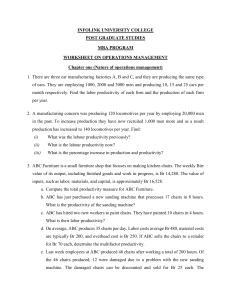

INFOLINK UNIVERSITY COLLEGE POST GRADUATE STUDIES MBA PROGRAM WORKSHEET ON OPERATIONS MANAGEMENT Chapter one (Nature of operations management) 1. There are three car manufacturing factories A, B and C, and they are producing the same type of cars. They are employing 1000, 2000 and 3000 men and producing 10, 15 and 25 cars per month respectively. Find the labor productivity of each firm and the production of each firm per year. 2. A manufacturing concern was producing 120 locomotives per year by employing 20,000 men in the past. To increase production they have now recruited 1,000 men more and as a result production has increased to 140 locomotives per year. Find: (i) What was the labour productivity previously? (ii) What is the labour productivity now? (iii) What is the percentage increase in production and productivity? 3. ABC Furniture is a small furniture shop that focuses on making kitchen chairs. The weekly Birr value of its output, including finished goods and work in progress, is Br 14,280. The value of inputs, such as labor, materials, and capital, is approximately Br 16,528. a. Compute the total productivity measure for ABC Furniture. b. ABC has just purchased a new sanding machine that processes 17 chairs in 8 hours. What is the productivity of the sanding machine? c. ABC has hired two new workers to paint chairs. They have painted 10 chairs in 4 hours. What is their labor productivity? d. On average, ABC produces 35 chairs per day. Labor costs average Br 480, material costs are typically Br 200, and overhead cost is Br 250. If ABC sells the chairs to a retailer for Br 70 each, determine the multifactor productivity. e. Last week employees at ABC produced 46 chairs after working a total of 200 hours. Of the 46 chairs produced, 12 were damaged due to a problem with the new sanding machine. The damaged chairs can be discounted and sold for Br 25 each. The undamaged chairs are sold to a department store retail chain for Br 70 each. What was the labor productivity ratio for last week? If labor productivity was Br 15 in sales per hour the previous week, what was the change in labor productivity? 4. Dashen Bank employs three loan officers, each working eight hours per day. Each officer processes an average of five loans per day. The bank’s payroll cost for the officers is Br 820 per day, and there is a daily overhead expense of Br 500. The bank has just purchased new computer software that should enable each officer to process eight loans per day, although the overhead expense will increase to Br 550. Evaluate the change in labor and multifactor productivity before and after implementation of the new computer software. 5. Tabor Ceramics makes ceramic vases for a chain of department stores. The output and cost figures over the past four weeks are shown here. Labor costs Br10 an hour, and materials are Br 4. Calculate the (a) labor productivity (in hrs), (b) material productivity, and (c) multifactor productivity for each week. Comment on the results. Week 1 2 3 4 2000 4000 5000 7000 Number of workers 4 4 5 6 Hours per week per worker 40 48 56 70 Material cost 286 570 720 1000 Units of output Chapter Two (Operation strategy and competitiveness) 1. A manager has the option of purchasing one, two, or three machines. Fixed costs and potential volumes are as follows: Number of machines 1 2 3 Total annual fixed costs 9600 15000 20000 Corresponding range of output 0 to 300 301 to 600 601 to 900 Variable cost is Br.10 per unit, and revenue is Br.40 per unit. (a) Determine the break-even point for each range. (b) If projected annual demand is between 580 and 660 units, how many machines should the manager purchase? 2. Process X has fixed costs of Br. 20,000 per year and variable costs of Br. 12 per unit, whereas process Y has fixed costs of Br. 8,000 per year and variable costs of Br. 22 per unit. At what production quantity (Q) are the total costs of X and Y equal? 3. Discuss the requirements from an operations perspective of competing on (a) quality, (b) cost, (c) flexibility, (d) speed, (e) innovation, and (f) service. Give examples of manufacturing or service firms that successfully compete on each of the criteria listed. 4. Explain the concept of core competencies in your own words. Provide examples of a core competency for a bank, a retail store, and an auto manufacturer. 