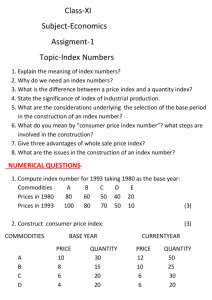

Commodities Research Deutsche Bank@ Global Markets Research September 2008 A User Guide To Commodities Table of Contents Introduction .................. 3 Energy .......................... 4 Precious Metals.......... 36 Industrial Metals......... 47 Minor Metals .............. 67 Mineral Sands............. 83 Rare Earth Metals....... 85 Agriculture .................. 87 Livestock .................. 110 Exchanges ................ 115 Conversion Factors... 118 London Michael Lewis 44 20 7545 2166 Hong Kong Amanda Lee, CFA 852 2203 8376 New York Joel Crane 1 212 250 5353 Washington Adam Sieminski, CFA 1 202 662 1624 Paris Mark Lewis 33 1 4495 6761 Isabelle Curien 33 1 4495 6616 Deutsche Bank AG/London David Folkerts-Landau Managing Director Global Head of Research All prices are those current at the end of the previous trading session unless otherwise indicated. Prices are sourced from local exchanges via Reuters, Bloomberg and other vendors. Data is sourced from Deutsche Bank and subject companies. Deutsche Bank does and seeks to do business with companies covered in its research reports. Thus, investors should be aware that the firm may have a conflict of interest that could affect the objectivity of this report. Investors should consider this report as only a single factor in making their investment decision. DISCLOSURES AND ANALYST CERTIFICATIONS ARE LOCATED IN APPENDIX 1 September 2008 A User Guide To Commodities Table of Contents Introduction........................................................................................................................................... 3 Energy .................................................................................................................................................... 4 Crude Oil ................................................................................................................................................. 5 Oil Products ............................................................................................................................................ 8 Refining................................................................................................................................................. 11 Coal-to-Liquids & Gas-to-Liquids ........................................................................................................... 14 Oil Sands............................................................................................................................................... 15 Oil Transportation.................................................................................................................................. 17 US Natural Gas...................................................................................................................................... 19 Liquefied Natural Gas ........................................................................................................................... 21 US Power.............................................................................................................................................. 22 Thermal Coal ......................................................................................................................................... 24 Uranium ................................................................................................................................................ 26 Ethanol .................................................................................................................................................. 28 CO2 Emissions ..................................................................................................................................... 30 Renewable Energy................................................................................................................................ 34 Precious Metals................................................................................................................................... 36 Gold....................................................................................................................................................... 37 Silver ..................................................................................................................................................... 39 Platinum ................................................................................................................................................ 41 Palladium............................................................................................................................................... 43 Rhodium................................................................................................................................................ 45 Other Platinum Group Metals: Ruthenium, Iridium & Osmium ............................................................ 46 Industrial Metals & Bulk Commodities............................................................................................. 47 Aluminium............................................................................................................................................. 48 Copper .................................................................................................................................................. 51 Lead ...................................................................................................................................................... 53 Nickel .................................................................................................................................................... 55 Tin ......................................................................................................................................................... 57 Zinc ....................................................................................................................................................... 59 Iron Ore................................................................................................................................................. 61 Ferro-Chrome........................................................................................................................................ 63 Metallurgical Coal.................................................................................................................................. 64 Steel...................................................................................................................................................... 65 Minor Metals ....................................................................................................................................... 67 Cobalt.................................................................................................................................................... 68 Gallium .................................................................................................................................................. 70 Lithium .................................................................................................................................................. 71 Magnesium ........................................................................................................................................... 72 Manganese ........................................................................................................................................... 73 Molybdenum......................................................................................................................................... 75 Rhenium................................................................................................................................................ 77 Tantalum ............................................................................................................................................... 78 Thorium................................................................................................................................................. 79 Titanium ................................................................................................................................................ 80 Tungsten ............................................................................................................................................... 81 Vanadium .............................................................................................................................................. 82 Mineral Sands ..................................................................................................................................... 83 Rare Earth Metals ............................................................................................................................... 85 Agriculture........................................................................................................................................... 87 Cocoa .................................................................................................................................................... 89 Coffee ................................................................................................................................................... 91 Corn ...................................................................................................................................................... 93 Cotton ................................................................................................................................................... 95 Palm Oil................................................................................................................................................. 97 Rapeseed .............................................................................................................................................. 99 Rice ..................................................................................................................................................... 100 Rubber ................................................................................................................................................ 102 Soybeans ............................................................................................................................................ 104 Sugar................................................................................................................................................... 106 Wheat ................................................................................................................................................. 108 Livestock............................................................................................................................................ 110 Feeder & Live Cattle ........................................................................................................................... 111 Lean Hogs & Pork Bellies ................................................................................................................... 113 Commodity Exchanges & Turnover ................................................................................................ 115 Conversion Factors ........................................................................................................................... 118 Page 2 Global Markets Research September 2008 A User Guide To Commodities Introduction September 11, 2008 To Deutsche Bank’s Clients Since the publication of the first Deutsche Bank User Guide To Commodities in July 2006, the universe of financially traded commodities has expanded to include, for example, steel billet futures on the London Metal Exchange and the first derivatives contract with iron ore as the underlying. Next year, the LME plans to launch futures contracts for cobalt and molybdenum. To address the increasing importance of commodities during this decade, we are publishing an update to the 2006 User Guide to Commodities, which not only includes the major commodity markets covered in the first edition, but also extends the coverage to include smaller, less mainstream commodity markets. This report is divided into five broad sections: energy, precious metals, industrial metals, agriculture and livestock. It covers over 50 commodity markets and identifies, among other things, the key producer and consumer nations, the commodity’s major uses and, where applicable, the commodity exchanges on which they are traded. I hope you, our clients, find this guide instructive. Michael Lewis Global Head of Commodities Research michael.lewis@db.com Figure 1: Commodity Scorecard since 2002 Figure 2: Top 20 commodity futures by turnover % returns 31-Dec-01 to 9-Sep-2008 Palladium WTI Crude Oil (NYMEX) Lumber Soy Meal (DCE) Sugar #11 Brent Crude Oil (ICE) Corn (DCE) Cotton Corn (CBOT) Aluminium No. 1 Soybeans (DCE) Zinc Rubber (SHFE) Wheat Aluminium (LME) Silver Gluten Wheat (ZCE) Platinum Soybeans (CBOT) Corn Natural Gas (NYMEX) Gasoline Gold (NYMEX) Gold Gas Oil (ICE) Soybeans Copper (LME) Coffee Sugar #11 (NYBOT) US natural gas Wheat (CBOT) Copper Gold (TCE) WTI crude oil Heating Oil (NYMEX) Heating oil Copper (LME) Coal API#4 Soybean Oil (CBOT) -150 -50 50 150 250 350 450 0 25 50 75 100 125 Turnover (million lots, 2007) Source: DB Global Markets Research, Bloomberg Global Markets Research Source: NYMEX, ICE, DCE, LME, NYBOT, TCE, SHFE, CBOT, ZCE Page 3 September 2008 A User Guide To Commodities Energy Global energy consumption has nearly doubled since the 1973 oil crisis. In terms of the energy mix, oil provides approximately 36% of total primary energy consumption, that is primary fuels that are commercially-traded. Despite the implications for global warming and the environment, coal represents 29% of total energy use followed by natural gas, which meets 26% of energy demand. Hydro-power and nuclear energy account for approximately 6% each. Not surprisingly, the surge in oil prices during this decade has encouraged the development of alternative energy sources such as modern bio-fuels and renewable energies such as wind, solar, geothermal and tidal power. However, altogether these represent less than 2% of global energy demand. Fuels such as wood, peat and animal waste are still important in many economies, for example the International Energy Agency estimates that more than 10% of China’s energy use in 2007 was in the form of such traditional biomass. However, these are generally not counted in global energy statistics. Going forward, we expect it will require the development and expansion of all economic energy sources to meet rapid population growth, urbanisation and to sustain the improvement in living standards underway in many parts of the developing world. Even allowing for rapid growth in alternative energies, we believe the world economy will remain heavily dependent on fossil fuels, including coal, oil and natural gas, over the next two to three decades. Energy markets, and specifically crude oil, are the deepest and most liquid of all the five broad commodity sectors. The Nymex WTI crude oil futures contract is the most actively traded commodity future anywhere in the world, with annual turnover in 2007 of just over 120 million lots. The NYMEX WTI futures contract is therefore twice as liquid as its nearest rival, the ICE Brent futures contracts. In the past two years, turnover on both contracts has more than doubled. Figure 1: Global energy use by region in 2007 Contract Exchange Hydro Electric WTI crude oil NYMEX 59.65 121.53 104% 80 Nuclear Energy Brent crude oil ICE 27.41 59.73 118% 70 Coal WTI crude oil ICE n/a 51.39 - US natural gas NYMEX 19.14 29.79 56% Gasoil ICE 10.97 24.51 123% Fuel oil Shanghai Futures Exchange 9.81 24.01 145% 90 mmb/d oil equivalent Figure 2: Energy futures turnover 60 Natural Gas 50 Oil 40 30 20 2005 2007 % change Gasoline NYMEX 13.17 19.79 50% Heating oil NYMEX 13.14 18.08 38% Gasoline Tokyo Commodity Exchange 17.45 7.53 -57% Gasolie Central Japan Commodity Exchange 11.97 3.64 -70% 10 Kerosene Central Japan Commodity Exchange 9.79 2.69 -73% 0 Kerosene Tokyo Commodity Exchange 7.30 2.35 -68% Crude oil Tokyo Commodity Exchange 1.98 1.49 -25% UK natural gas Intercontinental Exchange 0.44 1.23 180% Africa S. & Cent. America Source: BP Statistical Review Page 4 Middle East North America Europe & Eurasia Asia Pacific Source: NYMEX, ICE, TOCOM, SHFE, CJCE (Turnover in million lots) Global Markets Research September 2008 A User Guide To Commodities Crude Oil History & properties Petroleum, or crude oil, is a complex mixture of various hydrocarbons found in the upper layers of the Earth’s crust. The word petroleum derives from the Greek petra meaning rock and elaion meaning oil. In ancient Mesopotamia around 4000BC, a tarry crude was used to make ships watertight as well as being used as an adhesive. Crude oil was also used in the construction of the pyramids, embalming by the Egyptians and as body paint by Native Americans. It was believed to have medicinal th benefits in ancient Persia and Sumatra. The first oil wells were drilled in 4 Century China using bits attached to bamboo poles. However, the commercial drilling of oil began in Titusville, Pennsylvania by Edwin Drake in 1859. There are hundreds of different grades of crude oil around the world. Their grades are mainly a function of sulphur content and gravity. The highest quality crudes are those with low sulphur content and a high specific gravity. Specific gravities measure the weight of the oil relative to water. The higher the API gravity (measured in degrees, º), the lighter the compound. Figure 2 identifies the main benchmark crude oils according to specific gravity and sulphur content. On this basis West Texas Intermediate (WTI), the US benchmark crude oil and Malaysia’s Tapis are the best quality crude oils in the marketplace. The heavier, sour crudes from the United Arab Emirates and Mexico are of a poorer quality and consequently trade at a discount to WTI. Sweet crudes are defined as those with 0.5% sulphur content or less while sour crudes have a sulphur content of 1.5% or more. The area between 0.5-1.5% is sometimes referred to as intermediate sweet or intermediate sour. The reference to sweet and sour relates to the early days of crude oil production as one of the easiest ways to judge the sulphur content of crude oil and products was by taste and smell. Major producers Saudi Arabia is the world’s largest producer as well as exporter of crude oil. Although the US is the world’s third-largest oil producing nation, it is also the world’s largest importer of oil, representing 25% of cross-border trade in oil. In terms of annual production, OPEC's market share has declined from about 50% in 1973 to 32% in 1987 and has averaged approximately 43% over the 2005 to 2008 period. This share is expected to rise going forward since the 12 OPEC member countries hold 75% of the world’s proved crude oil reserves. The largest oil reserves exist in Saudi Arabia, Iran and Iraq, Figure 5. Figure 1: The world’s top 10 oil producers, consumers, exporters and importers in 2007 % of % of % of mmb/d world Consumers mmb/d world Exporters Saudi Arabia 10.41 13% USA 20.70 24% Saudi Arabia 8.26 15% USA Russia 9.98 12% China 7.85 9% Russia 7.28 13% USA 6.88 8% Japan 5.05 6% Iran 2.78 Iran 4.40 5% India 2.75 3% UAE China 3.74 5% Russia 2.70 3% Mexico 3.48 4% Germany 2.39 3% Canada 3.31 4% S. Korea 2.37 UAE 2.91 4% Canada Kuwait 2.63 3% Brazil 2.61 3% Venezuela World 81.53 mmb/d world % of Producers Importers mmb/d world 13.82 25% Japan 5.03 9% 5% China 4.11 7% 2.46 4% Germany 2.37 4% Kuwait 2.35 4% S. Korea 2.35 4% Norway 2.34 4% India 1.95 4% 3% Nigeria 2.10 4% France 1.90 3% 2.30 3% Venezuela 2.02 4% Italy 1.62 3% 2.19 3% Algeria 1.73 3% Spain 1.61 3% Saudi Arabia 2.15 3% Angola 1.66 3% Taiwan 1.00 2% World 83.22 World 54.82 World 54.82 Source: BP Statistical Review, International Energy Agency, DB Global Markets Research Global Markets Research Page 5 September 2008 A User Guide To Commodities Figure 2: Crude oil price since 1970 Figure 3: Different crude oil grades compared 4 140 Cheap Maya (Mexico) SOUR 100 80 SULPHUR CONTENT (%) Real W TI Price ($2008) 120 60 40 20 1970 1975 1980 1985 1990 1995 WTI (nominal) 2000 SWEET 0 2005 WTI (CPI) 3 Arab Heavy (Saudi) BCF-17 (Venezuela) Bow River (Canada) 2 Basrah (Iraq) Mars (US) Saudi Lt (Saudi) Expensive Urals (Russia) 1 ANS (US) Oman (Oman) Brent (UK) Bonny Lt (Nigeria) Daqing (China) 0 15 20 HEAVY Source: US DOE/EIA, Bloomberg (monthly data as of end June 2008) Kuwait (Kuwait) Dubai (UAE) 25 30 35 °API GRAVITY WTI (US) Tapis (Malaysia) 40 45 50 LIGHT Source: EIA Major consumers The United States remains the largest consumer of oil, accounting for 24% of world consumption in 2007. In 2005, China overtook Japan to become the world’s second th largest oil consumer. Since 1995 India has moved from being the 13 largest oil th consuming nation to the world’s 4 . Brazil has also moved up the league table of oil th th consuming nations from 12 to 9 place over the same period. In terms of oil demand growth, China is expected to post the largest incremental increase in oil demand during the current decade, Figure 4. In addition to rising GDP, the role of oil subsidies at the consumer level remains an important factor in driving oil demand in the Asia Pacific and Middle East regions. Policies aimed at dismantling fuel subsidies are being adopted in a number of Asian nations, but this has not been as prevalent in other regions such as the Middle East or OPEC countries in Africa and South America. Major uses Fuel products constitute the vast majority of demand for petroleum. Gasoline is used to power automobiles, light trucks, boats, recreational vehicles and farm equipment. Kerosene is used for commercial aircraft, while distillate fuel oils such as diesel and heating oil are used to power buses, trucks, trains and machinery, heat buildings and fire industrial boilers. Liquefied petroleum gases (LPGs) such as propane, ethane and butane are used for domestic heating and cooking, farming and as a gasoline alternative. Petroleum is also used in the petrochemical production of solvents, lubricating oils, waxes, asphalt, fertilizers, pesticides, synthetic rubber and plastics. Figure 4: Oil demand growth in key consuming nations Region Avg. annual growth Avg. annual growth Total demand 2000-2007 kb/d 2000-2007 (%) mmb/d 2010E Asia Pacific 614 2.7 Middle East 212 4.0 27.5 6.9 North America 211 0.9 25.2 S. & C. America 84 1.6 5.7 Europe & Eurasia 76 0.4 20.2 Africa 71 2.7 3.1 World 1,268 1.6 88.6 China 440 7.4 9.6 USA 142 0.7 21.1 Source: BP Statistical Review, IEA, DB Global Markets Research Page 6 Global Markets Research September 2008 A User Guide To Commodities Figure 5: Crude oil reserves by country Estimated world oil reserves 1238 billion barrel at end of 2007 Expected global oil demand growth by region in 2008 Saudi Arabia 1.5 Iran Iraq 23% 2% Kuwait 2% United Arab Emirates 3% Venezuela Russian Federation 3% Libya 3% 12% Kazakhstan Nigeria 7% US Canada 7% 10% 8% Source: BP Statistical Review Qatar 1.01 million barrels per day 10% 2% 8% Figure 6: Global oil demand by region in 2008 1.0 0.80 0.5 0.24 0.0 -0.5 -0.45 -1.0 Non-OECD operating fuel subsidies Non-OECD unsubsidised OECD Total oil demand Other Source: IEA, DB Global Markets Research Exchange traded Crude oil futures and options are traded primarily on the New York Mercantile Exchange (Nymex) and the Intercontinental Exchange (ICE). Brent crude is generally accepted to be the world benchmark as it is used to price two-thirds of the world’s internationally traded crude oil supplies. In the US, the West Texas Intermediate (WTI) crude oil is the benchmark. Price conventions & codes Crude oil is priced in US dollars per barrel. The Bloomberg tickers for the WTI and Brent crude oil generic one month futures contracts are CL1 <Commodity> and CO1 <Commodity> respectively. The Bloomberg ticker for the DB Crude Oil total returns and excess returns indices are DBRCLTR <Index> and DBRCL <Index> respectively. The Bloomberg ticker for the DB Crude Oil-Optimum Yield total returns and excess returns indices are DBLCOCLT <Index> and DBLCOCLE <Index> respectively. Global Markets Research Page 7 September 2008 A User Guide To Commodities Oil Products History & properties The commercial drilling of crude oil by Edwin Drake in 1859 was first seen as an opportunity for kerosene, refined from rock oil, to compete with whale oil in the illumination market. However, technical progress in petroleum refining from simple distillation, boiling the crude oil in a vacuum, to the extraction of gasoline and other light products, via more sophisticated thermal and catalytic cracking and reforming, for transportation and heating purposes led to rapid demand growth for crude oil. For more details see the Refining section that follows this article. The different types of oil products contained in a barrel of crude oil will each have their own boiling temperature. As a result, oil products are lumped into groups called fractions, which are determined according to that product’s boiling point, Figure 1. Figure 1: Refined products by type Boiling Point (ºF) Fraction Less than 90ºF Liquefied Petroleum Gases: Butanes, Propanes & Lighter 90-220ºF Gasoline 220-315ºF Naphtha 315-450ºF Kerosene, Jet Fuel 450-800ºF Diesel, Gas, Fuel & Heating Oils 800ºF and higher Residue Source: Petroleum Refining, William Leffler, DB Global Markets Research Since there are many different crude oil grades, refineries can be optimised to produce “cuts” or fractions that are best suited to the characteristics of the crude oil being run and the type of products that are most in demand in local markets. Figure 2 shows the sectoral demand for oil products while Figure 3 outlines the proportion of the various petroleum products that are derived from a US and European barrel of crude oil. The reason for WTI crude oil typically being priced above Brent reflects its more superior barrel, which comprises more gasoline and less residual fuel oil and other heavy oils. Figure 2: Global oil use by sector in 2007 Figure 3: A barrel of US and European crude oil: the petroleum products spectrum 100% Light Propane/LPGs Gasoline/Naphtha 52% Residential 6% Commercial 3% Industrial Transportation Electricity 33% Yields in % volume on crude intake 6% Kerosene/Jet Fuel 80% Diesel/Heating Oil Residual Fuel Oil Other Oils 60% 40% 20% Heavy 0% US (W TI) Source: US DOE/EIA Page 8 Europe (Brent) Source: Nymex, ICE Global Markets Research September 2008 A User Guide To Commodities The stream of oil products • Petroleum gas is the lightest hydrocarbon chain, commonly known by the names methane, ethane, propane and butane. It is a gas at room temperature, easily vaporised and is used for heating, cooking and making plastics. It is often liquefied under pressure to create liquefied petroleum gas (LPG) which is transported by pipeline, filled tanks or large bottles. • Naphtha is a light, easily vaporised, clear liquid used for further processing into petrochemicals, most notably in Western Europe and Asia, as well as being used a solvent in dry cleaning fluids, paint solvents and other quick-drying products. It is also an intermediate product that can be further processed to make gasoline. • Gasoline is a motor fuel that vaporises at temperatures below the boiling point of water. It evaporates quickly. Gasoline is rated by octane number, an index of quality that reflects the ability of the fuel to resist detonation and burn evenly when subjected to high pressures and temperatures inside an engine. Premature detonation produces “knocking”, wastes fuel and may cause engine damage. Previously a form of lead was added to cheaper grades of gasoline to raise the octane rating, but, with the environmental crackdown on exhaust emissions, this is no longer permitted in most countries. New formulations of gasoline designed to raise the octane number contain increasing amounts of aromatics and oxygencontaining compounds, or oxygenates. Cars are now also equipped with catalytic converters that oxidise un-reacted gasoline. • Kerosene is a liquid fuel used for jet engines or as a starting material for making other products. • Gasoil or diesel distillate is a liquid used for automotive diesel fuel and home heating oil, as well as a starting material for making other products. • Lubricating oil is a liquid used to make motor oil, grease and other lubricants. It does not vaporise at room temperature and varies from the very light through various thicknesses of motor oil, gear oils, semi-solid greases, and petroleum jellies. • Heavy gasoil or fuel oil is a liquid fuel used in industry for heat or power generation and as feedstock for making other products. Heavy grades of fuel oil are also used as ‘bunker oil’ to fuel ships. Most of the contaminants of oil (sulphur, metals, etc.) tend to concentrate in the heavy end of the barrel. Taken together with a heavy fuel oil’s low hydrogen to carbon ratio, this makes it the most potentially polluting fraction of the oil barrel. • Residual fuel (or resid) is a very viscous industrial fuel. • Coke, asphalt, tar and waxes are generally the lowest value products in the barrel, but, can also be used as starting materials for making other products. Refined products by use Not surprisingly, different parts of the crude oil barrel have different uses. The US tends to favour crudes with a high gasoline cut and favours complex refineries that can produce clean, light products. Also, the US emphasises liquefied petroleum gas (LPG). Propane is a liquid under low pressure, is easy to burn and is typically used in locations where natural gas is not available. It is also used as a chemical feedstock for making ethylene and propylene. Butane is used predominantly as a motor gasoline blending component as it is good for starting cold engines. Normal butane is also used as a chemical feedstock. Global Markets Research Page 9 September 2008 A User Guide To Commodities Terminology for oil products can vary around the world. For example, heating oil in the US is referred to as “gas oil” in Europe. Jet fuel in the US and Europe is referred to as kerosene in Asia. The term gasoline is used globally in spark-ignited combustion engines although “petrol” is a more common term for gasoline in the UK. In the US, gasoline is often referred to as “gas” but should not be confused with natural gas. The term distillate normally refers to middle distillate fuels which incorporate the middle cuts of the refined barrel: jet fuel, diesel, gas oil, fuel oil and heating oil. Figure 4: Refined product futures turnover by contract 30 Annual turnover (futures only, million lots 2007) 25 20 15 10 5 0 Gasoil (ICE) Fuel Oil (SFE) Gasoline (NYMEX) Heating Oil (NYMEX) Gasoline (TOCOM) Gasolie (CJCE) Kerosene (CJCE) Kerosene (TOCOM) Crude Oil (TOCOM) Source: TOCOM, Nymex, CJCE, ICE, SFE Prices The Bloomberg tickers for the one month generic heating oil and gasoline futures contract are HO1 <Commodity> and XB1 <Commodity> respectively. The Bloomberg codes for the DB Heating Oil total returns and excess returns indices are DBRHOTR <Index> and DBRHO <Index> respectively. The Bloomberg codes for the DB Heating Oil-Optimum Yield total returns and excess returns indices are DBLCOHOT <Index> and DBLCOHOE <Index> respectively. Page 10 Global Markets Research September 2008 A User Guide To Commodities Refining Description Refining is the process of converting crude oil into usable products. Crude oil is a mixture of hundreds of different types of hydrocarbons with carbon chains of different lengths. These can be separated through refining. The shortest chain hydrocarbons are gases (under five carbon atoms); chains containing five to 18 carbon atoms are liquids; and chains of 19 or more carbon atoms generally form solids at room temperature. Oil refining produces a wide variety of products that are prevalent in many every day uses: gasoline for motor vehicles; kerosene; jet fuel; diesel and heating oil to name just a few. Petroleum products are also used in the manufacture of rubber, nylon and plastics. A typical product yield or a refinery product slate (the proportion of refined products obtained by refining one barrel of crude) obtained from a complex refinery in Western Europe is shown in Figure 1. This yield reflects both the refineries configuration and the type of crude oil that is processed. Figure 1: Typical Western European product yield Product Petroleum Gas Western Europe (%) 3 Naphtha 6 Gasoline 22 Kerosene 6 Gasoil/ Diesel (aka middle distillates) 34 Fuel Oil 20 Others (residuals, lubricants) 9 Source: Deutsche Bank The initial product yield can be improved by further processing the oil products using more sophisticated refining units to crack, unify and/or alter the hydrocarbons. Refinery yields also tend to vary slightly over the year as refiners respond to both the regular seasonal swings in product demand (more heating oil in the winter, more gasoline in the summer) and irregular movements in product prices (the best and most flexible refineries can quickly alter their output to produce the highest priced mix). How a refinery works The function of a refiner is to convert crude oil into finished products required by the market in the most efficient, and therefore profitable, manner. How this is done varies widely from refinery to refinery, depending upon the location of the site, the configuration of the refinery, crude oil processed and many other factors. In general, there are four major refining steps taken to separate crude oil into useful substances: • Physical separation through crude distillation • Conversion or upgrading of the basic distillation streams • Product treatment to purify and remove contaminants and pollutants • Product blending to create products that comply with market specifications Global Markets Research Page 11 September 2008 A User Guide To Commodities Figure 2: The oil refinery crude distillation process – fractionation through blending 200C Gases 700C Light Distillates Reforming Gases (C1 to C4) Naphtha (C5 to C9) Hydrotreating Gasoline (C5 to C10) 1200C Alkylation 1700C Kerosene (C10 to C16) Middle Distillates Diesel (C14 to C20) Cracking 2700C Heavy Distillates Lubricating oil (C20 to C50) Coking Fuel Oil (C20 to C70) 6000C Residue (> C70) Distillation Conversion Treatment Blending Final Products Source: Deutsche Bank Crude distillation, also known as ‘Topping’ or ‘Skimming’ Distillation or fractionation is a process by which crude oil is separated into groups of hydrocarbon compounds of differing boiling point ranges called “fractions” or “cuts”. It uses the property of differing boiling points of different sizes of carbon chains in the crude oil, such that the longer the chain, the higher the boiling point. Two types of distillation can be performed: Atmospheric distillation: This takes place at atmospheric pressure, when the crude is heated to 350-4000C. The liquid falls to the bottom and the vapour rises, passing through a series of perforated trays (sieves). The lighter products, liquid petroleum gases (LPG), naphtha, and so-called "straight run" gasoline, are recovered at the lowest temperatures. Middle distillates such as jet fuel, kerosene, home heating oil and diesel fuel) come next. Finally, the heaviest products, such as, residuum or residual fuel oil (resid) are recovered. Vacuum distillation: To recover additional heavy distillates from this residue, it may be piped to a second distillation column where the process is repeated in vacuum conditions. Vacuum distillation allows heavy hydrocarbons with boiling points of 450°C and higher to be separated without the feedstock partially cracking (breaking down) into unwanted products such as coke and gas. Conversion (or upgrading) Unlike distillation, which maintains the chemical structure of the hydrocarbons, conversion alters their size and/or structure. Using several processes to improve the natural yield of products achieved through simple distillation, upgrading enables refiners to more closely match their output with the requirements of the market. For example, the typical output from a light crude oil might include around 25% gasoline but 40% resid, after further processing in a sophisticated refinery the product slate can be altered to something nearer 60% gasoline, and 5% resid, far more in line with the demand from end markets. Page 12 Global Markets Research September 2008 A User Guide To Commodities The following are the major types of conversion processes: Cracking: Cracking processes break down heavier hydrocarbon molecules (high boiling point oils) into lighter products such as petrol and diesel, using heat (thermal) or catalysts (catalytic). Thermal cracking involves heating the hydrocarbons, sometimes under high pressure, resulting in decomposition of heavier hydrocarbons. Thermal cracking may use steam cracking, coking (severe form of cracking - uses the heaviest output of distillation to produce lighter products and petroleum coke), visbreaking (mild form of cracking -quenched with cool gasoil to prevent overcracking, used for reducing viscosity without affecting the boiling point range). Catalytic cracking describes the chemical breakdown of the feedstock under controlled heat (450-500°C) and pressure in the presence of a catalyst, a substance which promotes the reaction without itself being chemically changed, such as silica. Fluid catalytic cracking uses a catalyst in the form of a very fine powder, which is maintained in an aerated or fluidized state by oil vapours. Feedstock entering the process immediately meets a stream of very hot catalyst and vaporizes. Hydrocracking uses hydrogen as a catalyst. Unification/Alteration: These processes combine lighter hydrocarbons to create heavier hydrocarbons of the desired characteristics. Alkylation is one such process and uses a catalyst such as sulphuric acid to convert lighter hydrocarbons into alkylates, a mixture of high-octane hydrocarbons used to blend with gasoline. Processes such as isomerization and catalytic reforming for “rearranging” the chemical structure of hydrocarbons also fall into this category. Catalytic reforming uses a catalyst to produce higher-octane components under controlled temperatures and pressure. The process also produces hydrogen, a valuable by-product. Treatment A number of contaminants are found in crude oil. As the fractions travel through the refinery processing units, these impurities can damage the equipment, the catalysts and the quality of the products. There are also regulatory limits on the contents of some impurities, such as sulphur, in products. Treatment includes processes such as dissolution, absorption, or precipitation to remove/separate these undesirable substances. Desalting (dehydration) is used to remove impurities such as inorganic salts from crude oil. Catalytic hydro-treating is a hydrogenation process used to remove about 90% of contaminants such as nitrogen, sulphur, oxygen, and metals from liquid petroleum fractions. Formulating and Blending Blending involves the mixing and combining of hydrocarbon fractions, additives, and other components to produce finished products with specific performance properties. Additives including