 250K SLAT ASYM (SECT 1) FSEU (SECT 1) 15 20 UP 25 FSEU (SECT 2) NOTE : INBOARD SLATS SHOWN OUTBOARD SLATS SIMILAR ATA 27-80 11/11/13 EFF - ALL 190K 170K FLAP INDICATOR (P3-1) SLAT DISAGREE INDICATION Page - 149 205K FLAPS 30 B767-3S2F 215K 5 1 TRAINING MANUAL FOR TRAINING PURPOSES ONLY B767-3S2F Page - 150 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY SLAT ASYMMETRY AND FAILURE PROTECTION SHUTDOWN Operation Asymmetry Protection Shutdown: An asymmetry condition detected by the Proximity Switch Electronic Unit (PSEU), in the inboard or outboard slat systems, is signaled to the Flap Slat Electronic Unit (FSEU) for protective shutdown. The asymmetry signal is latched in the FSEU and annunciated until the signal is removed by the PSEU. If the flap lever is moved with a latched asymmetry, the FSEU energizes the inboard or outboard slat fail protection and asymmetry relay to bypass the hydraulic motor. The shutdown and asymmetry annunciation are latched and will not reset if the PSEU removes the asymmetry signal. Cycling the alternate slat arm switch on and off will reset the asymmetry shutdown latch, de-energize the fail relay, and energize the bypass valve normal relay to restore hydraulic motor operation and clear the asymmetry annunciation. Failure Protection Shutdown when: The FSEU compares the flap lever and power drive unit (PDU) transmitters (RVDT) to detect uncommanded movement of the inboard or outboard slat systems. If the slats are moving away from the flap lever position, the FSEU operates the fail relay to bypass the hydraulic motor. The failure shutdown latch can be reset by cycling the alternate slat arm switch to de-energize the fail relay, energize the normal relay and restore hydraulic motor operation. The latch also resets when the flap lever is up and the slats are retracted. Maintenance Practices When the inboard or outboard fail protection and asymmetry relay is energized, other than by an asymmetry shutdown latch, LE SLAT SHUTDOWN status and maintenance messages will be displayed. Cycling the alternate slat arm switch on and off will clear the message and restore hydraulic motor operation by positioning the bypass valve from the bypass to the normal position. 115V AC STBY BUS FSEU SENSOR POWER XMTR 28V DC SLAT ALT ARM SW P37 NORM SLAT BYPASS VLV NORMAL RELAY UNCOMMANDED MOTION XMTR 1 28V AC POWER SUPPLY SLAT MOVING BYPASS 1 AWAY FROM POSN SLAT BYPASS VALVE SLATS = LEVER SLAT PDU 2 ALT ARM SW ARMED LATCH TO ALT ELEC MOTOR (CLUTCH) SLAT XMTR FAILURE FLAP XMTR FAILURE ASYMMETRY (SHUTDOWN) 1 A XMTR 2 FLAP LEVER LEVER MOVEMENT S/D LATCH ALT ARM SW ARMED SLAT XMTR FAILURE INBD SLAT FAIL PROT AND ASYM RELAY FLAP XMTR FAILURE ASYMMETRY (NO SHUTDOWN) 1 ALT ARM SW ARMED LE SLAT A SHUTDOWN PDU POSN = LEVER PSEU (E1-2) LEVER IN DETENT LATCH ASYMMETRY ANNUNCIATION SLAT ASYM FSEU (SECT 1) NOTE: INBD SHOWN OUTBD IS SIMILAR CYCLE THE ALT SLAT ARM SW TO RESET 1 SLAT ASYMMETRY & FAILURE PROTECTION SHUTDOWN B767-3S2F Page - 151 ATA 27-80 11/11/13 EFF - ALL TRAINING MANUAL FOR TRAINING PURPOSES ONLY (S/M) EICAS