5. List and explain the five steps of strategy formulation. Follow the steps to outline a strategy for a company or organization with which you are familiar. Chapter Three - Five 1. The new Health-care facility is targeted to serve seven census tracts in Delhi. The table given below shows the coordinates for the centre of each census tract, along with the projected populations, measured in thousands. Customers will travel from the ten census tract centres to the new facility when they need health-care. Four locations being considered for the new facility are at (5.5, 4.5) , (7, 2), (5,2) and (4,3) which are the centres of census tracts A, D, F and G. Details of seven census tract centres, co-ordinate distances along with the population for each centre are given below. If we use the population as the loads and use rectilinear distance, which location is better in terms of its total load-distance score? Number Census tract (x,y) Population 1 A (5.5, 4.5) 2 2 B (5,2) 5 3 C (3,3) 10 4 D (7,2) 7 5 E (8,6) 10 6 F (5,2) 20 7 G (4,3) 14 8 H (5,3) 20 9 I (6,2) 8 10 J (7,3) 12 2. Following is the time (in hours) required in the refitting shop and the paint shop for each of the five cars. Assuming that cars go through the refitting operations before they are repainted, can the owner meet the time requirements and get the contract? Use the Johnson’s rule to minimize the flow time Car A B C D E Refitting time (Hours) 6 0 5 8 2 Repainting time (Hours) 3 4 2 6 1 3. Twenty samples of n = 200 were taken by an operator at a workstation in a production process. The number of defective items in each sample were recorded as follows. Sample 1 2 3 4 5 6 7 8 9 10 Number of defectives 12 18 10 14 16 19 17 12 11 14 p 0.060 0.090 0.050 0.070 0.080 0.095 0.085 0.060 0.055 0.070 Sample 11 12 13 14 15 16 17 18 19 20 Number of defectives 16 14 12 16 18 20 18 20 21 22 p 0.080 0.070 0.060 0.080 0.090 0.100 0.090 0.100 0.105 0.110 Management wants to develop a p-chart using 3-sigma limits. Set up the p-chart and plot the observations to determine if the process was out of control at any point. 4. Telecom manufactures electronic components for computers. One measure it uses to monitor the quality of its distribution process is the number of customer invoice errors. The distribution center manager monitored the company’s order processing and distribution by recording the number of invoice errors for 30 days. The sample results are as follows: Day 1 2 3 4 5 6 7 8 79 10 11 12 13 14 15 Number of errors 4 6 2 5 1 3 4 7 6 5 10 8 9 9 7 Day 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Number of errors 6 9 12 10 11 8 8 7 3 4 7 10 12 12 14 Construct a c-chart with 3𝜎 limits for invoice errors and indicate if the process was out of control at any time. 5. From the following data select the most advantageous location for setting a plant for making transistor radios. Total initial investment Total expected sales Distribution expenses Raw material expenses Power and water supply expenses Wages and salaries Other expenses Community attitude Employee housing facilities Site X 200,000 250,000 40,000 70,000 40,000 20,000 25,000 Indifferent Poor Site Y 200,000 300,000 40,000 80,000 30,000 25,000 40,000 Want business Excellent Site Z 200,000 250,000 75,000 90,000 20,000 20,000 30,000 Indifferent Good 6. Schedule the following six jobs through two machines in sequence to minimize the flow time using Johnson’s rule: Job A B C D E F Machine 1 5 16 1 13 17 18 Operating time Machine 2 2 15 9 11 3 7 7. Michael provides copy services for students in Awada campus. Five customers submitted their orders at the beginning of the week. Specific scheduling data are as follows: Jobs A B C D E a. b. c. d. e. Processing time(Days) 3 4 2 6 1 Due date 5 6 7 9 2 What is the first-come, first-served (FCFS) schedule? What is the shortest operating time (SOT) schedule? What is the last-come, first-served? What is the earliest due date (EDD) schedule? What are the mean flow times for each of the schedules above? f. Find the late time under each schedules? g. Make a decision under each schedule and identify which jobs are late and which are performed on time. 8. The following table gives the operation times and due dates for five jobs which are to be processed on machine. Assign the jobs according to the shortest operation time and calculate the mean flow time. Jobs 01 02 03 04 05 Processing time(Days) 6 7 4 9 5 Due date 5 3 4 7 2 9. BooksCDs.com sells books, videos, DVDs, and CDs through its Internet Web site. The company ships thousands of orders each day from seven national distribution centers. BooksCDs.com wants to establish a p-chart to monitor the quality of its distribution process, specifically the number of “problem” orders. A problem order is one that is delivered to a customer late (i.e., after five days), incorrect or incomplete. The company sampled 500 orders every other day for 20 samples and tracked them to final customer delivery, the results of which are as follows: Sample 1 2 3 4 5 6 7 8 9 10 Number of problems orders 14 22 36 17 25 41 18 19 26 28 Sample 11 12 13 14 15 16 17 18 19 20 Number of problems orders 38 24 15 12 10 16 9 21 18 12 Construct a c-chart for this process using 3𝜎 limits and indicate if the process was out of control. 