octane enhancers, metal deactivators, anti-oxidants, anti-knock agents, gum and rust inhibitors, detergents, etc., are added during and/or after blending to provide specific properties not inherent in hydrocarbons. Global Markets Research Page 13 September 2008 A User Guide To Commodities Coal-To-Liquids & Gas-To-Liquids History & properties Gas-to-liquids (GTL) and coal-to-liquids (CTL) refer to the technologies that convert natural gas or coal into synthetic petroleum products in the form of clean-burning liquid fuels. There are two leading technologies for converting coal into liquid fuels. The first one is direct liquefaction: a highly efficient process in which coal is dissolved in a solvent at high temperature and pressure. The liquid produced is further refined to achieve high grade fuel characteristics. Indirect liquefaction is the second method. Coal is gasified to form a mixture of hydrogen and carbon monoxide (syngas) which are condensed using a catalyst. Ultra-clean, high quality products can then be produced by the Fischer-Tropsch process. The history of Fischer-Tropsch process dates back to two German scientists Franz Fischer and Hans Tropsch, who were searching for an alternative source of liquid fuels in petroleum-poor, but, coal-rich Germany in the 1920s. They discovered that in the presence of either an iron or cobalt catalyst at high pressures and temperatures, they could produce liquid, long chain, carbon molecules (synthetic petroleum) by combining carbon monoxide with hydrogen. The synthetic petroleum could be used as fuel which contained no sulphur or other impurities and so it enhanced engine performance. It became an important source of energy supply for countries in need of transport fuels but have problems securing reliable crude oil supply. Major GTL producers Despite the fact that the Fischer-Tropsch process has been used for nearly a century, commercial GTL plants are still rare. Today, there are only three plants operating commercially: Petro SA (producing 22.5kb/d in South Africa), Shell (producing 14.7kb/d in Malaysia) and Sasol, which built the 34kb/d Oryx facility in Qatar recently. Limiting factors in development have been high capital costs, poor energy efficiency of the chemical process and problems associated with the technology. Major CTL producers South Africa has the only commercial coal-to-liquids facility in operation today. The country has been producing coal-derived fuels since 1955 and currently about 30% of the gasoline and diesel in the country is produced from domestic coal. We estimate that 160kb/d of total capacity exists in South African CTL operations. Countries with large domestic reserves of coal but limited resources of oil and gas such as the US, China and India are potential candidates for using CTL in our view. There are a number of CTL projects which are at various stages of development in the world. For example, China is targeting a planned capacity of 1 Mt/y of liquid products using direct liquefaction. Figure 1: The GTL process Air Remove impurities and longer chain gases Natural Gas Gas Gas Air Separation Processing + Pre-Treat - H2S, CO2, H2O, other C5+, LPG & (Ethane) Hydrogen CH 4 O2 Syngas CO Generation H 2 Fischer Tropsch (cobalt catalyst) Mix syngas with liquid wax slurry such that it diffuses into it and creates more wax Product Upgrade LPG Naphtha Kero/Diesel (plus specialties) Use of hydro-cracking to crack wax and create desired chain length No sulphur, no aromatics, high performance fuels Source: Deutsche Bank Page 14 Global Markets Research September 2008 A User Guide To Commodities Oil Sands History & properties Oil sands is a generic term used to describe a heavy, viscous form of crude oil that is found mixed with sand, clay and water. Deposits are known to exist in many parts of the world, but the largest proved oil sands resources are in Alberta, Canada, and in the Orinoco area of Venezuela. Some of the earliest records of commercial oil sands activity are associated with the Pechelbronn oil-field in France where oil sands mining began as early as 1735. In Canada, the first large-scale production of oil from the Athabasca oil sands was launched by Suncor in 1967, followed by Syncrude in 1972. During the 1980s, oil prices declined to very low levels, resulting in considerable retrenchment in the oil industry. With the rise in oil prices this decade, numerous projects are under development or in planning. The bitumen contained in oil sands in Canada is extracted and processed using two main methods: Mining: According to the Canadian Association of Petroleum Producers (CAPP), about 20% of the oil sands in Alberta (or 35 billion barrels of recoverable reserves) is less than 50 meters deep and can be surface -mined using large trucks and shovels. After processing in separators and upgrading in special-purpose refineries, a synthetic crude oil results that can then be sent on to standard refineries for conversion into petroleum products. In-situ: This method of extraction relies on the injection of steam (or more recently, chemicals) to extract the petroleum without the need for mining. According to CAPP, approximately 80% of the oils sands resources in Alberta are more than 50 meters deep (recoverable reserves of 140 billion barrels). The two most common forms of insitu recovery are Steam Assisted Gravity Drainage (SAGD) and the Cyclic Steam (CS) process. After extraction, the bitumen is upgraded in the same way that mining bitumen is processed. Major producers By company, Suncor, ExxonMobil and Shell are the three key leading oil sands producers at the present time. These three companies account for nearly half of Canadian oil sand production, with output in 2007 of about 277kb/d by Suncor, followed by ExxonMobil (155kb/d) and Shell (130kb/d). There has been a surging interest in the development of Canada’s oil sands as the oil price has climbed. Oil sands production represented approximately a third of Canada’s total crude oil production in 2007. According to Wood Mackenzie estimates, the production of around 1.4mb/d in 2007 is expected to rise to around 3.7mb/d by 2015, at a 15% CAGR (compound annual growth rate). However, because of the sheer speed at which the region has developed, spurred by the rapid rise in crude oil prices, accompanying pressures such as equipment cost, labour, taxes, regulatory & environmental costs have been equally dramatic. Figure 1: Major Canadian projects (>50kb/d) Mining Companies Suncor Mining Project Syncrude Project Athabasca Oil Sands Project Joslyn Horizon Northern Lights Fort Hills Kearl Suncor IMO, PCA, NXY, Canadian Oil Sands, COP Shell, Chevron, Western Oil Sands Total, Enerplus Canadian Natural Resources Synenco, Sinopec PetroCanada, UTS, Teck-Cominco Imperial Oil 410 550 500 205 270 100 170 300 In Situ Primrose/Wolf Lake Cold Lake Foster Creek Christina Lake Suncor Firebag Kai Kos Dehseh Long Lake Surmont Sunrise Hangingstone Lewis Canadian Natural Resources Imperial Oil EnCana EnCana Suncor StatoilHydro OPTI, Nexen ConocoPhillips, Total Husky JACOS, Nexen PetroCanada 75 180 100 70 140 200 70 110 200 50 60 Source: Wood Mackenzie, DB Global Markets Research Global Markets Research Final Capacity kb/d Figure 2: Canadian oil sands production outlook 4500 thousand barrel/day 4000 3500 In-situ 3000 M ining 2500 2000 1500 1000 500 0 1996 1998 2000 2002 2004 2006 2008E 2010E 2012E 2014E 2016E Source: Wood Mackenzie, DB Global Markets Research Page 15 September 2008 A User Guide To Commodities Figure 3: Diagrammatic representation of Cyclic Steam Simulation (CSS) Source: Courtesy of Shell Figure 4: Diagrammatic representation of Steam Assisted Gravity Drainage (SAGD) Source: Courtesy of Shell Major uses The bitumen extracted from the oil sands is very heavy and viscous. Once extracted, lighter hydrocarbons can be added to the bitumen by the oil sands producer in order to be further processed or upgraded into a form of synthetic crude oil (SCO) that is less viscous. After that, it can be sold to a traditional oil refinery, though some bitumen is also sold in raw form for the production of heavy products like tar and asphalt. Page 16 Global Markets Research September 2008 A User Guide To Commodities Oil Transportation History & properties Energy resources such as oil and natural gas are often found in distant locations far away from where they are consumed. Tankers and pipelines are the main transportation methods used to move these products to major population and manufacturing centres. Tankers are more important than pipelines in terms of the amount of oil transported. Tankers move around 2 billion tons of oil every year, or roughly 2/3 of all the petroleum produced. The remainder goes predominantly by pipeline, but sometimes by rail, and then via trucks for retail product delivery. Oil pipelines Pipelines are the only feasible way to transport large volumes of oil by land over long distances. Oil pipelines are tubes typically made from high-strength steel with inner diameters usually ranging from 4 to 48 inches. Most pipelines are buried to a depth of 3 to 6 feet and are powered by pump stations that keep the oil in motion at a speed of flow of about 1 to 6 metres per second. Oil pipelines date back to the 1860s when a six-mile long, two-inch diameter wrought iron pipeline was built to connect an oil field to a rail road station in Oil Creek, Pennsylvania. Currently, the Druzhba pipeline and the Baku-Tbilisi-Ceyhan pipeline (BTC pipeline) are two of the longest oil pipelines in the world. The Druzhba pipeline is the longest oil pipeline and it transports oil from southeast Russia to terminals in Ukraine, Hungary, Poland and Germany. It is therefore the principal channel for the transportation of Russian oil across Europe. The BTC pipeline is the world’s second largest oil pipeline, carrying oil from fields in the Caspian Sea to the Mediterranean, connecting Baku (the capital of Azerbaijan); Tbilisi (the capital of Georgia); and Ceyhan (a port on the south-eastern Mediterranean coast of Turkey). Figure 1: The BTC pipeline Source: BP Global Markets Research Page 17 September 2008 A User Guide To Commodities Oil Tankers Crude tankers are designed to carry unrefined crude oil from the extraction points to refineries while product tankers (often referred to as “clean” tankers) transport refined products to consuming markets that do not have sufficient refining capacity. The first commercially recorded oil tanker was Nobel’s Zoroaster, designed in Sweden and first run from Baku to Astrahan in 1878. Today, the Jahre Viking, which was built in 1979 at Oppama Shipyard in Japan, is the world’s largest oil tanker. It has a length of 1504 feet, making it the largest ship ever constructed. Natural gas According to the BP Statistical Review, in 2007 some 550 billon cubic metres of natural gas flowed in international trade via pipeline and an additional 226 billion cubic meters moved by LNG tanker. For more details see the following section on LNG. Disruption risks According to EIA estimates, global seaborne oil trade was approximately 43 million barrels per day in 2007. Of that 16.5-17 million barrels per day, or about two-fifths of all the seaborne traded oil in the world, moves through the Straits of Hormuz. The Straits are therefore the world major oil trading route. The Strait of Malacca close to Singapore is the second most important oil trading channel with around 15 mmb/d of oil using this trading route. The next four are the Suez Canal, Babel Mandab, the Turkish Straits, and the Panama Canal with 4.5 mmb/d, 3.3 mmb/d, 2.4 mmb/d, and 0.5 mmb/d flow respectively. Recent events in Georgia highlight the vulnerability of transit point since some 1.3 mmb/d of Caspian oil moves through Georgia’s pipelines and ports. Figure 2: Straits of Hormuz Source: DOE/EIA Page 18 Global Markets Research September 2008 A User Guide To Commodities US Natural Gas History & properties Natural gas is a colourless, odourless, highly flammable gaseous hydrocarbon which gives off a great deal of energy when burned. Although it consists primarily of methane, it can also contain ethane, propane, butane and pentane. These coproducts, once removed from the gas stream, are called natural gas liquids (NGLs). Natural gas is relatively clean burning, emitting relatively low levels of harmful combustion by-products. Although there is some evidence for the abiogenic existence of methane in the earth’s mantle, most geologists favour the view that gas, like coal and oil, was formed via the compression and decomposition of organic material over long periods of time. It is typically found in the same geologic formations below the earth’s surface that trap oil, that is, in permeable mineral layers that are capped by non-porous sedimentary rock. Natural gas seeps were first discovered in Iran between 6000BC and 2000BC. These naturally occurring surface leaks could sometimes be ignited by lightning strikes. A similar ‘burning spring’ was found in Greece around 1000BC and became the site of the Temple of Oracle in Delphi. Around 500BC, the Chinese used natural gas to boil sea water to produce fresh water. The first gas well in the US was drilled in 1825, and connected by pipeline to users in Fredonia, New York. Like oil, natural gas is described as sweet or sour depending on, in the case of gas, its hydrogen sulphide content. Hydrogen sulphide is highly poisonous and is removed during processing. Because methane is odourless, natural gas distribution companies add a harmless, but, stinky chemical (mercaptans) to the gas prior to distribution to end-users so that consumers can more easily detect leaks. Gas is also described as wet or dry depending on the presence of natural gas liquids (NGLs) and other energy gases. If natural gas is greater than 90% methane then it is referred to as dry. Wet gas can be “stripped” of the NGLs (or LPGs) at facilities called gas processing plants. Finally, natural gas is described as associated or non-associated depending upon whether or not it is associated with significant oil production. In the US, only 20% of natural gas reserves are believed to be oil associated. Major producers The US and the countries of the former Soviet Union are the largest producers of natural gas. The Russian natural gas industry is dominated by Gazprom, which controls 95% of production. In the US, Texas, Louisiana, Alaska, New Mexico and Oklahoma hold more than half of the country’s reserves. Other major producers include Canada, Iran, Norway, Algeria, Saudi Arabia, and the United Kingdom. World natural gas reserves are estimated at 6,261 trillion cubic feet (tcf). The Middle East holds 41% of world reserves, while an additional 40% is located in the former Soviet Union, with only 9% held in the OECD countries. Figure 1: The world’s top 10 natural gas producers, consumers, exporters and importers in 2007 % of % of Producers bcf/d world Consumers Russia 58.8 21% USA USA 52.8 19% Canada 17.8 Iran bcf/d % of % of world Exporters bcf/d world Importers 63.2 22% Russia 16.3 22% USA Russia 42.5 15% Canada 8.7 12% 6% Iran 10.8 4% Norway 8.3 11% bcf/d world 10.4 14% Japan 8.7 12% Germany 8.0 11% 10.8 4% Canada 9.1 3% Algeria 5.7 8% Italy 7.5 10% Norway 8.7 3% UK 8.8 3% Turkmenistan 4.4 6% Ukraine 4.4 6% Algeria 8.0 3% Japan 8.7 3% Qatar 3.8 5% France 4.1 5% Saudi Arabia 7.3 3% Germany 8.0 3% Trinidad 3.2 4% S. Korea 3.6 5% UK 7.0 3% Italy 7.5 3% Indonesia 3.2 4% Spain 3.4 5% China 6.7 2% Saudi Arabia 7.3 3% Malaysia 3.1 4% Turkey 3.4 5% 6.5 2% China 6.5 2% Netherlands 2.6 4% UK 1.8 2% Turkmenistan World 284.5 World 282.7 World 75.0 World 75.0 Source: BP Statistical Review, DB Global Markets Research Global Markets Research Page 19 September 2008 A User Guide To Commodities Figure 2: World natural gas reserves by country Figure 3: US natural gas price since 1976 Estimated world gas reserves 6261 trillion cubic feet at end of 2007 26% 25% Iran Qatar Saudi Arabia UAE US 3% 3% Nigeria 3% 16% 3% Venezuela Algeria 3% 4% Source: BP Statistical Review 14% Natural Gas Prices (USD/mmBtu) 16 Russia 14 12 10 8 6 4 2 0 1976 1980 1984 1988 1992 1996 2000 2004 2008 Other US NatGas Nominal US NatGas Real (CPI) Source: Nymex, US DOE/EIA, DB Global Markets Research Major uses Burning natural gas is relatively clean, producing 30% less carbon dioxide than petroleum and 45% less than coal. The major use for gas is in homes, businesses and factories for heating, cooking and cooling. Natural gas is increasingly used as a source of energy for electricity generation via gas turbines and steam turbines. Compressed natural gas is used as a vehicle fuel for public transport buses. In addition, natural gas is used as a base ingredient in the manufacture of ammonia, antifreeze, fabrics, glass, steel, plastics and paint. Regulatory matters Natural gas was originally considered an undesirable by-product of oil production. As a gas, it is more difficult to transport than oil and it was often flared-off, or burned at the wellhead as a disposal method. Gas flares are still common in Africa, the Middle East and parts of the Former Soviet Union that do not yet have the infrastructure for the utilisation of gas. Rules that prohibit flaring are now becoming increasingly common. Around 1950, the development of high-strength steel pipelines made it possible to transport natural gas over much longer distances and this, combined with the development of offshore drilling, has resulted in a significant increase in the use of natural gas. The emergence of LNG has supported the development of a global gas market. In many countries, natural gas tends to be much more highly regulated than oil because of the tendency for natural gas transportation and distribution to be concentrated in the hands of fewer suppliers. Exchanges & prices Natural gas futures are traded on the New York Mercantile Exchange (Nymex) in units of 10,000 million British thermal units (mmBtu), for delivery via the Sabine Pipe Line Co. Henry Hub in Louisiana. There is also a natural gas futures contract listed on the ICE, but turnover in 2005 was negligible. The Bloomberg ticker for the one month generic US natural gas futures contract is NG1 <Commodity>. The Bloomberg tickers for the total returns and excess returns of the Deutsche Bank US Natural Gas-Optimum Yield index are DBLCYTNG <Index> and DBLCYENG <Index> respectively. Page 20 Global Markets Research September 2008 A User Guide To Commodities Liquefied Natural Gas (LNG) History & properties The liquid formed when natural gas is cooled to -162°C is called liquefied natural gas, or LNG It is clear, odourless, non-toxic and non-corrosive. Liquefaction takes place when natural gas is cooled under high pressure, condensed, and then reduced in pressure for storage. The resulting liquid is 1/600th of the volume of natural gas, and about half as dense as water. Purified LNG is usually composed of 90% methane and small amounts of ethane, propane, butane and heavier alkanes. th The history of natural gas liquefaction dates back to the 19 Century. Commercial LNG plants were built in West Virginia in 1912 and Ohio in 1941. The first LNG tanker, the Methane Pioneer, transported LNG from Louisiana to the UK in 1959, demonstrating the viability of long-range transport. In 1964, Algeria became the first continuous large-scale exporter. LNG’s primary benefit is its ease of transportation and density of storage. It can be transported efficiently over long distances where pipelines are not an option. Specially designed seagoing vessels incorporate double hulls and specialized storage tanks. At the receiving terminal, LNG can be stored or reheated to return to gaseous form and distributed via pipeline. Major producers and users The world’s largest LNG producers and exporters are Qatar, Malaysia, and Indonesia, with exports going to Japan, South Korea and Taiwan. US supplies come mainly from Trinidad, while Algeria and Nigeria mainly supply Europe. Russia and Iran possess the world’s largest proved gas reserves, but do not yet have liquefaction capability, although there are LNG projects currently underway in both countries. The demand for LNG has been rising significantly during this decade. Earthquakes in Japan and China have disrupted domestic nuclear of hydro power capabilities which has necessitated both countries to increase LNG imports. Droughts in Spain as well as the emergence of new demand centres in Kuwait, Singapore, Chile and Argentina are now competing for US summer LMG imports. Short supply has polarized returns, driving shipping & regas often below the cost of capital, yet upstream returns to exceed 50% IRR. Strong international demand plus a security of supply and environmental premium in Asia and Europe has left international prices set by the marginal price of demand, pushing long-term contracts to straight line oil parity, with implied pricing of USD17/mmBtu at USD100/bbl oil. Exchange traded The trade in LNG is conducted via long-term sale and purchase agreements (SPA) which typically extend for over 15 years. Figure 1: Major exporters & importers of LNG Exporters bcf/d % of World Importers bcf/d % of World Qatar 3.7 17% Japan 8.6 39% Malaysia 2.9 13% South Korea 3.3 15% Indonesia 2.7 12% Spain 2.3 11% Algeria 2.4 11% US 2.1 10% Nigeria 2.0 9% France 1.3 6% Australia 2.0 9% Taiwan 1.1 5% Trinidad 1.8 8% India 1.0 4% Egypt 1.3 6% Turkey 0.6 3% Oman 1.2 5% China 0.4 2% Brunei 0.9 4% Belgium 0.3 1% Other 1.1 5% Other 1.0 5% World 21.9 100% World 21.9 100% Source: BP Statistical Review, DB Global Markets Research (2007 data) Global Markets Research Figure 2: Global LNG supply/demand balance 350 mmt/y Greenfield Supply 300 Base Supply 250 Total Demand 200 150 100 50 0 1995 2000 2005 2010E 2015E Source: Wood Mackenzie, DB Global Markets Research Page 21 September 2008 A User Guide To Commodities US Power History & properties The origins of the commercial US power industry date back to 1882 and the establishment of the Pearl Street electricity generating station in New York City. Electricity is measured in watts and watt-hours and unlike other commodities is difficult to store economically, although advances in capacitor and battery technology are improving this characteristic in many applications. The market for electricity involves three activities: production, transmission and distribution. The US operates approximately 10,000 power plants with an average thermal efficiency of 33%. Efficiency has not changed much since 1960 due to the long life of a power plant. The average age of a power plant in the US is 30 years. In terms of transmission, the US operates 275,000 miles of high voltage power lines arranged in three networks. The average loss in transmission is around 5-7%. Distribution involves the handoff from high voltage lines to low voltage distribution networks to deliver power to the consumer. In 1940, 10% of the US’s total energy consumption was used to produce electricity. Today it is over 40%. Annual revenues for electrical utilities are around USD370bn or 2.5% of GDP. Consumers spend some 2.3% of their disposable income on household electricity and gas purchases. Electricity is also one of the most capital intensive sectors in the US with current assets valued at USD1.3tn. The US power market is fragmented along regional lines and according to Regional Reliability Councils. The move towards deregulation of the US power sector began in the 1970s. Moreover the 1970 Clean Air Act as well as the subsequent two oil price shocks encouraged the more efficient use of fossil fuels as well as the development of alternative energy sources. Trust in the nuclear power was damaged by the Three Mile Island accident in 1979. Figure 1: The US power market Source: EIA, Annual Energy Review 2007 Page 22 Global Markets Research September 2008 A User Guide To Commodities Figure 2: US power generation by fuel source Figure 3: US planned power capacity additions 221 GW to Year 2013 Total US net generation (2007E) 4,100,000 GWhours 7% 3% 18% Coal 7% Coal 49% Petroleum Natural Gas 17% Nuclear Natural Gas 19% 19% Wind Nuclear Hydro 1% Renewbles 38% 20% Other Renewable Other Gas 2% Source: US DOE/EIA, DB Global Markets Research Source: Wood Mackenzie, DB Global Markets Research Today there are three types of utility companies in the US: Publicly owned utilities: These are owned and operated by municipalities, states or the federal government. They produce electricity and sell it to consumers or other utilities at cost. Investor owned utilities (IOUs): These are owned by private shareholders. Most IOUS are beginning to divest their energy production and focus on distribution. Around three-quarter of the US power grid is owned by these companies. Cooperative utilities: These were created by the government to provide electricity to rural areas deemed unprofitable by the IOUs. They are government subsidised nonprofit entities free from state or local taxes. There are two basic types of power generators today and they can be distinguished by the type of load they handle namely base or peak load. Base-load plants are typically steam driven. These must be run at full capacity and are difficult to start up and shut down. Peak load plants usually use gas turbines. They operate at a lower efficiency, but can be started up and shut down rapidly. Exchange traded In February 2003, the Commodity Futures Trading Commission (CFTC) approved Nymex’s monthly, weekly and daily Pennsylvania / New Jersey / Maryland (PJM) electricity futures contracts. The monthly contract started trading on April 11, 2003 and is based on the electricity prices in the Pennsylvania/New Jersey/Maryland (PJM) Western hub at 111 delivery points, mainly on the utility transmission systems of PPL Corporation and FirstEnergy Corporation. This contract is priced in US dollars per megawatt hour. At the beginning of this year, Nymex launched a further five electricity futures contracts. The new contracts are: ISO New England peak daily futures, NYISO A peak daily futures, NYISO G peak daily futures, NYISO J peak daily futures and Cinergy hub peak daily futures. The PJM Interconnection administers the largest electricity market in the world serving more than 44 million customers in Delaware, Illinois, Indiana, Kentucky, Maryland, New Jersey, Ohio, Pennsylvania, Tennessee, Virginia, West Virginia and Washington D.C. The power companies within PJM operate more than 1,000 generating units, representing more than 137,000 megawatts of capacity fuelled with coal, natural gas, oil, nuclear and hydro power. This generating and distribution network is also tied to the power grids of the Midwest, New York State and other areas in the mid-Atlantic states. Global Markets Research Page 23 September 2008 A User Guide To Commodities Thermal Coal History & properties Coal is a fossil fuel. It is a combustible, sedimentary, organic rock which is composed mainly of carbon, hydrogen and oxygen. Coal is classified into four types, lignite, subbituminous, bituminous and anthracite according to its carbon, ash, sulphur and water content. The harder the coal, the less moisture it has and the more efficient when it is used as a fuel. Lignite, or thermal coal, has the lowest carbon content and heating value and alongside sub-bituminous coals are used primarily for electricity generation. Anthracite, also referred to as metallurgical coal, has the highest carbon content with the lowest amount of moisture and hence has the highest energy content of all coals. It is used in high-grade steel production. Bituminous is sub-divided into thermal and metallurgical coal, but, often referred to as semi-soft. It is used for both electricity generation and for making coke in steel production. Historians believe coal was first used commercially in China for smelting copper and for casting coins around 1,000BC. The demand for coal surged during the 19th Century during the industrial revolution and at the end of that century, the development of the coal industry became closely tied to electricity generation when the first coal-fired electrical power plant came into operation in New York in 1882. Production There are two mining methods in coal production: surface or ‘open cut' mining (40% share) and underground or ‘deep’ mining (60% share). The choice of mining method is largely determined by the geology of the coal deposit. Two-thirds of the world’s coal reserves are located in Europe, Eurasia and the Asia Pacific. At current consumption levels, there is enough coal in the world to last for several more centuries. Major uses Thermal coal, also referred to as steaming coal, is used to generate electricity. Approximately 40% of electricity production worldwide is generated via thermal coal. At most coal-fired power stations, the coal is first milled into a fine powder and then blown into a combustion chamber of a boiler where it is burnt at high temperature. The heat converts water into steam which is pressurised and passed into a turbine which generates electricity. According to the World Coal Institute, consumption of steaming coal is projected to grow by 1.5% per year until 2030. Asia is the biggest market, currently accounting for around 55% of global coal consumption, with the bulk being made up by China. Most countries in the region do not have sufficient domestic supplies and consequently turn to the seaborne trade market to meet their energy requirements, particularly Japan, Taiwan and South Korea. Major producers The largest thermal coal producing countries are China, USA, India, Australia and South Africa. Because there are vast differences in coal qualities and due to the shear volume produced, detailed statistics of total global production are not readily available nor are they important for market dynamics. Rather global supply and demand balances and the ensuing effect on prices is determined by the global seaborne market or coal exports. Two countries, Australia and South Africa, dominate the high quality market for seaborne coal. While Indonesia tops the list in terms of total export, the quality of their coal is poor. Columbian material is almost exclusively headed to the US. By volume, China is the world’s largest producer, but most material is poor quality and consumed domestically. Page 24 Global Markets Research September 2008 A User Guide To Commodities Figure 1: Major exporters and importers of thermal coal in 2007 Tonnes Exporters Indonesia (Mn) 196 Australia 113 Russia 78 Colombia Tonnes % of world 32.8% Importers Japan (Mn) 116 % of world 19.7% 18.8% Korea 64 10.8% 13.0% Taiwan 58 10.0% 67 11.1% UK 38 6.5% South Africa 66 11.1% India 33 5.6% China 45 7.6% USA 32 5.4% Poland 11 1.8% Germany 28 4.8% USA 9 1.5% Spain 20 3.5% Venezuela 8 1.3% Italy 17 2.9% Canada 5 0.8% China 13 2.3% World 598.0 World 586.5 Source: AME Exchange traded Thermal coal is priced according to its calorific content measured as Kcalories/kg with the standard level at 6500kcal/kg. Most thermal coal is procured through negotiated annual contracts between producers and consumers. In the Asia-pacific market, annual contracts have historically been set between Japanese power utilities and Australian producers on a Japanese financial year basis. The European market is dominated by South African supply, but, prices are generally priced on a spot basis that is highly influenced by the Asian price. Coal futures are traded on NYMEX. The contract trades in units of 1,550 tons and is priced in USD per ton. The two main coal price contracts are the Tradition Financial Services (TFS) API#2 and API#4 Coal Indices. The API#2 is the arithmetic average of the McCloskey Coal Information Services (MCCIS) NWE Steam Coal Marker, which tracks steam coals used for electricity generation and the International Index compiled by Energy Argus in its Coal Daily index. This tracks shipments of coal to northwest Europe. The TFS API#4 price is the arithmetic average of three prices: the FOM Richards Bay price published in the McCloskey Fax, the Spot Coal Price Index published in the South African Coal Report and the FOB Richards Bay published in Energy Argus Coal Daily. Figure 2: Spot thermal coal prices 200 USD/t Figure 3: Global coal consumption, million tonnes oil equivalent 3500 Richards Bay FOB (South Africa) 180 Newcastle FOB (Australia) 160 Annnual contract price ROW Asia Pacific 3000 Europe 2500 140 120 North Am erica 2000 100 1500 80 1000 60 40 500 20 Source: Argus (data as of March 2008) Global Markets Research 2007 2005 2003 2001 1999 1997 1995 1993 1991 1989 1987 1985 1983 1981 1979 1977 2008 1975 2007 1973 2006 1971 2005 1969 2004 1967 0 2003 1965 0 2002 Source: BP Page 25 September 2008 A User Guide To Commodities Uranium History & properties Uranium, a silvery white metal, has the symbol U and atomic number 92. A common element, it occurs naturally at low levels in virtually all rock, soil and water found throughout the world. Uranium is as about as common as zinc and about 40 times as abundant as silver. The German chemist Martin Klaproth was responsible for discovering uranium in the mineral called pitchblende in 1789. It was named after the planet Uranus, which had been discovered eight years earlier. Mined uranium ore is a mildly radioactive element with two principle isotopes, U-235 and U-238, with the former suitable for use as nuclear fuel. This material must be processed before it can be used as a fuel for a nuclear reactor, and the first step, milling, is usually done at the mine site. Ore is crushed and ground and then treated with acid to dissolve the uranium, which is recovered from solution. Uranium oxide concentrate (U3O8) is the form in which uranium is typically sold and often referred to as yellowcake because of its khaki colour. Following this, uranium must be enriched to increase the proportion of U-235 to about 3.5% in order for it to be used in power generation. The enrichment process typically consists of converting the uranium oxide to a gas, uranium hexafluoride (UF6), and then separating the heavier isotopes using a gas centrifuge. Because natural uranium contains such a small percentage of U-235, the enrichment process results in the creation of large amounts of depleted uranium, which is mostly U-238. Major producers In 2007, Canada was the world’s largest producer of uranium, amounting to 9.5Kt, although Kazakhstan is set to surpass Canada as the top global producer in the coming years. Australia has the world’s largest reasonably assured reserves of uranium, amounting to 1,142,000 tonnes, representing 30% of the world’s total. However, there are tight restrictions on new uranium mining in Australia that will likely remain in place for the next several years which will restrict access to most Australian material, though we think these policies will eventually be overturned. Other major producing countries are South Africa, Namibia, Russia and Niger. Major uses Today, nearly 100% of all uranium produced goes to nuclear reactors for electricity generation, with a very small amount used in research, medical applications and as fuel for nuclear-powered ships and submarines. In its final physical form, uranium dioxide (UO2) is a ceramic powder, pressed into small cylindrical pellets. These pellets are loaded into zirconium alloy or stainless steel fuel rods which are assembled into bundles to form an array of reactor fuel assemblies. Figure 1: Uranium production by country Canada Australia Kazakhstan Russia Niger Namibia USA Uzbekistan South Africa Ukraine China Czech Rep. World Tonnes 9,000 9,000 7,000 4,000 3,000 3,000 2,000 2,000 1,000 1,000 1,000 400 43000 Source: UxC, DB Global Markets Research (2007 data) Page 26 Market share 21% 21% 16% 9% 7% 7% 5% 5% 2% 2% 2% 1% Figure 2: The leading uranium mining companies Com pany nam e Country Controlled % of w orld production (tonnes) Cameco Corporation Canada 9,000 20% Rio Tinto plc UK 8,000 19% Kazatomprom Kazakhstan 5,000 12% Areva SA France 5,000 12% BHP Billiton Australia 4,000 9% Tvel Corporation Russia 4,000 9% Navoi Mining Uzbekistan 3,000 7% Vostochny Mining Ukraine 2,000 5% State of Niger Niger 1,000 2% Anglogold Ashanti S. Africa 1,000 2% Source: Raw Materials Group Global Markets Research September 2008 A User Guide To Commodities Figure 3: The nuclear fuel cycle Figure 4: Sources of global electricity generation 1% 16% Thermal Hydro Nuclear 17% Renewables 66% Source: DB Global Markets Research Source: DOE/EIA (2007) Pricing and exchange traded The uranium market is very small relative to other commodities. Transactions are either publicly tendered to market participants, or solicited from individual counterparties or via a broker and remain undisclosed to the wider market. Transactions are ‘over the counter’ with the market split between long term supply (~90% market volume) contracting and a spot market (~10%). The spot market generally consists of all contracts for delivery of material within a six-month period. The majority of material is delivered under long-term contracts which are arranged in one of two ways: 1) Specified Pricing, which sets a base price at a specific date which can be escalated by various public economic indexes agreed upon by the contracting parties to the date of delivery; and 2) Market Pricing, which refers to contracts that are tied to the prevailing spot price as of the delivery date. The average delivery term and volume vary by transaction, but as an example, a typical contract does not usually begin before 2-3 years and lasts roughly 3-5 years with an average volume per delivery of around 115t. Figure 5: Spot uranium price since 1968 150.00 USD/lb Sum m er 2003: M cArthur River flooding 125.00 100.00 75.00 October 2006: Cigar Lake flood April 1986: Chernobyl Accident October 2001: Olym pic Dam fire M arch 1979: 3 M ile Island Accident 1994: Russian HEU enters US m arket 50.00 25.00 1968 1973 1978 1983 1988 1993 1998 2003 2008 Source: UxC, DB Global Markets Research Global Markets Research Page 27 September 2008 A User Guide To Commodities Ethanol History & properties Ethanol is a volatile, flammable, colourless liquid that burns with a smokeless blue flame that is not always visible in normal light. Ethanol is most frequently known as a drinking alcohol, but in recent years it is increasingly used in vehicle transportation. Except for the use of fire, the fermentation of sugar into ethanol is most probably the earliest organic reaction known to man. Major producers & consumers World production of ethanol in 2007 was 13,101 million gallons, with 88% of the world supply coming from Brazil (38%) and the United States (50%). Fuel ethanol production in Brazil is largely sugar cane based while in the US it is largely corn based. US ethanol production has increased by just over 50% in the last two years alone. The Energy Independence and Security Act signed at the end of last year mandates an increase in overall renewable fuels of 9,000 billion gallons of biofuels rising to 24 billion gallons by 2017. Of this total, a rising proportion will be met by advanced biofuels such as cellulosic ethanol and biodiesel. Major uses The largest single use of ethanol is as a motor fuel and fuel additive. Brazil leads the world in the use of fuel ethanol. Brazilian gasoline is required by law to contain at least 25% ethanol. As of 2005, 80% of all new cars in Brazil have flexible-fuel engines, which can run on any combination of gasoline and ethanol. The increasing use of ethanol as a gasoline additive in the US was enhanced in 2006 by government action to ban the use of methyl tert-butyl ether (MTBE) as