International Journal of lndustrial Ergonomics, 3 (1988) 89-102

Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands

89

HEAT STRESS INDICES: A REVIEW PAPER

Mohamed Youssef Beshir

Modern Co. for Textile Industries, 10 TH of Ramadan City (Egypt)

and Jerry D. Ramsey

Texas Tech University, Industrial Engineering Dept., Lubbock, TX 79409 (U.S.A.)

(Received January 18, 1987; accepted in revised form September 30, 1987)

ABSTRACT

This paper represents a review of the thermal

indices commonly used for assessing heat stress

conditions in an environment, e.g., Corrected Effective Temperature, New Effective Temperature, Heat

Stress Index, Wet Bulb Globe Temperature and Wet

Globe Temperature. The advantages and disadvantages of the indices are included, as well as an

example of calculations and procedures required to

determine the resulting values of each heat stress

index. Separate sections for Programmed Hand

Held Calculators, the Mean Equivalence Lines and

the International Organization for Standardization

(ISO) standards are also provided in the paper.

INTRODUCTION

also considered potential major factors contributing to the changes occurring in human physiological response due to heat exposure, i.e., heat

strain. There is a general agreement that a major

criterion for evaluating the effectiveness and usefulness of a heat stress index is its correlation with

heat strain (WHO, 1969; Peterson, 1970; Astrand

et al., 1975). The major physiological responses to

heat stress are increases in: (1) body temperature,

(2) heart rate, and (3) sweat production (Wyndham and Heyns, A973; Belding, 1976).

An ideal heat stress index which integrates all

the climatic, physical, and personal factors into a

single number and hence correlates them to one or

more physiological response has not yet been

found (Belding, 1970; D u k e s - D o b o s , 1976;

Kuhlemeier and Wood, 1979; Beshir, 1981). How-

Assessment of heat stress is most commonly

presented in terms of a heat stress index. A heat

stress index is a quantitative composite measure

which integrates into a single number one or more

of the thermal, a n d / o r physical, and personal

factors affecting heat transfer between the person

and the environment. Many heat stress indices

have been developed and these can be classified as

those based on: physical factors of the environment, thermal comfort assessment, "rational" heat

balance equations, and physiological strain

(Witherspoon and Goldman, 1974).

In addition to the climatic and physical factors,

personal factors such as: age, sex, physical fitness,

health status, clothing, and acclimatization are

0169-8141/88/$03.50

© 1988 Elsevier Science Publishers B.V.

90

ever, each of the available heat indices has some

advantages that make it more appropriate for use

in specific environmental conditions.

Some of the available heat stress indices are

useful for occupational and field measurements,

while others are more accurate in predicting heat

strain, and useful for research and laboratory

studies. Heat stress indices also provide a necessary composite measure of the thermal environment which is required when considering human

performance and worker safety (Hancock, 1987;

Ramsey et al., 1983). The principal criteria for a

recommended standard heat stress index for industrial use have been established by the National

Institute for Occupational Safety and Health

(NIOSH, 1972 and 1986).

The purpose of this paper is to review the

major heat stress indices reported in the literature.

The advantages and disadvantages of each index

have been summarized and a numerical example is

given to demonstrate the procedures and calculations required to compute each of these indices.

The Mean Equivalence Lines (MEL) (Wenzel,

1978), and the ISO standards for hot environments (ISO, 1983) are described in the paper.

CORRECTED

TURE (CET)

EFFECTIVE

globe temperature, so that the effective temperature is corrected for the radiant heat effects.

The CET, therefore, combines the climatic factors: air temperature, humidity, air velocity, and

radiation into a single reading. In measuring the

CET of an environment, globe temperature (Tg);

wet bulb temperature (Twb) and air velocity (v)

values are required. The CET of the environment

can be determined from a nomogram (Ellis et al.,

1972; Kerslake, 1972).

The advantages of the CET are its ability to

integrate the main four climatic factors in a single

reading (Goelzer, 1977); its simplicity and ease to

use (WHO, 1969) and it is thought by some to be

a useful index for engineers (Fuller and Smith,

1981). The disadvantages are its limited ability to

allow for the effects of clothing and metabolic

heat; different climates sharing the same CET

value do not necessarily impose the same heat

strain particularly below 40% rh (Goelzer, 1977);

it underestimates the adverse effect of humidity

and low air movement especially when the environmental conditions approach the tolerance

limit (Ramanathan and Belding, 1973) and the

updating findings cannot be assimilated into the

scale to extend its scope or improve its accuracy

(WHO, 1969).

TEMPERA-

Bedford (1946) modified the effective temperature scales (ET) developed by Houghten and

Yaglou (1923) and called them the Corrected Effective Temperature scales (CET). The ET scales

were based on equivalent subjective estimates of

thermal sensation of the thermal environment with

different combinations of air temperature, air

velocity, and humidity. All conditions having the

same thermal sensation were grouped together

under the same "Effective Temperature" (ET)

which is the air temperature of a still saturated

environment (i.e., zero air velocity and 100% relative humidity (rh)). Two ET scales were developed

by Houghten and Yaglou (1923): (1) the normal

scale, which is applied for men wearing ordinary

summer clothing, and (2) the basic scale, which is

applied for men stripped to the waist. The modifications of the ET scales as suggested by Bedford

(1946) were to replace the air temperature by the

SKIN WETTEDNESS (w)

Gagge (1937) defined the skin wettedness as the

fraction of the skin that is wet, and derived it from

the skin evaporative loss (Esk) according to the

following equation:

Esk = h e w ( P~k - ~ )

(1)

where E~k = total skin evaporative loss (W/m2),

h e = evaporative heat transfer coefficient ( W /

m 2°C), w = skin wettedness (no dimension), P~k

= saturated vapor pressure at T~k (mmHg), Pa =

saturated vapor pressure at Ta (mmHg), T~k = skin

temperature ( o C), and Ta = air temperature ( o C).

The skin wettedness (w) is calculated from the

ratio between the total skin evaporative loss (E~k)

and the maximum evaporative loss from a fully

wetted skin surface (Emax) (i.e., w=Esk/Emax)

(Gagge, 1937). When Esk is defined as the

evaporative heat loss necessary for the regulation

of body temperature (i.e., heat storage ( S ) = 0),

91

then skin wettedness w x 100 has been defined by

Belding and Hatch (1955) as the Heat Stress Index

(HSI) (see Heat Stress Index section below). The

minimum value of w is 0.06 when there is skin

diffusion but no sweating, and the maximum value

of w is 1.0 when the skin is fully covered by sweat

(Gagge, 1981). It has been reported that the sweating efficiency is related to the skin wettedness

level, and that the decline in intensity of sweating

is linked to maximal inefficient sweat drippage

before the onset of hidromeiosis (Candas et al.,

1983).

