SPIRAX SARCO - Design Of Fluid Systems - STEAM UTILIZATION (1991) - libgen.lc

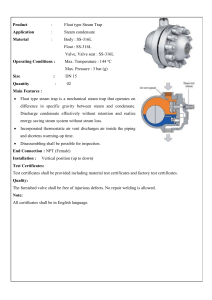

advertisement