an oxygenate fuel additive, which has been responsible for groundwater and soil contamination. Ethanol produces fewer emissions of carbon monoxide and oxides of nitrogen, and can be produced at lower cost than gasoline. Fuel ethanol takes two basic forms: anhydrous ethanol (with all water removed) to use for blending with gasoline (E-10, E25, E-85, where the number refers to the percentage of ethanol mixed with gasoline; and hydrous ethanol (with some water), to be used as a standalone fuel in nearly pure form. In the US, all vehicles can run on a 10% ethanol blend, E10, but it is commonly available only in the US Midwest. However, ethanol production is heavily subsidised by up to USD0.51 per gallon yet ethanol only has 66% of the energy content of gasoline. Other countries requiring various ethanol blends include Argentina, Thailand and India. Brazil is the most efficient producer of ethanol, by virtue of the fact that its primary feedstock is sugar cane rather than corn. For each unit of energy used in production, sugar cane yields 8.3 units, while corn yields only 1.3 units. One difficulty with ethanol is that it cannot be transported by pipeline due to its chemical volatility. Figure 1: The world’s top fuel ethanol producers Gallons (m illion) % of w orld USA 6,499 49.6% Brazil 5,019 38.3% Figure 2: Ethanol price since 2005 4.5 EU-27 570.3 4.4% China 486.0 3.7% Canada 211.3 1.6% 3.0 Thailand 79.2 0.6% 2.5 Columbia 74.9 0.6% 3.5 India 52.8 0.4% 2.0 australia 26.4 0.2% 1.5 Turkey 15.8 0.1% Other 66.6 0.5% World 13,102 100% Source: Renewable Fuels Association (2007) Page 28 Ethanol price (USD/gallon) 4.0 1.0 Jun-05 Nov-05 Apr-06 Sep-06 Feb-07 Jul-07 Dec-07 May-08 Source: DB Global Markets Research, Bloomberg (data as Aug-08) Global Markets Research September 2008 A User Guide To Commodities Figure 3: World fuel ethanol production Figure 4: World fuel biodiesel production Brazil (Sugar cane) 25000 4000 Canada China Canada 20000 EU Argentina Brazil 3000 Gallons (million) USA Gallons (million) Ukraine & Russia 3500 15000 10000 USA 2500 EU 2000 1500 1000 500 5000 0 2004 0 2004 2005 2006 2007 2008 2009 2010 2011 2005 2006 2007 2008 2009 2010 2011 2012 2012 Source: USDA Source: USDA The United States fuel ethanol industry is based largely on corn. According to the Renewable Fuels Association, as of July 2008, 162 grain ethanol bio-refineries in the United States have the capacity to produce 9.4 billion US gallons of ethanol per year. An additional 48 construction projects underway (in the U.S.) can add 4.2 billion gallons of new capacity in the next 18 months. Over time, it is believed that a material portion of the 150 billion gallon per year market for gasoline will begin to be replaced with fuel ethanol. Exchange & prices Ethanol futures are traded primarily on the Chicago Board of Trade (CBOT) in units of 29,000 US gallons (approximately one rail car), for delivery by tank car, on track, at shipping origin with seller responsible for transporting product to buyer’s destination. The Bloomberg ticker for one month generic denatured fuel ethanol contract traded on the CBOT is DL1 <Commodity>. In April 2007, Brazil launched a futures contract for anhydrous ethanol on the Brazilian Mercantile and Futures Exchange. This new anhydrous contract is quoted in US dollars in unit of 30 cubic meters (30,000 litres) and uses the Santos port as a delivery reference, with Bloomberg ticker AFA1 <Commodity>. There was an ethanol futures contract listed on the ICE, but, it was de-listed as of Dec 18, 2007. Figure 5: Biofuel production & land use by major producing country in 2006/07 Country Biofuel production Biofuel feedstocks Biofuel yield Implied feedstock area Arable land Country Ethanol Biodiesel Ethanol Biodiesel Ethanol Gallons (million) Argentina - 117 Brazil 5,284 105 Canada 159 27 China EU-27 469 488 USA 6,485 30 1,480 509 12,884 2,267 Ethanol Biodiesel Gallons/acre Biofuel total Area share Acres (million) % Soy - 65 - 1.8 1.8 70 2.5 Sugar Soy 710 65 7.4 1.1 8.5 146 5.8 Corn - 370 - 0.3 - 0.7 113 0.6 Wheat - 115 - 0.4 - - - - Corn - 215 - 1.6 - 2.4 354 0.7 Wheat - 185 - 0.8 - - - - Wheat Rape 182 140 1.3 6.8 12.3 281 4.4 Sugar Soy 550 60 0.3 3.9 - - - Corn Soy 403 66 15.7 5.7 22.1 431 5.1 146 - 0.7 - - - - Sorghum Total Biodiesel 28.5 19.3 47.8 1,395 3.4 Source: USDA Global Markets Research Page 29 September 2008 A User Guide To Commodities Carbon Emissions History & properties CO2 is the molecular formula for carbon dioxide, an atmospheric gas comprising one carbon and two oxygen atoms. CO2 was first recognized as a gas distinct from air in th the 17 Century by the Flemish chemist Jan Baptist van Helmont, who noticed it as a product of combustion after burning charcoal. CO2 is one of the greenhouse gases (GHGs) that contribute to the natural greenhouse effect, the process by which solar energy is trapped within the Earth’s atmosphere. In recent decades, concern has grown across the international scientific community over the increasing concentration of GHGs within the atmosphere. Industrialisation over the past 250 years has been held responsible for the rising levels of carbon in the atmosphere. Antarctic ice-core samples indicate that CO2 concentrations in the atmosphere were fairly constant at around 280 parts per million (ppm) until the Industrial Revolution, but that since 1800 there has been a steady increase in CO2 concentrations up to today’s level of 375ppm. This concentration continues to increase at the rate of approximately 1.5ppm per annum. A similar trend has been observed with concentrations of other GHGs. The concern is that the increase in GHG concentration levels has intensified the natural warming effect of existing GHGs in the atmosphere, and increased the average temperature of the Earth by approximately 0.6°C between 1850 and 2000. The International Panel on Climate Change (IPCC), a UN body set up in 1988 to improve understanding of global warming, estimates that if the current rate of increase in GHG emissions in general, and CO2 in particular, is not arrested, the Earth’s average temperature will rise by between 1.8°C and 4°C by 2100, with increasingly severe and potentially catastrophic consequences for the planet. Emissions trading as a response to climate change: Kyoto and the EU-ETS The recommendations of the IPCC and the United Nations Framework Convention on Climate Change (UNFCCC) are to slow the rate of increase in and then reduce GHG emissions. In adopting this stance the UNFCCC has identified six GHGs. It is these that the 1997 Kyoto Protocol commits its signatories to reducing relative to their 1990 emissions levels. The six gases are ranked in terms of an index that measures their global warming potential (GWP) relative to carbon dioxide. So, carbon dioxide has a GWP of 1, methane of 23, and so on, all the way up to sulphur hexafluoride, which is 22,200 times more powerful than carbon dioxide in terms of its impact on the Earth’s temperature when released into the atmosphere, Figure 1. Greenhouse Gas Global Warming Potential (GWP) Carbon dioxide(CO2) 1 Methane (CH4) 23 Nitrous Oxide (N2O) 296 Hydrofluorocarbons (HFCs) 12-12,000 Perfluorocarbons (PFCs) 5,700-11,900 Sulphur hexafluoride (SF6) 22,200 Figure 2: Observed prices for Kyoto-credit transactions since 2005 30 Carbon assets prices (€) Figure 1: Index of global warming potential of GHGs relative to CO2 25 20 15 10 5 0 Source: UNFCCC Page 30 primary Secondary CER CER 2005 ERU primary Secondary CER CER ERU 2006 primary Secondary CER CER ERU 2007-early 2008 Source: World Bank, DB Global Markets Research Global Markets Research September 2008 A User Guide To Commodities The Kyoto Protocol established a framework for international emissions trading, enabling industrialized countries known as Annex-1 countries under the UNFCCC terminology to trade emissions allowances both between themselves and with developing countries known as Annex-B countries. Kyoto established three main types of carbon credits, all of which are denominated in units of one tonne of CO2 equivalent (CO2e): 1. Assigned Amount Units, or AAUs (these are the units of compliance for Annex-1 countries with emissions limits under Kyoto, whereas Annex-B countries do not have limits under Kyoto and so do not have AAUs either); 2. Certified Emission Reductions, or CERs (these are the carbon credits generated under the Clean Development Mechanism, or CDM, a flexible project mechanism designed to incentivize clean-infrastructure projects in Annex-B countries); 3. Emission Reductions Units, or ERUs (these are the carbon credits generated under the Joint Implementation, or JI, mechanism, a flexible project mechanism designed to incentivize clean-infrastructure projects in Annex-1 countries). The CDM enables projects in developing countries to sell CERs to both governments and companies in developed countries, and has so far been much more important than the JI mechanism in generating credits. CERs that are bought direct from projects are known as primary CERs, while CERs bought on a guaranteed basis from market intermediaries are known as secondary CERs. Figure 2 shows the prices for primary and secondary CERs over the past two years. As part of its strategy for enabling European-Union Member States to comply with their Kyoto targets, the EU established an emissions-trading scheme (ETS) in 2005 for heavy industry covering about 42% of all GHG emissions in the EU. Phase 1 of the ETS operated over 2005-07, Phase 2 is concurrent with the Kyoto compliance period over 2008-12, and Phase 3 will run over 2013-20. The carbon credits traded in the EU-ETS are known as European Unit Allowances (EUAs). In Phase 1 EUAs collapsed to zero, but action by the European Commission to enforce tougher national allocation plans in Phase 2 have meant EUA prices have been rising steadily for the past eighteen months, Figure 3. Figure 3: Phase-1 & 2 EUA & CER prices Figure 4: The current state of the global carbon market EU Emission Certificate (Dec 07) 35 EU Emission Certificate (Dec 08) Price EUR/tonne 30 CER Swap (Dec'08) CCX ($72M) 25 ($50bn) 20 Asia 60% of all CDM Projets that issued credits Kyoto related projects* 15 South America 39.2% of all CDM 10 5 0 Jan-05 * EU ETS projects* Phase 1 Aug-05 Mar-06 Oct-06 May-07 Source: Datastream (data as of August 2008) Global Markets Research Dec-07 Africa 0.8% of all CDM projects* New South Wales ($224M) Jul-08 Source: World Bank, Unep Risoe, DB Global Markets Research Page 31 September 2008 A User Guide To Commodities Also shown in Figure 3 is the price trend for secondary CERs, as these can also be used in the EU-ETS for compliance purposes. Since the beginning of Phase 2 ERUs are also admissible, but so far none have been issued so there is no meaningful price history. Note, however, that there is a fixed limit on the use of both CERs and ERUs within the EU-ETS, as the EU is keen for the price of EUAs to reflect the cost of domestic abatement within the EU. EUAs are traded over the counter and on various European exchanges, for example, Bluenext, the EEX, and Nordpool. CERs and ERUs are mainly traded over the counter, but can also be traded on exchanges. All the CO2 emissions-allowances are priced in Euros per tonne. Future prospects for the global carbon market The outlook for carbon markets globally is best considered on three levels, namely (i) the EU-ETS, (ii) the prospects for a new international agreement to succeed Kyoto after 2012, and (iii) policy developments in other industrialized jurisdictions to: (i) The EU-ETS: Phase 3 of the ETS still under debate The ETS remains by far the largest driver of the global carbon market at the moment accounting for 78% of total turnover in 2007 ($50bn out of $64bn), and for up to 90% when EU purchasing of CERs is taken into account, Figure 4 The EU-ETS is also the market that has the highest degree of future certainty, in that we know it will exist beyond 2012, and that Phase 3 will run over 2013-20. The rules governing the operation of the ETS are currently being revised under a process known as the ETS Review, which formally began in January 2008 with the recommendations from the European Commission. The main recommendations made by the European Commission in its Review are as follows: - - - the cap by 2020 be 21% below the actual level of 2005 emissions for EU-ETS installations (i.e. a cap of 1,720Mt by 2020). However, it also recommends that the cap be reduced progressively over this period, rather than reduced in one go in 2013 and then held constant over the whole of Phase 3. if no new international agreement is reached the use of CERs/ERUs in Phase 3 will be limited to the CERs/ERUs eligible for use in Phase 2 of the EU ETS as part of the limits fixed on each installation but not actually used by the end of 2012. There will be unlimited banking between Phase 2 and Phase 3 the Commission wants to see very much higher levels of auctioning in Phase 3, with 100% of all allowances for the power-generation sector already auctioned as of 2013, and a phased reduction for the other sectors such that by 2020 there are no more free allowances for any installations. The EU Parliament and EU Council of Ministers have yet to adopt their formal positions on the Commission’s recommendations, but if all goes to plan the French presidency of the European Union will have the revised ETS Directive finalized by the end of 2008. Page 32 Global Markets Research September 2008 A User Guide To Commodities (ii) A new international framework beyond 2012 The Kyoto Protocol expires at the end of 2012, and beyond this the international framework for action against climate change at the UNFCCC level has not yet been agreed. However at the UNFCCC’s thirteenth Conference-of-the-Parties’ (COP) meeting in Bali last December, a so-called roadmap was agreed to deliver a binding international agreement to succeed Kyoto by the time of the fifteenth COP meeting in Copenhagen in December 2009. Before that, the fourteenth COP meeting will take place in Poznan, Poland, in December 2008. However, there are very important differences in the approach of many leading countries (both industrialized and developing countries) to negotiating an international agreement, and, in our view, this makes the political process for reaching agreement by December 2009 very challenging. Figure 5 sets out the timeframe for agreement and ratification according to the COP process. (iii) The outlook for other jurisdictions In addition to the EU-ETS and the existing Kyoto framework, a number of countries and jurisdictions have either already established trading schemes of their own, for example New Zealand, or are moving towards doing so in the next few years, for example Australia, Japan and California. In addition, 13 north-eastern states in the US have formed a regional trading scheme known as the regional Greenhouse-Gas Initiative, or RGGI. Eventually this may encompass the whole of the United States. Figure 5: Toward a post-2012 agreement Towards mandate (Art.3.9) 2nd Review of the K.P. (art. 9) Dialogue under UNFCCC New mandates for Kyoto ? 2008 COP 14 Poznan 2009 Clear picture of post 2012 framework Negociated post 2012 agreement COP 15 Copenhagen 2010 COP 16 2011 COP 17 2012 COP 18 NEGOTIATIONS NEGOTIATIONS RATIFICATION Japan G8 Italy G8 New US President Source: Point Carbon, DB Global Markets Research Global Markets Research Page 33 September 2008 A User Guide To Commodities Renewable Energy History and properties Renewable energy is produced from resources which are naturally replenished, such as rain, wind, sunlight, oceanic streams, geothermal heat and biomass. In order to get rid of the intermittency inherent in renewables, storage capacities and integration to the electricity’s transportation network are essential, not even taking into account the potential of smart grids in the future. Hydropower is the most commonly of all renewable energy sources for electricity generation. Hydropower generates electricity by harnessing or directing moving water. Typically, water flowing through a penstock or a pipe, turns and pushes against the blades in a turbine to spin a generator to produce electricity. Hydropower has been used for thousands of years to turn stones for grinding grains and consequently it is one of the oldest harnessed sources of energy. However, it did not become th widely used until the 20 Century when the technology to transmit electricity over long distances was developed. Wind power uses wind turbines to generate electricity. The power output of a turbine increases dramatically as wind speed increases. Areas where winds are more constant and stronger, such as high altitude sites and offshore regions, are better albeit more expensive locations for wind farms. Wind energy has also been used by people since ancient times as a source of power to grind grains and other materials. th The earliest windmills were built in Persia in the 7 century. Solar power describes the conversion of solar energy into other forms of energy, such as heat and electricity. Solar energy can be converted into electricity using photovoltaic (PV) devices or solar power plants. Photovoltaic generates electricity directly from sunlight. Solar power plants can also generate electricity indirectly using thermal collectors to focus the sun’s rays to heat fluid at a high temperature. The heated fluid then produces steam that is used to operate a turbine and generate electricity. British astronomer John Herschel used a solar thermal collector box to cook food during an expedition to Africa in the 1830s. Geothermal energy is the energy derived from the hot interior of the earth. It is a renewable energy because heat is continuously produced inside the earth by the slow decay of radioactive particles. Water heated by the geothermal energy rises naturally to the surface via fissures in the earth’s crust at hot springs and geysers. Heated underground steam or water are tapped and brought to the surface to operate steam turbines and generate electricity, a practise common in Iceland. Biomass energy is generated from non-fossilized materials derived from plants. The main sources of biomass energy are wood and wood waste, followed by energy from municipal solid waste (MSW) and alcohol fuels. Biomass in the form of organic waste can be converted through gasification to produce a biogas (normally methane). The biogas is then burnt to produce energy. When using biomass as a renewable source of energy it is absolutely necessary to consider the durability of the source via land management practises. Major producers and consumers China is the world’s largest producer of energy using renewable resources. In 2007, about 820 megawatts of solar PV were produced in China, second only to Japan. Canada, the largest producer of hydropower in the world, produces about 3.1 billion kilowatt hours of hydropower per year, followed by the United States. China is the world leader in total renewable energy consumption, followed by the United States and Canada. However, the United States consumes the most non-hydro renewable energy, consuming twice as much non-hydro renewable energy as Germany and more than three times as much as Japan. Page 34 Global Markets Research September 2008 A User Guide To Commodities Figure 1: Renewable power capacities in 2006 Solar PV (grid) 250 Geothermal Biomass 200 Wind Gigawatts Small hydro 150 100 50 0 World Developing World EU-25 China Germany United States Spain India Japan Note: Excludes large hydropower Source: REN21 Renewables 2007 Global Status Report Global Markets Research Page 35 September 2008 A User Guide To Commodities Precious Metals Precious metals production ranges from just over 17,000 tonnes in silver to a mere 4 tonnes for iridium. Iridium is one of the rarest metals on the planet representing less that 1 part per billion of the earth’s crust. However, it is regularly found in meteorites and has been linked to theories on the extinction of dinosaurs. One of the major distinguishing features of the precious metals complex and specifically the gold market compared to other commodities is that annual mine production for gold is less than 10% of total above ground stocks. This tends to mean that the gold forward curve is always in contango and level of volatility tends to be lower than other commodity markets where inventories are significantly lower compared to annual demand and supply. Gold held by central banks amounted to just over 29,800 tonnes as of the end of June 2008. The lion’s share of these holdings is held by the United States, Germany, France and Italy. These countries gold holdings are equivalent to around two-thirds of total reserves, compared to a world average of just over 10%. In contrast, gold to total reserve ratios are significantly lower in Asia and the Middle East and in some circumstances below 3% of total reserves. The performance of the gold price has been closely linked to the course of the US dollar and the level of real interest rates in the United States. Figure 1: Precious metals production in 2007 2007 production (tonnes) Silver production=17,337t 3000 2500 Figure 2: Central bank gold reserves 9000 Top 14 Central Bank Gold Holdings (tonnes, June 2008) World total = 29,813 tonnes Top 14 constitute 73% of w orld total 78 8000 2447 7000 6000 2000 5000 1500 4000 1000 66 59 3000 2000 500 234 205 36 25 Palladium Platinum Ruthenium Rhodium 40 1000 4 0 Gold % share of gold to total reserves 68 2 61 1 25 2 4 87 3 0 Iridium US GER FRA ITA SWZ JPN NETH CHN ECB RUS TAI PORT IND Source: CPM Group Source: IMF, World Gold Council (data end June 2008) Figure 3: Gold returns in different US real interest rate environments Figure 4: The top precious metals futures contracts Year-on-year returns 1970-2007 100 Gold yoy returns (%) 80 60 40 Contract Exchange Turnover Turnover % change 2005 2007 Gold NYMEX 15.9 25.1 58% Gold Tokyo Commodity Exchange 18 18.2 1% Platinum Tokyo Commodity Exchange 8.6 9.2 7% Silver NYMEX 5.5 6.8 23% 20 Gold CBOT 0.6 1.5 130% 0 Silver Tokyo Commodity Exchange 0.8 0.5 -35% Platinum NYMEX 0.4 0.5 32% Palladium NYMEX 0.3 0.4 25% Palladium Tokyo Commodity Exchange 0.3 0.2 -35% -20 -40 -5 -4 -3 -2 -1 0 1 2 3 4 5 Real short-term Fed funds rate (%) Source: DB Global Markets Research, Bloomberg Page 36 6 7 8 9 Source: TOCOM, NYMEX, CBOT (data are in million lots) Global Markets Research September 2008 A User Guide To Commodities Gold History & properties Gold has the symbol Au derived from the Latin word aurum. Gold has the atomic number 79 and was first mined in Egypt more than 4,000 years ago. It was used in the world’s first coinage around 640BC in Lydia, in what is now modern day Turkey. Gold is a dense, lustrous, yellow precious metal that has been used for millennia as a store of value, as a unit of exchange and in jewellery. It is the most malleable and ductile metal known to man such that a single gram of gold can be beaten into a sheet of one square metre or a wire more than one mile long. Gold is a good conductor of heat and electricity, and it is unaffected by air, heat, moisture and most solvents. It is occasionally found in nuggets, but occurs more commonly as minute grains between mineral grain boundaries. Historically, gold was obtained by panning streambeds, but modern extraction techniques can economically recover gold from ore grades as low as 0.5 parts per million. Gold was used as a benchmark for the world monetary system between 1944 and 1971, when the Bretton Woods agreement fixed the world’s paper currencies to the US dollar, which, in turn, was tied to gold. The collapse of this system at the end of 1971 heralded not only freely floating exchange rates, but, also gold prices. Major producers Since 1905, South Africa had been the world’s largest producer of gold. However, last year China surpassed South African production by 16 tonnes. During this decade South African production has suffered from declining ore grades, maturing mines, power disruptions and labour unrest. Today China, South Africa, Australia and the US account for approximately 40% of the world’s annual gold mine production. Major holders Global central banks remain a powerful community in terms of the world gold market. Their combined holdings amounted to 29,813 tonnes as of June 2008. The largest holder of reserves is the United States with 8,134 tonnes, equivalent to 78.2% of total reserves. The average gold to total reserve ratio across all central banks is 10.8%. However, in Europe ratios are significantly higher with Greece holding the highest gold to total reserve ratio at 89.9%. While European central banks can still be considered to be ‘overweight’ gold, aggressive central bank intervention across Asia over the past few years has led to a dramatic increase in their FX reserves and consequently a decline in their gold to total reserve ratios. In the case of Japan and China, gold to total reserve ratios currently stand at 2.1% and 1.0% respectively. Figure 1: The world’s top 10 gold producers and consumers in 2007 by country and region Producers Tonnes % of world China Tonnes 270.6 % of world Consumers 11.1% Middle East* 643.8 22.2% South Africa 254.6 10.4% India 438.0 15.1% Australia 245.7 10.0% Thailand 373.2 12.9% USA 241.1 9.9% Asia** 317.2 11.0% Peru 170.1 7.0% Italy 220.9 7.6% Russia 166.1 6.8% Japan 196.5 6.8% Indonesia 112.8 4.6% USA 150.9 5.2% Canada 101.7 4.2% Germany 34.2 1.2% Uzbekistan 87.1 3.6% Africa*** 31.4 1.1% Ghana 82.4 3.4% Latin America 30.1 1.0% World 2,447 World 2,892 * Middle East includes Pakistan ** Asia excludes Japan and Thailand *** Africa excludes South Africa World production data excludes secondary supply. World consumption excludes investment demand Source: CPM Group Global Markets Research Page 37 September 2008 A User Guide To Commodities Figure 2: Gold demand by sector in 2007 Company Tonnes Ounces (mn) Market share Barrick Gold 250.7 8.06 10.3% Anglogold Ashanti 170.4 5.48 7.0% Newmont Mining 164.3 5.28 6.8% Other industrial Gold Fields 130.4 4.19 5.4% Dental & medical Freeport McMoran 72.4 2.33 3.0% Goldcorp 71.3 2.29 2.9% Harmony Gold Mining 60.3 1.94 2.5% Navoi Metals and Mining 58.2 1.87 2.4% Newcrest Mining 54.7 1.76 2.3% Kinross Gold 47.3 1.52 1.9% Jewellery 3.4% 1.8% 6.3% Bars, coins & medallions Producer de-hedging 6.6% Figure 3: Top 10 gold producing companies in 2007 Electronics ETF and similar 10.1% 61.3% 10.4% Source: CPM Group, DB Global Markets Research Source: CPM Group, DB Global Markets Research Major uses The lion’s share of gold consumption comes from the jewellery sector, accounting for 61.3% of total demand in 2007. Alloys of gold with silver, copper and other metals are often used because pure gold is too soft for ordinary use. When used in jewellery, it is measured in karats (k), with pure gold being 24k, and lower numbers indicating higher copper or silver content. Gold has some industrial uses, due to its electrical conductivity, resistance to corrosion, reflectiveness and other physical and chemical properties. It is used in electrical connectors and contacts, electronics, restorative dentistry, medical applications, chemistry and photography. Exchange traded & price conventions Gold is traded on the Tokyo Commodity Exchange (TOCOM), the New York Mercantile Exchange (NYMEX) and the Chicago Board of Trade (CBOT). The Bloomberg ticker for the spot gold price is GOLDS <Commodity>. The Bloomberg codes for the DB Gold total returns and excess returns indices are DBRGCTR <Index> and DBRGC <Index> respectively. The Bloomberg codes for the DB GoldOptimum Yield total and excess returns indices are DBLCOGCT <Index> and DBLCOGCE <Index>. Figure 4: Gold price since 1964 1200 Figure 5: Gold turnover by exchange Gold spot price (USD/oz) 1000 800 600 30 Annual turnover in 2007 (standard futures, million lots) 25 20 15 400 10 200 5 0 1964 1968 1972 1976 1980 1984 1988 1992 1996 2000 2004 2008 0 NYMEX Source: DB Global Markets Research, IMF (monthly data as of end Aug-08) Page 38 TOCOM CBOT Source: TOCOM, NYMEX, CBOT (*Data excludes mini gold futures traded on CBOT & TOCOM) Global Markets Research September 2008 A User Guide To Commodities Silver History & properties Silver has the symbol Ag derived from the Latin argentum. It has the atomic number 47. First mined on a large scale around five thousand years ago in an area that is modern-day Turkey, its use was widespread due to its ease of access since silver deposits were on or near the earth’s surface. Silver is often found in close proximity to other ores, such as lead, copper and zinc. Silver has the highest electrical conductivity of all metals, but its cost being 64 times more expensive than copper has prevented it from being used more widely for electrical purposes. It is also ductile, malleable, superior conductor of heat and good reflector of light. Sterling silver is a commonly used alloy of silver containing 92.5% silver and 7.5% copper. Major producers & consumers Approximately three-quarters of silver is mined from gold, copper, lead and zinc mines as a by product of these metals. Peru is the world’s largest producer of silver at 3,494 tonnes in 2007, followed by Mexico, China, Australia and Chile. Given silver’s importance in industrial applications, the US and Japan are the largest consumers representing almost than 40% of world fabrication demand. India and China are the world’s third and fourth largest consumers of the metal. Major uses Throughout history, silver has been used in the manufacture of ornaments, utensils, jewellery and coins. Today demand for silver is dominated by three main categories: jewellery and silverware, industrial applications and photography. Jewellery and silverware is not only the largest category of demand, but, it is also the most sensitive to price. Unlike gold, silver has significantly more industrial applications helped by the fact that silver is 50 times cheaper than gold. Due to its conductivity silver is used extensively in the electronics sector as well as in photography. However, photographic fabrication demand of silver has fallen steadily over the past several years due to the increasing popularity of digital cameras. Other industrial applications of silver inlcude catalyst use, water purification, electrical applications, brazing and soldering, mirror and other coating and electroplating. Figure 1: The world’s top 10 silver producers and consumers* in 2007 Producers Tonnes Tonnes % of world Peru 3,493.9 % of world Consumers 20.2 USA 5,371.6 23.3 Mexico 3,094.8 17.9 Japan 3,760.4 16.3 China 2,690.5 15.5 India 2,674.9 11.6 Australia 1,928.4 11.1 China** 1800.0 7.8 Chile 1,835.1 10.6 Italy 1,660.9 7.2 Poland 1,306.3 7.5 Germany 1,583.2 6.9 Russia 1,259.7 7.3 Thailand 1,570.7 6.8 USA 1,181.9 6.8 Belgium 902.0 3.9 Kazakhstan 870.9 5.0 UK 870.9 3.8 Canada 862.3 5.0 France 653.2 2.8 World 17,337.1 World 28,023 World production data excludes secondary supply, Consumption figures excludes investment demand Source: CPM Group, **DB Global Markets Research estimate Global Markets Research Page 39 September 2008 A User Guide To Commodities Figure 2: Silver fabrication demand by sector in 2007 Figure 3: Top 10 silver producing companies in 2007 Com pany Photography 23% 24% Jewellery & Silverware Tonnes Ounces (m n) Market share 1448.4 46.57 6.7% 1420.8 45.68 6.6% 1215.0 39.06 5.6% Volcan 657.5 21.14 3.1% Kazakhymys 590.5 18.99 2.7% Pan American Silver 531.9 17.10 2.5% Goldcorp 531.0 17.07 2.5% Polymetal 495.0 15.92 2.3% Grupo Mexcio 473.7 15.23 2.2% Cia de Minas Buenaventura 459.3 14.77 2.1% Industrias Penoles BHP Billiton Group ` KGHM Polska Miedz Electronics and Batteries Other uses 17% 36% Source: CPM Group, DB Global Markets Research Source: CPM Group Exchange traded Silver is traded on the COMEX division of the New York Mercantile Exchange (NYMEX), the Chicago Board of Trade (CBOT), and the Tokyo Commodities Exchange (TOCOM). The COMEX silver futures contract specifies delivery of 5,000 troy ounces, and is quoted in US cents per troy ounce. The Bloomberg ticker for the spot silver price is SLVRLN <Commodity> and is quoted in US cents per troy ounce. The Bloomberg codes for the Deutsche Bank Silver Optimum Yield total returns and excess returns indices are DBLCYTSI <Index> and DBLCYESI <Index> respectively. Figure 4: Silver price from 1968 45 Figure 5: Silver turnover by exchange Silver spot price (USD/oz) 8 Annual turnover in 2007 (standard & mini futures, million lots) 40 35 6 30 25 20 4 15 10 2 5 0 1968 1972 1976 1980 1984 1988 1992 1996 2000 2004 2008 0 NYMEX Source: DB Global Markets Research, IMF (monthly data as of end-Aug-08) Page 40 CBOT TOCOM Source: NYMEX, TOCOM, CBOT Global Markets Research September 2008 A User Guide To Commodities Platinum History & properties Platinum has the symbol Pt and the atomic number 78. The English word platinum derives from the Spanish word platina meaning little silver as the Spaniards named the metal when they first encountered it in Colombia. Platinum is one of the noble metals, that is very few chemicals will react with it or corrode it. It is 30 times rarer than gold, representing around 3 parts per billion of the Earth’s crust. In addition, it is both twice as expensive as well as heavy as gold. Like gold, platinum is pliable such that one gram can be rolled into a fine wire over one mile long. The metal has excellent catalytic properties and its resistance to tarnishing makes it well suited for making jewellery. It is extremely corrosion resistant and has a high melting point. Fuel cells use it as a catalyst to convert hydrogen and oxygen to electricity. Platinum has been found in objects from ancient Egyptian civilisation as early as 700BC. However, it is claimed to have been discovered by astronomer, Antonio de Ulloa in the mid-1700s and was formally recognised as a new metal in 1751. Until recently, the definition of a metre was based on the distance between two marks on a platinum/iridium bar housed at the Bureau International des Poids et Mesures in Sèvres, France. Even today, the definition of a kilogram is based on a platinum/iridium cylinder also housed in the Bureau. Major producers Around 80% of the world’s reserves and production of platinum occur in Southern Africa primarily in South Africa’s Bushveld Igneous Complex, just north of Pretoria. Platinum also occurs in Zimbabwe’s Great Dyke, which bisects the country from north to south. Of the remaining global deposits, Russia’s are the most significant and these are predominantly a by-product of Norilsk’s nickel deposits. The next major producers are Canada and the US. Again this production is mostly a by-product of nickel and palladium production. In terms of yield, 7 to 12 tonnes of ore are required to produce just one troy ounce, or approximately 31 grams, of platinum. Figure 1: The world’s top 5 platinum producers and consumers in 2007 Producers Ounces % of world 5,186,311 Ounces 78.6 Western Europe 2,263,000 30.9 Russia 800,000 12.1 USA 2,215,000 30.3 Canada 255,000 3.9 Japan 1,449,000 19.8 Zimbabwe 170,000 2.6 Other countries 870,000 11.9 USA 134,300 2.0 China 560,000 7.7 World 7,317,000 South Africa World % of world Consumers 6,599,000 Source: CPM Group; 1 tonne = 32,151 troy ounces Figure 2: Platinum demand by sector in 2007 4.5% 2.9% 1.0% Autocatalyst Figure 3: Platinum turnover by exchange 10 9.2 5.1% Jewellery 5.6% Annual turnover in 2007 (Futures only, million lots) 8 Other Electrical 6.3% 6 Chemical 4 54.2% Glass Petroleum 2 20.4% 0.5 Investment 0 TOCOM Source: Johnson Matthey, DB Global Markets Research estimate Global Markets Research NYMEX Source: TOCOM, NYMEX Page 41 September 2008 A User Guide To Commodities Figure 4: Major platinum producing companies Com pany Tonnes Ounces (m n) Market share Anglo Platinum 77.0 2.47 36.5% Impala 54.7 1.76 26.0% Lonmin 25.8 0.83 12.2% Norilsk Nickel 23.0 0.74 10.9% Aquarius Platinum 7.1 0.23 3.4% Northam 6.2 0.20 2.9% Vale 4.4 0.14 2.1% Stillw ater Mining 3.9 0.12 1.8% Koryak 2.5 0.08 1.2% Eastplats 2.2 0.07 1.0% Figure 5: Platinum price since 1976 2500 Platinum spot price (USD/oz) 2000 1500 Source: CPM Group 1000 500 0 1976 1980 1984 1988 1992 1996 2000 2004 2008 Source: Datastream, Bloomberg (data as of end July 2008) Major uses Autocatalytic applications are the largest single use of platinum, accounting for over 50% of total platinum usage. Its use is predominantly to clean tailpipe emissions in light duty diesel automotives. Jewellery is the second most important demand category, accounting for around 20% of total demand with Japan and China representing the majority of the global platinum jewellery market. Platinum is also becoming increasingly important as an industrial metal in the chemical, electrical and glass manufacturing industries. However, it is platinum as well as ruthenium’s role as a catalyst in hydrogen fuel cell technology which could revolutionise demand for these metals particularly in an environment of high oil prices. Fuel cells convert the energy of a chemical reaction directly into electricity, with heat as a by-product. Unlike fossil fuels, the exhaust product of a fuel cell is water. Exchange traded & price conventions The main exchange for trading platinum futures is the Tokyo Commodities Exchange, but, they are also listed on the New York Mercantile Exchange. The Bloomberg ticker for the platinum spot price is PLAT <Commodity>. Page 42 Global Markets Research September 2008 A User Guide To Commodities Palladium History & properties Palladium has the symbol Pd and the atomic number 46. Palladium has similar chemical attributes to platinum, although it is less dense with a specific gravity of 12 compared to 21.5 for platinum. Palladium also has the lowest melting point of all the platinum group metals at 1,555˚C compared to 1,768˚C for platinum. The metal has excellent catalytic properties and although not as resistant to tarnishing as platinum, it is still well suited for jewellery. Palladium was discovered by the English chemist, William Hyde Wollaston in 1803. Until recently, palladium chloride was used in the treatment of tuberculosis and has played an important role in cold fusion experiments. Major producers The Russian mining company Norilsk Nickel is a major producer of palladium as a byproduct of its nickel operations. In 2007, it represented around 43% of world supply. However, 80% of the world’s reserves of palladium occur in Southern Africa primarily in South Africa’s Bushveld Igneous Complex, but, also in Zimbabwe’s Great Dyke. Of the remaining global deposits, the United States and Canada constitute a few percent of global reserves, with little of any consequence elsewhere in the world. Major uses Like platinum, autocatalytic applications is the largest category of demand, accounting for 58% of total palladium usage. In 2007, electronics and jewellery accounted for nearly 15% and 10% respectively of palladium demand. Palladium is also used in electronic and dental industries as well as in anti-cancer medication as it works to inhibit cell division. Figure 1: The world’s top palladium producers and consumers in 2007 Producers Million ounces % of world Russia Million ounces 3.10 % of world Consumers 41.3 US 2.49 30.3 South Africa 2.72 36.2 Japan 2.48 30.1 Canada 0.57 7.6 W Europe 1.78 21.7 US 0.43 5.7 China 0.88 10.7 Zimbabwe 0.13 1.8 Other 0.60 7.2 World 7.51 World 8.22 Source: CPM Group; 1 tonne = 32,151 troy ounces Figure 2: Palladium demand by sector in 2007 4.7% 4.6% Autocatalyst Figure 3: Palladium turnover by exchange 0.5 Annual turnover in 2007 (Futures only million lots) Electronics 