NEW EFFECTIVE TEMPERATURE (ET*)

Gagge et al. (1971) developed the New Effective Temperature scale (ET*). The ET* is similar

to the ET scale, but it uses as a reference an

environment at 50% rh. The ET* is defined as the

dry bulb temperature at 50% rh in which the total

heat exchange from the skin surface would be the

same as in the actual environment (Gonzalez et

al., 1978). Quantitatively, ET* is the solution (by

iteration) of the following equation (Gagge and

Gonzalez, 1973):

ET* + w[2.2hc/(h~+h~)](O.5P~T.-Pw) = To

(2)

where E T * = new effective temperature ( ° C ) ; w

= skin wettedness (no dimension); h c = convective

heat transfer coefficient and is a function of air

velocity ( W / m 2°C). It may be evaluated by the

following equation (Nishi, 1977):

h~ = 8.6v °53

(3)

h~ = linear r a d i a t i o n exchange coefficient

( W / m 2° C). Its value is rather constant at normal

temperature range and is approximately 4.7

W / m 2 ° C (Nishi, 1977); P f f T * = saturation vapor

pressure at ET* (mmHg). It can be determined

from a psychrometric chart or by Antoine's formula (Nishi, 1977):

P~T* = exp[18.669

- 4030.18/(ET* + 235)] mmHg

of the net thermal effect of convection and radiation. To is determined from the air and mean

radiant heat temperatures according to the following equation (Gagge, 1981):

TO= ( h r T r + hcTa)/(h ~+ hc)

Tr = mean radiant temperature ( o C) (see Table 1).

Approximate values for w and h~ can be assumed, however, accurate determination of these

variables requires the measurements of skin temperature (Tsk), clothing temperature (T~I), oxygen

consumption (VO 2), and the subject's body weight

and height. It has been reported that ET* can be

applied in hyper and hypo environments (i.e., high

altitudes and lower than sea level as in underground mines, respectively) (Nishi and Gagge,

1977). The ET* scale is useful for comfort and

thermal sensation studies.

The advantages of ET* are: it is a good indicator of physiological strain and warmth discomfort

(Gonzalez et al., 1978); it provides a theoretically

accurate estimate of human heat transfer (Gagge

et al., 1971), and it is more comparable to our own

every day experience than the ET scale (Gagge

and Gonzalez, 1973). The disadvantages of the

ET*, however, are: it is difficult to apply and

requires complicated instruments, measurements

and computations; it is not suitable for occupational studies; it assumes a normally clothed

sedentary human subjects and its usefulness is

limited for exposure times shorter than an hour

(Gagge et al., 1971).

HEAT STRESS INDEX (HSl)

Belding and Hatch (1955) developed the Heat

Stress Index (HSI) (initially called the Belding and

Hatch Index (BHI)). The HSI is calculated from

the equation:

Heat Stress Index (HSI) =

Required evaporative heat ( Ereq )

Maximum evaporative heat (Ema x )

(4)

Pw = ambient vapor pressure at Ta (mmHg); and

To = operative temperature (°C). It is a single

temperature figure that is physically representive

(5)

X 100

(6)

where E r e q = evaporative heat loss required to

maintain the body in thermal equilibrium (i.e.,

S = 0), and E m a x = maximum evaporative capacity

of the climate.

92

TABLE 1

HSI equations and coefficients (adapted from Ramsey and Chat, 1983)

Coefficients ( K )

R = K R (T r - 3 5 )

C = K c v0.6 ( T a - 3 5 )

E ...... = K F t,0.6 ( 4 2 - P~)

Shorts

Standard

clothing

Standard

plus coat

12.8(11.0)

13.6 (11.7)

27.1 (23.3)

7.7 (6.6)

8.1 (7.0)

16.3 (14.0)

6.2 (5.3)

6.5 (5.6)

13.0 (11.2)

rr = r~ +1.8,0s (Tg - r~l)

Ere q M + R + C

HSI = ( Ereq / E m a x ) X 100

=

Where T~, = air temperature ( o C), Tg = Vernon globe temperature ( o C), Tr = mean radiant temperature which can be estimated from

Tg ( o C), t, = air velocity ( m / s ) , Pw = water vapor pressure of ambient air (mmHg), M = metabolic rate of body heat production (W

(kcal/h)), R = radiant heat exchange (W (kcal/h)), C = convective heat exchange (W (kcal/h)), Ere q = an expression of stress in

terms of requirement for evaporation of sweat (W (kcal/h)), and Em~,x = m a x i m u m evaporative heat loss which can be achieved at a

given P,, and r, (W (kcal/h)).

Table 1 (Witherspoon and Goldman, 1974;

Ramsey and Chat, 1983) summarizes the equations and coefficients needed to calculate HSI.

The index (and coefficients in Table 1) assumes a

standard man (i.e., 70 kg weight, 1.7 m height, and

1.8 m 2 body surface area), dressed in shorts and

gym shoes, experiencing a skin temperature of

35 ° C (95 ° F), and uniformly wetted with sweat. If

the workers has a surface area (A) greatly different from that of the standard man, the coefficients

in Table 1 can be corrected if multiplied by A/1.8.

The coefficients for shorts and standard clothing

have been experimentally validated and the coefficients for standard clothing plus coat are an extrapolation of these values (Ramsey and Chat,

1983). Different authors, however, recommended

slightly different values for these coefficients.

Some investigators (Vogt et al., 1982) concluded that 3 6 ° C is a more accurate estimate of

mean skin temperature for use in heat transfer

equations, than the 35 ° C assumed by Belding and

Hatch (1955) for the HSI. K a m o n and Rayn (1981)

modified the HSI by assuming 36 ° C for the mean

skin temperature and called their index the Effective Heat Strain Index (EHSI).

The maximum sweat production that can be

maintained by the average man through an eight

hour period is assumed to be one liter per hour,

which is equivalent to an evaporite heat loss of

about 698 W (600 kcal/h). Therefore, the value of

E m a x c a n n o t exceed this value of 698 W. An HSI

of 100 was proposed by Belding and Hatch (1955)

as the m a x i m u m that a healthy young adult male

can tolerate for eight hour work shift, 70-90 indicates very severe heat strain, 40-60 represents

moderate to severe heat strain, and 10-30 represents a mild to moderate heat strain.

In addition to the analytical procedure (i.e.,

using the equations given in Table 1 to determine

the HSI values, nomographs are also available as

an aid to determine E r e q a n d E .... (McKarns and

Brief, 1966). Based on the values of E r e q and

E ..... the allowable exposure times (AET) in the

hot environments for a 1 ° C ( 2 ° F ) rise in body

temperature, and the minimum recovery times

(MRT) in a cooler rest location for restoration of

normal body temperature were suggested by McKarns and Brief (1966). It was assumed that the

average man can tolerate a I ° C body temperature

rise and that his temperature will rise I ° C for

each 73.25 W gained. The following equations

evaluate allowable exposure and minimum recovery times in minutes:

A E T = (73.25

× 60)/(Ere

M R T = (73.25 × 6 0 ) / ( E

q - Emax)

. . . .