8.2% 0.4 Jewellery Dental 9.9% 0.3 Chemical Other 0.2 0.1 14.6% 58.0% 0 NYMEX Source: CPM Group, DB Global Markets Research Global Markets Research TOCOM Source: TOCOM, COMEX Page 43 September 2008 Figure 4: companies Com pany A User Guide To Commodities Major palladium producing Tonnes Ounces (m n) Market share Norilsk Nickel 96.8 3.11 43.3% Anglo Platinum 43.2 1.39 19.3% Impala 28.6 0.92 12.8% Stillw ater Mining 12.8 0.41 5.7% Lonmin 11.9 0.38 5.3% North American Palladium 8.9 0.29 4.0% Vale 5.9 0.19 2.7% Aquarius Platinum 3.8 0.12 1.7% Northam 2.6 0.08 1.2% Xtrata 2.0 0.07 0.9% Figure 5: Palladium price since 1987 1200 Palladium spot price (USD/ ) 1000 800 600 Source: CPM Group 400 200 0 1987 1990 1993 1996 1999 2002 2005 2008 Source: Bloomberg, DB Global Markets Research (data as of end July 2008) Exchange traded & price conventions Until 2000, when onerous restrictions were imposed on various contracts, the Tokyo Commodities Exchange was the main exchange for trading palladium futures. During this decade COMEX, which forms part of NYMEX has become the largest more liquid exchange for trading palladium. The Bloomberg ticker for the palladium spot price is PALL <Commodity>. Page 44 Global Markets Research September 2008 A User Guide To Commodities Rhodium History & properties Rhodium has the symbol Rh and the atomic number 45. The English word rhodium derives from the Greek rhodon meaning rose. Rhodium is an extremely rare metal, representing less than 1 part per billion of the Earth’s crust. The metal was discovered by the English chemist, William Hyde Wollaston in 1803, shortly after he discovered palladium. Around 400g of rhodium can be recovered from each ton of spent nuclear fuel. These rhodium isotopes have a half life of three years and as a consequence need to be stored for at least 20 years. Major producers Like the rest of the PGM complex, the majority of the world’s reserves occur in Southern Africa. It is produced primarily as a by-product of platinum mining in South Africa, which accounts for over 80% of world supply. Anglo Platinum is the single largest producer of rhodium in the world, which accounted for nearly half of South African supply in 2007. Major uses Fabrication demand for Rhodium is dominated by autocatalytic applications. According to CPM consultants, auto catalysts have accounted for about 88% of total rhodium fabrication demand in 2007. Like platinum and palladium, it is predominantly used to clean tailpipe emissions in light duty diesel automotives and “lean-burn” gasoline automotives. The metal has also become increasingly important to the glass manufacturing sector where it is used in the tooling for new flat screen and LCD displays. Exchange traded & price conventions Rhodium is not an exchange traded commodity. The Bloomberg ticker for the rhodium Johnson Matthey spot price is JMATRHOD <CMDTY>. The Reuters instrument code (RIC) for rhodium spot price is RHOD-LON. Figure 1: The world’s top rhodium producers and consumers in 2007 Producers Ounces Ounces % of world South Africa 654,819 82.2 USA 415,650 38.7 Russia 94,000 11.8 Europe 290,400 25.6 Canada 27,700 3.5 Japan 182,000 17.0 Zimbabwe 14,000 1.8 Other 184,800 17.2 USA 4,000 0.5 796,519 100% World 1,072,850 100% World % of world Consumers Source: CPM Group Figure 2: Rhodium demand by sector in 2007 3.2% 3.1% 2.0% Autocatalyst 3.9% Source: CPM, DB Global Markets Research Global Markets Research 10000 Glass 8000 Electronics 6000 Chemical 4000 Other 87.9% Figure 3: Rhodium price since 1994 Rhodium price USD/oz 2000 0 1994 1996 1998 2000 2002 2004 2006 2008 Source: Reuters (data as of end July 2008) Page 45 September 2008 A User Guide To Commodities Other PGMs: Ruthenium, Iridium & Osmium History & major uses Iridium (Ir) and ruthenium (Ru) and Osmium (Os) are lesser known Platinum Group Metals, discovered in 1803, 1844 and 1803 respectively. These metals are largely produced as by products of nickel, platinum and palladium. While iridium is rare on earth, it is relatively common in meteorites and has been linked to theories on the extinction of dinosaurs. Iridium is also the most corrosion-resistant metal known to man. Ruthenium is a rare transition metal of the PGM family and can also be recovered from spent nuclear fuel. Osmium is the densest natural element. Ruthenium’s primary demand category is the electronics sector (65%) where it significantly increases the storage capacity and durability of hard disk drives. It is also used in the making of plasma display screens. Ruthenium is also used in various chemical catalysts. Iridium is primarily used in high-strength alloys, capable of withstanding very high temperatures. It is also used in electronics and in the manufacture of crucibles required for the production of high quality single crystals, spark plug electrodes and other chemical applications. Osmium’s major use is as a catalyst in making steroids. Due to its hardness and corrosion resistance osmium is often used in the production of extremely hard alloys. Alloys of osmium are used in fountain pen nibs, electrical contacts and armourpiercing shells. Exchange traded & price conventions The markets for iridium and ruthenium are small and illiquid and as a result futures markets are non-existent. The Bloomberg tickers for the iridium and ruthenium Johnson Matthey spot price are JMATIRID <Commodity> and JMATRUTH <Commodity> respectively. The Reuters code for iridium and ruthenium are RUTHLON and IRID-LON respectively. The osmium market is extremely small both in terms of traded volume and the number of companies involved in the production and consumption of the metal. Figure 1: Ruthenium price since 1994 Figure 2: Iridium price since 1994 1000 600 Ruthenium price USD/oz Iridium price USD/oz 800 400 600 400 200 200 0 1994 1996 1998 2000 2002 Source: Reuters (data as of end July 2008) Page 46 2004 2006 2008 0 1994 1996 1998 2000 2002 2004 2006 2008 Source: Reuters (data as of end July 2008) Global Markets Research September 2008 A User Guide To Commodities Industrial Metals Industrial metals are non-ferrous metals, meaning they do not contain an appreciable amount of iron. The industrial metals complex is comprised of aluminium, copper, lead, nickel, tin and zinc. These six metals are traded on several exchanges around the world. However, the benchmark contracts are listed on the London Metal Exchange (LME). The LME was founded for in 1877 and much of the business is still conducted through open outcry trading in the ‘Ring.’ Volume on the LME is dominated by the aluminium, copper and zinc contracts, which combined represent around 85% of all turnover on the exchange. The LME is a highly liquid market and in 2007 turnover reached a new record of 93 million lots, equivalent to USD9,500 billion. During this decade the LME have been increasing the number of listed futures contracts for example polypropylene, low density polyethylene and steel billets. Aluminium is the most actively traded metal on global exchanges. The annual production of aluminium, which reached 38.1 million tonnes in 2007, exceeds the output of all other industrial and precious metals combined, with the exception of steel. One of the most important trends during this decade has been China’s voracious appetite for industrial raw materials, which has accelerated since the country joined the World Trade Organisation in 2001. This has led the country’s share of world consumption of not only industrial metals, but all major raw materials to increase substantially, Figure 3. Figure 1: Metallgesellschaft Metals Index Figure 2: Industrial metals primary production 500 40 450 35 400 2007 production (tonnes, million) 38.1 30 350 25 300 20 250 200 18.0 15 11.2 150 5 50 0 1957 8.1 10 100 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: Reuters, IMF; (Monthly data as of end Aug-08) ; Note: The MGMI is a composite price index of the six LME metals which is weighted according to traded volume Figure 3: China’s raw materials consumption as a percent of global consumption 60% 2000 40% 30% 20% 10% 0% Copper Lead Nickel Zinc Source: Brook Hunt, UNCTAD, Tex Report, AME Global Markets Research Crude Steel Iron Ore 0.4 Aluminium Copper Zinc Lead Nickel Tin Source: Brook Hunt, World Bureau of Metal Statistics Figure 4: The world’s top metals futures contracts Contract Exchange Turnover 2005 Turnover 2007 % change Aluminium LME 30.4 40.2 32% Copper LME 19.2 21.4 11% Copper Shanghai Futures Exchange 12.4 16.3 32% 2010E 50% Aluminium 1.4 0 Zinc LME 10.6 12.6 19% Aluminium Shanghai Futures Exchange 2.1 4.8 126% Lead LME 4.1 4.7 16% Nickel LME 3.5 3.8 9% Copper NYMEX 4 3.8 -5% Tin LME 1.1 1.3 18% NASAAC LME 10 1.2 24% 0.5 0.5 -1% Aluminium alloy LME Source: LME, TOCOM, NYMEX, SFE, OME (million lots) Page 47 September 2008 A User Guide To Commodities Aluminium History & properties Aluminium has the symbol Al and atomic number 13. Its name derives from the Latin word alumen. It is one of the most abundant metallic elements in the earth’s crust and is a silvery white colour. However, it is very rare in its free form, occurring often in volcanic mud, but more often is found combined in other minerals, and specifically bauxite ore. Its most important characteristics are its resistance to corrosion and its light weight. Aluminium has been commercially produced since 1888. Today, more aluminium is produced annually than all other non-ferrous metals combined. Aluminium is extremely difficult to separate from the ore body (bauxite) and consequently difficult to refine, requiring enormous amounts of energy. Two to three tonnes of bauxite are required to produce one tonne of alumina (aluminium oxide) and two tonnes of alumina are required to produce one tonne of aluminium metal. The basis for aluminium production today dates back to 1886 when scientists invented a new electrolytic process whereby aluminium oxide (alumina) was dissolved in a bath of molten cryolite and a powerful electric current passed through them. Molten aluminium would be then deposited at the bottom of the bath. Major producers & consumers The world’s major primary aluminium producers are China, Russia and Canada. In terms of exports, Russia accounts for the lion’s share with 22%. The main importers are the Japan, US, and Germany. However, in terms of bauxite mine production Australia, Brazil, China, India and Guinea accounted for over 75% of world mine production in 2007. In terms of identified bauxite resources, the US Geological Survey estimates these at between 55 to 75 billion tonnes located in South America (33%), Africa (27%), Asia (17%) and Oceania (13%). Rio Tinto, Rusal and Alcoa are the three largest companies in terms of aluminium smelting, with a production share of 32% in 2007. Major uses Aluminium combines unique characteristics that make it highly attractive. It is lightweight, but, very strong and durable. It is highly conductive, non-corrosive, malleable, recyclable and has historically been priced cheaply compared to its peer metals. It is primarily used in the transportation, packaging (cans), defence and consumer electronic industries. Most materials that claim to be aluminium are in fact an aluminium alloy. Since aluminium weighs less than one-third as much as steel, its high strength-to-weight ratio makes aluminium suitable for the construction of aircraft, cars and train carriages. Building construction and transportation equipment account for around 50% of aluminium consumption, Figure 4. Given the cost of production, recovery of this metal from scrap has become an important component of the aluminium industry. Figure 1: The world’s top 10 aluminium producers, consumers, exporters and importers in 2007 Refined Tonnes % of Refined production China Russia Canada USA Australia Brazil Norway India S. Africa UAE World (000s) 12,559 3,955 3,083 2,560 1,959 1,655 1,354 1,223 898 890 38,087 consumption China USA Japan Germany Italy Korea Russia India Brazil France World world 33% 10% 8% 7% 5% 4% 4% 3% 2% 2% Tonnes % of (000s) 12,347 5,580 2,197 2,008 1,087 1,081 1,020 1,020 854 737 37,246 world 33% 15% 6% 5% 3% 3% 3% 3% 2% 2% Refined exports Russia Canada Australia Norway Brazil Netherlands S. Africa China Iceland Germany Total Tonnes (000s) 3,949 2,501 1,659 1,610 823 795 625 546 446 423 17,671 % of world 22% 14% 9% 9% 5% 4% 4% 3% 3% 2% Refined Tonnes % of imports Japan USA Germany Korea Italy Netherlands Belgium France Norway Taiwan Total (000s) 2,986 2,951 2,231 1,169 1,079 1,043 754 587 508 504 19,171 world 16% 15% 12% 6% 6% 5% 4% 3% 3% 3% Source: World Bureau of Metal Statistics, Brook Hunt Page 48 Global Markets Research September 2008 Figure 2: producers A User Guide To Commodities The world’s top Country Tonnes (000s) Australia 62,428 Brazil 22,836 10 bauxite % of world Figure 3: The world’s top 10 bauxite producers Country Tonnes (000s) % of world 33% China 20,900 26% 12% Australia 19,248 24% 7,132 9% China 21,600 11% Brazil India 19,308 10% USA 4,636 6% Guinea 18,908 10% Jamaica 3,997 5% Jamaica 14,568 8% Russia 3,322 4% Russia 6,054 3% India 3,178 4% Surinam 5,273 3% Surinam 2,178 3% Kazakhstan 5,000 3% Ireland 1,806 2% 3% Ukraine 1,653 2% Total 81,053 Venezuela 4,936 World 191,655 Source: Brook Hunt (2007 data) Source: Brook Hunt (2007 data) Exchange traded Aluminium is traded on the London Metal Exchange (LME), the New York Mercantile Exchange (NYMEX), the Tokyo Commodity Exchange, the Osaka Mercantile Exchange (OME) and the Shanghai Futures Exchange (SFE). The LME aluminium forward is quoted in US dollars per tonne. On NYMEX, aluminium is quoted in US cents per pound. The Bloomberg ticker for the 3M aluminium forward is LMAHDS03 <Index>. The Bloomberg ticker for the Deutsche Bank Aluminium total returns and excess returns indices are DBRMALTR <Index> and DBRMAL <Index> respectively. The Bloomberg ticker for the DB Aluminium-Optimum Yield total returns and excess returns indices are DBLCOALT <Index> and DBLCOALE <Index> respectively. LSAH <Index> tracks aluminium inventories on the London Metal Exchange. Figure 4: Aluminium consumption by first use in 2007 Figure 5: Aluminium prices since 1957 4000 10% 22% Building & Construction Aluminium cash price (USD/tonne) 3500 3000 Transport 22% Electrical 2500 2000 1500 Packaging 11% 35% 1000 500 Consumer Goods 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: Brook Hunt Global Markets Research Source: Reuters, IMF; (Monthly data as of end Aug-08) Page 49 September 2008 A User Guide To Commodities Figure 6: Controlling companies in aluminium smelting in 2007 Company name Rio Tinto plc United Company Rusal Alcoa Inc Norsk Hydro ASA BHP Billiton Group State of United Arab Emirates State of Bahrein Glencore International AG State of Venezuela AdityaBirla Group Country UK Russia USA Norway Australia UAE Bahrain Switzerland Venezuela India Controlled production (‘000 tonnes) 4,364 4,178 3,693 1,688 1,372 890 875 765 616 455 % of world 11.6% 11.1% 9.8% 4.5% 3.6% 2.4% 2.3% 2.0% 1.6% 1.2% Source: Raw Materials Group Figure 7: Controlling companies in alumina refining in 2007 Company name Alcoa Inc United Company Rusal State of China Rio Tinto plc Alumina Ltd BHP Billiton Group Companhia Vale do Rio Doce (Vale) Glencore International AG Norsk Hydro ASA State of Venezuela Country USA Russia China UK Australia Australia Brazil Switzerland Norway Venezuela Controlled production (‘000 tonnes) 10,080 9,806 9,675 9,406 5,813 4,551 2,445 2,125 1,944 1,900 % of world 13.1% 12.7% 12.6% 12.2% 7.6% 5.9% 3.2% 2.8% 2.5% 2.5% Source: Raw Materials Group Figure 8: Controlling companies in bauxite mining in 2006 Company name Alcoa Inc Alumina Ltd Rio Tinto plc BHP Billiton Group Alcan Inc Glencore International AG Companhia Vale do Rio Doce State of Guinea Rusal - Russky Aluminii Siberian-Urals Aluminium Company Group Country USA Australia UK Australia Canada Switzerland Brazil Guinea Russia Russia Controlled production (Mn tonnes) 27.6 16.6 16.1 12.0 11.3 8.4 7.3 6.6 6.2 5.5 % of world 16.1% 9.7% 9.4% 7.0% 6.5% 4.9% 4.3% 3.9% 3.6% 3.2% Source: Raw Materials Group Page 50 Global Markets Research September 2008 A User Guide To Commodities Copper History & properties Copper has the symbol Cu and has the atomic number 29. It is reddish in colour and highly electrically conductive. The word copper originates from the Mediterranean island of Cyprus, or Kupros in Greek, where it was originally mined. It is the oldest mined commodity in the world dating back more than 10,000 years. When mixed with tin it becomes bronze and when combined with zinc it produces brass. Major producers & consumers The world’s major copper mine producing countries are Chile, the United States, Peru and Australia. However, Chile accounts for over 35% of world exports. The stateowned Chilean mining company Codelco and US producer Freeport McMoran each control around 10% of the world’s copper production. BHP Billiton, Xstrata and Rio Tinto are the next three largest mining companies followed by Grupo Mexico. The top 10 copper mining companies controlled 58% of copper production in 2007. Along with aluminium and nickel, the copper market is one of the most concentrated in the mining sector. In 2007, China overtook the USA as the largest importer of refined copper. Similarly, copper imports of many other developing economies are rising rapidly as a result of urbanisation and the consequent structural shift in global consumption trends. Major uses Copper is used extensively in electrical applications accounting for about 75% of total copper usage with building construction being the single largest market. Since copper is biostatic, that is bacteria will not grow on its surface, it is also used in airconditioning systems, and as an anti-germ surface in hospitals. In terms of substitutes, aluminium can replace copper’s use in power cables, electrical equipment, automobile radiators and cooling and refrigeration tubes while plastic can substitute for copper in water and drain pipes and plumbing fixtures. Figure 1: The world’s top 10 copper producers, consumers, exporters and importers in 2007 Mine Tonnes % of Refined Tonnes % of Refined Tonnes % of Refined Tonnes % of production Chile USA Peru Australia China Indonesia Russia Canada Zambia Poland (000s) 5,557 1,223 1,190 870 831 773 770 589 544 452 world 36% 8% 8% 6% 5% 5% 5% 4% 4% 3% consumption China USA Germany Japan Korea Italy Russia Taiwan India France (000s) 4,861 2,170 1,392 1,252 857 764 687 603 442 337 world 27% 12% 8% 7% 5% 4% 4% 3% 2% 2% exports Chile Peru Zambia Japan Kazakhstan Canada Australia Russia Poland Belgium (000s) 2,910 512 491 428 357 298 295 275 240 201 world 39% 7% 7% 6% 5% 4% 4% 4% 3% 3% imports China Germany USA Italy China France Korea Thailand Brazil Malaysia (000s) 1496 844 832 746 615 432 419 245 218 196 world 22% 12% 12% 11% 9% 6% 6% 4% 3% 3% World 15,541 World 17,964 Total 7,472 Total 6,936 Source: World Bureau of Metal Statistics, Brook Hunt Global Markets Research Page 51 September 2008 A User Guide To Commodities Figure 2: Refined copper production by country in 2007 Country Tonnes (000s) % of world China 3,497 19% Chile 2,937 Japan USA Figure 3: Identified copper resources Reserves Reserve base Country Tonnes (000s) Tonnes (000s) Chila 140,000 360,000 16% USA 35,000 70,000 1,577 9% Indonesia 35,000 38,000 1,351 8% Peru 30,000 60,000 Poland 30,000 48,000 Russia 962 5% India 719 4% Germany 666 4% Australia 24,000 43,000 S. Korea 584 3% Russia 2,000 30,000 Zambia 522 3% Zambia 19,000 35,000 3% Kazakhstan 14,000 20,000 Other countries 67,000 130,000 Canada 453 World 17,972 Mexico 27,000 40,000 China 26,000 63,000 Source: Brook Hunt Source: US Geological Survey (2007 data) Exchange traded & price conventions Copper is traded on the London Metal Exchange (LME), the COMEX division of the New York Mercantile Exchange (NYMEX) as well as the Shanghai Futures Exchange (SFE). The copper price is quoted in USD per tonne on the LME and US cents per pound on NYMEX. The Bloomberg ticker for the LME 3M copper forward is LMCADS03 <Index>. The Bloomberg ticker for the DB Copper-Optimum Yield total returns and excess returns indices are DBLCYTCU <Index> and DBLCYECU <Index> respectively. LSCA <INDEX> tracks copper inventories on the LME. Figure 4: Copper consumption by first use Figure 5: Copper price since 1957 10000 Copper cash price (USD/tonne) 9000 10% Construction 8000 11% 35% Electronic products 7000 6000 Industrial Machinery Transport 12% 5000 4000 3000 Consumer Products 2000 1000 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 32% Source: Brook Hunt (2007 data) Source: Reuters, IMF; (Monthly data to end-Aug 08) Figure 6: Controlling companies in copper mining in 2007 Company name Freeport McMoran Copper & Gold Inc Corporacion Nacional del Cobre de Chile (Codelco) BHP Billiton Group Xstrata plc Rio Tinto plc Grupo Mexico SA de CV Anglo American plc KGHM Polska Miedz SA Norilsk Nickel Mining & Metallurgical Company Antofagasta plc Country USA Chile Australia Switzerland UK Mexico UK Poland Russia UK Controlled production (‘000 tonnes) 1680 1668 1155 938 801 789 665 460 434 428 % of world 10.9% 10.8% 7.5% 6.1% 5.2% 5.1% 4.3% 3.0% 2.8% 2.8% Source: Raw Materials Group Page 52 Global Markets Research September 2008 A User Guide To Commodities Lead History & properties Lead has the symbol Pb and atomic number 82 and is a bluish-white lustrous metal. The symbol Pb is derived from the Latin word plumbum. The use of lead in pipes also gave rise to the English word for plumber. It is very soft, highly malleable, ductile, but, is a relatively poor conductor of electricity. Lead is very resistant to corrosion, but, tarnishes upon exposure to air. Lead was one of the first metals to be used by man, dating back more than 5,500 years. It is usually found in association with zinc, silver as well as copper ores. Major producers & consumers China and Australia are the world’s major producers as well as refined consumers of lead. Secondary production or recycling is now widely practised and currently accounts for more than 50% of usage worldwide. Major uses The principal use of lead is in the manufacture of batteries, primarily for use in automobiles, motorcycles and electric cars and bicycles. While the metal had been widely used in plumbing and petroleum products, it has more recently been phased out from these uses because of its toxic nature. Exchange traded The only international exchange where lead is traded is the London Metal Exchange (LME). The Bloomberg ticker for the 3M forward price is LMPBDS03 <Index>. The Bloomberg ticker for the DB Lead-Optimum Yield total returns and excess returns indices are DBLCYTPB <Index> and DBLCYEPB <Index> respectively. Figure 1: Lead price since 1957 25000 Figure 2: Lead consumption by first use in 2007 Lead cash price (USD/tonne) Batteries - SLI Replacement 20.77 20000 Batteries - SLI Original Equipment 15000 42.08 10000 Batteries - Traction 12.25 Batteries - Stationary 5000 10.59 0 1957 Non Battery Uses 14.30 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: Reuters, IMF; (Monthly data to end-Aug 08) Source: Brook Hunt Figure 3: The world’s top 10 lead producers, consumers, exporters and importers in 2007 Mine Tonnes production (000s) China 1,205 Australia 605 USA 410 Peru 304 Mexico 125 Canada 78 Sweden 66 Ireland 57 Morocco 46 Poland 43 World % of Refined Tonnes % of Refined Tonnes % of Refined Tonnes % of world 36% 18% 12% 9% 4% 2% 2% 2% 1% 1% consumption China USA Germany S. Korea Spain Italy UK Mexico Japan France (000s) 2,665 1,570 408 340 270 269 239 238 218 216 exports China Australia Canada Peru Germany Belgium Singapore Russia UK Sweden (000s) 244 222 169 120 113 112 74 68 68 60 world 15% 13% 10% 7% 7% 7% 4% 4% 4% 4% imports USA Spain France S. Korea Germany Italy Taiwan Thailand Indonesia Czech Rep. (000s) 257 139 113 112 108 94 78 68 67 65 world 15% 8% 7% 7% 6% 5% 5% 4% 4% 4% World 8,377 Total 1,655 Total 1,716 3,355 world 32% 19% 5% 4% 3% 3% 3% 3% 3% 3% Source: World Bureau of Metal Statistics, Brook Hunt Global Markets Research Page 53 September 2008 A User Guide To Commodities Figure 4: Refined lead production by country Country Tonnes (000s) China 2,896 USA 1,273 Germany 381 Figure 5: Identified lead resources % of world 36% 16% 5% Reserves Reserve base Country Tonnes (000s) Tonnes (000s) Australia 15,000 28,000 China 11,000 36,000 USA 8,100 20,000 Kazakhstan 5,000 7,000 Peru 3,500 4,000 Canada 2,000 9,000 Mexico 1,500 2,000 Morocco 500 1,000 500 1,000 Japan 259 3% South Korea 255 3% Mexico 251 3% UK 244 3% Australia 244 3% Kazakhstan & CIS 231 3% Sw eden Canada 227 3% South Africa 400 700 World 8,083 Other countries 19,000 30,000 Source: Brook Hunt (2007 data) Source: US Geological Survey (2007 data) In recent years, significant lead reserves have been found in association with zinc and/or silver or copper deposits in Australia, Canada, Chile, Ireland, Mexico, Peru, Portugal and the US. Identified lead resources of the world are estimated to total more than 1.5 billion tonnes, according to the US Geological Survey. In terms of substitutes, plastics have reduced the use of lead in building construction, electrical cable covering, cans and containers. Aluminium, iron, plastics and tin compete with lead in other packaging and protective coating. Tin has replaced lead in solder for new or replacement potable water systems in the US. In the electronics industry, there has been a discernible move towards lead-free solders with varying compositions of tin, bismuth, silver and copper. Figure 6: Controlling companies in lead mining in 2007 Company name BHP Billiton Doe Run Co Xstrata plc Teck Cominco Ltd Volcan Cia Minera SA Vedanta Resources plc Zinifex Ltd (Oz Minerals) Industrias Penoles SA de CV Boliden AB Cia de Minas Buenaventura SA Country Australia USA Switzerland Canada Peru UK Australia Mexico Sweden Peru Controlled production (‘000 tonnes) 258.3 230.0 215.2 147.2 114.8 75.0 65.3 59.3 54.2 52.1 % of world 7.2% 6.4% 6.0% 4.1% 3.2% 2.1% 1.8% 1.7% 1.5% 1.5% Source: Raw Materials Group Page 54 Global Markets Research September 2008 A User Guide To Commodities Nickel History & properties Nickel has the symbol Ni and atomic number 28. It is a hard, malleable, ductile metal that has a silvery tinge that can take on a high polish. Nickel occurs in nature principally as oxides, sulphides and silicates. Nickel is primarily used in the production of stainless steel and other corrosion-resistant alloys. Major producers The major nickel producing countries are Russia, Canada, Indonesia and Australia. Ores of nickel are mined in about 20 countries on all continents, and are smelted and/or refined in about 25 countries. Russia, Canada and Norway are the world’s largest nickel exporters accounting for almost 80% of world exports. Major uses The chief use of nickel is in the production of stainless steel accounting for 70% of nickel usage in 2007. Nickel helps to improve the durability and corrosion resistance of steel, making it highly attractive for specialty products and applications exposed to the weather Apart from the steel industry, nickel has uses in the production of other steel and non-ferrous alloys including "super" alloys, often for highly specialized industrial, aerospace and military applications. It is also used in plating and coins. Exchange traded Nickel is traded on the London Metal Exchange (LME) and is quoted in US dollars per tonne. The Bloomberg ticker for the 3M forward is LMNIDS03 <Index>. The Bloomberg ticker for the DB Nickel-Optimum Yield total returns and excess returns indices are DBLCYTNI <Index> and DBLCYENI <Index> respectively. Figure 1: Nickel consumption by first use in 2007 8% Figure 2: Stainless steel consumption by first use in 2007 3% 5% Household and catering 6% Stainless and Alloy Steel 9% 33% Plating Industrial equipment 14% Transport 10% Non-ferrous Alloys Construction Other 70% Welded tubes 17% Foundry 25% Source: CRU Other Source: CRU Figure 3: The world’s top 10 nickel producers, consumers, exporters and importers in 2007 Mine Tonnes production (000s) Russia 288.0 Canada 254.8 Indonesia 188.4 Australia 184.0 N Caledonia 125.2 Columbia 100.5 Philippines 79.5 Cuba 78.4 China 67.5 Brazil 38.4 World % of Refined Tonnes % of Refined Tonnes % of Refined Tonnes % of world 18% 16% 12% 12% 8% 6% 5% 5% 4% 2% consumption China Japan USA Germany Taiwan S. Korea Italy Spain Belgium Sweden (000s) 330.0 169.0 134.6 96.5 69.5 62.5 53.8 44.0 41.1 36.5 world 23% 12% 9% 7% 5% 4% 4% 3% 3% 3% exports Russia Canada Norway Australia Finland UK S. Africa Belgium China Brazil (000s) 244.0 135.3 88.5 71.6 43.3 31.4 20.7 16.7 14.6 13.3 world 36% 20% 13% 11% 6% 5% 3% 2% 2% 2% imports China USA Germany Australia Japan Belgium Taiwan Sweden Spain S. Korea (000s) 107.5 102.0 75.9 70.5 58.6 39.8 29.0 27.0 21.0 19.5 World 1,323 Total 679 Total 551 1600 world 20% 19% 14% 13% 11% 7% 5% 5% 4% 4% Source: World Bureau of Metal Statistics, Brook Hunt Global Markets Research Page 55 September 2008 A User Guide To Commodities Figure 4: Refined nickel production by country Country Tonnes (000s) Russia 272 Figure 5: Identified nickel resources % of world 19% Reserves Reserve base Country Tonnes (000s) Tonnes (000s) Australia 22,000 27,000 Russia 6,600 9,200 China 199 14% Japan 166 12% Canada 163 11% Australia 111 8% Brazil 4,500 8,300 Norway 88 6% New Caledonia 4,400 12,000 Finland 55 4% South Africa 3,700 12,000 Colombia 49 3% Indonesia 3,200 13,000 1,100 7,600 Cuba 5,600 23,000 Canada 4,900 15,000 New Caledonia 45 3% China Cuba 42 3% Philippines 940 5,200 Other countries 5,205 10,710 World 1,431 Source: Brook Hunt (2007 data) Source: US Geological Survey (2007 data) Identified land-based resources averaging 1% nickel or greater contain at least 130 million tonnes of nickel. Around 65-70% of this resource is in laterites and the rest in sulphide deposits. Although sulphide deposits are usually deeper to mine, lateritic deposits contain different quantities of iron, magnesium and silica and must be processed differently which only until very recently was viewed as uneconomical. Indonesia, Australia and New Caledonia combined account for around 60% of global nickel laterite reserves and several new projects are expected to bring new material to the market in the coming years. There are dozens of grades of stainless steel, most of which require high-grade nickel to produce the ideal anti-corrosive base material for a number of commercial applications. Aluminium, coated steels and plastics can replace stainless steel to a limited extent in some construction and transportation applications. Nickel-free speciality steels are sometimes used in place of stainless steels with the power generating, petrochemical and petroleum industries. Titanium alloys or speciality plastics can substitute for nickel metal or nickel-base alloys in highly corrosive chemical environments. Historically, substitutes for nickel would result in increased cost or a trade-off in the performance of the end products. However, a more recent substitution has appeared that has dramatically affected the nickel market. China began importing laterite ores in 2005 in order to produce a low nickel bearing product called pig iron. Although cheaper to produce than primary nickel, pig iron is also labour intensive, energy inefficient and polluting. So far, most pig iron produced has only been suitable for utilisation in the lower grades of stainless steel. It is expected that superior pig iron for use in higher quality stainless will eventually occur. Figure 6: Controlling companies in nickel mining in 2007 Company name Norilsk Nickel Companhia Vale do Rio Doce (Vale) BHP Billiton Group PT Antam Tbk Xstrata plc State of Cuba State of China Anglo American plc Eramet-SLN Sumitomo Metal Mining Co Ltd Country Russia Brazil Australia Indonesia Switzerland Cuba China UK France Japan Controlled production (‘000 tonnes) 278.8 228.1 131.5 110.0 85.2 60.0 55.0 42.8 33.6 31.3 % of world 18.1% 14.8% 8.5% 7.1% 5.5% 3.9% 3.6% 2.8% 2.2% 2.0% Source: Raw Materials Group Page 56 Global Markets Research September 2008 A User Guide To Commodities Tin History & properties Tin has the symbol Sn and atomic number 50. It is silvery-white, lustrous grey metallic element. It is also soft and pliable. The symbol Sn is derived from the Latin word stannum, meaning dripping because the metal melts easily. Tin is one of the earliest metals known to man and because of its hardening effect on copper, it was used in bronze implements as early as 3,500BC. Major producers The principle ore of tin is the mineral cassiterite, the majority of which is found in Indonesia, China and Peru. World resources, principally in West Africa, South East Asia, Australia, Bolivia, Brazil, China and Russia are sufficient to sustain recent annual production rates well into this century. Major uses The main uses of tin are in soldering in the electronics industry and tinplating. It is also commonly used in glass manufacture and super-conducting magnets. Aluminium, glass, paper, plastic or tin-free steels can substitute for tin in cans and containers. Other materials that substitute for tin are epoxy resins for solders, copperbased alloys and plastics for bronze, plastic for bearing metals that contain tin and compounds of lead and sodium for some tin in chemicals. Figure 1: Tin prices since 1957 Figure 2: US tin consumption by finished product Tin cash price (USD/tonne) 25000 12% 20000 2% Solders 8% 39% 15000 Chemicals Tinplate 10000 15% Bronze and brassware Tinning 5000 Others 24% 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: Reuters, IMF; (Monthly data to Aug-08) Source: CRU (2007) Figure 3: The world’s top 10 tin producers, consumers, exporters and importers in 2007 Mine Tonnes % of Refined Tonnes % of Refined Tonnes % of Refined Tonnes % of production China Indonesia Peru Bolivia DRC Brazil Vietnam Russia Malaysia Nigeria (000s) 136.3 102.0 39.0 16.0 12.0 9.6 5.4 5.1 2.8 2.4 world 41% 30% 12% 5% 4% 3% 2% 2% 1% 1% consumption China USA Japan Germany S. Korea Taiwan India France Spain Brazil (000s) 132.2 33.7 34.2 22.7 16.1 12.7 8.1 7.1 7.0 6.0 world 37% 9% 10% 6% 4% 4% 2% 2% 2% 2% exports Indonesia Singapore Peru China Thailand Malaysia Bolivia USA Brazil India (000s) 75.5 50.0 34.8 23.5 18.8 13.5 11.8 8.4 5.6 4.7 world 29% 19% 13% 9% 7% 5% 5% 3% 2% 2% imports Singapore USA Japan Germany S. Korea Taiwan UK Netherlands France Spain (000s) 47.5 34.6 33.5 23.9 16.4 13.7 13.6 7.9 7.7 7.1 world 20% 15% 14% 10% 7% 6% 6% 3% 3% 3% World 335.4 World 358.5 Total 260.9 Total 236.5 Source: World Bureau of Metal Statistics Global Markets Research Page 57 September 2008 A User Guide To Commodities Figure 4: Refined tin production by country Country Tonnes (000s) Figure 5: Identified tin resources % of world Reserves Reserve base Country Tonnes (000s) Tonnes (000s) China 1,700 3,500 China 147 42% Indonesia 78 22% Malaysia 1,000 1,200 USA 38 11% Indonesia 800 900 Peru 36 10% Peru 710 1,000 Malaysia 25 7% Brazil 540 2,500 Bolivia 450 900 Russia 300 350 Thailand 170 200 Australia 145 300 Portugal 70 80 USA 20 40 Other countries 180 200 Thailand 18 5% Bolivia 12 3% Brazil 10 3% Belgium 8 2% Russia 5 1% World 351 Source: World Bureau of Metal Statistics (2007 data) Source: US Geological Survey (2007 data) Exchange traded Tin is traded on the London Metal Exchange (LME) and is quoted in US dollars per tonne. The Bloomberg ticker for the 3M forward is LMSNDS03 <Index>. However, turnover is very illiquid, representing less than 2% of total turnover on the LME in 2005. Figure 6: Controlling companies in tin mining in 2007 Company name PT Timah Tbk Minsur SA Straits Trading Co Ltd State of Bolivia Paranapanema SA Metals X Ltd Glencore International AG State of UK Country Indonesia Peru Singapore Bolivia Brazil Australia Switzerland UK Controlled production (‘000 tonnes) 61.8 39.0 11.3 7.7 6.0 2.0 1.3 1.3 % of world 18.7% 11.8% 3.4% 2.3% 1.8% 0.6% 0.4% 0.4% Source: Raw Materials Group Page 58 Global Markets Research September 2008 A User Guide To Commodities Zinc History & properties Zinc has the symbol Zn and atomic number 30 and is bluish grey in colour. Centuries before zinc was recognised as a distinct element, zinc ores were used for making brass in India and China. Zinc was recognised as a separate metal in Europe in 1546. Englishman William Champion established the first commercial zinc smelter in Bristol in 1747. Zinc is the fourth most common metal in use, behind iron, aluminium and copper in terms of annual production. Major producers Zinc ores are mined in more than fifty countries with Canada and Australia being the leading exporters. China dominates zinc refining, commanding one third of global production in 2007. Zinc has several substitutes since aluminium, steel and plastics substitute for galvanised steel. Plastic coating, paint, cadmium and aluminium alloy coating can also replace zinc for corrosion protection. Unlike nickel and copper, the share of zinc production in the hands of the top 10 mining companies is less than 50%. Major uses Roughly 55% of all metallic zinc produced today is used to galvanise other metals such as steel or iron to prevent corrosion. Large quantities of zinc are used to produce die castings, which are used extensively by the automotive, electrical and hardware industries. Zinc is also used as a chemical compound in rubber, ceramics, paints and agriculture. Figure 1: Zinc price since 1957 5000 Figure 2: Zinc demand by first use in 2007 Zinc cash price (USD/tonne) 15% 4500 Construction 4000 3500 7% Transport 3000 2500 Industrial Machinery 49% 2000 18% 1500 Consumer Products 1000 Infrastructure 500 0 1957 11% 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: Reuters, IMF; (Monthly data to Aug-08) Source: Brook Hunt Figure 3: The world’s top 10 zinc producers, consumers, exporters and importers in 2007 Mine Tonnes % of Refined Tonnes % of Refined Tonnes % of Refined Tonnes % of production China Australia Peru USA Canada India Kazakhstan Mexico Ireland Namibia (000s) 3,163 1,412 1,395 756 618 533 450 435 401 223 world 28% 13% 13% 7% 6% 5% 4% 4% 4% 2% consumption China USA Japan Germany India Korea Italy Belgium Spain France (000s) 3,531 1,097 599 559 469 554 348 332 244 295 world 31% 10% 5% 5% 4% 5% 3% 3% 2% 3% exports Canada Australia Netherlands China Finland Korea Spain Mexico Namibia Norway (000s) 614 404 301 276 260 257 220 197 152 131 world 22% 14% 11% 10% 9% 9% 8% 7% 5% 5% imports USA Italy Germany Netherlands Taiwan Belgium France China UK Malaysia (000s) 758 315 315 286 229 210 165 149 135 114 world 28% 12% 12% 11% 9% 8% 6% 6% 5% 4% World 11,115 World 11,495 Total 2,812 Total 2,676 Source: World Bureau of Metal Statistics, Brook Hunt Global Markets Research Page 59 September 2008 A User Guide To Commodities Figure 4: Refined zinc production by country in 2007 Country Tonnes (000s) Figure 5: Identified zinc resources Reserves Reserve base Country Tonnes (000s) Tonnes (000s) % of world China 3,714 33% Canada 802 7% China 33,000 92,000 Australia 33,000 80,000 USA 30,000 90,000 Kazakhstan 30,000 35,000 South Korea 708 6% Japan 610 5% Australia 506 5% Spain 494 4% India 448 4% Peru 16,000 20,000 Kazakhstan 340 3% Canada 11,000 31,000 Mexico 8,000 25,000 Other countries 59,000 87,000 Mexico 331 3% Finland 307 3% World 11,238 Source: International Lead and Zinc Study Group Source: US Geological Survey (2007 data) Exchange traded Zinc is traded on the London Metal Exchange (LME) and is quoted in US dollars per tonne. The Bloomberg ticker for the 3M forward is LMZSDS03 <Index>. It is the third most liquid contract on the LME, after aluminium and copper. The