--

Ereq )

(7)

(8)

The advantages of the .HSI are: it permits

estimation of tolerance time and required resting

time (Goelzer, 1977); it is useful in designing and

evaluating the efficiency of environmental control

systems (Goelzer, 1977); it can be continuously

93

improved in scope and accuracy as fresh information on heat exchange is acquired (WHO, 1969); it

differentiates between thermal conditions in correct order of physiological strain (Belding and

Hatch, 1955) and it has been used widely and

successfully as a tool for evaluating hot woi'k-environments (Ramsey and Beshir, 1987). The disadvantages are: it is difficult to apply to variable or

intermittent heat exposure (Goelzer, 1977); it is

validated only on young acclimatized when

(Goelzer, 1977); it involves difficult calculations

and requires more instruments than several other

indices (Goelzer, 1977); it underestimates the adverse effect of low wind speeds and hot humid

environments (Ramanathan and Belding, 1973)

and it does not correctly differentiate between

heat gained from work and that gained by convection or radiation (Ramsey and Beshir, 1985).

WET BULB

(WBGT)

GLOBE

TEMPERATURE

Yaglou and Minard (1957) developed the Wet

Bulb Globe Temperature (WBGT) index for use

in controlling heat casualties at military training

centers. It was not based on analysis of a new set

of prime data but was, in fact, derived from and

as a means for estimating the Corrected Effective

Temperature (CET).

The W B G T combines the effect of the four

main climatic factors contributing to heat stress:

air temperature, humidity, air velocity and radiation. Air temperature is measured directly by the

dry bulb temperature (Tab), while the combined

effect of humidity and air velocity is measured by

the natural wet bulb temperature (Tnwb) and radiation is measured by the globe temperature (Tg).

The W B G T at one time was calculated according

to the following equation (AIHA, 1975):

W B G T = 0.7Tnwb + 0 . 3 [ ( T g - TdblK + TdU]

(91

indoor, night or sunless day exposure, K equals 1

(Goelzer, 1977). W B G T can be measured either by

the method recommended by N I O S H (1972) or by

using an integrated electronic instrument.

1. NIOSH Method

N I O S H (1972) recommended the W B G T index

as the standard heat stress index for industrial use.

This recommendation was based on the principal

criteria established by N I O S H (1972) for a recommended standard heat stress index. N I O S H also

suggested the instruments and procedures for

measuring W B G T so that it could be used as the

parameter in determining the environmental conditions for implementation of work practices. The

standard tree for measuring WBGT, as suggested

by NIOSH, consists of a tripod, a mercury-in-glass

thermometer to measure Tdh, a 15 cm (6 in.) globe

with mercury-in-glass thermometer placed in the

center of the globe to measure Tg and a mercuryin-glass thermometer with its bulb covered by a

clean wetted wick to measure Tnwb. The wick is

immersed in a 125 ml flask filled with distilled

water.

NIOSH selected values for K in eqn. (9) equal

to 1 and 2 / 3 for indoor and outdoor heat exposures, respectively. Consequently, N I O S H recommended the following equations to calculate

the WBGT:

For indoor exposure, or outdoor exposure with

no solar load:

W B G T = 0.7T, wb + 0.3Tg

For outdoor sunlit exposure:

W B G T = 0.7Tnwb + 0.2Tg + 0.1Tdb

(11)

In continuous heat exposure, the time-weighted

average W B G T values are calculated on an hourly

basis, and in a two-hour basis in intermittent heat

exposure. The time-weighted average W B G T is

determined by the equation (NIOSH, 1972):

Av. WBGT

For outdoor exposures with solar load, the value

of K is related to the clothing or the type of skin,

e.g., 0.75 for green or gray outer clothing, 0.65 for

military khaki uniform, and 0.45 for clean white

clothes. For seminude, K equals 0.82 for negroid,

0.78 for Hindu, and 0.60 for white skin. For

(10)

WBGTlXtl+WBGT2×t2+'"+WBGT"×tn

tl + t2 + ... + t n

(12)

where: W B G T D W B G T 2. . . . . WBGT. are calculated values of W B G T for various work or rest

areas occupied during the total time period; and

94

t 1, t 2. . . . . t, are the elapsed times in minutes spent

in the corresponding areas which are determined

by a time study.

The WBGT index, its measuring techniques

and calculation procedures as recommended by

NIOSH (1972), were later supported by the Occupational Safety and Health Administration

(OSHA) advisory committee (Ramsey, 1975), and

the American Conference of Governmental Industrial Hygienists (ACGIH, 1987). The original

NIOSH criteria document (1972) was revised to

reflect acclimatized versus unacclimatized workers

and exposure limits versus alert limits (NIOSH,

1986). Values for ceiling limits were given in the

revised criteria. Following these recommendations,

many investigators have used the WBGT index for

evaluating heat stress (Ramsey and Beshir, 1987).

The WBGT has been applied for evaluating heat

stress in many industrial plants, e.g., aluminum

reduction plants (Horvath, 1976), steel plants

(Parker and Pierce, 1984; Minard, 1976), glass

container plants (Polhemus, 1976), and chemical

plants (Rodgers, 1976) as well as in underground

mines (Ramsey et al., 1986). Recently, the WBGT

index has been adopted by the International

Organization for Standardization (ISO, 1982) as

the international standard heat stress index. The

WBGT has been used for assessing the effects of

workplace thermal conditions on safe work behavior (Ramsey et al., 1983).

2. Integrated electronic instruments

Integrated electronic instruments for measuring

W B G T are also commercially available (e.g.,

Reuter Stokes models RSS-211, 212, 213, 214 and

217, Yellow Springs Heat Stress Instrument, and

Vista Scientific Corporation Heat Stress Monitor).

Such instruments provide a direct or digital readout of WBGT, and for some models individual

thermal measurements as Tdb, Twb, Tg and v can

be obtained as well as an access to a self contained

data logger for loading directly to a printer or a

computer. The stabilization time required for the

integrated electronic instruments is usually around

5 rain since all the sensors are resistance thermometers and the globe has a small diameter

(about 4.2 cm) (Kuehn and MacHattie, 1975).

The advantages of WBGT are: it is simple to

measure and calculate heat stress (Astrand et al.,

1975; ACGIH, 1987); the need for measuring each

climatic the need for measuring each climatic factor separately (i.e., air temperature, humidity and

radiation) in order to determine the W B G T provides information which are useful for evaluating

efficiency of environmental control systems if

coversion factors between wet-bulb and natural

wet-bulb temperatures are used (Ramsey and Chai,

1983); air velocity does not have to be measured

separately (Dukes-Dobos, 1976; Goelzer, 1977); it

is a reliable indicator and has a reasonable degree

of precision (Ramsey, 1976); it is practical for

industrial purposes (Astrand et al., 1975); it apparently correlates well with the resulting physiological reactions due to heat exposure (Ramsey,

1976; Onkaram et al., 1980); it has proved to be of

value in eliminating adverse effects of heat at

military training centers (Onkaram et al., 1980);

its applicability in industrial use has been proven

(Horvath, 1976; Minard, 1976; Polhemus, 1976;

Rodgers, 1976) and the integrated electronic instruments have small size, require short stabilization time, and are simple to use (Kuehn and

MacHattie, 1975).

The disadvantages of the WBGT are: the

WBGT estimate gets progressively poorer under

low humidity conditions (Ramsey, 1976; Goelzer,

1977); the same W B G T value does not have consistent physiological meaning independent of the

climatic factors (Ramanathan and Belding, 1973;

AIHA, 1975; Goelzer, 1977); higher air temperatures and work rates would exaggerate these inconsistencies (Ramanathan and Belding, 1973); it

does not consider the metabolic workload (Ramsey

and Beshir, 1985); the standard tree is bulky,

awkward, and requires 20 min estabilization period

(Astrand et al., 1975; Onkaram et al., 1980); the

integrated electronic instruments have high initial

cost and sensitive to electronic failure (Ciriello

and Snook, 1977; Beshir et al., 1982); the electronic circuit a n d / o r the plastic case of the integrated instrument may be damaged by the high

temperatures that would be experienced if the

instrument were left exposed for a long period

(Parker and Pierce, 1984) and when NIOSH determined that the studies of Lind (1963) provided

the best basis for establishing a heat standard, the

environmental conditions were measured in Lind's

study by the ET scale and NIOSH declared ET to

be impractical and substituted W B G T for it,

95

Study

therefore, W B G T is a secondary measure and ET

was the primary unit (Botsford, 1976).

WET GLOBE TE M PER A T U R E

Botsford (1971) developed the Wet Globe Temperature (WGT) which is measured with a Botsball (BB) thermometer. The W G T combines the

effect of the four basic climate factors: air temperature, humidity, air velocity, and radiation into a

single reading. The main concept considered in

developing this index was to design a simple device that exchanges heat with the thermal environment in a manner qualitatively similar to the

human.

The Botsball (BB) consists of a dial thermometer with its metal probe inserted in a plastic tube

which is surrounded by an aluminum tube. The

heat sensor at the end of the metal probe is placed

in the center of a 6 cm (2~ in.) diameter hollow

copper sphere connected to the plastic and

aluminum tubes. The copper sphere is painted

black and covered with a double layer of black

cloth which is saturated with water. The BB has a

water reservoir of about 7 cc capacity. If the BB

will be in continuous use for long periods, a

siphon into an auxiliary water source (e.g., the

plastic bottle furnished with each Botsball) should

be used in order to prevent the dryness of the

cloth which causes inaccurate measurements.

The stabilization time for the BB is approximately 5 min when the temperature differential

between subsequent readings is small ( 5 - 1 0 ° C ) ,

but may require 15 rain when this differential is

large ( > 15°C) (Beshir et ai., 1982). A summary

for the advantages and disadvantages of the W G T

and the W B G T observed by numerous investigators and a comprehensive comparison between the

two indices has been reported (Beshir, 1981).

Since N I O S H (1972) recommended the W B G T

as a standard index for industrial use, and because

of the potential advantages of the Botsball, several

researchers have studied the relationship between

the two indices indoor (Brief and Confer, 1971;

Sundin et al., 1972; Mutchler and Vecchio, 1977;

Ciriello and Snook, 1977; Beshir et al., 1982;

Parker and Pierce, 1984) and outdoor (Onkaram

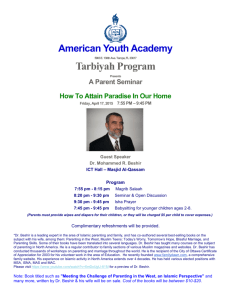

et al., 1980). Predictive equations with high coefficient of correlation (ranging from 0.913 to 0.980)

No.

RegressionEquation

No. of

Obs.

WBGT

Range

°C

r

(°C)

O

Beshir, e t . . l .

r'l

Clde~lo & Snook

~,

Mutchler & Vsc©hio

O

13489

W B G T = 1.01 W G T + 2.60

0 - 37

0.956

210

W B G T = 1.07 W G T + 0.80

16 - 4 8

0.948

1023

W B G T = 1.05 W G T + 1.14

11 - 4 2

0.913

W G T = 0.958 W B G T - 2.52

21 - 41

0.957

W B G T = 0.0212 ( W G T ) 2

+ 0.192 ( W G T ) + 9.5

18 - 56

0.976

Bdel & Conler

34

Sundin, et.al.

379

--

Rsmsey & Beshir

W B G T = W G T + 3.00

---

Rsmsey

W B G T = 1.1 W G T

O

5O

//

/

W B G T = 1.1 W G T - ~ I ~ . / / & / ~

40

W B G T = W G T + 3.0

O

ov

I-

30

m

2O

/

A

10

o

I

,o

,'o

1o

I

,o

5'0

W G T (° C)

Fig. 1. Relationships between W B G T and WGT.

for the relationship between the W B G T and W G T

have been reported. All the reported predictive

equations are linear except in one study (Sundin et

al., 1972). Ramsey et al. (1982) suggested that as a

simple approximation for indoor measurements,

the W B G T value can be obtained by adding 3 ° C

to the Botsball reading. G o l d m a n (1981) suggested

adding 1 ° C to the Botsball to approximate the

W B G T value for outdoor measurements. Based on

the relationships between the two indices which

have been reported by the previous investigators, a

simple relationship was suggested for indoor use

(Ramsey, 1987):

W B G T = 1.1 W G T ° C

(13)

Figure 1 summarizes the relationships between

W B G T and W G T reported in several individual

studies. Any of these equations are basically valid,

but the last two ( W B G T = W G T + 3 . 0 ° C or

W B G T = 1.1 W G T ) are much simpler to remember and use and could be argued to be as valid as

any of the individual studies. A word of caution is

in order, however, since this correlation implies a

moderate level of both humidity and radiant heat;

96

at both high and low levels for either of these two

variables the well behaved relationship shown in

Fig. 1 may not be valid. For example, environments with moderate heat, high humidity and no

radiant heat, have WBGT and W G T values which

are almost equal (Ramsey, 1987).

Recently, a NIOSH Workshop on Recommended Heat Stress Standards (NIOSH, 1980)

concluded that "the primary heat stress index to

be used for monitoring the industrial environment

should be the WGT, with the alternative of using

the WBGT, the ET or equivalent". The W G T was

suggested as a basic index because of its simplicity

and ease of use in industry. The primary purpose

for using a single and simple index would be to

establish a point at which some other more detailed observations must be made.

The advantages of W G T are: the Botsball is a

practical, rugged, simple and reliable device (Beshir et al., 1982); the instrument's small size provides for non-invasive placement near the worker

and enhances accurate assessment of the environment (Beshir et al., 1982); the required stabilization time is relatively short (Ciriello and Snook,

1977; Beshir et al., 1982); it combines the effects

of the four main climatic factors into a single

reading (Gershoni, 1979); it requires no calculations (Ramsey and Beshir, 1987); it is less expensive than the WBGT standard tree or the integrated electronic instruments (Onkaram et al.,

1980) and high correlations between W G T and

other indices, especially WBGT, have been reported (Ramanathan and Belding, 1973; Botsford,

1976; Beshir, 1981; Lee and Ramsey, 1987).

The disadvantages of W G T are: correlation

between W G T and physiological responses to heat

exposures has not been fully established

(Ramanathan and Belding, 1973); although predictive relationship between W G T and WBGT

have been developed (Beshir et al., 1982; Lee and

Ramsey, 1987), some combinations of environment can result in large errors (Ciriello and Snook,

1977); when the wick is dry, erroneous measurements will be obtained (Beshir et al., 1982); lack

of positive adjustment for flow rate and wick

wettedness (Beshir et al., 1982); the small size of

the globe resulted in a much higher sensitivity to

air velocity than man exhibits (Hatch, 1973) and

only an integrated measure of the environment is

obtainable, rather than individual climatic factors

which may be useful in further in-depth analysis

(Ramsey and Beshir, 1987).