Bloomberg ticker for the DB Zinc-Optimum Yield total returns and excess returns indices are DBLCYTZN <Index> and DBLCYEZN <Index> respectively. Figure 6: Controlling companies in zinc mining in 2007 Company name Country Controlled production (‘000 tonnes) % of world Xstrata plc Switzerland 840.0 7.5% Teck Cominco Ltd Canada 705.5 6.3% Zinifex Ltd (Oz Minerals) Australia 621.6 5.6% Glencore International AG Switzerland 539.7 4.8% Vedanta Resources plc UK 535.0 4.8% Volcan Cia Minera SA Peru 345.5 3.1% Anglo American plc UK 335.7 3.0% Boliden AB Sweden 319.4 2.9% Votorantim, SA Industrias Brazil 180.0 1.6% Industrias Penoles SA de CV Mexico 179.8 1.6% Source: Raw Materials Group Page 60 Global Markets Research September 2008 A User Guide To Commodities Iron Ore History & properties Iron has the symbol Fe and is one of the most abundant of all metals in the Earth’s crust. It exists naturally in chemical combination with oxygen (or iron oxide) and concentrations of iron oxide in the earth’s crust are known as iron ore. Ideally, iron ore contains only iron and oxygen, but contaminants such as silica, phosphorus, aluminium and sulphur are often present in varying concentrations. Iron ore is the primary raw material input into iron and steel production, thus one of the most consumed commodities on the market. Taken literally, iron ore refers to the actual rocks from which metallic iron is extracted, which are generally a rusty red colour as a result of oxidization. Around 85% of global production is obtained from open pit mines with the rest coming from underground mines. Depending on the ore quality (iron content), iron ore is either crushed into manageable sized rock or ground and treated to remove some of the impurities such as silicon, phosphorus, aluminium, and/or sulphur as well as impregnations of waste rock. The output comes in various forms of different sizes or strengths (lump, fines, sinter or pellets) which are then sold to steel makers for use as feed in blast furnaces. Major producers By volume, the global iron ore market towers over other metals. In 2007, total global production of iron ore was 2,220 million tonnes while the combined out put of the six LME metals was 77.3 million tonnes. Approximately 60% of the two billion tonnes of iron ore produced globally is used domestically, with the remaining amount shipped long distances. Although China is technically the largest producer of iron ore, most production is used domestically. The global market is dominated by two countries: Brazil (335Mt in 2007) and Australia (294Mt in 2007). Combined the three largest producing companies Vale, BHP Billiton and Rio Tinto, supply 70% of the world’s iron ore exports. Major uses Almost all iron ore mined (98%) is used for steelmaking. Other than the iron content and impurities, iron ore consists mainly of oxygen. In order to remove the oxygen, the ore is placed in a blast furnace at high temperatures and mixed with a carbon element in the form of coke, which “reduces” the iron or strips the oxygen off the iron forming carbon dioxide as a result. The result is a molten metal when cooled becomes pig iron. By itself, raw iron can be brittle because of its high carbon content and thus not strong and hard enough for construction and other applications. Therefore raw iron is alloyed with various other elements such as nickel, chromium, manganese, vanadium and tungsten to make steel. Other than steel making, iron ore is also used in production of metallurgy products, magnets, auto parts, chemical catalysts and paints. Figure 1: Major exporters and importers of iron ore in 2007 Exporters Brazil Australia India S. Africa Canada Russia Ukraine Sweden Kazakhstan Mauritania Total Tonnes (miillon) 270 265 100 30 29 26 21 19 16 12 834.0 % of world 32% 32% 12% 4% 4% 3% 3% 2% 2% 1% Importers China Japan S. Korea Germany France UK Taiwan Italy Netherlands Belgium/Luxembourg Total Tonnes (Million) 383.6 138.9 44.3 44.1 20.7 16.7 16.0 17.2 12.5 9.5 % of world 46% 17% 5% 5% 3% 2% 2% 2% 2% 1% 834.1 Source: AME Global Markets Research Page 61 A User Guide To Commodities Figure 2: Iron ore prices lag steel prices 1400 USD/ t 1200 US HRC 140 Japan HRC 120 China HRC 1000 80 600 60 400 40 200 20 0 Sep-86 Mar-92 Sep-97 Feb-03 2500 0 A ug-08 Source: CRU, DB Global Markets Research, (Data to 10-Aug-08) Apparent demand for iron ore Equivalent world production 2000 100 I 800 Figure 3: Global iron ore demand & production Tonnes (million) September 2008 1500 1000 500 2000 2001 2002 2003 2004 2005 2006 2007 2008E 2009E 2010E Source: AME, IISI, DB Global Markets Research Pricing Around 90-95% of all iron ore is procured on a contractual basis on a Japanese financial year basis, based on annual negotiations between producers and steel makers. A spot market does exist and third party industry consultants provide weekly indications of those levels. More recently, there has been an OTC swap market emerging with some banks, including Deutsche Bank, able to offer contracts with tenors up to 12 months. The spot reference price for Deutsche Bank's Index is an average of the indices reported by Metal Bulletin and Steel Business Briefing. They are quoted in US dollars per tonne on a cost and freight difference (CFR) which incorporates adjustment for iron content and moisture levels. As a consequence of the variance in iron ore qualities and products, each has different properties and preferences among consumers. Thus prices are based on each region’s largest volume brand and there is not one global benchmark price. The following outlines the primary regions from which prices are settled. • Mount Newman/Hamersley (lump and fines): Iron ore form the Pilbara region in Western Australia. • Yandi (fines): Also from the Pilbara, but contains a higher phosphorous content and lower iron and is generally priced around a 6% discount to Hamersley. • Carajas (fines and lump): Material from a high quality deposit in the eastern part of the Amazon Cratone and sent via a 900km railway to Ponta da Madeira sea terminal. • Itabira (fines): Iron ore from rich reserve in central southeast Brazil. • Tubarão (pellets): Vale’s benchmark pellet price referring to material shipped from this port in southern Brazil. Figure 4: Controlling companies in iron ore mining in 2006 Company name Companhia Vale do Rio Doce (Vale) Rio Tinto plc BHP Billiton Group State of China Metalloinvest Management Company Anglo American plc Cleveland Cliffs Inc Mitsui & Co Ltd Steel Authority of India Ltd National Mineral Development Corp Ltd Country Brazil UK Australia China Russia UK USA Japan India India Controlled production (Mn tonnes) 271.1 129.8 115.2 60.5 38.1 32.5 29.9 27.6 24.5 23.7 % of world 18.1% 8.7% 7.7% 4.0% 2.5% 2.2% 2.0% 1.8% 1.6% 1.6% Source: Raw Materials Group Page 62 Global Markets Research September 2008 A User Guide To Commodities Ferro Chrome History & properties Ferrochrome (FeCr) is an alloy of iron and chrome containing between 50% to 65% chrome. Ferrochrome is produced from chromium ore (chromite) by subjecting it to a chemical reaction with coke and coal under high temperatures. As an element that helps makes stainless steel corrosion resistant, ferrochrome is primarily used in the production of steel products. Major producers The main source of ferrochrome is chromite, which is an iron-magnesium-chromium oxide ore. It is a reasonably abundant ore with known deposits equating to 384 years of production at 2006 production rates. According to the USGS more than 95% of world’s chromite production in 2006 was smelted in electric-arc furnaces to produce ferrochromium for the metallurgical industry. In 2006, South Africa, India and Kazakhstan accounted for 74% of chromite production and in the same year, South Africa, Kazakhstan and China accounted for 71% of ferrochrome production. Ferrochrome production from chromite is very energy intensive process, requiring around 4kWhr per kg of material. Although there are many different grades of ferrochrome produced and used globally, they can be broadly grouped into three types: Low/medium carbon, high carbon and charge chrome. Production share of low and medium carbon ferrochrome have remained at around 10% over the last decade, but high carbon ferrochrome has been increasing its share gradually by around five percentage points, at the expense of charge chrome. Charge chrome is the newest of the three products and it is the primary feed for modern stainless steel plants. Major uses Around 68% is used in stainless steel and 27% is consumed as an in alloy steel. A typical tonne of stainless steel might contain 18% chrome, 8% nickel and 1% molybdenum. Exchange traded & price conventions Ferrochrome is not traded on any exchange. Metals Bulletin provide price data with the Bloomberg ticker is MBCMCM02 <Index>. Figure 1: Production of ferro-chrome & chromite by country Country Ferro-chrom e % of w orld Country production (Mt) Chrom ite Figure 2: Chrome consumption by first use in 2007 1% % of w orld 3% production (Mt) South Africa 3.03 41.0% South Africa 7.42 37.6% Kazakhstan 1.20 16.2% India 3.60 18.2% China 1.00 13.5% Kazakhstan 3.60 18.2% India 0.63 8.6% Turkey 1.06 5.4% Russia 0.60 8.1% Russia 0.97 4.9% Finland 0.24 3.3% Brazil 0.62 3.1% Brazil 0.20 2.7% Zimbabw e 0.60 3.0% Zimbabw e 0.20 2.7% Finland 0.55 2.8% Sw eden 0.14 1.8% Australia 0.25 1.3% Turkey 0.07 0.9% Iran 0.25 1.1% Albania 0.04 0.5% China 0.20 1.0% World 7.39 World 19.75 Source: USGS (2006 data) Global Markets Research 1% Stainless Steel 27% Alloy Steel Foundries & Castings Nickel Alloys 68% Others Source: Heinz Pariser Page 63 September 2008 A User Guide To Commodities Metallurgical Coal History & properties Coal is classified according to its carbon, ash, sulphur and water content. Anthracite, also referred to as metallurgical coal, has the highest carbon content with the lowest amount of moisture and hence has the highest energy content of all coals. It is used in high-grade steel production. Bituminous is sub-divided into thermal and metallurgical coal. It is used for both electricity generation and for making coke. Major uses Metallurgical coal, also referred to as hard or coking coal, is essential for iron and steel production. Most iron in steel is produced in blast furnaces which use iron ore, coke (made from metallurgical coal) and small quantities of other raw materials. The coking coals need to be higher quality that is of lower sulphur and phosphorous content. As a result, they are more expensive than thermal coal used for electricity generation. Coking coal is first crushed and washed, then ‘purified’ or ‘carbonised’ in a series of coke ovens, known as batteries. During this process, by-products are removed and coke is produced. Major producers Australia dominates in terms of both production and exports of metallurgical coal. The next major producers are the US, Canada and Russia. Figure 1: International metallurgical supply & demand in 2007 Production Australia USA Canada Russia Indonesia China Czech Republic New Zealand Poland Colombia Total Tonnes % of (Mn) 134.0 28.5 24.8 16.5 7.0 4.5 4.0 2.8 2.8 2.5 235.6 world 56.9% 12.1% 10.5% 7.0% 3.0% 1.9% 1.7% 1.2% 1.2% 1.1% Importers Japan India S. Korea Brazil Germany Ukraine Taiwan France UK Italy Total Tonnes % of (Mn) 63.3 23.3 21.2 14.8 10.5 10.0 8.6 8.0 7.4 7.1 238.4 world 26.6% 9.8% 8.9% 6.2% 4.4% 4.2% 3.6% 3.4% 3.1% 3.0% Source: AME Pricing There are no exchange traded mechanisms for metallurgical coal. Around 90-95% of all metallurgical coal is procured on an annual contractual basis between coal producers and steel makers and priced for the Japanese financial year, which runs from April to March. Figure 2: Metallurgical benchmark prices coal annual Figure 3: China became a net exporter of steel in 2005 7.0 350 Hard coking coal benchmark (USD/tonne) Mt 6.0 300 5.0 4.0 250 3.0 200 2.0 150 1.0 Net Exports 0.0 100 Net Im ports -1.0 -2.0 50 -3.0 2000 0 1972 1976 1980 1984 1988 Source: AME (data as of Q1 2008) Page 64 1992 1996 2000 2004 2001 2002 2003 2004 2005 2006 2007 2008 2008 Source: Reuters Global Markets Research September 2008 A User Guide To Commodities Steel History & properties Steel is a metal alloy made up primarily of iron with small amounts of carbon. An ironnickel alloy obtained from meteorites was first used in Egypt to form weapons and ornaments around 4,000BC. Beginning around 3,000BC, smelted iron was used in Anatolia, Egypt and Mesopotamia to fashion ornamental weapons. The widespread adoption of iron, however, did not occur until approximately 1,000BC in Greece, Mesopotamia, and central Europe. Around 200BC in China and India, steel was being produced by melting together wrought iron and cast iron or charcoal. The first European blast furnaces for smelting were built in Sweden between 1150 and 1350. The modern mass-production of steel was made possible by Henry Bessemer in 1855 and Sir William Siemens in 1867. The addition of varying amounts of carbon allows for greater hardness and strength, but also results in increased brittleness. Steel typically contains between 0.2% and 2.1% carbon by weight; higher carbon content alloys are referred to as cast iron, and lower carbon content alloys are called wrought iron. Iron is typically found in the form of iron oxide or iron pyrite. Extraction of iron from iron oxide is performed through a process called smelting whereby the ore is heated to a liquid state and the oxygen removed as it bonds with carbon. Following this, the iron is reprocessed to remove excess carbon. By itself, raw iron can be brittle because of its high carbon content and thus not strong and hard enough for construction and other applications. Therefore raw iron is alloyed with various other elements such as nickel, chromium, manganese, vanadium and tungsten to make steel. Major producers The largest steel-producing country is China. In 2007 production reached 489 million tonnes, or 36% of global production. China and India also represent the largest areas of production growth with output rising 15.3% and 19.3% respectively in 2007. Major uses Steel is one of the most versatile and common industrial materials. The construction industry is the largest market, utilizing steel in modular building systems, bridge and highway construction, harbours, tunnels and culverts. In automobile manufacturing, steel accounts for more than 50% of the weight of a typical car in the form of the car body, engine, gearbox and transmission. Additional transport uses include the construction of commuter trains, rail tracks, buses, trucks, ships, aircraft and jet engines. In the power and energy industries, steel is used in the construction of oil and gas wells, offshore oil platforms, pipelines, and turbines for power generation. Figure 1: Major producers of steel in 2007 Tonnes % of Companies (Mn) world ArcelorMittal 116.4 9.1% China 489.2 Nippon Steel 35.7 2.8% Japan 120.2 8.9% JFE 34.0 2.6% USA 98.2 7.3% POSCO 31.1 2.4% Russia 72.2 5.4% Baosteel 28.6 2.2% India 53.1 3.9% Tata Steel 26.5 2.1% S. Korea 51.4 3.8% Anshan-Benxi 23.6 1.8% Germany 48.6 3.6% Jiangsu Shagang 22.9 1.8% Ukraine 42.8 3.2% Tangshan 22.8 1.8% Brazil 33.8 2.5% US Steel 21.5 1.7% Italy 32.0 2.4% Total 1285 Countries Total Tonnes % of (Mn) world 36.4% 1344 Source: International Iron and Steel Institute Global Markets Research Page 65 September 2008 A User Guide To Commodities Steel is delivered to the market in a number of ways, divided into two categories, finished products and semi-finished products. Finished Products – Plates (construction, ship-building) – Flat rolled (appliances, external automotive panels, food containers / cans) – Long products: Wire rod, merchant bar, strural beam products, rebar (transportation, construction) Semi-finished Products – further processed into finished products such as rebar (billets and blooms) or plates (slab) Exchange traded Historically there have been no exchange traded mechanisms for steel as prices were negotiated between producers and consumers on a regional basis. The market has traditionally relied on price indicators from industry consultants such as CRU who compile indices from a weighted basket of steel prices by product and region. However, the market is gradually becoming more sophisticated with the London Metal Exchange (LME) launching a steel contract (billet) in 2008 in two regions – Far East and Mediterranean delivery. Lot sizes are 65 metric tonnes with delivery points in Inchon, South Korea and Johor, Malaysia (Far Eastern) and Marmara, Turkey and Dubai, UAE (Mediterranean). The maturity is initially limited to 15 months. Figure 2: China dominates steel consumption growth Mature economies Emerging markets ex-China China Mature economies as a % of World China as a % of world 2000 1500 Figure 3: Hot rolled coil (HRC) prices by region 1400 50% US HRC USD/t Japan HRC 1200 China HRC 40% 30% 1000 1000 800 600 20% 500 10% 0 0% 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 Source: IISI, AME, DB Global Markets Research Page 66 400 200 0 2003 2004 2005 2006 2007 2008 Source: CRU (data up to Feb-08) Global Markets Research September 2008 A User Guide To Commodities Minor Metals Introduction Minor metals are generally defined as industrial metals which due to their small market size and light trading volumes are not listed on major public metals exchanges like the London Metals Exchange or the New York Mercantile Exchange. Most minor metals are by-products, and in some cases by-products of by-products of non-ferrous metals. Minor metals prices are therefore sensitive to the same economic cycles as industrial metals prices. However, with in come cases minor metal production levels less than 5% of industrial metals production these smaller markets can be more susceptible to price spikes in environments of strengthening demand. Minor metals have varied uses ranging from fuel efficient components in aircraft engines, rechargeable batteries, television screens to nuclear reactors and missiles. These high-tech uses combined with limited supply and few sources can make many of the minor metals strategically important commodities. The Minor Metals Trade Association (MMTA) founded in 1973 facilitates trading in minor metals by bringing together producers and consumers, who generally enter into long or short term contracts based on the contract specifications provided by MMTA. MMTA has defined strict specifications for all the different impurities, sizing and packing, warehousing and transportation for most minor metals. Figure 1: Minor metals production in 2007 compared 10 Tonnes (million) Non-exchange traded commodities Manganese: 11,600,000 Ferrochrome: 7,396,690 Titanium: 6,100,000 Magnesium: 670,000 Molybdenum: 187,000 Rare Earths: 124,000 Tungsten: 89,600 Cobalt: 62,300 Vanadium: 58,600 Lithium: 25,000 Thorium: 6,500 Tantalum: 1,400 Gallium: 80 Rhenium: 50 12 8 6 4 2 Figure 2: Commodity price performance since 2001 Exchange traded commodities 1400% % change since end 2001 1200% 1000% 800% 600% 400% 200% 0% Rhenium Gallium Tantalum Thorium Lithium Vanadium Cobalt Tungsten Rare Earths Molybdenum Magnesium Titanium Ferro Chrome Manganese Aluminium Zinc Gold Silver Nickel Lead Tin Copper Titanium Magnesium Cobalt 99.6% Tungsten Manganese Ferrochrome Cadmium 99.5% Global Markets Research Vanadium Source: US Geological Survey Molybdenum 0 Source: Reuters, DB Global Markets Research; Data as of end Aug-08 Page 67 September 2008 A User Guide To Commodities Cobalt History & properties Cobalt has the symbol Co and atomic number 27. In its pure form, it is a silvery-blue, hard, brittle metal and is often produced as a by-product of copper or nickel mining. The word cobalt is derived from the German “Kobold,” the name of a mischievous goblin in German mythology. When yields declined in silver mines across Saxony in th the 16 Century, Kobold was blamed for stealing the silver and leaving behind worthless rock. This rock was later found to be cobalt ore, and the name transferred to cobalt metal. However, it was the Swedish chemist George Brandt who first isolated cobalt in 1735, and showed that it was the cause of the blue colour in glass. Cobalt has a high melting point (1,493°C) and retains strength at a high temperature. It is ferromagnetic and retains its magnetism up to 1,100°C, which is a higher temperature (Curie point) than any other material. It is stable in air and water, has low toxicity, but is a possible carcinogen. As the main component of the vitamin B-12, it is an essential trace element for humans. Major producers Cobalt production is mainly derived as a by-product of the mining and processing of copper and nickel ores, but advances in hydrometallurgical extraction techniques and higher prices have seen the development of more primary cobalt projects. The main sources of ores are founds in the copper-cobalt deposits in the Democratic Republic of Congo and Zambia, the nickel sulphide ore bodies in Australia, Canada, Finland and Russia, the nickel oxide ore bodies in Cuba, New Caledonia, Australia and Russia and primary recovery from mixed ores, tailings and slag in Congo and Zambia. Major uses Cobalt as a pure metal has few applications, but it is used as an alloying constituent or as a chemical compound in a wide range of commercial applications. The largest contemporary uses of cobalt are in rechargeable batteries and superalloys for jet turbine parts. When used as an alloying element, cobalt allows use of elevated temperatures and it is more resistant to corrosion by sulphur than nickel. The metal is used in electroplating because of its appearance, hardness, and resistance to oxidation. Cobalt’s melting point makes it attractive for high-speed alloys for cutting tools. The metal’s ferromagnetic properties make it an important constituent of permanent magnets. Both the British Geological Survey and the USGS forecast that the increase in demand for cobalt in rechargeable batteries may decline as cobalt is substituted in lithium-ion cells by cheaper metals like manganese and nickel. Figure 1: Major producers and reserves of cobalt Mine production 2007 (tonnes) % of world Reserves (tonnes) Reserve base (tonnes) USA - - 33,000 860,000 Congo 22,500 36% 3,400,000 470,000 Canada 8,000 13% 120,000 350,000 Australia 7,500 12% 1,400,000 1,700,000 Zambia 7,000 11% 270,000 680,000 Russia 5,000 8% 250,000 350,000 Cuba 4,000 6% 1,000,000 1,800,000 China 2,300 4% 72,000 4,700,000 North Caledonia 2,000 3% 230,000 860,000 Morocco 1,500 2% 20,000 NA Other countries 1,300 2% 130,000 1,100,000 Brazil 1,200 2% 29,000 40,000 World 62,300 7,000,000 13,000,000 Source: USGS Page 68 Global Markets Research September 2008 A User Guide To Commodities Figure 2: Cobalt price since 1993 55 Figure 3: Composition of cobalt demand by use in 2007 USD/lb Superalloys 7% 50 22% 8% Batteries 45 Hardmetals 40 9% 35 Catalysts 30 Other 25 10% 20 22% 15 Tyre adhesives/soaps/driers 11% 10 Pigments 11% Magnets 5 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 Source: Reuters (Data to end 2007) Source: Cobalt Development Institute Exchange traded & price conventions Cobalt is not traded on any futures market. Cobalt is priced on the Shanghai Changjiang non-ferrous spot market. Its Bloomberg ticker is CCSMCOBL <Index>. The price convention in Shanghai Changjiang market is Chinese yuan per tonne. The Reuters code is COB-CATH-LON and is priced in USD per pound. Figure 4: Controlling companies in cobalt mining in 2006 Company name Companhia Vale do Rio Doce (Vale) Norilsk Nickel Mining & Metallurgical Company Glencore International AG State of Cuba Vedanta Resources plc Xstrata plc Sherritt International Corp Copperbelt Development Foundation Votorantim, SA Industrias Eramet-SLN Country Brazil Russia Switzerland Cuba UK Switzerland Canada Luxembourg Brazil France Controlled production (Tonnes, ‘000s) 5.0 4.4 4.1 2.8 1.8 1.6 1.3 1.0 0.9 0.9 % of world 9.3% 8.2% 7.6% 5.1% 3.3% 2.9% 2.3% 1.8% 1.7% 1.7% Source: Raw Materials Group Global Markets Research Page 69 September 2008 A User Guide To Commodities Gallium History & properties Gallium is silver in colour and brittle in solid form, but liquefies just above room temperature. It is found as a trace element in coal, bauxite and other minerals. Gallium is used in semiconductor technology and as a component of various lowmelting alloys. Its symbol and atomic number are Ga and 31 respectively. Its melting o point is 29.78 C. Major producers Gallium occurs in very small concentrations in ores of other metals. Most gallium is produced as a by-product of treating bauxite, and the remainder is produced from zinc-processing residues. Only part of the gallium present in bauxite and zinc ores is recoverable, and the factors controlling the recovery are proprietary. Therefore, an estimate of current reserves that is comparable to the definition of reserves of other minerals cannot be made. The world bauxite reserve base is so large that much of it will not be mined for many decades; hence, most of the gallium in the bauxite reserve base cannot be considered to be readily available in the short term. In 2007, the USGS estimated the world primary production amounted to approximately 80 tonnes, little changed from the previous year. China, Germany, Japan and the Ukraine are the leading producers with smaller production occurring in Hungary, Kazakhstan, Russia and Slovakia. Refined gallium production in 2007 is estimated to be about 103 tonnes including some scrap refining. China, Japan, and the United States are the principal producers of refined gallium. World primary gallium production capacity in 2007 was estimated to be 184 tonnes with refinery capacity of 167 tonnes and recycling capacity of 78 tonnes. Major uses Gallium arsenide (GaAs) and gallium nitride (GaN) electronic components represented about 98% of gallium consumption in the United States. About 66% of the gallium consumed was used in integrated circuits (ICs) in defence applications, highperformance computers, and telecommunications. Optoelectronic devices, which include light-emitting diodes (LEDs), laser diodes, photodetectors, and solar cells, represented 20% of gallium demand. The remaining 14% was used in research and development, specialty alloys, and other applications. Optoelectronic devices were used in areas such as aerospace, consumer goods, industrial equipment, medical equipment, and telecommunications. Exchange traded & price conventions Gallium is not traded on any exchange. Spot prices are available from the Minor Metals Trade Association. The Reuters RIC for Gallium Ingots is GALL-ING-LON. Figure 1: Gallium prices since 1993 1800 Figure 2: Composition of gallium demand by use in 2007 Gallium price (USD/Kg) 1600 14% Integerated Circuits 1400 1200 1000 800 20% Optoelectronic devices 600 66% 400 Research and development 200 0 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 Source: Bloomberg (data as of end Aug-08) Page 70 Source: USGS Global Markets Research September 2008 A User Guide To Commodities Lithium History & properties Lithium is a soft alkali metal with a silver white colour. Its symbol is Li, atomic number is 3 and melting point is 180.54oC. Lithium is the lightest metal and least dense solid element under standard conditions. It is highly reactive and corrodes quickly in the moist air to form a black tarnish. It is therefore typically stored under the cover of oil. Lithium’s main source is of petalite (lithium aluminium silicate) and spodumene. On a commercial scale, lithium metal is isolated electrolytically from a mixture of lithium chloride and potassium chloride. Its major application is in making batteries, in metallurgy, in ceramic, glass industry, pharmaceutical industry, aeronautics and has use in several other industries. Major producers In 2007, Chile was the leading lithium chemical producer in the world, followed by Australia, Argentina and China. Figure 1: Major producers of lithium Producers 2007 (tonnes) % of world Reserves tonnes) Reserves base (tonnes) Chile 9,400 38% 3,000,000 3,000,000 Australia 5,500 22% 160,000 260,000 Argentina 3,000 12% NA NA China 3,000 12% 540,000 1,100,000 Russia 2,200 9% NA NA Canada 710 3% 180,000 360,000 Zimbabwe 600 2% 23,000 27,000 Portugal 320 1% NA NA Brazil 240 1% 190,000 910,000 USA W* W* 38,000 410,000 Bolivia - - - 5,400,000 World 25,000 4,100,000 11,000,000 *W: withheld to avoid disclosing company proprietary data; Source: USGS Major uses Lithium has a strong presence in the consumer electronic and telecommunication products, with its use in batteries expanding rapidly in recent years because rechargeable lithium batteries are increasingly being used in portable devices (laptops, mobile phones) and electric vehicles. About 20% is used in lithium-ion batteries, nearly 22% is used in glass and ceramic industry with another 17% of lithium used in lubricating greases. The Bloomberg ticker for lithium is MBLILI02 <Index>. Figure 2: Lithium uses in 2007 Figure 3: Top 10 companies in lithium mining Company Ceramics and glass 20% 21% Batteries Lubricating greases 6% Pharmaceuticals and polymers 20% 8% Air conditioning Primary aluminum production 9% Other uses 16% Source: USGS Global Markets Research Country Controlled % of production (000s tonnes) world Sons of Gw alia Ltd Australia 6 25% GEA Group AG Germany 5 19% FMC Corporation USA 3 13% Potash Corporation Canada 2 8% Yara International Norw ay 2 8% Cabot Corporation USA 1 3% Israel Chemicals Ltd Israel 1 3% Africa Resources Ltd Zimbabw e 1 2% Cia Brasileira de Litio Brazil 0 1% Sdada Mineira de Pegmatites Portugal 0 1% Source: Raw Materials Group (2007 data) Page 71 September 2008 A User Guide To Commodities Magnesium History & properties Magnesium constitutes about 2% of the Earth’s crust and is the eighth most abundant element in the world after hydrogen, helium, oxygen, neon, nitrogen, carbon and silicon. Magnesium and magnesium compounds are also produced from seawater, well and lake brines and bitterns. It is a relatively strong but lightweight metal of silvery white colour. Magnesium is a highly flammable substance most easily ignited when powdered or shaved into thin strips. Magnesite deposits were discovered in Austria and Greece during the latter half of the 19th century, and by 1890, magnesite was in general use in Europe for refractory linings in Bessemer and open-hearth furnaces. Because of its bright flash point, it was used in the early days of photography and currently used in fireworks and marine flares. Major producers Magnesium production has traditionally been concentrated in North America. The first magnesium plant in the United States was constructed by General Electric at Schenectady, New York in 1914. Magnesium production in the United States increased steadily through the decades, peaking during World War II because of the use of magnesium in incendiary bombs. By the mid-1990s, around half of world production originated in the US. Since then China has become the dominate producer. Magnesium production in China increased from 75Kt in 1996 to 534Kt by 2006. However, anti-dumping duties established in the United States have essentially eliminated China from the United States market, which leaves Canada, Israel, and Russia as the principal United States suppliers. Moreover with the closure of Norsk Hydro’s plant in Canada in the first quarter of 2007, a significant source of magnesium has been removed from the market. Major uses Aluminium alloying was the principal use for primary magnesium, accounting for 43% of total demand in 2006. Aluminium-magnesium alloys have improved ductility, enhanced resistance to saltwater corrosion, and are used in beverage cans, automobiles and machinery. Other major uses include die-casting and iron and steel desulphurisation. Exchange traded & price conventions Magnesium is not traded on a futures market. However, it is quoted on the Shanghai Changjiang non-ferrous spot market. Its Bloomberg ticker is CCSMMGIN <Index>. The price convention in Shanghai Changjiang market is Chinese Yuan per tonne. The Reuters code is MGN-CHINA and is priced in US dollars per tonne. Figure 1: Magnesium price since 2002 7000 Figure 2: Composition of magnesium demand in 2007 10% USD/tonne Aluminium alloying 6000 10% 5000 43% Die-casting 4000 Others 3000 2000 Steel desulphurization 37% 1000 2002 2003 2004 Source: Reuters (Data as of end 2007) Page 72 2005 2006 2007 Source: USGS Global Markets Research September 2008 A User Guide To Commodities Manganese History & properties A grey-white metal that resembles iron, manganese is hard and brittle, fusible with difficulty, but easily oxidised. Manganese is the twelfth most abundant element in the earth’s crust. Nevertheless it is rarely found in concentrations high enough to form a manganese ore deposit. It is designated by the symbol Mn and has an atomic number of 25. Manganese metal and its common ions are paramagnetic, meaning that while manganese metal does not form a permanent magnet, it does exhibit strong magnetic properties in the presence of an external magnetic field. The first utilization of manganese can be traced back to the Stone Age. Humans were already using manganese dioxide as a pigment for their cave paintings during the upper paleolithic period, 17.000 years ago. Later in Ancient Greece, the presence of manganese in the iron ore used by the Spartans is a likely explanation as to why their steel weapons were superior to those of their enemies. Manganese has also long been related to glass-making. The Egyptians and the Romans used manganese ore either to decolorize glass or to give it pink, purple and black tints. It has been continually used for this purpose until modern times. In the mid-17th century, the German chemist Glauber obtained permanganate, the first usable manganese salt. Nearly a century later, manganese oxide became the basis for the manufacture of chlorine. Yet manganese was only recognized as an element in 1771, by the Swedish chemist Scheele. It was isolated in 1774 by one of his collaborators, J.G. Gahn. At the beginning of the 19th century, both British and French scientists began considering the use of manganese in steelmaking, with patents granted in the U.K. in 1799 and 1808. In 1816, a German researcher observed that manganese increased the hardness of iron, without reducing its malleability or toughness. Major producers Manganese reserves are concentrated in Australia, Brazil, Gabon and South Africa, supplying over 90% of the international market. Manganese ore deposits are widely distributed in China, but they lack high grade ore and mines are generally situated far from the end-user industries. As a consequence, China imports high grade ores to blend with domestic material. Figure 1: Major producers of manganese Mine production 2007e (Tonnes, 000s) % of world Reserves (Tonnes, 000s) Reserve base (Tonnes, 000s) S. Africa 2,300 20% 100,000 4,000,000 Australia 2,200 19% 62,000 160,000 China 1,600 14% 40,000 100,000 Gabon 1,550 13% 20,000 160,000 Other countries 1,360 12% Small Small Brazil 1,000 9% 35,000 57,000 Ukraine 820 7% 140,000 520,000 India 650 6% 56,000 150,000 Mexico 130 1% 4,000 9,000 USA World 11,600 460,000 5,200,000 Source: USGS Global Markets Research Page 73 September 2008 A User Guide To Commodities Major uses Manganese is essential to iron and steel production by virtue of its sulphur-fixing, deoxidizing and alloying properties. Steelmaking, including its iron making component, has accounted for most manganese demand, presently in the range of 85% to 90% of the total demand. Among a variety of other uses, manganese is a key component of low-cost stainless steel formulations and certain widely used aluminium alloys. The metal is very occasionally used in coins; the only United States coins to use manganese were the "wartime" nickel from 1942–1945, and since 2000 dollar coins. The EU uses manganese in 1 and 2 Euro coins, due to its greater and cheaper availability. Figure 2: Manganese price since 1992 7000 Manganese price (USD/tonne) 6000 5000 4000 3000 2000 1000 0 1992 1994 1995 1996 1997 1999 2001 2003 2005 2007 Source: Bloomberg (data as of end July-08) Exchange traded & price conventions Manganese is not traded on any exchange although the price ticker for min. 99.7% electrolytic manganese flake is available from Metal Bulletin and has the Bloomberg code MBMNFMEL <Index>. The Reuters code is MNG-FERRO-LON. Page 74 Global Markets Research September 2008 A User Guide To Commodities Molybdenum History & properties Molybdenum has the symbol Mo and atomic number 42. The most significant naturally occurring compound containing molybdenum is molybdenite (MoS2) and occurs in association with copper sulphide. Mining of molybdenum is therefore often performed in conjunction with copper mining. Molybdenum ore is crushed and ground into fine particles, combined with oil, and separated by flotation in water. The resulting molybdenite concentrate is then heated at 600-700°C to yield molybdenum oxide, which is then sold in powder form or as briquettes for steelmaking. Molybdenum is used primarily as an alloying agent in steel, cast iron, and super-alloys to enhance strength, heat and corrosion resistance. It has one of the highest melting points of all elements. Molybdenum would have been indistinguishable from other materials such as lead, galena and graphite in ancient times and consequently were known collectively by their Greek word molybdos, meaning lead-like. Major producers The United States is world’s largest molybdenum producing country followed by China and Chile. The US also has the largest reserves, at 5.4 million tonnes, about 28% of the world’s total reserves, located mainly in the southwest. Other reserves are located in Canada, Central America and South America. Figure 1: Major producers and reserves of molybdenum Mine Reserves Reserves base production 2007 (tones) % of total Tonnes (000s) Tonnes (000s) USA 59,400 32% 2,700 5,400 China 46,000 25% 3,300 8,300 Chile 41,100 22% 1,100 2,500 Peru 17,500 9% 140 230 Canada 8,000 4% 450 910 Russia 3,100 2% 240 360 Armenia 3,000 2% 200 400 Mexico 4,000 2% 135 230 Iran 2,500 1% 50 140 Mongolia 1,500 1% 30 50 Uzbekistan 500 0.3% 60 150 Kazakhstan 400 0.2% 130 200 250 0.1% Kyrgyzstan World 187,000 100 180 8,600 19,000 Source: USGS Major uses Over two-thirds of all molybdenum is used in high-strength alloys with resistance to corrosion and stress corrosion cracking and there are few substitutes. These alloys are used in oil refineries, oil wells, pipelines, power plants, petrochemical plants, mechanical parts, high-speed cutting tools and construction. A steel containing 2% molybdenum called Type 316 is used in architectural applications for its resistance to wind-borne chlorides in coastal environments, such as Canary Wharf in London and the Petronas Towers in Kuala Lumpur. The ability of molybdenum to withstand extreme temperatures without significantly expanding or softening makes it useful in applications that involve intense heat, including the manufacture of aircraft parts, electrical contacts, industrial motors and filaments. Global Markets Research Page 75 September 2008 A User Guide To Commodities Figure 2: Molybdenum price since 1993 4000 Figure 3: Composition of molybdenum demand by use in 2008 Molybdenum price (Usc/lb) 5% 3500 Constructional Steel 6% 6% 3000 Stainless Steels 35% 2500 Chemicals 9% 2000 Tool & Highspeed Steel 1500 Mo Metal 14% 1000 Cast Iron 500 0 1982 25% Superalloys 1984 1986 1988 1990 1992 1994 1996 1998 2000 2002 2004 Source: Bloomberg (data as of end July 2008) 2006 2008 Source: IMOA Exchange traded & price conventions The Bloomberg price ticker for molybdenum from Purchasing Magazine is PURDP021 <Commodity>. Purchasing Magazine's Transaction Price data series are not producer list prices; rather, they reflect actual prices paid by large volume industrial buyers in the US. The Reuters code is MLY-OXIDE-LON. Figure 4: Controlling companies in molybdenum mining in 2007 Company name Freeport McMoran Copper & Gold Inc Codelco State of China Grupo Mexico SA de CV Rio Tinto plc Antofagasta plc Thompson Creek Metals Co Inc Anglo American plc Xstrata plc Cronimet Mining GmbH Country USA Chile China Mexico UK UK Canada UK Switzerland Germany Controlled production (‘000 tonnes) 31.9 28.0 25.8 19.7 14.9 10.2 7.4 4.4 3.8 3.7 % of world 16.0% 14.1% 13.0% 9.9% 7.5% 5.1% 3.7% 2.2% 1.9% 1.9% Source: Raw Materials Group Page 76 Global Markets Research September 2008 A User Guide To Commodities Rhenium History & properties Rhenium has the symbol Re and atomic number 75 and is one of the rarest but most dispersed metallic elements in the Earth's crust. Molybdenite is the only significant host mineral for rhenium. Walter Noddack, the German chemist, is generally credited with the discovery of rhenium in 1925. At the University of Tennessee in 1942, A.D. Melaven and J.A. Bacon developed a process for extracting the element from the dust that accumulated in the roasting molybdenum ore. Major producers Rhenium mostly occurs with molybdenum in porphyry copper deposits and is developed as a by-product. Identified U.S. resources are estimated to be about 4.5 million kilograms, and the identified resources of the rest of the world are approximately 5.5 million kilograms, with Chile and Canada holders of major deposits. Rhenium also exists in sedimentary copper deposits. Figure 1: Major producers of rhenium Reserves Reserves 2007 (kg) % of total (kg) base (kg) Chile 22,900 46% 1,300,000 2,500,000 Kazakhstan 8,000 16% 190,000 250,000 USA 7,300 15% 390,000 4,500,000 Peru 5,000 10% 45,000 550,000 Others 2,000 4% 91,000 360,000 Canada 1,700 3% 32,000 1,500,000 Russia 1,400 3% 310,000 400,000 Armenia 1,200 2% 95,000 120,000 World 49,500 2,500,000 10,000,000 Mine production Source: USGS Major uses Rhenium has an ultra-high melting point (3,186 degrees C) and is primarily used in producing nickel-based super alloys, a vital resource for specialty metal users such as the aerospace industry. By aiding aircraft engines to run at higher temperatures, they become more fuel efficient. Thus in response to higher oil prices, the sector has demanded more and more of the metal. The metal is also used in petroleumreforming catalysts for the production of high-octane hydrocarbons, which are used in the formulation of lead-free gasoline. Price conventions The Bloomberg ticker is ENGHRHEN <Commodity>. Figure 2: Rhenium price since 2001 Figure 3: Composition of rhenium demand in 2006 5000 4500 Rhenium price (USD/lb) 8% 4000 15% 3500 Superalloys & powder metallurgy 3000 2500 Catalysts 2000 1500 Others 1000 77% 500 0 2001 2002 2003 2004 2005 Source: Bloomberg (data as of end Q2 2008) Global Markets Research 2006 2007 2008 Source: USGS Page 77 September 2008 A User Guide To Commodities Tantalum History & properties Tantalum is a chemical element with the symbol Ta and atomic number 73. A rare, hard, blue-gray, lustrous, ductile metal, tantalum is highly conductive of heat and electricity. The metal is renowned for its resistance to corrosion by acids. Tantalum's high melting point of 3,017 C is exceeded only by tungsten and rhenium. Tantalum was discovered in 1802 by the Swedish chemist Anders Ekeberg and named after the mythological character Tantalus because of the tantalizing problem of dissolving the oxide in acids. It is often found with niobium, and for many years it was believed that these two metals were actually the same element, until Heinrich Rose in 1844 proved otherwise. Major producers The main source of primary ore is Australia which has the two largest mines in the world: Greenbushes in the south of Western Australia and Wodgina in the north of the same state. These two mines supply over one half of the world’s production. Tantalum mining also occurs in Canada, Brazil, China, Democratic Republic of Congo, Rwanda and Ethiopia. Figure 1: Major producers of tantalum Mine production 2007 (tonnes) % of world Reserves (tonnes) Reserve Base (tonnes) Australia 850 61% 40,000 84,000 Brazil 250 18% 88,000 90,000 Canada 70 5% 3,000 >3,000 Ethiopia 70 5% NA NA Mozambique 70 5% NA NA Rwanda 60 4% NA NA Other countries 30 2% NA NA USA - World 1,400 - - Negligible 130,000 180,000 Source: USGS Major uses The major use for tantalum in powder form is in the production of electronic components, mainly capacitors and some high-power resistors. Because of the size and weight advantages, tantalum capacitors are attractive for portable telephones, pagers, personal computers and automotive electronics. Tantalum is also used to produce a variety of alloys that have high melting points, are strong and have good ductility. Alloyed with other metals, it is also used in making carbide tools for metalworking equipment and in the production of superalloys for jet engine components, nuclear reactors and missile parts. Due to its resistance to attack by body fluids and is also non-irritating, tantalum is widely used in making surgical instruments and implants. Page 78 Global Markets Research September 2008 A User Guide To Commodities Thorium History & properties Thorium is a chemical element that has the symbol Th and atomic number 90. Thorium was discovered in 1828 by the Swedish chemist Jons Jakob Berzelius, who named it after Thor, the Norse god of thunder. As a naturally occurring, slightly radioactive metal, thorium has been considered as an alternative nuclear fuel to uranium. When pure, thorium is a silvery white metal. However, when it is exposed to oxygen, thorium slowly tarnishes, becoming grey and eventually black. Thorium dioxide, also called thoria, has the highest melting point of any oxide (3300°C). Thorium has the largest liquid range of any element: 2946 K between the melting point and boiling point. Major producers Large thorium reserves are found in Australia, Brazil, Canada, Greenland, India, South Africa and the United States. The leading share is contained in placer deposits. Resources of more than 500,000 tonnes are contained in placer, vein, and carbonatite deposits. Disseminated deposits in various other alkaline igneous rocks contain additional resources of more than 2 million tonnes. Figure 1: Major thorium reserves Country Reserves (tonnes) Reserve base (tonnes) Australia 300,000 340,000 India 290,000 300,000 Norway 170,000 180,000 USA 160,000 300,000 Canada 100,000 100,000 Other countries 90,000 100,000 South Africa 35,000 39,000 Brazil 16,000 18,000 Malaysia 4,500 4,500 World 1,200,000 1,400,000 Source: USGS Major uses The principal use of thorium has been in mantles in portable gas lights. It is also used to coat tungsten wire used in electronic equipment. However, the use of thorium in the United States has decreased significantly over the past two decades as a consequence of the high cost of disposal due to its radio-activity. Thorium as a nuclear fuel Like uranium, thorium can be used as nuclear fuel. It is an attractive alternative because it is much more abundant than uranium, easier to extract from the ground and safer to use. Unlike uranium and plutonium, thorium is not fissle and cannot undergo nuclear fission by itself. However, there are many barriers for thorium to gain acceptance in the nuclear industry. For one, nuclear power industry has already built its infrastructure around uranium and has little reason to invest in changing it. Furthermore, the technology is not available to make it economically attractive. Because thorium cannot sustain a nuclear reaction once it starts, it needs to be constantly exposed to enough neutrons to keep the reaction going unlike uranium which only needs to be “zapped” once. Exchange traded Thorium is not traded on any exchange. However USGS sources its prices from the domestic and international miners and processors. Global Markets Research Page 79 September 2008 A User Guide To Commodities Titanium History & properties Titanium is a durable, lightweight metal derived from minerals such as ilmenite or rutile. The chemical element has the symbol Ti and atomic number 22 and is grayish in colour. It is highly valued due to its resistance to corrosion and because of it has the highest strength-to-weight ratio of any metal. In its unalloyed condition, titanium is as strong as some steels, but 45% lighter. Major producers Australia and South Africa are the largest producers of titanium and combined account for 44% of world production. Although China is fourth in terms of annual production, it has the largest pool of reserves, constituting more than one fourth of total world reserves, followed by Australia and India. Figure 1: Major producers of titanium (ilmenite and rutile) 2007 Reserves Reserve base (tonnes) % of world (tonnes) (tonnes) Australia 1,549 25% 149,000 191,000 South Africa 1,181 19% 71,300 244,000 Canada 816 13% 31,000 36,000 China 500 8% 200,000 350,000 Norway 380 6% 37,000 60,000 India 358 6% 92,400 230,000 Ukraine 337 6% 8,400 15,500 USA 300 5% 6,400 60,800 Vietnam 200 3% 1,600 14,000 Brazil 133 2% 44,200 86,500 Other countries 189 3% 68,900 154,600 103 2% 16,480 21,570 730,000 1,500,000 Mine production Mozambique World 6,100 Source: USGS Reserves constitute of economically extractable reserves, though facilities might or might not be operative. Reserve Base encompasses economic, marginally economic and sub economic resources. Major uses Titanium can be alloyed with aluminium, iron, vanadium, molybdenum among others to produce strong lightweight materials. About two thirds of all titanium metal produced is used in aircraft engines and frames. Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high temperatures without creeping, titanium alloys are used in aircraft, armour plating, naval ships, spacecraft, missiles, wheelchairs and sports equipment. Exchange traded & price conventions Titanium prices are priced off the Australian export TZMI Titanium Dioxide Pigment Mineral Sands spot price and sourced from ABS. The Bloomberg ticker is TZMIPIGM <Index>. Page 80 Global Markets Research September 2008 A User Guide To Commodities Tungsten History & properties Tungsten, also known as Wolfram, is a chemical element that has the symbol W and atomic number 74. A steel-gray metal, tungsten is found in the minerals wolframite, scheelite, ferberite and hübnerite. It is valued for its robust physical properties as well as possessing the highest melting point (3,422 °C) of all the non-alloyed metals and the second highest of all the elements after carbon. Tungsten is often brittle and hard to work in its raw state. The metal oxidizes in air and must be protected at elevated temperatures. It also has excellent corrosion resistance. In 1781, Carl Wilhelm Scheele ascertained that a new acid could be made from scheelite (at the time named tungstenite): tungstic acid. Scheele and Torbern Bergman suggested that it could be possible to obtain a new metal by reducing this acid. In 1783 José and Fausto Elhuyar found an acid made from wolframite that was identical to tungstic acid. In Spain later that year the brothers succeeded in isolating tungsten through reduction of this acid with charcoal. They are credited with the discovery of the element. Major producers World tungsten supply is dominated by Chinese production and exports. More than 80% of the world’s tungsten resources exist in China, much of the remainder being supplied by Russia. Various companies worked towards developing tungsten deposits or reopening inactive tungsten mines in Australia, Canada, China, Kyrgyzstan, Mexico, Spain, Thailand, the United States, Uzbekistan, and Vietnam. Figure 1: Major producers of tungsten Reserves Reserve Base Mine production (tonnes) % of world (tonnes) (tonnes) China 77,000 86% 1,800,000 4,200,000 Russia 4,400 5% 250,000 420,000 Canada 2,600 3% 260,000 490,000 Other countries 2,040 2% 420,000 740,000 2007 Austria 1,300 2% 10,000 15,000 Bolivia 870 1% 53,000 100,000 Portugal 800 1% 4,700 62,000 North Korea 600 1% NA 35,000 USA W* 140,000 200,000 World Total 89,600 2,900,000 6,300,000 *W: withheld to avoid disclosing company proprietary data; Source: USGS Major uses Tungsten is used in many extreme-temperature applications such as light bulbs, cathode-ray tubes, vacuum tube filaments as well as nozzles on rocket engines. It is also suitable for aerospace and other high temperature uses such as electrical, heating, and welding applications. It is also used in electrodes and electron microscopes. The metal is also used in X-ray targets. The hardness and density of tungsten find uses in heavy metal alloys that are used in armament, heat sinks, and high density applications. Tungsten, which has a similar density to gold, is sometimes used in jewellery as an alternative to gold or platinum. Its hardness makes it ideal for rings that will resist scratching, are hypoallergenic and will not need polishing. Exchange traded & price conventions Tungsten is not traded on any exchange although the price ticker for Tungsten APT European is available from Metal Bulletin and has the Bloomberg code MBWOEUFM <Index>. The Reuters codes are APT-CHINA and TUN-FERRO-LON. Global Markets Research Page 81 September 2008 A User Guide To Commodities Vanadium History & properties Vanadium is a soft, silver-gray metallic element with the symbol V and atomic number 23. It is found in about 65 different minerals, phosphate rocks and certain iron ores, and is also present in some crude oils in the form of organic complexes. Vanadium was first discovered by Andres Manuel del Rio in 1801. However, due to an incorrect counter-claim from a French chemist the element was rediscovered in 1830 by Sefstrom, who named the element after the Scandinavian goddess, Vanadis, because of its beautiful multi-coloured compounds. It was isolated in nearly pure form by Roscoe, who in 1867 reduced the chloride with hydrogen. Vanadium has good corrosion resistance to alkalis, sulphuric and hydrochloric acid, and salt water, but the o metal oxidizes above 660 C. The metal has good structural strength and a low fission neutron cross section, making it useful in nuclear applications. Major producers South Africa is the world’s largest producer and exporter of vanadium. China and Russia are also major producers. The US Geological Survey currently puts the total world reserves of vanadium at over 63 million tonnes. Vanadium is not traded on any exchange, although the price ticker from Metal Bulletin is available: MBVAUS80 <Index> for Ferro-Vanadium and the Reuters code for Ferro-Vanadium is VANFERRO-LON. Figure 1: Major producers and reserves of vanadium 2007e (tones) Mine production % of world Reserves (tonnes) Reserve base (tonnes) S. Africa 23,000 39% 3,000,000 12,000,000 China 18,500 32% 5,000,000 14,000,000 Russia 16,000 27% 5,000,000 7,000,000 Other countries 1,100 2% NA 1,000,000 USA World - - 45,000 4,000,000 13,000,000 38,000,000 58,600 Source: USGS Major uses The key use of vanadium is as an alloying element in a number of types of steel, where it increases strength and fatigue resistance. Over 85% of vanadium’s current production is used as ferro-vanadium to be added to steel. These hard, strong ferrovanadium alloys are used to make armor plating for military vehicles. It is also used to make car engine parts, such as piston rods and crank shafts. It is also used in the steel “skeleton” or frames of high-rise buildings and oil drilling platforms. Some vanadium is used in other industrial applications. For example, vanadium pentoxide (V2O5) is used in the production of glass and ceramics and as a chemical catalyst. Figure 2: Ferro-vanadium price since 1993 60 Figure 3: Vanadium uses in 2008 Ferro-Vanadium price (USD/lb) 5% 10% 50 High strength steel 40 30 Titanium, aluminium, vanadium alloys - aerospace industry 20 10 85% 0 1993 1994 1995 1996 1997 1998 1999 2000 2001 Source: Bloomberg (data as of end 2007) Page 82 2002 2003 2004 2005 2006 Catalysts, glasses & pigments, ceramics, electronics & batteries - chemical industry 2007 Source: http://www.stockhouse.com Global Markets Research September 2008 A User Guide To Commodities Mineral Sands History & properties Mineral sands refer to concentrations of heavy minerals with high specific gravity, which include minerals rich in titanium, zirconium and rare earths. The mineral sands industry is orientated primarily towards the supply of titanium raw materials, for use in the production of titanium dioxide pigment and titanium metals. However, zircon and pig iron are also classified within mineral sands mining. Mineral sands tend to accumulate in river channels or along coastal shorelines. Beach sands contain the most important accumulations of these minerals, so they are also sometimes known as beach sands. However, they are also found in varying levels above the present sea level and some deposits have been located up to 35km inland. Major producers Australia is a major producer of heavy minerals. During 1998, deposits in Western Australia, New South Wales and Queensland supplied 0.25 millon tonnes or 58% of the world’s rutile concentrate, 2.4 Mt or 27% of world’s ilmenite, and 0.40 Mt or 40% of the world’s zircon. Major uses The titanium dioxide pigment industry is the major end-user of titanium feedstock. A majority of titanium dioxide pigment comes from rutile and ilmenite, as they produce a superior pigment. About 90% of the world’s titanium mineral production is used in the manufacture of white titanium dioxide pigment. Titanium dioxide pigment is white in colour, with high opacity and resistance to colour change, used primarily in paints as a whitener, and also in plastics, paper and rubber products. Because it is non-toxic it also has minor uses in cosmetics, sun protection creams and pharmaceuticals. About 6% is used to manufacture titanium metal, a light, strong, corrosion-resistant metal used in aircraft, spacecraft and medical prostheses. Other minor uses include welding rod coatings, sand blasting and water filtration. The group of primary mineral sands mined are: Zircon: Zircon is the third most heavy mineral in mineral sands and is a colourless to off-white mineral, with a specific gravity between 4.6 to 4.7,that is it is 4.6-4.7 times heavier than water. It is used as the raw material for making refractory bricks and furnace linings due to its melting point of over 2500 degrees Celcius. It is also used widely in the ceramics industry as a speciality glaze and foundry medium. A small percentage of pure zircon is used to make nuclear fuel containers. Zircon is the world’s major source of zirconium products which are used as alloying agents in materials that are exposed to corrosive agents such as space vehicle parts, surgical appliances and explosive primers. Rutile: Rutile is a red to black, naturally occurring titanium dioxide. Theoritically its composed of 100% titatnium dioxide, but, practically impurities mean it typically contains about 95% titanium dioxide. Rutile has a specific gravity of 4.25. Finely powdered rutile is used in paints, plastics, papers, foods, and other applications that call for a bright white colour. Ilmenite: Ilmenite is the most abundant titanium mineral, theoretically containing 52.7% titanium dioxide, although in reality this figure ranges from 35-65%. Iimenite is black and opaque with a specific gravity between 4.5 to 5.0 and it can be slightly magnetic. Similar to rutile, ilmenite in fine powder form is a highly white substance used as a base in high-quality paint, paper and plastics applications. Global Markets Research Page 83 September 2008 A User Guide To Commodities Pig iron: Pig iron is a metallic iron containing greater than 90% iron, and is most commonly produced from the smelting of iron ore in a blast furnace. It is relevant to mineral sands because it is also a co-product of titanium slag production. In this operation, iron is recovered from the smelting of ilmenite, and is collected as a high grade molten iron. Around 500-600 kilograms of pig iron is produced per 1,000 kilograms of titanium slag produced. Monazite: Monazite is the rarest mineral that exists as a rare earth phosphate. It contains about 30% throrium, which makes it mildly radiocative. Monazite grains are yellowish to brown with the specific gravity of about 4.6 to 5.4. It is used in colour television screens, screen luminescence materials, video monitors and high efficiency lights. Its potential also lies in futuristic computer, medical and electronic industries. Leucoxene: Leucoxene is not a definable mineral species, but rather refers to a range of commercial titanium-bearing products, typically containing between 65% to 92% of titanium dioxide. If leucoxene contains higher concentrations of titanium dioxide then it is classified as rutile. Leucoxene is physically characterised by a weak magnetic susceptibility; and is often coated in surface impurities. The major markets for leucoxene fall into two categories: as a direct feedstock for the production of chlorine grade pigment; and in the manufacture of welding electrode flux. Page 84 Global Markets Research September 2008 A User Guide To Commodities Rare Earth Metals History & properties Rare earths metals are a group of fifteen metallic elements consisting of the Lanthanide series on the periodic table as well the element Yttrium. The rare earth metals can be subdivided into the light or ceric elements of Cerium, Lanthanum, Neodymium, and Praseodymium and the heavy elements of Yttrium, Samarium, Europium, Gadolinium, Terbium, Dysprosium, Holmium, Erbium, Ytterbium and Lutetium. The three most important ores on a global scale are the minerals bastnäsite, monazite and ion adsorption clays. Despite their title, some of the rare earth metals such as cerium and lanthanum are relatively abundant in the earth’s crust. Major producers According to US Geological Survey, the largest producer of rare earth metals is China followed by India, Brazil and Malaysia. Although production has been concentrated in these four countries in 2007, plans to boost rare earth metals production is occurring in other countries around the world, such as the United States and Kazakhstan. Figure 1: Major producers and reserve holders of Rare Earth Metals Reserves Reserves base Producers Tonnes 2007 % of world Tonnes Tonnes China 120,000 97% 27,000,000 89,000,000 India 2,700 2% 1,100,000 1,300,000 Brazil 730 1% 48,000 84,000 Malaysia 200 30,000 35,000 Russia & CIS 19,000,000 21,000,000 Other countries 22,000,000 23,000,000 Australia 5,200,000 5,800,000 USA 13,000,000 14,000,000 87,378,000 154,219,000 World 124,000 Source: USGS Major uses Rare earth metals play a critical role in the automotive, electronics, environmental, protection and petrochemical sectors. They are the world’s strongest magnets, and have been attributable to the miniaturization of many technologies, such as iPods. The major applications that drive the demand are: Catalysts: Automotive catalytic converters (autocats) use rare earths particularly cerium. Stricter environmental legislation is expected to sustain the strong demand for rare earth metals in emission controls systems. Cracking catalysis: Rare earth metals are also used in the petroleum refining industry. Their applications are in the cracking process as they are able to enhance the gasoline yield. Glass: Rare earths, most notably cerium and lanthanum, are used in a variety of applications in digital cameras and fibre optics. Magnets: Rare earth magnets are the world’s strongest permanent magnets. They are used extensively in the automotive and electronic sectors for example in hard disk drives and hybrid car motors. NiMH batteries: Lanthanum based batteries are used extensively for hybrid vehicles as they are rechargeable and portable. Phosphors: Many rare earth metals are fluorescent and have there applications for flat screen displays and energy efficient lighting. Polishing powders: Cerium oxide is used in the polishing industry for televisions, silicon wafers and chips. Global Markets Research Page 85 September 2008 A User Guide To Commodities Figure 2: Rare earth metals demand by use in 2006 3% 3% Automotive catalytic converters 6% 25% 10% 120,000 Metallurgical additives and alloys 100,000 Lighting, televisions, computer monitors, radar, X-ray Permanent magnets 22% 20% Medical and lasers Other World production (tonnes, lhs) 140,000 Petroleum refining catalysts Glass polishing and ceramics 11% Figure 3: World rare earth production & prices 9,000 Price (USD/tonne) 8,000 80,000 7,000 60,000 40,000 6,000 20,000 5,000 0 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 Source: USGS Page 86 Source: USGS Global Markets Research September 2008 A User Guide To Commodities Agriculture The United States and China are the world’s superpowers when it comes to agricultural production. Their combined output of corn, wheat, rice, soybeans and sugar is approximately double that of their nearest rivals, India and the EU-27 countries. However, what distinguishes these two countries apart is that while the US is a major exporter of agricultural commodities, China has become increasingly dependent on agricultural imports. For example, in 2007-08, the US accounted for 30%, 41% and 63% of world exports for corn, soybeans and wheat respectively while China has became the world’s largest importer of cotton, palm oil, rubber and soybeans. Of all the agricultural commodities, corn and wheat dominate in terms of world production. However, global wheat production has declined over the past two years in response to significant droughts in major wheat producing countries, such as Australia. In contrast, global corn production has risen by 15% over the past two years following an increase in US corn plantings. This has occurred to supply the US ethanol industry, which now consumes approximately 25% of the annual US corn harvest compared to less than 5% at the beginning of the decade. Figure 1: The world’s top agricultural producers Agricultural output in 2007-08 (million tonnes) 500 Sugar Soybean Rice 400 Wheat Corn 300 Figure 2: Total world production of a selection of agricultural commodities 900 World production (million tonnes, 2007-08) 789 800 700 610 600 500 429 400 200 300 100 218 164 200 119 100 0 47 41 10 4 4 e oc oa C C of fe n ap es ee d Pa lm oi l R ub be r ot to C R Su ga r R ic e So yb ea ns he at W C or n R us si a In do ne si a C an ad a Pa ki st an M ex ic o Th ai la nd Vi et na m -2 7 Br az il Ar ge nt in a In di a EU S U C hi na 0 Source: USDA Source: USDA, World Cocoa Organization Figure 3: US & world exports of a selection of agricultural commodities in 2007-08 Figure 4: China’s trade position in agriculture 120 US exports (million tonnes) Rest of world exports (million tonnes) 100 China's net trade balance in: 20000 10000 80 0 60 -10000 40 -20000 Soybeans Corn Wheat Cotton Rising net imports -30000 20 Tonnes (000s) -40000 0 Wheat Corn Source: USDA Global Markets Research Soybeans Sugar Rice (milled) 1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 Source: USDA, DB Global Markets Research Page 87 September 2008 A User Guide To Commodities Global inventory-to-use ratios for many agricultural commodities have been low and declining throughout most of this decade. This has been in response to strong demand due to rapid population growth, strong economic growth and rising per capita consumption of meat. Land and water constraints globally have also led to a slowdown in agricultural production growth. During this decade rising fuel costs, the rapid expansion of biofuels production, most notably in the United States, adverse weather events and government policies in a number of agricultural exporting nations to curb agricultural exports have contributed to many agricultural commodity prices hitting all time nominal highs in 2008. Figure 5: The world’s top agricultural futures contracts Turnover Turnover 2005 2007 Dalian Commodity Exchange 36.7 64.7 76% Corn Dalian Commodity Exchange 21.9 59.4 172% Corn Chicago Board of Trade 28.0 54.5 95% No. 1 Soybeans Dalian Commodity Exchange 40.0 47.4 18% Rubber Shanghai Futures Exchange 9.5 42.1 344% Strong Gluten Wheat Zhengzhou Exchange 16.6 39.0 135% Soybeans Chicago Board of Trade 20.2 31.7 57% Sugar #11 New York Board of Trade 12.4 21.4 73% Wheat Chicago Board of Trade 10.1 19.6 94% Non-GMO-Soybean Tokyo Grain Exchange 11.0 12.3 12% Soybean Oil Chicago Board of Trade 7.7 13.2 72% Soybean Meal Chicago Board of Trade 8.3 12.2 47% Rubber Tokyo Commodity Exchange 7.2 7.1 -1% Cotton #2 New York Board of Trade 3.9 6.3 65% Coffee ‘C’ New York Board of Trade 4.0 5.1 29% Corn Tokyo Grain Exchange 5.2 4.7 -10% Coffee Robusta EURONEXT 3.3 4.4 36% Wheat Kansas City Board of Trade 3.7 4.3 17% Crude Palm Oil Malaysia Derivatives Exchange 1.2 3.5 200% Cocoa CC New York Board of Trade0 2.6 3.3 29% Cotton Zhengzhou Exchange 10.9 3.0 -72% Canola (Rapeseed) Winnipeg Commodity Exchange 1.7 3.0 79% White Sugar EURONEXT 1.5 2.1 39% Spring Wheat Minneapolis Grain Exchange 1.4 1.8 30% Contract Exchange Soy Meal % change Turnover is futures only and in millions of lots. Contract sizes are typically 10 times larger in the US than China. Source: DCE, CBT, NYBOT, ZCE, TGE, SFE, KCBT Figure 6: Corn, soybean & wheat inventory-touse ratios 180 Total available stocks divided by daily consumption Figure 7: Corn, soybean & wheat prices in real terms Corn inventory-to-use ratio 40 Wheat inventory-to-use ratio 160 Soybean inventory-to-use ratio 140 Deflated by US PPI 35 Corn price in real terms (2005 US dollars) 30 Soybean price in real terms (2005 US dollars) USD bushel Days of use 120 100 80 60 40 Wheat price in real terms (2005 US dollars) 25 20 15 10 20 5 0 1965 Source: USDA Page 88 1970 1975 1980 1985 1990 1995 2000 2005 0 1972 1975 1978 1981 1984 1987 1990 1993 1996 1999 2002 2005 2008 Source: Bloomberg (data as of end July-08) Global Markets Research September 2008 A User Guide To Commodities Cocoa History & properties The first traces of the consumption of cocoa appear to have been in South America th and specifically during the Mayan civilisation in the 6 Century. By the time of the th Aztecs around the 15 Century, cocoa beans had become a unit of currency across the whole of Central America. Cocoa derives from the cacao tree, which grows to around 12 meters (40 feet), bears fruit or pods which are more than 30cm long. Each pod holds between 30 to 40 cocoa beans, with approximately 400 beans required to make one pound of chocolate. Cacao trees typically grow in hot and humid tropical climates, with an average rainfall of 1150mm to 2500mm and a temperature range of between 18 to 32 degrees Centigrade. Consequently production tends to occur between 10 to 20 degrees north and south of the equator and specifically in the Ivory Coast, Ghana and Indonesia. A cacao tree takes about five years to reach maturity, but, can live for up to 50 years with the peak growing period lasting for around 10 years. The growing season is continuous such that ripe pods can be found on cacao trees throughout the year. However, the main harvesting period starts from September and can extend into the first few months of a new year. The fruit from the cacao tree can be classified according to three broad types: Criollo, Forestero and Trinitario. Forestero accounts for over 85% of global cocoa production and is largely concentrated in Africa. Criollo beans are primarily grown in Central and South America and are generally considered superior in quality. Two-thirds of cocoa bean production is used to make chocolate and one-third to make cocoa powder. Major producers & consumers While the cacao tree is a native of the Americas, today West Africa dominates the world production of cocoa. Ivory Coast, Ghana and Indonesia account for 70% of global cocoa production, with Ivory Coast the most dominant producer in the world. Disease is a major factor affecting production such as witches broom, monilia and black pod disease. Military conflict in West Africa has also been responsible for disrupting cocoa production. Cocoa consumption is measured by grindings or processing. The Netherlands and the US remain the major cocoa processing countries, with grindings of more than 400,000 tonnes in 2006/07. Major uses Cacoa beans are fermented for up to seven days and are then sun-dried. The drying process takes between one and two weeks. The beans are then polished by machine and roasted at which point the shells are removed and the beans are ready to make chocolate, chocolate paste, cocoa powder and cocoa butter. Figure 1: The world’s top 7 cocoa producers & consumers in 2006 Producer Tonnes (000s) % of world Consumer Tonnes (000s) % of world Ivory Coast 1,292 38.0% Netherlands 465 12.9% Ghana 614.0 18.1% USA 418 11.6% Indonesia 490.0 14.4% Germany 357 9.9% Nigeria 190.0 5.6% Ivory Coast 336 9.3% Cameroon 166.0 4.9% Malaysia 270 10.3% Brazil 126.0 3.7% Brazil 224 6.2% Ecuador 114.0 3.4% Indonesia 140 3.9% World 3,380 World 3,639 Source: International Cocoa Organization; Consumers are measured by grindings/cocoa processing Global Markets Research Page 89 September 2008 A User Guide To Commodities Figure 2: Cocoa turnover by exchange Figure 3: Cocoa prices since 1957 Annual turnover in 2007 (Futures only, million lots) 4 3.3 5000 3.3 Cocoa price (USD/tonne) 4000 3 3000 2 2000 1 1000 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 0 Cocoa (ICE) Cocoa (EURONEXT) Source: NYBOT, EURONEXT Source: DB Global Markets Research, IMF monthly data as of end July-08 International organizations & exchange traded The International Cocoa Organization (ICCO) was established in 1973 with the aim over time to boost farm incomes and market access for major cocoa exporting countries. The International Cocoa Council is the governing body of the ICCO and consists of 13 cocoa exporting and 29 cocoa importing member countries. Cocoa is traded on the New York Board of Trade and on EURONEXT. The futures contract calls for the delivery of 10 tonnes of cocoa and is priced in US dollars per tonne. The Bloomberg ticker for the one month generic cocoa futures contract is CC1 <Commodity>. The Bloomberg codes for the total return and excess return DBLCI-Optimum Yield Cocoa Index are DBLCYTCC <Index> and DBLCYECC <Index> respectively. Figure 4: Cocoa market balance Figure 5: Cocoa inventory-to-use ratio since 1997 4000 400 3500 300 3000 200 2500 100 2000 0 1500 -100 1000 -200 60 Inventory-to-grindings ratio (%) 55 Market balance (rhs) 500 Production (lhs) -400 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 Source: International Cocoa Organization Page 90 45 40 35 -300 Grindings (lhs) 0 Tonnes (000s) Tonnes (000s) 50 30 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 Source: International Cocoa Organization; Years run from September to August such that the end of the 2007 marketing year takes place in August 2008 Global Markets Research September 2008 A User Guide To Commodities Coffee History & properties Coffee first came to prominence in Ethiopia more than 2,000 years ago. According to legend, an Ethiopian goatherd witnessed the lively behaviour of his goats after they consumed the berries of a coffee tree. He then enjoyed their unusual properties and monks in a local monastery took this discovery and turned it into a beverage. The first coffee houses sprang up in and around Mecca and pilgrims helped to spread the beverage beyond Arabia. Coffee was then traded through Mocha, a port city on the th Red Sea coast of Yemen, which gave its name to a fine quality of coffee. By the 17 Century coffee houses had spread across Europe and had become an important meeting place for traders and merchants. Both Lloyd’s of London and the London Stock Exchange were founded in coffee houses. Coffee is generally classified according to two types of bean: Arabica and Robusta. The most widely produced coffee is arabica, which makes up just over 60% of world production. It is also considered superior and trades at a premium to the robusta bean. Robusta is the stronger of the two beans with more caffeine, a bitter taste and is grown at lower altitudes. Major producers & consumers Coffee was introduced to Brazil in 1727 from French Guiana. Today, Brazil and Colombia are the world’s largest producers of arabica coffee. 80% of all coffee produced in Brazil is of the arabica variety. Coffee in Brazil is grown in the states of Paraná, Espirito Santos, São Paulo, Minas Gerais, and Bahia. Vietnam, which specializes in robusta production, has seen strong growth in its coffee production over the past few years. Robusta coffee production is also concentrated in Indonesia and West Africa. The EU and the US constitute 70% of world coffee consumption. Major uses Coffee berries are picked, defruited, dried, sorted and sometimes aged to yield the green coffee bean. The beans are then roasted and ground before being prepared to make coffee. Price conventions & organisations The International Coffee Organization was set up in London in 1962. The last International Coffee Agreement was signed in September 2007 and outlined among its objectives to promote not only coffee consumption, but, also its quality. Coffee is measured in 60 kilogramme bags, with one bag equivalent to 132.3 pounds. The coffee marketing year runs from 1 October to 30 September. The coffee price is quoted in US cents per pound as well as US dollars per tonne. The Bloomberg ticker for the NYBOT Coffee ‘C’ one month generic coffee futures contract is KC1 <Commodity>. Figure 1: The world’s top 10 coffee producers, consumers, exporters and importers in 2007 % of % of % of % of Producers 000s world Consumers 000s world Exporters 000s world Importers 000s world Brazil 46,700 35.0% US 20,667 17.2% Brazil 28,088 29.3% US 24,225 24.4% Vietnam 21,250 15.9% Brazil 16,100 13.4% Vietnam 17,936 18.7% Germany 19,660 19.7% Colombia 12,164 9.1% Germany 9,151 7.6% Colombia 11,300 11.8% Italy 8,027 8.1% Indonesia 6,665 5.0% Japan 7,268 6.1% Indonesia 4,149 4.3% Japan 7,086 7.1% Ethiopia 4,800 3.6% Italy 5,593 4.7% Guatemala 3,726 3.9% France 6,372 6.4% India 4,363 3.5% France 5,278 4.4% Honduras 3,312 3.5% Spain 4,946 5.0% Mexico 4,550 3.4% Russia 3,177 2.6% India 3,256 3.4% Belgium 4,014 4.0% Guatemala 4,200 3.1% Canada 3,097 2.6% Mexico 2,912 3.0% UK 3,781 3.8% Honduras 4,050 3.0% UK 3,057 2.5% Peru 2,879 3.0% Netherlands 3,449 3.5% Peru 3,207 2.4% Spain 3,017 2.5% Uganda 2,693 2.8% Poland 2,204 2.2% Total 133,547 Total 119,901 Total 99,430 Total 95,967 Source: USDA, International Coffee Organization (Units are 60kg bags) Global Markets Research Page 91 September 2008 A User Guide To Commodities Figure 2: Coffee turnover by exchange 6 Figure 3: Coffee prices since 1957 Annual turnover in 2007 (Futures only, million lots) 5.13 5 Coffee price (US cents/pound) 400 350 4.44 300 4 250 3 200 2 150 0.72 1 100 0.60 0.07 0 Coffee C Arabica (NYBOT) Coffee Robusta Coffee Arabica Coffee Arabica Coffee Robusta (EURONEXT) (BM&F) (TGE) (TGE) Source: TGE, NYBOT, EURONEXT, BM&F 50 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: IMF, Bloomberg (monthly data as of end July-08) Exchange traded Coffee futures and options are traded on the Tokyo Grain Exchange (TGE), the Coffee, Sugar and Cocoa Exchange Division of the New York Board of Trade (NYBOT), EURONEXT London and the Brazilian Mercantile & Futures Exchange (BM&F). The NYBOT Coffee “C” Futures contract was first listed in 1955 and is for delivery of arabica coffee, in a contract size of 37,500 pounds and quoted in US cents per pound. Since October 2007, NYBOT offers a Robusta coffee futures contract. This reflects the growing importance of robusta production, which regularly accounts for around 40% of global coffee production. The size and pricing conventions are the same as for the Coffee “C” futures contract. The EURONEXT London robusta coffee futures contract calls for delivery of robusta coffee in a contract size of five tonnes, quoted in US dollars per tonne. The TGE trades both the arabica and robusta bean futures contracts. The Bloomberg codes for the total return and excess return DBLCI-Optimum Yield Coffee C Index are DBLCYTKC <Index> and DBLCYEKC <Index> respectively. Figure 4: Per capita coffee consumption Figure 5: Coffee inventory-to-consumption ratio 2500 14 Coffee inventory-to-consumption ratio Total available stocks divided by daily consumption Per capita coffee consumption (kg, 2007) 12 2000 Days of use 10 8 6 1500 1000 4 500 2 0 Fin Nor Den Neth Swz Source: International Coffee Organization Page 92 Ger Ita USA Japan Russia 0 1961 1970 1979 1988 1997 2006 Source: DB Global Markets Research, USDA Global Markets Research September 2008 A User Guide To Commodities Corn History & properties Corn or maize is a native grain of the Americas. It is part of the coarse grain family, which also includes barley, sorghum, oats and rye. Corn is the world’s largest cereal crop in terms of global production, amounting to 789 million tonnes in 2007, compared to wheat production of 611 million tonnes during the same year. Fossils of corn pollen have been found in lake sediment under Mexico City dating back over 80,000 years. Corn can be cultivated in very diverse environments from sea level to as high as 12,000 feet. It can also grow in climates with as little as 12 inches or as much as 400 inches of rainfall per annum. Major producers & consumers The United States is the world’s largest producer and exporter of corn, representing 42% of global production and 63% of world exports in 2007. The largest corn producing states in the US are Iowa, Illinois, Nebraska, Minnesota and Indiana. After the US, Argentina is the world’s second largest exporter of corn. China is the world’s second largest consumer of corn while Japan is the world’s largest importer, importing more than three times as much corn as it does wheat and soybeans. 