PROGRAMMED HAND HELD CALCULATORS

Programmed hand held calculators are increasingly being used for evaluating occupational environments. The heat stress indices utilizing such

calculators, are those which are well correlated to

human physiological responses but have complicated computations such as the New Effective

Temperature (Nishi, 1977) and the Heat Stress

Index (Kamon and Ryan, 1981). For example,

instead of applying the tedious computations suggested by Gagge and Gonzalez (1973) to determine the value of ET*, the programmed hand

held calculator developed by Nishi (1977) to determine this value can be used. This calculator

performs those boring computations and needs as

input data: Za, Twb (or rh), To, h~, h r, metabolic

rate, human mechanical efficiency, effective clothing insulation and mean skin temperature.

Programmed calculators provide the user not

only with the heat stress level, but may also provide work practice information such as the time

limits of exposure and the rest period required.

Computer programs have been also developed for

determination of some heat stress indices (Gagge,

1973; Chai, 1981; Cvejanovich, 1983). The use of

programmed hand held calculators and computers

for assessment of occupational heat and thermal

indices is expected to be more widely practiced in

the future.

MEAN EQUIVALENCE LINES (MEL)

Influencing factors of heat ~tress can be classified as climatic variables and non-climatic variables. Climatic variables consist of: air temperature, air velocity, humidity and radiant heat while

non-climatic variables include: activity level (i.e.,

heat production in the body) and thermal resistance of the clothing. In order to assess the heat

stress effects, it is necessary to know how far the

various influencing factors compensate each other,

or in other words, what combinations of the variables produce equal effect.

97

Wenzel (1978) investigated the reactions of a

number of men to systematically varied combinations of all the climatic and non-climatic variables

mentioned above, to drive those combinations

which produce equal effects on various physiological reactions and to check the statements of all

the indices in use. The author developed the Mean

Equivalence Lines (MEL) which are represented

in psychrometric charts and describe combinations of climatic and non-climatic conditions in

which equal heart rates as well as equal rectal and

skin temperatures would be reached.

Wenzel (1978) reported that the combinations

of ambient temperatures and humidities that were

found to be equivalent under the given conditions

of physical activity corresponded particularly well

with the Index of Physiological Effect (Robinson

et al., 1945). There was also good agreement with

the Predictive 4 hour Sweat Rate index (McArdle

et al., 1947). The combinations corresponded with

other indices (i.e., HSI, ET and WBGT) only

within limited ranges of climate depending upon

work level.

INTERNATIONAL ORGANIZATION FOR

STANDARDIZATION (ISO) STANDARDS

The ISO has recently issued a standard for hot

environments. ISO (1982) specifies the required

measurements and procedures for the estimation

of the heat stress on working man, based on the

W B G T index.

The ISO has also proposed a method of analytical evaluation and interpretation of the thermal stress experienced by a subject in a hot environment (ISO, 1983). The method is based on

the comparison between the required skin wettedness and the required sweat rate as a result of the

working conditions, and the skin wettedness and

sweat rate which it is physiologically possible to

achieve.

ISO (1983) recommends that ambient conditions acceptable for an 8 hour should satisfy the

following conditions:

Ep = Ere q

(14)

Wreq < Wlim

(15)

SWp <

(16)

Omax/8

where

E p = predicted evaporation rate ( W m - 2 ) ,

required evaporation rate ( W m - 2), w req

required skin wettedness (dimensionless), w lim =

skin wettedness compatible with a steady state of

b o d y t e m p e r a t u r e s (dimensionless), SWp =

predicted sweat rate ( W m - 2 ) , and Dmax =

m a x i m u m acceptable dehydration (Win-2).

Equations for calculating the above mentioned

variables are included. N o time limits have been

suggested for the work shift, if the three conditions are satisfied. In this case SWp can be used as

a comparison index for the equivalence of heat

stress conditions.

ISO (1983) emphasizes that it is necessary to

calculate an allowable exposure time (DLE), if

one or other of these three conditions is not

satisfied. The D L E can be determined from the

m a x i m u m heat storage (Qmax) compatible on the

one side with the normal execution of a task and

on the other with the absence of pathological

effects. The raising of the deep body temperature

corresponding to this m a x i m u m heat storage is

taken to be between 0.8 and 1°C.

If the required evaporation rate is not achievable

Ere q =

=

D L E 1 = 60Q ..... / ( Ereq - -

Ep)

(17)

If the required skin wettedness is excessive and

incompatible with a stable regime of body temperatures

DLE 2 =

60Qrnax//(Wreq

-

Wlim)

(18)

If the required sweat rate involves an exaggerated dehydration

D E E 3 = 60Oma,,/SWp

(19)

The allowable exposure time (DLE) which is to

be taken into consideration in the limiting duration of work, is the shortest DLE, i.e., the minim u m value of D L E 1, D L E 2 and D L E 3. When

D L E 1 or D L E 2 are the determining factors, it is

advised to allow the worker a rest period sufficient

to bring about a return to normal body temperature before being exposed again to a hot environment. When D L E 3 is the determining factor, no

further exposure should be allowed during the

day.

This proposed standard provides a programme

in BASIC which allows the calculation of the

98

required sweat rate and of the D L E for all situations where the following parameters are known:

the metabolic heat production, the thermal insulation of the clothing and climatic parameters.

The method of analytical estimation and interpretation of thermal stress (ISO, 1983) allows a

more precise approach than the method based on

the W B G T (ISO, 1982) as well as a more rational

choice of means of protection. However, at the

present state of techniques of measurement and

calculation, its application takes longer and is

more difficult. The ISO (1983) procedures can be

used either when an in-depth analysis of hot working conditions is needed, or as a complement of

the ISO (1982) standard when its reference values

are exceeded.

A NUMERICAL EXAMPLE

The following example reviews the procedures

and calculations required to determine the values

of the heat stress indices discussed in this paper.

The climatic factors of an indoor industrial

workplace were measured with the appropriate

instruments as follows:

Air temperature (Ta) = 36 ° C

Natural wet bulb temperature (Tnwb) = 30 ° C

Psychrometric wet bulb temperature (Twb)=

29°C

Globe temperature (T~) = 40 ° C

Air velocity (v) = 0.5 m / s

Botsball reading ( W G T ) = 29.5 o C

The worker was wearing a normal summer

clothing (i.e., clo = 0.6), and performing a m o d erate workload task and his metabolic energy was

250 W.

1. Corrected Effective Temperature (CET)

The corrected effective temperature value can

be determined from a n o m o g r a m (Ellis et al.,

1972; Kerslake, 1972) by applying Tg = 40, Twb =

29 and v = 0.5:

C E T = 31.6 ° C

2. Skin wettedness (w)

The skin wettedness can be determined from

the relation:

w = HSI/100

= 199.5/100

= 1.995

(see section 4 below for the calculation of HSI)

Since w cannot exceed 1, therefore the value of

the skin wettedness in this example is 1. This

means that the worker's b o d y was fully covered by

sweat.