80% of Japan’s corn imports come from the US and their value is greater than any other good imported from the US. In China, domestic corn consumption is rising rapidly, particularly as an animal feed. This is in response to the increasing consumption of meat. Strong consumption growth has been met by a significant drawdown in corn inventories and a sharp drop in Chinese corn exports. Major uses Corn is used for livestock feed, human consumption and as a feedstock for ethanol production, most notably in the US. Since 1990, corn demand for ethanol purposes has risen from 360 million bushels to 3,230 million bushels or equivalent to 26% of total US corn production. The United States Department of Agriculture estimates that by 2010 the US ethanol industry will absorb 4.3 billion bushels of corn per annum, equivalent to one-third of US corn production. Other feedstocks used for ethanol production include sugar and sorghum. Demand for corn as an animal feed has also been rising due to the improvement in living standards and specifically more high protein diets across Asia. Cattle are voracious consumers of grains, such that approximately seven pounds of feed are required to generate an additional one pound in weight. Figure 1: The world’s top 10 corn producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Tonnes % of Producers (000s) world Consumers (000s) Tonnes % of world Exporters (000s) world Importers (000s) world US 332,092 42.1% US 264,044 34.1% US 61,598 63.3% Japan 16,600 17.4% China 151,830 19.2% China 149,000 19.3% Argentina 15,500 15.9% EU-27 13,000 13.6% Brazil 57,500 7.3% EU-27 61,500 8.0% Brazil 9,000 9.3% Mexico 9,200 9.6% EU-27 47,324 6.0% Brazil 42,500 5.5% India 2,200 2.3% Korea 9,100 9.5% Mexico 22,650 2.9% Mexico 32,000 4.1% Ukraine 2,000 2.1% Egypt 4,200 4.4% Argentina 21,000 2.7% India 16,900 2.2% Paraguay 1,500 1.5% Taiwan 4,200 4.4% India 19,310 2.4% Japan 16,500 2.1% S. Africa 1,500 1.5% Colombia 3,500 3.7% Canada 12,000 1.5% Canada 13,800 1.8% Canada 600 0.6% Canada 3,100 3.2% S. Africa 11,650 1.5% Egypt 10,400 1.3% China 600 0.6% Iran 2,700 2.8% Indonesia 7,500 1.0% Korea 9,100 1.2% EU-27 600 0.5% Malaysia 2,500 2.6% World 789,150 World 773,369 World 97,278 World 95,473 Source: USDA (metric tons); To convert tonnes into bushels multiply by 39.367 Global Markets Research Page 93 September 2008 A User Guide To Commodities Figure 2: Corn turnover by exchange Figure 3: Corn price since 1972 Annual turnover on in 2007 (Million lots 2007) 70 59.4 60 8 1st nearby corn futures price (USD/bushel) 7 54.5 6 50 5 40 4 30 3 20 2 10 4.6 0.1 1 1972 1976 1980 1984 1988 1992 1996 2000 2004 2008 0 Corn (DCE) Corn (CBOT) Corn (TGE) Corn (KCE) Source: DCE, CBOT, Tokyo Grain Exchange, Kansai Commodity Exchange Source: Bloomberg (data as of end July-08) Exchange traded The two most important commodity exchanges in terms of corn futures turnover in 2007 were the Dalian Commodity Exchange (DCE) and the Chicago Board of Trade (CBOT). While turnover on the DCE exceeded that on CBOT last year, there is a significant difference in terms of contract size which for the CBOT corn future is 5,000 bushels, but, for the DCE corn future is just under 400 bushels. The CBOT futures exchange calls for the delivery No. 2 yellow corn. Corn futures are also traded on the Tokyo Grain Exchange (TGE) as well as the Kansai Commodity Exchange, Bolsa de Mercadarios & Futuros (BM&F) in Brazil, the Budapest Commodity Exchange, the Mercado a Termino de Buenos Aires, EURONEXT Paris, the Johannesburg Securities Exchange and the Minneapolis Grain Exchange. Price conventions The corn price is quoted in US cents per bushel. The contract months for the Chicago Board of Trade corn future are March, May, July, September and December. The Bloomberg ticker for the first nearby corn futures contract is C 1 <Commodity>. The Bloomberg ticker for the total returns and excess returns Deutsche Bank Corn Indices are DBRCTR <Index> and DBRC <Index> respectively. The DB CornOptimum Yield total return and excess return index codes are DBLCOCNT <Index> and DBLCOCNE <Index> respectively. Figure 4: Global corn inventory-to-consumption ratio Total available stocks divided by daily consumption 160 Corn production 160 140 Corn inventories 140 120 Corn inventory-to-use ratio Tonnes (million) Days of use 180 Figure 5: Chinese corn production and inventory 120 100 80 100 80 60 60 40 40 20 20 1960 1965 1970 1975 1980 1985 Source: DB Global Markets Research, USDA Page 94 1990 1995 2000 2005 0 1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 Source: USDA Global Markets Research September 2008 A User Guide To Commodities Cotton History & properties Cotton is one of the oldest fibres known to man. It has been in use for over 5,000 years and has its origins in modern day Pakistan. However, there is evidence that it was prevalent in Mexico even earlier. The English name derives from the Arabic word al qutun. The quality of the cloth compared to wool so impressed Europeans during th the 14 century that they believed cotton fibre came from lambs that grew on trees, hence the German word “baumwolle” or “tree wool”. Today, cotton is the most important textile fibre in the world, making up more than 40% of total world fibre production. Cotton is classified according to the staple, grade and character of each bale. Staple refers to the fibre length. Grade ranges from coarse to premium and is a function of colour, brightness and purity. Character refers to the fibre’s strength and uniformity. Cotton is measured in terms of bales, with one bale equivalent to 480 pounds in weight. Major producers & consumers The largest producers of cotton are China, India and the US, constituting two-thirds of world production. China is not only the world’s largest producer, but also the largest consumer and importer of cotton. China’s cotton needs are a result of its dominance in the global textile industry. The majority of Chinese cotton acreage is grown on small farms located in the Yellow River valley, Yangtze River valley and Northwest region. The US is the second-largest producer of cotton, but, the world’s top exporter, making up more than a third of total world trade in cotton. The US cotton belt extends from Florida and northern Carolina westward to California. The planting season varies across the US from the beginning of February in Texas to as late as June is the northern part of the US cotton belt, which extends from Texas eastwards to Georgia. In India, the introduction of genetically engineered Bt cotton six years ago helped to propel the country from being a net importer to the world’s second largest net exporter of cotton. Although representing just 6% of world exports, Brazil is also expected to move up the league table of cotton exporters in the years ahead. Major uses Cotton’s properties such as softness, absorbency and insulation make it suited to a diverse range of applications. Its fibres are used to make a variety of textiles that are used in clothing, furnishings and industry. Figure 1: The world’s top 10 cotton producers, consumers, exporters and importers in 2007 Producers Tonnes % of (000s) world Consumers (000s) Tonnes % of world Exporters China 35,800 30% China 49,750 41% US India 24,800 21% India 18,400 15% US 19,207 16% Pakistan 12,325 10% Pakistan 8,900 7% Turkey 6,200 Brazil 7,150 6% US Uzbekistan 5,500 5% Turkey 3,100 Greece 1,325 Turkmenistan Tonnes % of (000s) world Tonnes Importers 13,900 36% China India 7,200 18% Uzbekistan 4,450 11% 5% Brazil 2,250 4,601 4% Australia Brazil 4,350 4% Greece 3% Bangladesh 2,760 2% 1% Indonesia 2,275 2% 1,300 1% Mexico 2,025 Syria 1,150 1% Thailand 1,975 Total 119,305 Total 121,182 (000s) % of world 11,500 30% Pakistan 3,700 10% Turkey 3,200 8% 6% Bangladesh 2,800 7% 1,150 3% Indonesia 2,300 6% 1,050 3% Thailand 1,950 5% Turkmenistan 800 2% Mexico 1,500 4% Burkina Faso 775 2% Russia 1,275 3% 2% Kazakhstan 775 2% Korea 1,050 3% 2% Egypt 550 1% Taiwan 1,000 3% Total 38,945 Total 38,159 Source: USDA (metric tons) Global Markets Research Page 95 September 2008 A User Guide To Commodities Figure 2: Cotton turnover by exchange 7 6.33 Figure 3: Cotton price since 1957 Annual turnover in 2007 (Futures only, million lots) 6 Cotton price (US cents/pound) 140 120 5 100 4 80 2.96 3 60 2 40 1 20 0 Cotton #2 (ICE) 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Cotton (ZCE) Source: ZCE, NYBOT Source: DB Global Markets Research, IMF (monthly data as of end July-08) Exchange traded & prices Cotton futures and options trade on the New York Board of Trade (NYBOT) as well as the Zhengzhou Commodity Exchange. Other exchanges which have listed cotton futures are the MCX and NCDE exchanges in India and the Bolsa de Mercadarios & Futuros (BM&F) in Brazil. The NYBOT Cotton No. 2 futures contract specifies delivery of 50,000 pounds net weight, certain minimum standards of basis grade and staple length, and is quoted in terms of US cents per pound. The five delivery months are March, May, July, October and December. The Bloomberg ticker for the NYBOT one month generic cotton futures contract is CT1 <Commodity>. The Bloomberg tickers for the total returns and excess returns Deutsche Bank Cotton Optimum Yield indices are DBLCYTCT <Index> and DBLCYECT <Index> respectively. Figure 4: Cotton yields since 1960 by country 7000 Cotton yields by country China 1400 US 1200 Pakistan India introduces Bt cotton 5000 4000 India 1000 India's net trade balance in cotton 6000 Bales (000s) Kg per hectare 1600 Figure 5: Biotechnology & Indian cotton exports Brazil 800 600 3000 2000 1000 0 400 -1000 200 0 1960 Source: USDA Page 96 India deploys GE technology 1965 1970 1975 1980 1985 1990 1995 2000 2005 -2000 -3000 1994 1996 1998 2000 2002 2004 2006 Source: USDA Global Markets Research September 2008 A User Guide To Commodities Palm Oil History & properties Trading in palm oil has been dated back to as early as 3,000 BC. Crude palm oil or CPO is produced from the fruits of the oil palm plant, which is native to West Africa. The plant thrives in humid tropical climates within 20 degrees of the equator and at altitudes of less than 1,600 feet. The plum-sized fruits of the oil palm grow in large bunches of between 1,000-3,000 fruits, termed fresh fruit bunches (FFB). The fruit of the oil palm produces two types of oils, palm oil (90%) from the flesh of the fruit and palm kernel oil (10%) from the seed of the fruit. The oil palm has become a popular source of edible oil thanks to its superior oil yield of four tonnes per planted hectare which is 10 times that of soybeans and six times that of rapeseed, making it the most efficient oil-bearing crop in the world. The plant can be harvested throughout the year and has a long productive lifespan of 25-30 years. Major producers & consumers Since oil palm’s introduction to Indonesia and Malaysia in the late 1800s, the two countries have grown to become the largest palm oil producers in the world. According to the USDA, Indonesia and Malaysia accounted for 45% and 42% global CPO production respectively in 2007. Both countries were also the world’s largest exporters of CPO. Oil World estimates that Indonesia’s CPO production is set to rise further and to account for more than 50% of global production by 2011. On the demand side, China was the largest consumer and importer of CPO in 2007, constituting over 14% of global consumption and almost 20% of global imports. According to Oil World, CPO is the world’s most consumed oil, forming 25% of consumption of the 17 major oil and fats in 2007. Demand for CPO is largely driven by its use as a relatively cheap vegetable oil and increasingly as a feedstock for biodiesel. Major uses There are three main areas of palm oil usage, first as a food, second in the oleochemical industry and lastly as a biofuel feedstock. In its edible form, palm oil is used as cooking oil, margarine, confectionary fats and as a non-dairy creamer. As an oleochemical, palm oil is used in the production of soap, cosmetics, detergents and pharmaceutical/nutraceutical products. In recent years, palm oil along with other vegetable oils has also been used as a feedstock for biofuel. Figure 1: The world’s top 10 palm oil producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Producers Tonnes (million) world % of Consumers (million) world Exporters (million) Tonnes % of world Importers (million) world Indonesia 19,300 44.5% China 5,700 14.3% Malaysia 13,800 46.3% China 5,700 19.5% Malaysia 17,400 42.3% Indonesia 4,801 12.0% Indonesia 13,505 45.3% India 4,300 14.7% Thailand 1,050 2.6% India 4,380 11.0% Papua NG 380 1.3% EU-27 3,750 12.8% Colombia 930 2.0% EU-27 3,610 9.0% Thailand 300 1.0% Pakistan 2,420 8.3% Nigeria 820 2.0% Malaysia 3,371 8.4% Jordan 300 1.0% Bangladesh 1000 3.4% Papua NG 400 1.0% Pakistan 2,420 6.1% Colombia 295 1.0% USA 790 2.7% Ecuador 340 0.8% Nigeria 1,020 2.6% UAE 220 0.7% Egypt 750 2.6% Ivory Coast 320 0.8% Bangladesh 1,015 2.5% Singapore 180 0.6% Russia 700 2.4% Costa Rica 285 0.7% Thailand 815 2.0% EU-27 140 0.5% Vietnam 575 2.0% Congo 175 0.4% USA 779 1.9% Ecuador 140 0.5% Japan 530 1.8% World 41,122 World 39,984 World 29,818 World 29,218 Source: USDA (metric tons) Global Markets Research Page 97 September 2008 A User Guide To Commodities Figure 2: Palm oil turnover by exchange Figure 3: Palm oil price since 1958 Annual turnover (mllion lots, 2007) 60 1400 Crude palm oil price (USD/tonne) 54.5 1200 50 40 1000 31.7 30 800 21.4 19.6 20 13.2 12.2 10 8.6 7.3 6.3 600 5.1 4.3 3.5 3.3 400 Co rn So yb ea ns Su ga W r# he 11 at (C BO So T) yb So ean yb O il ea n M ea Li ve l Ca ttl Le an e H og C s ot to n #2 C of W f he ee ‘C at (K ’ C C ru B de T pa ) lm oi l C oc oa 0 Source: CBOT, NYBOT, CME, Bursa Malaysia 200 0 1958 1963 1968 1973 1978 1983 1988 1993 1998 2003 2008 Source: Oil World Monthly of 20 June 2008 Exchange traded The most liquid crude palm oil futures contract is traded on the Bursa Malaysia. Contracts are denominated in Ringgit with a contract size of 25 tonnes. There are also plans in place to introduce a US dollar denominated contract on the bursa Malaysia in the near future. A US dollar denominated CPO futures contract is already listed on the Joint Asian Derivatives Exchange (JADE) in Singapore. Other exchanges that trade CPO include India’s National Commodity & Derivatives Exchange and the National Multi-Commodity Exchange of India. Price conventions The CPO price is most often quoted in Malaysian Ringgits per tonne. The Bloomberg ticker for the first nearby palm oil futures contract is KO1 <Commodity> and the benchmark Malaysian Palm Oil Board CPO spot price ticker is PAL2MALY <Commodity>. The Bloomberg Contract Rotterdam CPO price, which is quoted in US dollars per tonne, is PALMROTT <Index>. Figure 4: Oilseed production compared 3.7% Figure 5: Land planted to various commodities 9.2% Palm & palm kernel oil 3.5% 4.1% Soya oil 9.2% 34.2% Rapeseed oil Soya 4.5% Cotton 9.4% 40.5% Sunflower oil Rape Sunflower Cottonseed oil Groundnut oil 15.2% Groundnut 10.1% Oil palm Others Others 11.3% 15.0% 30.1% Source: Oil World Monthly of 20 June 2008 Page 98 Total oilseed production in 2007/08 = 122.1 million tonnes Total area planted in 2007/08 = 232.4 million hectares Source: Oil World Monthly of 20 June 2008 Global Markets Research September 2008 A User Guide To Commodities Rapeseed History & properties Rapeseed production goes back 4,000 years, when it was used for cooking and as lamp oil in China and India. Today, it is the second largest oilseed crop after soybeans, and the third largest vegetable oil after soybean oil and palm oil. It has passed peanut, cottonseed, and sunflower in worldwide production during the past twenty years because of the increasing use of Canola. Canola is a genetic variation of rapeseed and was developed in Canada. The word canola derives from Canadian oil, low acid. Although rapeseed has been domestically grown since World War II, its popularity increased significantly from 1985 after canola oil was granted safe as a food additive by the US Food and Drug Administration. Major producers & consumers The European Union and China account for 60% of the world’s production of rapeseed. India and Canada, the next largest producers account for 12% and 9% respectively of global production. The major consumers are the European Union, China, India and Canada. Although the EU and China are large producers, they are net importers of rapeseed. In terms of exports, Canada is the world’s largest exporter accounting for almost 70% of world’s exports, followed by Ukraine and Australia. Major uses Processing of rapeseed for oil production provides animal meal as a by-product, which has a high protein content. Rapeseed is also a heavy nectar producer. A more recent development is the use of oil in the manufacture of bio-diesel. Europe is the world’s largest bio-diesel producer and rapeseed is its main feedstock. Exchange traded Rapeseed and/or canola futures and options are traded on EURONEXT, the Winnipeg Commodities Exchange and the Australian Stock Exchange. The EURONEXT rapeseed futures contract calls for the delivery of 50 tonnes of rapeseed. Rapeseed oil futures are listed on the Zhengzhou Commodity Exchange. Price conventions The Bloomberg ticker for the WCE one month generic canola futures contract is RS1 <Commodity>. The price of canola is quoted in Canadian dollars per tonne. Figure 1: The world’s top 10 rapeseed producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Tonnes % of Producers (‘000) world Consumers (‘000) world Exporters Tonnes % of (‘000) world Importers (‘000) world EU-27 18,333 38.8% EU-27 19,040 38.9% Canada 5,750 69.6% Japan 2,250 28.5% China 10,375 21.9% China 11,224 22.9% Ukraine 925 11.2% Mexico 1,200 15.2% Canada 8,750 18.5% India 5,866 12.0% Australia 550 6.7% Pakistan 900 11.4% India 5,450 11.5% Canada 4,347 8.9% USA 435 5.3% USA 874 11.1% Ukraine 1,100 2.3% Japan 2,243 4.6% EU-27 390 4.7% China 850 10.8% Australia 1,065 2.3% Mexico 1,200 2.5% Russia 125 1.5% EU-27 660 8.4% USA 659 1.4% Pakistan 1,090 2.2% Kazakhstan 50 0.6% UAE 480 6.1% Russia 632 1.3% USA 1,075 2.2% Paraguay 30 0.4% Turkey 260 3.3% Bangladesh 210 0.4% Australia 535 1.1% India 4 0.0% Canada 200 2.5% Pakistan 190 0.4% Russia 507 1.0% Chile 1 0.0% Bangladesh 150 1.9% World 47,310 World 48,909 World 8,261 Total 7,892 Source: USDA (metric tons) Global Markets Research Page 99 September 2008 A User Guide To Commodities Rice History & properties Rice is a staple diet for half of the world’s population, especially in tropical Latin America, and East, South and Southeast Asia. The plant, which measures 2-6 feet tall, has long, flat leaves and stalk-bearing flowers that produce the grain called rice. Rice is rich in genetic diversity, with thousands of varieties grown throughout the world. In addition, it is entirely non-allergenic and gluten-free. Although it can be grown practically anywhere, rice cultivation is well suited to regions with high rainfall and low labour costs, as it is very labour-intensive to cultivate and requires plenty of water. Major producers & consumers China and India account for more than half of the world’s production, with Asia combined constituting 90% of global rice production. The largest three exporting countries are Thailand (33.3%), Vietnam (15.2%) and the US (13.2%), while the largest three importers are the Philippines (7.8%), Bangladesh (6.6%) and Nigeria (6.2%). Although, China and India are the top producers of rice in the world, both countries consume most of the rice produced domestically leaving not much to be traded internationally. Both countries constitute around 30% and 22% of the world’s consumption respectively. Global rice production is forecast to rise to a record high of 431 million tones in 200809. However, fundamentals in the global rice market have been tightening for the past few years as US and global rice inventories have fallen to their lowest levels since the early 1980s. The size of the global traded market in rice has contracted this year in response to export restrictions being applied to a number of key exporting countries, most notably Vietnam and India. This has contributed to rice prices hitting record highs in the first half of this year. Major uses Apart from being a staple food, rice has other uses as well. Rice starch is used in making ice-cream, custard powder, puddings and gel. The bran is used in confectionary products. The defatted bran is also used as s cattle feed and organic fertilizer. Rice bran oil is used as edible oil and in manufacturing soaps and fatty acids. Rice husk is used as a fuel, in board and paper manufacturing, packing and building materials and as an insulator. Figure 1: The world’s top 10 rice producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Producers Tonnes (million) world % of Consumers (million) world Exporters (million) Tonnes % of world Importers (million) world China 129.8 30.3% China 127.3 30.2% Thailand 10.0 33.0% Philippines 2.0 7.8% India 96.4 22.5% India 90.8 21.5% Vietnam 4.8 15.7% Nigeria 1.6 6.3% Indonesia 35.5 8.3% Indonesia 36.4 8.6% India 4.1 13.5% Bangladesh 1.4 5.5% Bangladesh 28.6 6.7% Bangladesh 30.2 7.2% USA 3.4 11.2% EU-27 1.1 4.3% Vietnam 23.9 5.6% Vietnam 19.0 4.5% Pakistan 3.0 9.9% Indonesia 1.1 4.3% Thailand 18.5 4.3% Philippines 12.8 3.0% China 1.0 3.3% S. Arabia 1.0 3.7% Myanmar 10.7 2.5% Myanmar 10.3 2.4% Uruguay 0.8 2.6% Iran 0.9 3.5% Philippines 10.6 2.5% Thailand 9.5 2.2% Argentina 0.5 1.7% Iraq 0.9 3.5% Brazil 8.4 1.9% Brazil 8.4 2.0% Egypt 0.5 1.5% S. Africa 0.9 3.3% Japan 7.9 1.8% Japan 8.2 1.9% Brazil 0.4 1.4% Malaysia 0.8 3.1% World 429.0 World 422.0 World 30.3 Total 25.6 Source: USDA (metric tons) Page 100 Global Markets Research September 2008 A User Guide To Commodities Figure 2: Future trading compared 60 Figure 3: Rice price since 1989 Annual futures turnover in 2007 for various agricultural products on US exchanges (million lots) 54.5 50 25 1st nearby rough rice futures price (USD/cwt) 20 40 15 31.7 30 21.4 20 10 19.6 10 6.3 5 5.1 0.4 0 Corn (CBOT) Soybeans (CBOT) Sugar #11 (NYBOT) Wheat (CBOT) Cotton #2 (NYBOT) Coffee 'C' Rough Rice (NYBOT) (CBOT) Source: CBOT, NYBOT 0 1989 1991 1993 1995 1997 1999 2001 2003 2005 2007 Source: Bloomberg, CBOT (data as of end July 2008) Exchange traded Rice futures and options are traded on Chicago Board of Trade (CBOT). The deliverable grade is US No. 2 or better long grain rough rice with a total milling yield of not less than 65%, including head rice of not less than 48% with a contract size of 2000 cwt. Despite being one of the most important commodities in the world, futures trading in rice is virtually non-existent. We believe the relatively inactive trading in rice futures reflects the various grades available and the relatively small internationally traded market in rice. Price conventions The price of rice is quoted in US dollars per hundred pounds (cwt). The Bloomberg ticker for the CBOT one month rough rice futures contract is RR1 < Commodity>. Figure 4: Global rice production & exports 500 Figure 5: Rice inventory-to consumption ratio 140 World rice production World rice exports Rice inventory-to-consumption ratio (days) 120 400 Tonnes (million) 100 300 80 60 200 40 100 20 0 0 1960 1965 1970 Source: USDA Global Markets Research 1975 1980 1985 1990 1995 2000 2005 1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 Source: DB Global Markets Research, USDA Page 101 September 2008 A User Guide To Commodities Rubber History & properties The origins of rubber are in South America before it was discovered by European th explorers in the 15 century. The first popular use of the substance was in the late th 18 Century as an eraser to “rub out” pencil marks, hence the name rubber. There are two types of rubber that are in use today: natural and synthetic rubber. Natural rubber is obtained by coagulating the latex produced by the rubber tree also known as the Hevea Brasiliensis tree. Synthetic rubber is a petroleum product and is almost identical to natural rubber in its physical and chemical properties. However, it was not until WW1 when Germany developed the industrial version of synthetic rubber that it became commercially viable. Before that time the production of synthetic rubber was prohibitively expensive. The development of synthetic rubber production was further accelerated when US supplies from Asia were severely curtailed during the second world war and alternative supplies were required. The advantages of synthetic rubber over natural rubber are the former’s great resistance to oil, solvents, oxygen and certain chemicals, and a greater resilience over a wider temperature range. Major producers and consumers The largest producers of natural rubber are Thailand, Indonesia and Malaysia, accounting for just over 70% of global production in 2006. China, the US, EU-25 and Japan are the largest consumers and hence importers of natural rubber. China overtook the US to become the world’s largest consumer of natural rubber in 2000. Since then the country’s appetite for rubber as with other commodities has increased rapidly. Since 1999 China’s rubber consumption has nearly trebled. Today, China constitutes about 26% of the world’s rubber consumption. Major uses The characteristics and properties of rubber such as elasticity, water repellence, electrical resistance, heat tolerance and toughness make it suited for a variety of applications. The most common use of rubber is in the production of tyres and footwear. It is also extensively used in the production of a broad range of latex products, gloves and electrical insulators. Resistance to abrasion also makes rubber valuable for pump housings and piping. Thanks to the resistance of rubber to water, it is also widely used in rainwear, diving gear and chemical and medicinal tubing. Figure 1: The world’s top 10 rubber producers and consumers in 2006 Producers Tonnes (‘000) % of world Consumers Tonnes (‘000) % of world Thailand 3,137 32.4% China 2,400 26.0% Indonesia 2,637 27.3% USA 1,003 10.9% Malaysia 1,283 13.3% Japan 873 9.5% India 853 8.8% India 815 8.8% Vietnam 553 5.7% Malaysia 383 4.2% China 533 5.5% Korea 363 3.9% Ivory Cost 178 1.8% Indonesia 355 3.8% Sri Lanka 109 1.1% Thailand 320 3.5% Brazil 108 1.1% Brazil 286 3.1% 101 1.0% Germany 269 2.0% Liberia Total 9,676 Total 9,226 Source: International Rubber Study Group Page 102 Global Markets Research September 2008 A User Guide To Commodities Figure 2: Rubber trading by exchange Figure 3: Rubber price since 1972 Annual turnover in 2007 (Futures only, million lots) 50 1st nearby rubber futures price (JPY/kg) 350 42.2 300 40 250 30 200 150 20 100 10 7.1 0 SFE TOCOM 50 0.1 0.0 OME (RSS3) OME (TSR20) Source: SFE, TOCOM, OME 0 1988 1991 1994 1997 1999 2002 2005 2008 Source: Bloomberg (data as of end July-08) Exchange traded Natural rubber futures are listed on a number of exchanges around the world. The RSS3 natural rubber (Ribbed Smoked Sheets No. 3) contracts are traded on the Osaka Mercantile Exchange (OME), the Tokyo Commodity Exchange (TOCOM), the Singapore Commodity Exchange (SICOM), the Agricultural Futures Exchange of Thailand (AFE) and the Shanghai Futures Exchange (SHFE). The other exchange traded natural rubber grades include RSS 1(SICOM), TSR 20 (SICOM, CBOT) and SCR 5 (SHFE). The Bloomberg tickers for various RSS3 contracts are shown in Figure 4. Figure 4: RSS3 Bloomberg Tickers Exchange Ticker Agricultural Futures Exchange of Thailand A61 <CMDTY> Osaka Mercantile Exchange RQ1 <CMDTY> Singapore Commodity Exchange RG1 <CMDTY> Tokyo Commodity Exchange JN1 <CMDTY> Source: Bloomberg Global Markets Research Page 103 September 2008 A User Guide To Commodities Soybeans History & properties The soybean is a member of the oilseed family, which also includes canola, peanuts, rapeseed and sunflower seed. Soybeans are native to Asia and specifically China, Japan and Korea. The English word soy is derived from the Japanese word shoyu. It th was introduced into the US at the end of the 18 Century. Major producers & consumers The United States is the largest producer of soybeans in the world. It has overtaken wheat to be the country’s second largest production of any crop after corn. Soybean production is concentrated in Illinois, Iowa, Minnesota, Indiana, Nebraska and Ohio. Soybean crops in the US are planted in May or June and are harvested in autumn as the crop typically matures between 100-150 days after planting. Brazil and Argentina are the world’s second and third largest soybean producers and since 2002 the combined exports of these two countries have exceeded US soybean exports. Currently, 91% of all soybeans cultivated in the US are genetically modified. Genetically engineered soybeans have also been deployed in Argentina and Brazil. Consequently, of the total global area of soybeans under cultivation, 64% is genetically modified. In Brazil, of the 15 million hectares dedicated to GE crops, 14.5 million relate to GE soybeans and the remainder to Bt corn. Part of the success of GE soybean technology has been its ability to reduce fertilizer spraying by 50-80% and hence lower input costs into the farming process. The USDA estimates that soybean acreage in Brazil will grow by an average of 3% per annum into the next decade and by 2016 the country will overtake the US to become the world’s largest producer of soybeans. Major uses Soybeans are used to produce a wide variety of food products. The key value of soybeans is their relatively high protein content without the many negative factors associated with animal meat. Common forms of soy include soy meal used as animal feed for poultry and swine and more recently the aquaculture of catfish. Soy milk is used in imitation dairy products, such as soy yogurt, ice cream and soy cheese. Soybeans are also used in the industrial production of soap, cosmetics, resins, plastics, inks, crayons, solvents and bio-diesel. Typically the US, Brazil and Argentina have employed soybeans as a feedstock for bio-diesel production while Indonesia, Malaysia and the EU use palm oil and rapeseed oil. Figure 1: The world’s top 10 soybean producers, consumers, exporters and importers in 2007 Tonnes % of Producers (000s) world Consumers (000s) world Exporters (000s) USA 70,358 32.2% USA 51,410 22.3% USA 31,162 40.7% China 35,400 46.5% Brazil 61,000 28.0% China 48,650 21.1% Brazil 25,650 33.5% EU-27 14,500 19.1% Argentina 46,500 21.3% Argentina 37,316 16.2% Argentina 12,200 15.9% Japan 4,050 5.3% China 13,500 6.2% Brazil 35,450 15.3% Paraguay 4,360 5.7% Mexico 3,750 4.9% India 9,300 4.3% EU-27 15,381 6.7% Canada 1,720 2.2% Argentina 2,550 3.4% Paraguay 6,800 3.1% India 9,223 4.0% Uruguay 800 1.0% Taiwan 2,250 3.0% Canada 2,700 1.2% Japan 4,255 1.8% China 350 0.5% Thailand 1,600 2.1% Bolivia 1,050 0.5% Mexico 3,835 1.7% Ukraine 200 0.3% Indonesia 1,400 1.8% Uruguay 830 0.4% Paraguay 2,469 1.1% EU-27 41 0.1% S. Korea 1,250 1.6% Indonesia 780 0.4% Taiwan 2,265 1.0% Bolivia 30 0.0% Turkey 1,200 1.6% Total 218,231 Tonnes Total 230,986 % of Tonnes Total 76,576 % of world Importers Total Tonnes % of (000s) world 76,069 Source: USDA (metric tons) Page 104 Global Markets Research September 2008 A User Guide To Commodities Figure 2: Soybean trading by exchange 50 47.4 Figure 3: Soybean price since 1972 18 Annual turnover in 2007 (million lots) 16 40 1st nearby soybean futures price (USD/bushel) 14 31.7 12 30 10 8 20 12.3 6 10 4 1.2 2 0 No. 1 Soybeans (DCE) Soybeans (CBT) Non-GMO Soybeans (TGE) Soybeans (TGE) Source: DCE, CBT, TGE 0 1972 1976 1980 1984 1988 1992 1996 2000 2004 2008 Source: Bloomberg (data as of end July-08) Exchange traded Soybean futures and options are traded on the Dalian Commodity Exchange in China, the Chicago Board of Trade (CBOT) and the Tokyo Grain Exchange (TGE). In addition, soybean futures are also listed on the Bolsa de Mercadarios & Futuros (BM&F) in Brazil, the Mercado a Termino in Buenos Aries, the Kansai Commodity Exchange, the NCDEX in India and the South African Securities Exchange. Although the futures turnover on the DCE was approximately 50% greater than that of the CBOT soybeans futures contract in 2007, contract size is significantly lower with the DCE calling for the delivery of less than 400 bushels. In comparison the CBOT soybean futures contract calls for the delivery of 5,000 bushels of No. 2 yellow soybeans. Soybean meal and soybean oil futures contracts are also listed on the DCE and CBOT exchanges. Price conventions The soybean price is quoted in US cents per pound. The Bloomberg ticker for the CBOT one month generic soybean futures contract is S 1 <Commodity>. The Bloomberg tickers for the total returns and excess returns Deutsche Bank Soybean Optimum Yield indices are DBLCYTSS <Index> and DBLCYESS <Index> respectively. Figure 4: Soybean inventory-to-use ratio 100 Figure 5: Soybean yields since 1986 by country Soybean inventory-to-use ratio 4.0 Soybean yields by country 3.5 80 Tonne per hectare Days of use 40 Brazil Argentina China From 1996, the US, Argentina and Brazil deploy GE technology India 3.0 60 US 2.5 2.0 1.5 1.0 20 Total available stocks divided by daily consumption 0 1965 1970 1975 Source: USDA Global Markets Research 1980 1985 1990 1995 2000 2005 0.5 0.0 1986 1989 1992 1995 1998 2001 2004 2007 Source: DB Global Markets Research, USDA Page 105 September 2008 A User Guide To Commodities Sugar History & properties Sugar cane is thought to have originated in New Guinea as much as 9,000 years ago. However, the first reported production of sugar from sugar cane took place on the River Ganges around 2,000 years ago. The word sugar originates from the Indian Sanskrit word sharkara, which later became al zukkar in Arabic. Sugar did not arrive in th Europe until the 14 Century. At the time, sugar was so expensive that one ounce of gold could buy just 30 pounds of sugar. Today a similar amount of gold can buy 7,200 pounds of sugar. Sugar can be derived from both sugar cane and sugar beets, the latter being more costly to produce. There is little perceptible difference between the sugar derived from either source. Most sugar cane comes from countries with warm climates, such as Brazil, India, China and Australia. Beet sugar is grown in regions with cooler climates. Of all the sugar produced, almost 80% is processed from sugar cane. The International Sugar Organization currently has 83 members, which constitute just over 80% of world sugar production and 95% of world exports. Major producers & consumers Brazil is the largest producer and exporter of sugar in the world with Thailand a distant second in terms of exports. Brazil, Thailand, Australia and India account for approximately two-thirds of global exports. US production is evenly divided between beet and cane sugar. The largest sugar beet producing states are Minnesota, Idaho, North Dakota and Michigan. The largest cane producers are Florida, Louisiana, Texas and Hawaii. Subsidies and high import tariffs have made it difficult for other countries to export into the EU or compete with it on world markets. The World Trade Organisation ruling in April 2005 against EU sugar export subsidies heralded a four-year programme of subsidy cuts, which has seen a decline in EU sugar production, such that by 2006 the EU-27 became a net importer of sugar. Exchange traded The most actively traded sugar futures contract is the No. 11 (world) sugar contract on the New York Board of Trade (NYBOT). Other exchanges which have listed sugar futures are the Bolsa de Mercadorias & Futuros (BM&F), the Tokyo Grain Exchange (TGE), the Kansai Commodity Exchange, the Zhengzhou Commodity Exchange, EURONEXT and the MCX and NCDEX exchanges in India. Figure 1: The world’s top 10 sugar producers, consumers, exporters and importers in 2007 Producers Tonnes % of (000s) world Tonnes Consumers (000s) % of world Exporters Tonnes % of (000s) world Importers Tonnes % of (000s) world Brazil 31,450 19.2% India 22,113 14.8% Brazil 20,850 41.3% EU-27 4,338 9.4% India 30,780 18.7% EU-27 18,716 12.6% Thailand 4,705 9.3% Russia 3,300 7.2% EU-27 17,757 10.8% China 13,000 8.7% Australia 3,860 7.7% Indonesia 2,420 5.2% China 12,855 7.8% Brazil 10,800 7.2% India 2,680 5.3% UAE 2,180 4.7% USA 7,663 4.7% USA 8,993 6.0% EU-27 2,162 4.3% USA 1,887 4.1% Thailand 6,720 4.1% Russia 6,100 4.1% UAE 1,730 3.4% Korea 1,680 3.6% Mexico 5,633 3.4% Mexico 5,130 3.4% Guatemala 1,500 3.0% Iran 1,600 3.5% Australia 4,822 2.9% Indonesia 4,100 2.8% S. Africa 1,145 2.3% Malaysia 1,515 3.3% Pakistan 3,615 2.2% Pakistan 3,950 2.7% Colombia 942 1.9% S. Arabia 1,515 3.3% Russia 3,150 1.9% Egypt 2,598 1.7% Argentina 633 1.3% China 1,465 3.2% World 164,181 World 149,002 World 46,098 World 50,442 Source: USDA Page 106 Global Markets Research September 2008 A User Guide To Commodities Figure 2: Sugar turnover by exchange 25 Figure 3: Sugar price since 1957 Annual turnover in 2007 (Futures only, million lots) 21.4 20 Sugar price (US cents/lb) 60 50 15 40 10 30 20 5 2.1 10 0.4 0 Sugar #11 (ICE) White sugar (EURONEXT) Raw sugar (TGE) Source: NYBOT, EURONEXT, TGE 0 1957 1962 1967 1972 1977 1982 1987 1992 1997 2002 2007 Source: DB Global Markets Research, IMF (monthly data as of end July-08) The NYBOT No. 11 contract calls for the delivery of 112,000 pounds (50 long tons) of raw cane centrifugal sugar from any of the 28 producing countries and the United States. The majority (almost 80% of the total tonnage) delivered against NYBOT’s sugar futures contract is accounted for by Brazilian sugars. Futures on white sugar are traded on EURONEXT and call for the delivery of 50 metric tons of white beet sugar, cane crystal sugar or refined sugar of any origin. Price conventions The sugar price is quoted in US cents per pound. The Bloomberg ticker for the one month generic futures sugar contract is SB1 < Commodity>. The Bloomberg tickers for the total returns and excess returns Deutsche Bank Sugar Optimum Yield indices are DBLCYTSB <Index> and DBLCYESB <Index> respectively. Figure 4: Sugar inventory-to-consumption ratio 150 Figure 5: Sugar cane versus beet production Sugar inventory-to-consumption ratio 140 Global sugar cane production 140 100 Tonnes (million) Days of use 120 110 100 90 80 60 80 40 70 20 60 1960 Global sugar beet production 120 130 1965 1970 Source: USDA Global Markets Research 1975 1980 1985 1990 1995 2000 2005 0 1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 Source: USDA Page 107 September 2008 A User Guide To Commodities Wheat History & properties Wheat is believed to have originated in the area known as the Fertile Crescent, an area watered by the Nile, Jordan, Euphrates and Tigris rivers. The earliest archaeological evidence for wheat cultivation comes from Syria and Turkey around 10,000 years ago. It was only introduced into the United States at the beginning of th the 17 Century. Wheat is classified according to season, gluten content and grain colour. The different growing seasons mean that there is either winter wheat or spring wheat. Winter wheat in the United States is planted from September to December and harvested in early July. In terms of gluten content, wheat can either be hard or soft. Hard wheat has a high protein content while soft wheat has a high starch content. Wheat is also classified according to grain colour such as red, white or amber. Wheat planted in the spring is mostly red wheat while winter wheat is mostly white wheat. Major producers & consumers The world’s largest wheat producer is the European Union followed by China and India. The United States is the fourth largest producer of wheat in the world, but, it is the world’s largest exporter, representing 30% of global exports. Its share of world exports has risen in the last few years on account of production setbacks in other key exporting countries such as Australia. The largest US wheat producing states are Kansas, Oklahoma, Washington and Texas. Extreme weather events such as droughts in Australia, Russia and the Ukraine and flooding in the UK and France were responsible for disruptions to wheat production during 2007. For example, between 2005 and 2007 Australian wheat production fell from 24.5 million tonnes to just 13.0 million tonnes. This pushed the country from being the world’s second largest wheat exporter to the world’s seventh. This year, droughts in Iran are expected to lead to a significant increase in the country’s wheat imports, most notably from Russia. Major uses Wheat is a staple food used to make flour for bread, cakes, pasta and noodles as well as for fermentation to make alcohol. The husk of the grain, separated when milling white flour, is bran. Wheat is also planted as a forage crop for livestock while straw is also used for roofing thatch. Figure 1: The world’s top 10 wheat producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Producers (000s) world Consumers (000s) Tonnes % of world Exporters (000s) world Tonnes % of Importers (000s) EU-27 119,251 19.5% EU-27 118,465 19.1% USA 34,403 world 30.2% Egypt 7,500 China 109,860 18.0% China 104,000 16.8% Canada 6.8% 16,500 14.5% Brazil 7,000 India 75,810 12.4% India 75,850 12.3% 6.3% Russia 12,000 10.5% EU-27 6,500 USA 56,247 9.2% Russia 38,200 5.9% 6.2% EU-27 11,000 9.7% Japan 5,500 5.0% Russia 49,400 8.1% USA Pakistan 23,300 3.8% Pakistan 29,005 4.7% Argentina 10,000 8.8% Indonesia 5,300 4.8% 22,400 3.6% Kazakhstan 8,500 7.5% Algeria 5,200 Canada 20,050 3.3% 4.7% Turkey 16,800 2.7% Australia 7,470 6.6% Morocco 4,700 Kazakhstan 16,600 4.2% 2.7% Egypt 15,850 2.6% China 2,800 2.5% Mexico 3,600 Argentina 3.2% 16,000 2.6% Iran 15,500 2.5% Pakistan 2,200 1.9% Iraq 3,500 3.2% Turkey 15,500 2.5% Ukraine 12,900 2.1% Turkey 1,300 1.1% USA 3,065 2.8% World 610,537 World 619,007 World 113,958 World 110,895 Source: USDA; To convert tonnes into bushels multiply by 36.7437 Page 108 Global Markets Research September 2008 A User Guide To Commodities Figure 2: Wheat turnover by exchange Figure 3: Wheat prices since 1972 Annual turnover in 2007 (Futures only, million lots) 45 12 1st nearby wheat futures price (USD/bushel) 39.0 40 10 35 8 30 25 19.6 20 6 15 4 10 4.3 5 1.8 2 0 Wheat (ZCE) Wheat (CBT) Wheat (KCBT) Wheat (MGE) Source: CBT, KCBT, MGE, ZCE 0 1972 1975 1978 1981 1984 1987 1990 1993 1996 1999 2002 2005 2008 Source: Bloomberg (data as of end July 2008) Exchange traded Wheat futures and options are traded on the Chicago Board of Trade (CBOT), the Kansas City Board of Trade (KCBT) and the Minneapolis Grain Exchange (MGE). In China, the Zhengzhou Commodity Exchange trades the strong gluten wheat and the hard winter wheat contracts. Wheat futures are traded, albeit with considerably lower volumes on the Australian Stock Exchange, the Turkish Derivatives Exchange, the Mercado a Termino de Buenos Aires (MAT), EURONEXT, the South African Futures Exchange, the Budapest Commodity Exchange (BCE) and the MCX and NCDEX exchanges. The Chicago Board of Trade’s wheat futures contract calls for the delivery of soft red wheat (No. 1 and 2), hard red winter wheat (No. 1 and 2) and dark northern spring wheat (No. 1 and 2). Annual turnover for the wheat futures contract on the DCE in 2007 surpassed that of the equivalent CBOT futures contract. However, the contract size of the CBOT wheat future is 12 times larger than the DCE futures contract. Price conventions The wheat price is quoted in US cents per bushel. The Bloomberg ticker for the one month generic futures wheat contract is W 1 <Commodity>. The Bloomberg code for the Deutsche Bank Wheat total and excess returns indices are DBRWTR <Index> and DBRW < Index> respectively. The Bloomberg tickers for the total returns and excess returns Deutsche Bank Wheat Optimum Yield indices are DBLCOWTT <INDEX> and DBLCOWTE <Index> respectively. Deutsche Bank also employs the optimum yield technology on the Kansas City wheat contract. The Bloomberg index codes for the total and excess return indices on this contract are DBLCYTKW <Index> and DBLCYEKW <Index> respectively. Figure 4: Wheat inventory-to-consumption ratio 160 Figure 5: Iran’s trade balance in wheat Total available stocks divided by daily consumption Wheat inventory-to-use ratio 4 Iranian net trade balance in wheat 2 140 Tonnes (million) Days of use 0 120 100 -2 -4 -6 80 Net imports -8 -10 60 1980 1960 1965 1970 Source: USDA Global Markets Research 1975 1980 1985 1990 1995 2000 1984 1988 1992 1996 2000 2004 2008 2005 Source: USDA Page 109 September 2008 A User Guide To Commodities Livestock Of the five broad commodity sectors, livestock is one of the smallest in terms of production, world trade and futures turnover. The United States is the world’s largest producer of beef followed by Brazil and the EU-27 countries. However, the global trade in meat products is small compared to world production. In recent years, the internationally traded market in beef has also been negatively affected by the BSE virus and the subsequent import bans that were introduced by many countries across Asia and Europe. Today Brazil is the world’s leading exporter of beef while China is the world’s largest producer and consumer of pork. The livestock industry has had to contend with a significant increase in feedstock prices such as grains over the past few years. However, the improvement in living standards in many parts of the developing world is increasing the demand for more high protein diets. For example, per capita beef consumption in China has been rising rapidly over the past decade, but, still remains significantly below the newly industrialised nations across Asia such as Korea. Figure 1: Agricultural and livestock futures turnover on US exchanges in 2007 Livestock Annual turnover, mllion lots (2007) 60 54.5 Figure 2: Livestock & agricultural scorecard since 2006 200 Price appreciation since the end of 2005 (%) Agriculture 50 150 40 100 31.7 30 21.4 19.6 50 0 Source: CBT, KCBT, MGE, CME, NYBOT Source: Bloomberg (Data as of August 22, 2008) Figure 3: Meat consumption relative to income Figure 4: Meat consumption by type & country Meat consumption as a function of income 80 Beef Pork Chicken China India Row Turkey 12 10 China (2008) 8 6 4 Korea 2 China Japan Kg per capita per year Kg pf meat (beef & veal) per capita 14 Pork bellies Sugar Feeder cattle Live cattle Coffee Cotton Live hogs Cocoa Wheat Soybeans -50 Corn FCOJ Pork Belly Feeder Cattle Wheat (MGE) Cocoa Wheat (KCBT) Cotton #2 Soybean Meal Soybean Oil Wheat (CBOT) Soybeans Sugar #11 Corn 0 8.6 7.3 6.3 5.1 4.3 3.3 1.8 1.1 0.8 0.1 Coffee ‘C’ 10 Live Cattle 13.2 12.2 Lean Hogs 20 60 40 20 0 0 5,000 10,000 15,000 20,000 25,000 GDP PPP per capita Source: USDA, IMF Page 110 30,000 35,000 40,000 0 US EU World Source: USDA, FAO, IMF Global Markets Research September 2008 A User Guide To Commodities Feeder & Live Cattle History & properties The beef cycle, that is the time from birth to slaughter, typically lasts two years. Calves are born in the spring after a nine month gestation period. Weaning then takes place for the first six to eight months of the calf’s life. Once the calf reaches between six to eight months old, they are moved into the “stocker” operation. Calves spend between six to ten months in this stage until they reach between 600-800 pounds. At this point, the cattle are sent to a feedlot to become “feeder cattle” with the aim of encouraging rapid weight gain. This is typically achieved by a diet of grains and high protein, such as corn or wheat and soybeans. Cattle are voracious consumers of grains, such that in the US seven pounds of feed are required to generate an additional one pound in weight. When animals have reached a full weight of 1,200 pounds, normally after six months, they are ready for slaughter. This final stage of the animal’s life is referred to as “live cattle”. Major producers & consumers Global beef consumption has increased steadily over the last few years driven by the increased demand for beef from China. The United States is not only the largest producer of beef in the world, but also the largest consumer and importer of beef, accounting for 20% of the world’s production and 21% of global beef consumption. The international traded market in beef is relative small compared to world production. The traded market has had to contend with BSE events in a number of countries, which has led to the imposition of bans by many importing countries. For example, Korean and Japanese purchases of US beef had until recently fallen to 60% of pre-2003 levels. Major uses While feeder cattle are weaned calves that have not yet attained optimal weight for slaughter, live cattle have achieved an optimal weight for sale to packers. After sale to packers, the animal is slaughtered and the meat is divided into grades by both quality and yield, and sold boxed. This beef is used almost completely for human consumption: 50% as steaks and roasts, 45% as hamburger and 5% as stewing beef. The packer also sells the “drop,” or excess carcass products, which are used to produce leather, soaps, animal feed, and other products. Figure 1: The world’s top 10 bovine producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Producers (000s) world Consumers (000s) Tonnes % of world Exporters (000s) world Tonnes % of Importers (000s) USA 12,096 17.9% USA 12,380 21.4% Brazil 2,189 world 28.8% USA 1,384 19.1% Brazil 9,470 13.7% EU-27 8,674 14.5% Australia 1,400 EU-27 8,175 12.2% China 7,404 12.3% India 735 18.4% Russia 1,030 14.% 9.7% Japan 686 China 7,480 11.2% Brazil 7,311 12.2% USA 9.5% 649 8.5% EU-27 638 India 3,200 5.3% Argentina 2,673 4.5% 8.8% Argentina 532 7.0% Mexico 410 Argentina 2,500 4.8% Mexico 2,568 5.7% 4.3% N. Zealand 496 6.5% Korea 308 4.3% Australia 2,200 3.4% Russia Mexico 2,197 2.4% India 2,392 4.0% Canada 457 6.0% Egypt 300 4.1% 1,765 2.9% Uruguay 385 5.1% Canada 242 Russia 1,370 2.4% 3.3% Japan 1,182 2.0% Paraguay 197 2.6% Venezuela 210 Canada 1,310 1.9% 2.9% Pakistan 1,119 1.9% EU-27 139 1.8% Malaysia 154 Total 60,423 2.1% Total 59,985 Total 7,605 Total 7,237 Source: USDA Global Markets Research Page 111 September 2008 A User Guide To Commodities Figure 2: Livestock turnover on US exchanges 10 Annual turnover, mllion lots (2007) Figure 3: Live & feeder cattle prices since 1988 8.6 USc/pound Live cattle 130 Feeder cattle 120 8 110 100 6 90 80 4 70 2 60 1.1 50 0 Feeder Cattle 40 1988 Live Cattle Source: CME 1990 1992 1994 1996 1998 2000 2002 2004 2006 2008 Source: Bloomberg (data as of end July-08) Exchange traded Future and options are traded for both feeder and live cattle on the Chicago Mercantile Exchange (CME). In the mid-1960s, live cattle future contracts were introduced to the CME such contracts for a non-storable commodity departed from convention at the time. In 1971, feeder cattle futures were first listed on the CME, and options were introduced in 1987. For live cattle, the contract size is for 40,000 lbs of 55% choice, 45% select grade futures. For feeder cattle it is 50,000 lbs of 700-849 lb. steers futures. Price conventions Cattle are sold as units, and prices are quoted in dollars per pound. Contract months are February, April, June, August, October, and December. The Bloomberg ticker for the CME live cattle one month generic futures contract is LC1 <Commodity>. The Bloomberg ticker for the CME feeder cattle one month generic futures contract is FC1 < Commodity>. Figure 4: World production & trade in meat World production 120 80 International trade in meat 89.5 80 67.2 60 40 20 5 9.2 7.1 Pork Chicken China India Row Turkey 40 20 0.9 0 US Swine Source: USDA 60 13.7 0 Page 112 Beef 98.8 Kg per capita per year Tonnes (million) 100 Figure 5: Meat consumption by type & country Poultry Bovine EU World Lamb Source: USDA, FAO, IMF Global Markets Research September 2008 A User Guide To Commodities Lean Hogs & Pork Bellies History & properties The pork cycle, that is the time from birth to slaughter, typically lasts for six months. The life cycle begins with the baby piglet. Each sow is generally bred twice a year. These breeding hogs are kept in the breeding herd for an average of two years before being sent to slaughter. The gestation period is approximately 114 days and an average little size if between nine to the pigs. Weaning then takes place for the first three to four weeks of the pig’s life. The average litter size is reduced to an average of 8-9 pigs between farrowing and weaning due to disease or weather conditions leading to death loss. Pigs are fed a diet of grains such as corn, barley, oats and wheat. On average, 6.5 pounds of feed are required to generate an additional one pound in weight. When the animals have reached a full weight of approximately 250 pounds, after around six months, they are ready for slaughter. One hog yields an average of between 85-90 pounds of lean meat. Major producers & consumers Approximately 41% of all meat consumed across the world is pork. Therefore, to meet the growing demand in meat consumption, world pork production has increased 1% annually over the past five years. China is the largest producer and consumer of pork in the world, accounting for over 45% of both the world’s production and consumption. In China, pork is such a sensitive commodity that the government keeps a strategic reserve to adjust pricing. The US is a relatively new player on pork export markets. The country only became a net exporter of pork in 1995, but today it is the world’s largest exporter, selling primarily to Japan, Mexico and Canada. After negotiating several free trade agreements, the US is hoping to expand its market reach in Central America and Chile. Although Brazilian pork exports have gone mainly to Russia, it is looking into other markets due to new Russian quotas. Pork production and consumption are expected to rise in the EU as living standards improve in accession states. Japan is the world’s largest importer of pork, constituting about 24% of world imports. Major uses Once the hog is slaughtered, approximately 21% of the carcass weight is ham, 20% pork loin, 10% picnic, 7% Boston butt roast and blade steaks, 3% spareribs, and the pork belly is generally about 14% of carcass weight. The pork belly is cured and put into cold storage for up to a year to be used as bacon, which is unique among other meat products in its lack of substitutes. Figure 1: The world’s top 10 pork producers, consumers, exporters and importers in 2007 Tonnes % of Tonnes % of Tonnes % of Producers (000s) world Consumers (000s) Tonnes % of world Exporters (000s) world Importers (000s) world China 47,016 49.2% China 44,048 46.1% USA 1,424 27.6% Japan 1,210 23.8% EU-27 22,600 23.6% EU-27 21,257 22.2% EU-27 1,282 24.9% Russia 894 17.6% USA 9,962 10.4% USA 8,964 9.4% Canada 1,033 20.1% Korea 447 8.8% Brazil 2,990 3.1% Russia 2,803 2.9% Brazil 730 14.2% Mexico 445 8.8% Russia 1,910 2% Japan 2,472 2.6% China 350 6.8% USA 439 8.6% Canada 1,850 1.9% Brazil 2,260 2.4% Chile 148 2.9% Hong Kong 302 5.9% Vietnam 1,832 1.9% Vietnam 1,855 1.9% Mexico 81 1.6% China 198 3.9% Japan 1,250 1.3% Mexico 1,514 1.6% Australia 54 1% Canada 171 3.4% Philippines 1,245 1.3% Korea 1,270 1.3% Vietnam 19 .3% Australia 141 2.8% Mexico 1,150 1.2% Philippines 984 Korea 13 .3% Singapore 97 1.9% Total 95,658 Total 95,514 Total 5,152 Total 5,082 1% Source: FAS, USDA Global Markets Research Page 113 September 2008 A User Guide To Commodities Figure 2: Turnover by exchange 8 7.3 Figure 3: Live hog & pork belly prices Annual turnover, mllion lots (2007) 140 USc/pound Live hogs Pork belly 120 6 100 4 80 60 2 40 0.1 0 Lean Hogs Source: CME Pork Belly 20 1987 1989 1991 1993 1995 1997 1999 2001 2003 2005 2007 Source: Bloomberg (data as of end July-08) Exchange traded In 1961, the Chicago Mercantile Exchange (CME) began trading frozen pork belly futures; this was the first future contract based on frozen, stored meats. It was added to help meat packers and warehouse operators mediate the volatility of hog prices and the price risks associated with holding processed foods in inventory. Both frozen and fresh pork belly futures and contracts are currently listed on the CME. The trading unit for each of these contracts is 40,000 pounds of the product. For lean hogs, contract months are Feb, April, May, June, July, August, October and December. For pork bellies, these are February March, May, July and August. Price conventions Before 1997, hogs were traded based on their weight prior to slaughter, or their ‘live weight’. The CME then changed the hog contract to 40,000 pounds ‘lean weight,’ or post-slaughter weight. When live hogs are sold, price is based on expected percent lean weight. Prices are quoted in US cents per pound. The Bloomberg ticker for the CME pork bellies one month generic futures contract is PB1 <Commodity>. For CME lean hogs,’ the ticker for one month generic futures contract is LH1 <Commodity>. Page 114 Global Markets Research September 2008 A User Guide To Commodities Commodity Exchanges & Turnover Commodity exchanges by type of contract listed Commodity Energy Metals Electricity Fibres Grains & Oilseeds Softs Livestock Exchange Abbreviation New York Mercantile Exchange NYMEX Intercontinental Exchange ICE Shanghai Futures Exchange SHFE Central Japan Commodity Exchange CJCE Tokyo Commodity Exchange TOCOM Dalian Commodity Exchange DCE London Metal Exchange LME New York Mercantile Exchange COMEX Shanghai Futures Exchange SHFE Philadelphia Board of Trade PHLX Osaka Mercantile Exchange OME Tokyo Commodity Exchange TOCOM New York Mercantile Exchange NYMEX Nordic Power Exchange NORDPOOL European Energy Exchange EEX UK Power Exchange UKPX Amsterdam Power Exchange APX Paris Power Exchange POWERNEXT Chicago Mercantile Exchange CME New York Cotton Exchange NYCE Zhengzhou Commodity Exchange YCE Budapest Commodity Exchange BCE Chicago Board of Trade CBT Dalian Commodity Exchange DCE EURONEXT EURONEXT Fukuoka Futures Exchange FFE Johannesburg Securities Exchange JSE Kansas City Board of Trade KCBT Malaysian Derivatives Exchange MDE Mercado a Termino de Rosaio ROFEX Minneapolis Grain Exchange MGE Tokyo Grain Exchange TGE Winnipeg Commodity Exchange WCE New York Board of Trade NYBOT Bolsa de Mercadorias & Futuros BM&F Kansai Agricultural Commodities Exchange KANEX Tokyo Grain Exchange TGE EURONEXT EURONEXT National Commodity & Derivatives Exchange NCDEX Zhengzhou Commodity Exchange ZCE Chicago Mercantile Exchange CME Bolsa de Mercadorias & Futuros BM&F EURONEXT, Amsterdam EURONEXT Sydney Futures Exchange SFE Source: CRB Yearbook, DB Global Markets Research Global Markets Research Page 115 September 2008 A User Guide To Commodities Commodity Turnover The world’s top commodity futures contracts in 2007 Contract Exchange Turnover (million lots) WTI Crude Oil New York Mercantile Exchange 121.5 Soy Meal Dalian Commodity Exchange 64.7 Brent Crude Oil Intercontinental Exchange 59.7 Corn Dalian Commodity Exchange 59.4 Corn Chicago Board of Trade 54.5 No. 1 Soybeans Dalian Commodity Exchange 47.4 Rubber Shanghai Futures Exchange 42.2 Aluminium London Metal Exchange 40.2 Strong Gluten Wheat Zhengzhou Commodity Exchange 39.0 Soybeans Chicago Board of Trade 31.7 US Natural Gas New York Mercantile Exchange 29.8 Gold New York Mercantile Exchange 25.1 Gas Oil Intercontinental Exchange 24.5 Copper London Metal Exchange 21.4 Sugar #11 New York Board of Trade 21.4 Wheat Chicago Board of Trade 19.6 Gold Tokyo Commodity Exchange 18.2 Heating Oil No. 2 New York Mercantile Exchange 18.1 Copper Shanghai Futures Exchange 16.2 Soybean Oil Chicago Board of Trade 13.1 Zinc London Metal Exchange 12.6 Non-GMO-Soybean Tokyo Grain Exchange 12.3 Soybean Meal Chicago Board of Trade 12.2 Fuel Oil Shanghai Futures Exchange 12.0 Platinum Tokyo Commodity Exchange 9.2 Live Cattle Chicago Mercantile Exchange 8.6 Gasoline Tokyo Commodity Exchange 7.5 Lean Hogs Chicago Mercantile Exchange 7.3 Rubber Tokyo Commodity Exchange 7.1 Silver New York Mercantile Exchange 6.8 Cotton #2 New York Board of Trade 6.3 Coffee ‘C’ New York Board of Trade 5.1 Aluminium Shanghai Futures Exchange 4.8 Lead London Metal Exchange 4.7 Corn Tokyo Grain Exchange 4.6 Coffee Robusta EURONEXT 4.4 Wheat Kansas City Board of Trade 4.3 Nickel London Metal Exchange 3.8 Copper New York Mercantile Exchange 3.8 Gasoline Central Japan Commodity Exchange 3.6 Crude Palm Oil Malaysia Derivatives Exchange 3.5 Cocoa CC New York Board of Trade 3.3 Cocoa #7 EURONEXT 3.3 Canola (Rapessed) Winnipeg Commodity Exchange 3.0 Cotton Zhengzhou Commodity Exchange 3.0 Kerosene Central Japan Commodity Exchange 2.7 Kerosene Tokyo Commodity Exchange 2.4 White Sugar EURONEXT 2.1 Source: NYMEX, ICE, TOCOM, SFE, CJCE, LME, OME, BM&F, DCE, CBT, NYBOT, ZCE, TGE, KCBT, EURONEXT Page 116 Global Markets Research September 2008 A User Guide To Commodities Continued: The world’s top commodity futures contracts in 2007 Contract Exchange Turnover (million lots) Spring Wheat Minneapolis Grain Exchange 1.79 Crude Oil Tokyo Commodity Exchange 1.49 Gold Chicago Board of Trade 1.45 Tin London Metal Exchange 1.29 American Soybeans Tokyo Grain Exchange 1.25 NASAAC London Metal Exchange 1.23 US Natural Gas Intercontinental Exchange 1.23 Feeder Cattle Chicago Mercantile Exchange 1.10 White Maize Johannesburg Securities Exchange 0.96 Orange Juice (FCOJ) New York Board of Trade 0.85 Coffee Arabica Bolsa de Mercadorias & Futuros 0.72 Coffee Arabica Tokyo Grain Exchange 0.60 Mini Soybeans Chicago Board of Trade 0.54 Silver Tokyo Commodity Exchange 0.54 Platinum New York Mercantile Exchange 0.50 Aluminium Alloy London Metal Exchange 0.49 Raw Sugar Tokyo Grain Exchange 0.43 Oats Chicago Board of Trade 0.43 Palladium New York Mercantile Exchange 0.40 Red Beans Tokyo Grain Exchange 0.39 Class III Milk Chicago Mercantile Exchange 0.31 Palladium Tokyo Commodity Exchange 0.21 Corn Fukuoka Futures Exchange 0.10 Rubber (RSS3) Osaka Mercantile Exchange 0.09 Coffee Robusta Tokyo Grain Exchange 0.07 Pork Belly Chicago Mercantile Exchange 0.07 Aluminium Tokyo Commodity Exchange 0.07 Non-GMO Soybeans Fukuoka Futures Exchange 0.02 Aluminium Osaka Mercantile Exchange 0.02 Rubber (TSR20) Osaka Mercantile Exchange 0.01 Nickel Osaka Mercantile Exchange 0.01 Source: NYMEX, ICE, TOCOM, SFE, CJCE, LME, OME, DCE, CBT, NYBOT, ZCE, TGE, KCBT, EURONEXT Global Markets Research Page 117 September 2008 A User Guide To Commodities Conversion Factors Commonly Used Weights The troy, avoirdupois and apothecaries’ grains are identical in the U.S. and British weight systems, equal to 0.0648 gram in the metric system. One avoirdupois ounce equals 437.5 grains. The troy and apothecaries’ ounces equal 480 grains, and their pounds contain 12 ounces. Troy Weight & Conversions: 100 kilograms = 1 quintal 24 grains = 1 pennyweight 20 pennyweights = 1 ounce 12 ounces = 1 pound 1 troy ounce = 31.103 grams 1 troy ounce = 0.0311033 kilogram 1 troy pound = 0.37224 kilogram 1 kilogram = 32.151 troy ounces 1 tonne = 32,151 troy ounces Avoirdupois Weights & Conversions: 27 11/32 grains = 1 dram 16 drams = 1 ounce 16 ounces = 1 lb. 1 lb. = 7,000 grains 14 lbs. = 1 stone (U.K.) 100 lbs. = 1 hundredweight (U.S.) 112lbs. = 8 stone = 1 hundredweight (U.K.) 2,000 lbs. = 1 short ton (U.S. ton) 2,240 lbs. = 1 long ton (U.K. ton) 160 stone = 1 long ton 20 hundredwght = 1 ton 1 lb. = 0.4536 kilogram 1 hundredwght = 45.359 kilograms 1 short ton = 907.18 kilograms 1 long ton = 1,016.05 kilograms Metric Weights & Conversions: 1,000 grams = 1 kilogram 1 tonne = 1,000 kilograms=10 quintals 1 kilogram = 2.204622 lbs. 1 quintal = 220.462 lbs. 1 tonne = 2204.6 lbs. 1 tonne = 1.102 short tons 1 tonne = 0.9842 long ton U.S. Dry Volumes & Conversions 1 pint = 33.6 cubic inches = 0.5506 litre 2 pints = 1 quart = 1.1012 litres 8 quarts = 1 peck = 8.8098 litres 4 pecks = 1 bushel = 35.2391 litres 1 cubic foot = 28.3169 litres U.S. Liquid Volumes & Conversions 1 ounce = 1.8047 cubic inches = 29.6 millilitres 1 cup = 8 ounces = 0.24 litre = 237 millilitres 1 pint = 16 ounces = 0.48 litre = 473 millilitres 1 quart = 2 pints = 0.946 litre = 946 millilitres 1 gallon = 4 quarts = 231 cubic inches = 3.785 litres 1 millilitre = 0.033815 fluid ounce 1 litre = 1.0567 quarts = 1,000 millilitres 1 litre = 33.815 fluid ounces 1 imperial gallon = 277.42 cubic inches = 1.2 U.S. gallons = 4.546 litres Page 118 Global Markets Research September 2008 A User Guide To Commodities Agricultural Weights & Measurements Bushel Weights Wheat & soybeans Corn, sorghum & rye Barley grain Oats Barley malt = = = = = 60 lbs. 56 lbs. 48 lbs. 38 lbs. 34 lbs. Bushels to Tonnes: Wheat & soybeans Barley grain Corn, sorghum & rye Oats = = = = bushels x 0.0272155 bushels x 0.021772 bushels x 0.0254 bushels x 0.0172365 1 tonne (metric ton) equals: 2204.622 lbs. 1,000 kilograms 22.046 hundredweight 10 quintals 1 tonne (metric ton) equals: 36.7437 bushels of wheat & soybeans 39.3670 bushels of corn, sorghum or rye 45.9296 bushels of barley grain 68.8944 bushels of oats 4.5929 cotton bales (the statistical bale used by the USDA and ICAC contains a net weight of 480 pounds of lint) Area Measurements 1 acre = 43,560 square feet = 0.040694 hectares 1 hectare = 2.4710 acres = 10,000 square metres 640 acres = 1 square mile = 259 hectares Energy U.S Crude Oil (average gravity) 1 U.S. barrel = 42 U.S. gallons 1 short ton = 6.65 barrels 1 tonne = 7.33 barrels Barrels per tonne for various origins Abu Dhabi 7.624 Australia 7.775 Canada 7.428 Dubai 7.295 Indonesia 7.348 Iran 7.37 Kuwait 7.261 Libya 7.615 Mexico 6.825 Nigeria 7.41 Norway 7.41 Saudi Arabia 7.338 United Arab Emirates 7.522 United Kingdom 7.279 United States 7.418 Former Soviet Union 7.35 Venezuela 7.005 Global Markets Research Page 119 September 2008 A User Guide To Commodities Barrels per tonne of refined products: Aviation Gasoline 8.90 Motor Gasoline 8.50 Kerosene 7.75 Jet Fuel 8.00 Distillate, including diesel 7.46 Residual Fuel Oil 6.45 Lubricating Oil 7.00 Grease 6.30 White Spirits 8.50 Paraffin Oil 7.14 Paraffin Wax 7.87 Petrolatum 7.87 Asphalt & Road Oil 6.06 Petroleum Coke 5.50 Bitumen 6.06 Liquefied Petroleum Gas (LPG) 11.6 Approximate heat content of refined products: (million Btu per barrel, 1 British thermal unit is the amount of heat required to raise the temperature of 1 pound of water 1 degree Fahrenheit.) Petroleum Product Heat content Asphalt 6.636 Aviation Gasoline 5.048 Butane 4.326 Distillate Fuel Oil 5.825 Ethane 3.082 Isobutane 3.974 Jet Fuel, kerosene 5.67 Jet Fuel, naphtha 5.355 Kerosene 5.67 Lubricants 6.065 Motor Gasoline 5.253 Natural Gasoline 4.62 Pentanes Plus 4.62 Natural Gas Conversions Although there are approximately 1,031 Btu in a cubic foot of gas, for most applications, the following conversions are sufficient: Cubic Feet 1,000 1,000,000 10,000,000 1,000,000,000 1,000,000,000,000 = = = = = MMBtu 1Mcf 1MMcf 10MMcf 1Bcf 1Tcf Source: CRB Commodity Yearbook 2005 US Department of Energy Page 120 Global Markets Research September 2008 A User Guide To Commodities The author of this report wishes to acknowledge the contribution made by Gagan Singh, Anupama Hubli and Monodeep Shah employees of Infosys BPO, a third-party provider to Deutsche Bank of offshore research support services. Global Markets Research Page 121 September 2008 A User Guide To Commodities Appendix 1 Important Disclosures Additional information available upon request For disclosures pertaining to recommendations or estimates made on a security mentioned in this report, please see the most recently published company report or visit our global disclosure look-up page on our website at http://gm.db.com. Analyst Certification The views expressed in this report accurately reflect the personal views of the undersigned lead analyst(s). In addition, the undersigned lead analyst(s) has not and will not receive any compensation for providing a specific recommendation or view in this report. Michael Lewis Deutsche Bank debt rating key CreditBuy (“C-B”): The total return of the Reference Credit Instrument (bond or CDS) is expected to outperform the credit spread of bonds / CDS of other issuers operating in similar sectors or rating categories over the next six months. CreditHold (“C-H”): The credit spread of the Reference Credit Instrument (bond or CDS) is expected to perform in line with the credit spread of bonds / CDS of other issuers operating in similar sectors or rating categories over the next six months. CreditSell (“C-S”): The credit spread of the Reference Credit Instrument (bond or CDS) is expected to underperform the credit spread of bonds / CDS of other issuers operating in similar sectors or rating categories over the next six months. CreditNoRec (“C-NR”): We have not assigned a recommendation to this issuer. Any references to valuation are based on an issuer’s credit rating. Reference Credit Instrument (“RCI”): The Reference Credit Instrument for each issuer is selected by the analyst as the most appropriate valuation benchmark (whether bonds or Credit Default Swaps) and is detailed in this report. Recommendations on other credit instruments of an issuer may differ from the recommendation on the Reference Credit Instrument based on an assessment of value relative to the Reference Credit Instrument which might take into account other factors such as differing covenant language, coupon steps, liquidity and maturity. The Reference Credit Instrument is subject to change, at the discretion of the analyst. Page 122 Global Markets Research September 2008 A User Guide To Commodities Regulatory Disclosures 1. Important Additional Conflict Disclosures Aside from within this report, important conflict disclosures can also be found at https://gm.db.com/equities under the "Disclosures Lookup" and "Legal" tabs. Investors are strongly encouraged to review this information before investing. 2. Short-Term Trade Ideas Deutsche Bank equity research analysts sometimes have shorter-term trade ideas (known as SOLAR ideas) that are consistent or inconsistent with Deutsche Bank's existing longer term ratings. These trade ideas can be found at the SOLAR link at http://gm.db.com. 3. Country-Specific Disclosures Australia: This research, and any access to it, is intended only for "wholesale clients" within the meaning of the Australian Corporations Act. EU countries: Disclosures relating to our obligations under MiFiD can be found at http://globalmarkets.db.com/riskdisclosures. Japan: Disclosures under the Financial Instruments and Exchange Law: Company name - Deutsche Securities Inc. Registration number - Registered as a financial instruments dealer by the Head of the Kanto Local Finance Bureau (Kinsho) No. 117. Member of associations: JSDA, The Financial Futures Association of Japan. Commissions and risks involved in stock transactions - for stock transactions, we charge stock commissions and consumption tax by multiplying the transaction amount by the commission rate agreed with each customer. Stock transactions can lead to losses as a result of share price fluctuations and other factors. Transactions in foreign stocks can lead to additional losses stemming from foreign exchange fluctuations New Zealand: This research is not intended for, and should not be given to, "members of the public" within the meaning of the New Zealand Securities Market Act 1988. Russia: This information, interpretation and opinions submitted herein are not in the context of, and do not constitute, any appraisal or evaluation activity requiring a license in the Russian Federation. Global Markets Research Page 123 David Folkerts-Landau Managing Director Global Head of Research Stuart Parkinson Chief Operating Officer Global Company Research Global Fixed Income Strategies & Economics Guy Ashton Global Head Marcel Cassard Global Head Europe Germany Asia-Pacific Americas Pascal Costantini Regional Head Andreas Neubauer Regional Head Michael Spencer Regional Head Steve Pollard Regional Head Deutsche Bank AG London 1 Great Winchester Street London EC2N 2EQ Tel: (44) 20 7545 8000 Deutsche Bank AG New York 60 Wall Street New York, NY 10005 United States of America Tel: (1) 212 250-2500 Deutsche Bank AG Hong Kong Cheung Kong Center, 2 Queen's Road Central Hong Kong Tel: (52) 2203 8888 Deutsche Bank AG Japan 2-11-1 Nagatacho Sanno Park Tower Chiyoda-ku, Tokyo 100-6171 Tel: (81) 3 5156 6701 Deutsche Bank AG Frankfurt Große Gallusstraße 10-14 60272 Frankfurt am Main Germany Tel: (49) 69 910 0 Deutsche Bank AG Aurora business park 82 bld.2 Sadovnicheskaya street Moscow, 115035 Russia Tel: (7) 495 797-5000 Deutsche Bank AG Singapore One Raffles Quay South Tower Singapore 048583 Tel: (65) 6423 8001 Deutsche Bank AG Australia Deutsche Bank Place, Level 16 Corner of Hunter & Phillip Streets Sydney NSW 2000 Tel: (61) 2 8258 1234 Principal Locations Subscribers to research via email receive their electronic publication on average 1-2 working days earlier than the printed version. If you would like to receive this or any other product via email please contact your usual Deutsche Bank representative. Publication Address: Deutsche Bank AG London 1 Great Winchester Street London EC2N 2EQ United Kingdom (44) 20 7545 8000 Internet: http://gmr.db.com Ask your usual contact for a username and password. Global Disclaimer The information and opinions in this report were prepared by Deutsche Bank AG or one of its affiliates (collectively "Deutsche Bank"). The information herein is believed to be reliable and has been obtained from public sources believed to be reliable. Deutsche Bank makes no representation as to the accuracy or completeness of such information. Deutsche Bank may (1) engage in securities transactions in a manner inconsistent with this research report, (2) with respect to securities covered by this report, sell to or buy from customers on a principal basis, and (3) consider this report in deciding to trade on a proprietary basis. Opinions, estimates and projections in this report constitute the current judgment of the author as of the date of this report. They do not necessarily reflect the opinions of Deutsche Bank and are subject to change without notice. Deutsche Bank has no obligation to update, modify or amend this report or to otherwise notify a recipient thereof in the event that any opinion, forecast or estimate set forth herein, changes or subsequently becomes inaccurate. Prices and availability of financial instruments are subject to change without notice. This report is provided for informational purposes only. It is not an offer or a solicitation of an offer to buy or sell any financial instruments or to participate in any particular trading strategy. The financial instruments discussed in this report may not be suitable for all investors and investors must make their own informed investment decisions. Stock transactions can lead to losses as a result of price fluctuations and other factors. If a financial instrument is denominated in a currency other than an investor's currency, a change in exchange rates may adversely affect the investment. Past performance is not necessarily indicative of future results. Unless governing law provides otherwise, all transactions should be executed through the Deutsche Bank entity in the investor's home jurisdiction. In the U.S. this report is approved and/or distributed by Deutsche Bank Securities Inc., a member of the NYSE, the NASD, NFA and SIPC. In Germany this report is approved and/or communicated by Deutsche Bank AG Frankfurt authorized by the BaFin. In the United Kingdom this report is approved and/or communicated by Deutsche Bank AG London, a member of the London Stock Exchange and regulated by the Financial Services Authority for the conduct of investment business in the UK and authorized by the BaFin. This report is distributed in Hong Kong by Deutsche Bank AG, Hong Kong Branch, in Korea by Deutsche Securities Korea Co. and in Singapore by Deutsche Bank AG, Singapore Branch. In Japan this report is approved and/or distributed by Deutsche Securities Inc. The information contained in this report does not constitute the provision of investment advice. In Australia, retail clients should obtain a copy of a Product Disclosure Statement (PDS) relating to any financial product referred to in this report and consider the PDS before making any decision about whether to acquire the product. Deutsche Bank AG Johannesburg is incorporated in the Federal Republic of Germany (Branch Register Number in South Africa: 1998/003298/10). Additional information relative to securities, other financial products or issuers discussed in this report is available upon request. This report may not be reproduced, distributed or published by any person for any purpose without Deutsche Bank's prior written consent. Please cite source when quoting. Copyright © 2008 Deutsche Bank AG GRCM2008PROD014126