3. New effective temperature ( E T * )

In this example, the value of E T * is determined

by the iteration procedure (Gagge and Gozalez,

1973) to demonstrate the complexity of the computations. However, it is agreed that the computations would not be so hard, if they were performed on a p r o g r a m m e d hand held calculator

(Nishi, 1977).

The new effective temperature can be obtained

by solving eqn. (2) (by iteration).

E T * + w [ 2 . 2 h c / ( h c + hr) ] (0.5P~T. -- Pw) = To

hc = 8.6v °53

= 8.6(0.5) 0.53 --- 5 . 9 5 6 W / m 2 o C

Assuming h r = 4 . 7 W / m 2 ° C , then the operative temperature (To) can be determined from

eqn. (5):

To=(hrTr+hcTa)/(hr+hc)

= (4.7 × 45.09 + 5.956 X 3 6 ) / ( 4 . 7 + 5.956)

= 40°C

(see section 4 below for the calculation of T~)

The term w

[ 2 . 2 h c / ( h c + h r ) ] = 112.2 X 5 . 9 5 6 / ( 4 . 7 + 5.956)]

= 1.23

Knowing T~=36°C

and T w b = 2 9 ° C , then

from a psychrometric chart, the value of Pw is

equal to 26.5 m m H g . F r o m the above c o m p u t e d

values, eqns. (2) and (4) become:

If the effective temperature value is required,

use Ta instead of Tg:

E T * + 1.23(0.5P~T. -- 26.5) = 40

ET = 30.5° C

P~v* = exp(18.669 - 4 0 3 0 . 1 8 / [ E T * ]) m m H g

99

Therefore,

C = KeY° 6(Ta - 3 5 )

E T * + 1.23{0.5 exp[18.669 - 4 0 3 0 . 1 8 / ( E T * + 235)]

-

26.5

} =

40

The value of E T * can be determined from this

equation by trial and error.

First trial

Assume E T * = 4 0 ° C ,

equation will be:

then the L.H.S. of the

40 + 1.23{0.5 exp[18.669 - (4030.18/275)]

- 26.5 } = 41.449

Therefore, by assuming E T * = 40 ° C, the

L.H.S. of the equation (i.e., 41.449) becomes

greater than the R.H.S. (i.e., 40).

= 8.1(0.5)°6(36 - 35)

=5.3W

Ere q = M + R + C

= 250 + 77.7 + 5.3

= 333 W

Emax =

KE°°'6( 42 -- Pw)

= 16.3(0.5)°"6(42 - 26.5)

= 166.9 W

(the value of Pw (i.e., 26.5) is determined from a

psychrometric chart, see section 3 above)

Heat Stress Index ( H S I ) =

(Ereq/Emax) X 100

= (333/166.9) X 100

Second trial

Assume E T * = 39 ° C, the L.H.S. of the equation will be:

= 199.5

5. Wet Bulb Globe Temperature (WBGT)

39 + 1.23{0.5 e x p [ 1 8 . 6 6 9 - (4030.18/274)]

- 26.5 } = 38.676

By assuming E T * = 3 9 ° C , the L.H.S. of the

equation (i.e., 38.676) becomes smaller than the

R.H.S. (i.e., 40).

Third trial

Assume E T * = 39.5°C, the L.H.S. of the equation will be:

39.5 + 1.23{0.5 exp[18.669 - (4030.18/274.5)]

-

26.5

} =

40.05

In this iteration, the L.H.S. (i.e., 40.05) is approximately equal to the R.H.S. (i.e., 40), hence:

The wet bulb globe temperature is obtained

from eqn. (10):

W B G T = 0.7Tnw b + 0.3Tg

= 0.7 X 30 + 0.3 X 40

= 33°C

6. Wet Globe Temperature (WGT)

The wet globe temperature is obtained directly

from the Botsball reading:

W G T = 29.5 ° C

ET* = 39.5°C

Conclusions

4. Heat Stress Index (HSI)

The heat stress index can be obtained by using

the equations and coefficient given in Table 1:

Tr = Tg + 1.8v°5(Tg - Ta)

= 40 + 1.8(0.5)°'3(40 - 36)

= 45.09 ° C

R = KR(g

- 35)

= 7.7(45.09 - 35)

= 77.7 W

As described above, heat stress is the aggregate

of climatic (i.e., air temperature, humidity or vapor

pressure, air velocity and radiation) and physical

factors. Assessment of heat stress is performed by

measuring one or m o r e of these factors and then

utilizing the appropriate heat stress index. The

objective of assessing the occupational heat stress

by one of the available heat indices is to establish

safe heat exposure limits, and regulatory rules.

Several heat indices have been developed over

the years. Some of these indices were discussed in

this paper (i.e., CET, w, E T * , HSI, W B G T , W G T

100

and programmed hand held calculators). The measurements required, advantages and disadvantages

for each index were discussed. A numerical example was given to illustrate the procedures and

calculations required to compute each index. Mean

Equivalence Lines (MEL) developed by Wenzel

(1978) and the International Organization for

Standardization (ISO) standards for hot environments were also provided in the paper.

Other heat stress indices reported in the literature and not discussed in this paper include: the

cooling power of air measured by the wet-kata

thermometer, the Index of Physiological Effect

(IPE), the predicted 4 hour sweat rate (P4SR), the

wet bulb-dry index (W.D.), the temperature

humidity index (THI), the index of physiological

effect ( E p ) , the index of thermal stress (ITS), the

relative strain index (RS), the reference index (RI)

and others (Witherspoon and Goldman, 1974;

Ramsey and Beshir, 1987).

A heat stress index as defined above is a

numerical evaluation of the hot environment.

Therefore, by increasing the level of one or more

of the climatic factors, the numerical value of a

heat index will increase. Consequently, it is logical

to expect that strong correlations exist among

most of the heat indices, and this has been reported in several laboratory and field studies (Brief

and Confer, 1971; Jensen and Heins, 1976;

Mutchler and Vecchio, 1977; Pulket et al., 1980).

NIOSH (1972) recommended the WBGT among

the available heat stress indices as the standard

index for industrial use. This recommendation was

later widely accepted and supported by different

institutions and researchers nationally and internationally (Beshir and Hafez, 1984). It has been

proposed that the WBGT index, corrected for

energy expenditure and air velocity, can be used

as an international standard heat stress index

(Brown and Dunn, 1977). Recently, the WGT is

being highly recommended to be the primary heat

stress index to be used for monitoring the industrial environment (NIOSH, 1980; Beshir, 1981).

This is basically because of the simplicity, small

size and reliability of the Botsball. However, the

primary purpose for using a simple index such as

the WGT, or the WBGT would be to establish a

point at which some other more detailed observations and in-depth analysis of the working environment must be made.

REFERENCES

ACGIH, 1987. TLVs: Threshold limit values for chemical

substances and physical agents in the workroom environment with intended changes for 1986. American Conference of Governmental Industrial Hygienists.

AIHA, 1975. Heating and cooling for man in industry. American Industrial Hygiene Association, Akron, OH.

Astrand, 1., Axelson, O., Eriksson, U. and Olander, L., 1975.

Heat stress in occupational work. AMBIO, 4: 37-42.

Bedford, T., 1946. Environmental warmth and its measurement. Med. Res. Coun. Warn. Memo No. 17. HMSO,

London.

Belding, H.S., 1970. The search for a universal heat stress

index. In: J.D. Hardy, A.P. Gagge and J.A.J. Stolwijk

(Eds.), Physiological and Behavioral Temperature Regulation. Charles C. Thomas, Springfield, IL, Chap. 13, pp.

193-202.

Belding, H.S., 1976. Strains of exposure to heat. In: S.M.

Horvath and R.C. Jensen (Eds.), Standards for Occupational Exposure to Hot Environments. Proc. Symposium.

HEW Publication No. (NIOSH) 76-100, pp. 7-8.

Belding, H.S. and Hatch, T.F., 1955. Index for evaluating heat

stress in terms of resulting physiological strains.

H e a t . / P i p . / A i r Cond., 27: 129-136.

Beshir, M.Y., 1981. A comprehensive comparison between

WBGT and Botsball. Amer. Ind. Hyg. Assoc. J., 42: 81- 87.

Beshir, M.Y. and Hafez, H.A., 1984. A proposed Egyptian

standard for occupational exposure to hot environments.

In: Prec. 1st International Ain Shams University Conference on Production Engineering and Design for Development, Cairo, pp. 867-876.

Beshir, M.Y., Ramsey, J.D. and Burford, C.L., 1982. Threshold

values for the Botsball: A field study of occupational heat.

Ergonomics, 25: 247-254.

Botsford, J.H., 1971. A wet globe thermometer for environmental heat measurement. Amer. Ind. Hyg. Assoc. J., 32:

1-10.

Botsford, J.H., 1976. Application of the Botsball thermometer.

American Industrial Hygiene Association Conference,

Atlanta, GA.

Brief, R.S. and Confer, R.G., 1971. Comparison of heat stress

indices. Amer. Ind. Hyg. Assoc. J., 32: 11-16.

Brown, J.R. and Dunn, G.W., 1977. Thermal stress: The need

for an international standard. Amer. Ind. Hyg. Assoc. J.,

38: 180-183.

Candas, V., Libert, J.P. and Vogt, J.J., 1983. Sweating and

sweat decline of resting men in hot humid environments.

Eur. J. Appl. Physiol., 50: 223-234.

Chai, C.P., 1981. The assessment of the ability of various heat

stress indices to predict safe work behavior. Unpublished

Master Thesis, Texas Tech University, Lubbock, TX.

Ciriello, V.M. and Snook, S.H., 1977. The prediction of WBGT

from the Botsball. Amer. Ind. Hyg. Assoc. J., 38: 264-271.

Cvejanovich, G.J., 1983. Computer program for evaluating the

thermal environment. Amer. Ind. Hyg. Assoc. J., 44:

690-695.

Dukes-Dobos, F.N., 1976. Rationale and provisions of the

work practices standard for work in hot environments as

101

recommended by NIOSH. In: S.M. Horvath and R.C.

Jensen (Eds.), Standards for Occupational Exposure to Hot

Environments. Proc. Symposium. H E W Publication No.

(NIOSH) 76-100, pp. 27-42.

Ellis, F.P., Smith, F.E. and Waiters, J.D., 1972. Measurements

of environmental warmth in SI units. Br. J. Ind. Med., 29:

361-377.

Fuller, F.H. and Smith, Jr., P.E., 1981. Evaluation of heat

stress in a hot workshop by physiological measurements.

Amer. Ind. Hyg. Assoc. J., 42: 32-37.

Gagge, A.P., 1937. A new physiological variable associated

with sensible and insensible perspiration. Amer. J. Physiol.,

120: 277-287.

Gagge, A.P., 1973. A two-node model of h u m a n temperature

regulation in Fortran. In: J.F. Parker, Jr. and V.R. West

(Eds.), Bioastronautics Data Book. National Aeronautics

and Space Administration, Washington, DC, pp. 142-148.

Gagge, A.P., 1981. Rational temperature indices of thermal

comfort. In: K. Cena and J.A. Clark (Eds.), Bioengineering,

Thermal Physiology and Comfort. Elsevier, Amsterdam,

Chap. 5, pp. 79-98.

Gagge, A.P. and Gonzalez, R.R., 1973. Physiological bases of

warm discomfort for sedentary man. Arch. Sci. Physiol., 27:

A409-A424.

Gagge, A.P., Stolwijk, J.A.J. and Nishi, Y., 1971. An effective

temperature scale based on a simple model of h u m a n

physiological regulatory response. A S H R A E Trans., 77:

247-262.

Gershoni, H., 1979. Allowances for heat stress. Ind. Eng., 20:

20-24.

Goelzer, B., 1977. Evaluation of heat stress in the work environment. World Health Organization (WHO), O C H / 7 7 . 1 .

Goldman, R.F., 1981. Personal communication.

Gonzalez, R.R., Berglund, L.G. and Gagge, A.P., 1978. Indices

of thermoregnlatory strain for moderate exercise in the

heat. J. Appl. Physiol., 44: 889-899.

Hancock, P.A., 1987. Performance criteria as exposure limits in

h e a t stress. In: S.S. A s f o u r (Ed.), T r e n d s in

E r g o n o m i c s / H u m a n Factors IV. Elsevier, Amsterdam, The

Netherlands, pp. 333-340.

Hatch, T.F., 1973. Design requirements and limitations of a

single reading heat stress meter. Amer. Ind. Hyg. Assoc. J.,

34: 66-72.

Horvath, S.M., 1976. Heat stress in aluminum reduction plants.

In: S.M. Horvath and R.C. Jensen (Eds.), Standards for

Occupational Exposure to Hot Environments. Proc. Symposium. H E W Publication No. (NIOSH) 76-100, pp. 91-99.

Houghten, F.C. and Yaglou, C.P., 1923. Determining lines of

equal comfort. J. Amer. Soc. Heat Vent. Eng., 29: 163-176.

ISO, 1982. Hot environments-estimation of the heat stress on

working man, based on the W B G T index (wet bulb globe

temperature). International Organization for Standardization, I S O / T C 159, ISO-DIS 7243, Geneva.

ISO, 1983. W a r m environments--analytical determination and

interpretation of thermal stress using calculation of required sweat rates. International Organization for Standardization, I S O / O P 7933 Draft Standard, Geneva.

Jensen, R.C. and Heins, D.A., 1976. Relationship between

several prominent heat stress indices. D H E W (NIOSH)

Publication No. 77-109.

Kamon, E. and Ryan, C., 1981. Effective heat strain index

using pocket computer. Amer. Ind. Hyg. Assoc. J., 42:

611-615.

Kerslake, D. McK., 1972. The Stress of Hot Environments.

Cambridge University Press, London, England.

Kuehn, L.A. and MacHattie, L.E., 1975. A fast responding and

direct-reading W B G T index meter. Amer. Ind. Hyg. Assoc.

J., 36: 325-332.

Kuhlemeier, K.V. and Wood, T.B., 1979. Laboratory evaluation of permissible exposure limits for men in hot environments. Amer. Ind. Hyg. Assoc. J., 40: 1097-1103.

Lee, C.H. and Ramsey, J.D., 1987. Relationships between

W B G T and W G T under varying thermal components. In:

S.S. Asfour (Ed.), Trends in E r g o n o m i c s / H u m a n Factors

IV. Elsevier, Amsterdam, The Netherlands, pp. 359-365.

Lind, A.R., 1963. A physiological criterion for setting thermal

environmental limits for everyday work. J. Appl. Physiol.,

18: 51-56.

McArdle et al., 1947.

McKarns, J.S. and Brief, R.S., 1966. Nomographs give refined

estimate of heat stress index. H e a t . / P i p . / A i r Cond., 38:

113-116.

Minard, D., 1976. Physiological strain in steel workers in

relation to a proposed standard for occupational heat exposure. In: S.M. Horvath and R.C. Jensen (Eds.), Standards for Occupational Exposure to Hot Environments.

Proc. Symposium. H E W Publication No. (NIOSH) 76-100,

pp. 109-115.

Mutchler, J.E. and Vecchio, J.L., 1977. Empirical relationships

a m o n g heat stress indices in 14 hot industries. Amer. Ind.

Hyg. Assoc. J., 38: 253-263.

NIOSH, 1972. Criteria for a recommended s t a n d a r d - - o c c u p a tional exposure to hot environments. National Institute for

Occupational Safety and Health, HSM 72-10629, Washington, DC, Government Printing Office.

NIOSH, 1980. Proc. of a N I O S H Workshop on Recommended

Heat Stress Standards, edited by F.N. Dukes-Dobos and A.

Henschel. National Institute for Occupational Safety and

Health, D H H S (NIOSH) Publication No. 81-108.

NIOSH, 1986. Criteria for a recommended s t a n d a r d - - o c c u p a tional exposure to hot environments. Revised criteria 1986.

National Institute for Occupational Safety and Health,

D H H S (NIOSH) Publication No. 86-113.

Nishi, Y., 1977. Field assessment of thermal characteristics of

m a n and his environment by using a programmable calculator. A S H R A E Trans., 83(I): 103-124.

Nishi, Y. and Gagge, A.P., 1977. Effective temperature scale

useful for hypo- and hyperbaric environments. Aviat.

Space Environ. Med., 48: 97-107.

Onkaram, B., Stroschein, L.A. and Goldman, R.F., 1980. Three

instruments for assessment of W B G T and a comparison

with W G T (Botsball). Amer. Ind. Hyg. Assoc. J., 41:

634-641.

Parker, R.D.R. and Pierce, F.D., 1984. Comparison of heat

stress measuring techniques in a steel mill. Amer. Ind. Hyg.

Assoc. J., 45: 405-415.

Peterson, J.E., 1970. Experimental evaluation of heat stress

indices. Amer. Ind. Hyg. Assoc. J., 31: 305-317.

Polhemus, J., 1976. Heat stress experience in glass container

plant. In: S.M. Horvath and R.C. Jensen (Eds.), Standards

102

for Occupational Exposure to Hot Environments. Proc.

Symposium. H E W Publication No. (NIOSH) 76-100, pp.

133-153.

Pulket, C., Henschel, A., Burg, W.R. and Saltzman, B.E., 1980.

A comparison of heat stress indices in a hot humid environment. Amer. Ind. Hyg. Assoc. J., 41: 442-449.

Ramanathan, N.L. and Belding, H.S., 1973. Physiological

evaluation the W B G T index for occupational heat stress.

Amer. Ind. Hyg. Assoc. J., 34: 375-383.

Ramsey, J.D., 1975. Heat stress standard: OSHA's Advisory

Committee recommendations. Nat. Saf. News, 6: 89-95.

Ramsey, J.D., 1976. Reliability and comparability of heat

exposure indices. In: Proc. 1976 Annual Reliability and

Maintainability Symposium, pp. 1-3.

Ramsey, J.D., 1987. Practical evaluation of hot working areas.

Prof. Saf., 42-48.

Ramsey, J.D. and Beshir, M.Y., 1985. Comparison of indices

for assessing heat stress. In: I.D. Brown, R. Goldsmith, K.

Coombes and M.A. Sinclair (Eds.), Proc. 9th Congress of

the International Ergonomics Association, Bournemouth,

England, pp. 577-579.

Ramsey, J.D. and Beshir, M.Y., 1987. Thermal standards and

measurement techniques. In: P.G. Rentos (Ed.), The Industrial Environment, Its Evaluation and Control, 4th edn.

NIOSH.

Ramsey, J.D., Beshir, M.Y. and Burford, C.L., 1982. Using the

Botsball to measure occupational heat. American Industrial

Hygiene Association Conference, Cincinnati, OH.

Ramsey, J.D., Burford, C.L., Beshir, M.Y. and Jensen, R.C.,

1983. Effects of workplace thermal conditions on safe work

behavior. J. Saf. Res., 14: 105-114.

Ramsey, J.D., Burford, C.L., Dukes-Dobos, F.N., Tayyari, F.

and Lee, C.H., 1986. Thermal environment of an underground mine and its effect upon miners. Proc. International

Conference on the Health of Mines, Pittsburgh, PA. In

press.

Ramsey, J.D. and Chai, C.P., 1983. Inherent variability in

heat-stress decision rules. Ergonomics, 26: 495-504.

Robinson, S., Turrell, E.S. and Glrking, S.D., 1945. Physiologically equivalent conditions of air temperature and humidity. Amer. J. Physiol., 143: 21-32.

Rodgers, S.H., 1976. Data on industrial experience related to a

heat standard: Chemicals. In: S.M. Horvath and R.C.

Jensen (Eds.), Standards for Occupational Exposure to Hot

Environments. Proc. Symposium. HEW Publication No.

(NIOSH) 76-100, pp. 155-160.

Sundin, D., Dukes-Dobos, F.N., Jensen, R.C. and Humphreys,

C., 1972. Comparison of the A C G I H TLV for heat stress

with other heat stress indices. American Industrial Hygiene

Association Conference, San Francisco, CA.

Vogt, J.J., Candas, V. and Libert, J.P., 1982. Graphical determination of heat tolerance limits. Ergonomics, 25:

285-294.

Wenzel, H.G., 1978. Heat stress upon undressed m a n due to

different combinations of elevated environmental temperature, air humidity, and metabolic heat production: A critical comparison of heat stress indices. J. Hum. Ergon., 7:

185-206.

WHO, 1969. Health factors involved in working under conditions of heat stress. World Health Organization, Tech. Rep.

Ser. 412, Geneva.

Witherspoon, J.M. and Goldman, R.F., 1974. Indices for thermal stress. A S H R A E Bull., No. LO-73-8: 5-13.

Wyndham, C.H. and Heyns, A.J., 1973. The accuracy of the

prediction of h u m a n strain from heat stress indices. Arch.

Sci. Physiol., 27: A295-A301.

Yaglou, C.P. and Minard, D., 1957. Control of heat stress

casualities at military training centers. Arch. Ind. Health,

16: 302-316.