10. Let us assume that a new Soft drink company is to be located in Dilla. The location factors, factor rating and scores for two potential sites are shown in the following table. Which is the best location based on factor rating method? Number 1 2 3 4 5 6 7 Location factor Land and construction costs Proximity to customers Raw material availability Employee preferences Proximity to market Climatic condition Taxes and other expenses Factor rating 8 4 5 3 5 6 2 Rating Location 1 5 6 6 3 4 2 4 Location 2 5 6 7 8 4 5 6 11. The following table contains information regarding jobs that are to be scheduled through one machine: Jobs A B C D E F G a. b. c. d. e. Processing time(Days) 4 12 2 11 10 3 6 Due date 20 30 15 16 18 5 9 What is the first-come, first-served (FCFS) schedule? What is the shortest operating time (SOT) schedule? What is the last-come, first-served? What is the earliest due date (EDD) schedule? What are the mean flow times for each of the schedules above? 12. Let us assume that a new airplane station, is to be located in Addis Ababa. The location factors, weights, and scores (1 = poor, 5 = excellent) for two potential sites are shown in the following table. What is the weighted score for these sites? Which is the best location to establish the airplane station? Number 1 2 3 4 5 6 7 8 Location factor Land and construction costs Proximity to customers Raw material availability Employee preferences Proximity to market Climatic condition Taxes and other expenses Fee charge Weight 8 4 5 3 5 6 2 3 Rating Location 1 5 6 8 3 4 2 4 5 Location 2 5 6 8 8 4 5 6 7 13. The new Health-care facility is targeted to serve seven census tracts in Delhi. The table given below shows the coordinates for the centre of each census tract, along with the projected populations, measured in thousands. Customers will travel from the ten census tract centres to the new facility when they need health-care. Two locations being considered for the new facility are at (4, 3) and (6, 2), which are the centres of census tracts G and I. Details of ten census tract centres, coordinate distances along with the population for each centre are given below. Find the target area’s centre of gravity for the Health-care medical facility. Number 1 2 3 4 5 6 7 8 9 10 Census tract A B C D E F G H I J (x,y) (5.5, 4.5) (5,2) (3,3) (7,2) (8,6) (5,2) (4,3) (5,3) (6,2) (7,3) Population 2 5 10 7 10 20 14 20 8 12 14. A machine at the Pacific Fruit Company fills boxes with raisins. The labeled weight of the boxes is 9 ounces. The company wants to construct an R-chart to monitor the filling process and make sure the box weights are in control. The quality-control department for the company sampled five boxes every two hours for three consecutive working days. The sample observations are as follows: Samples 1 2 3 4 5 6 7 8 9 10 11 12 9.06 8.52 9.35 9.17 9.21 8.74 9.00 9.15 9.98 9.03 9.53 8.95 Box weights (kg) 9.13 8.97 8.85 8.61 9.09 9.21 8.95 9.20 9.03 9.21 9.05 9.01 8.87 8.71 9.05 8.35 8.50 9.06 9.21 9.05 9.23 9.20 9.23 9.15 8.90 8.81 9.05 9.10 9.26 9.46 9.02 9.11 8.88 9.10 9.00 9.06 8.46 8.95 8.42 9.53 9.35 8.89 8.78 9.06 9.13 8.47 8.92 8.95 Construct an R-chart from these data with 3 𝜎 control limits, plot the sample range values, and comment on process control. 15. The City Square Grocery and Meat Market has a large meat locker in which a constant temperature of approximately 40º F should be maintained. The market manager has decided to construct an R-chart to monitor the temperature inside the locker. The manager had one of the market employees take sample temperature readings randomly five times each day for 20 days in order to gather data for the control chart. Following are the temperature sample observations: Samples 1 2 3 4 5 6 7 8 9 46.3 41.2 40.1 42.3 35.2 40.6 33.2 41.8 42.4 48.1 40.5 41.3 44.1 38.1 41.7 38.6 40.0 41.6 Temperature (°F) 42.5 43.1 37.8 36.5 34.5 33.2 39.5 37.7 40.5 39.1 38.6 43.5 41.5 40.7 41.6 40.7 40.8 40.9 39.6 42.3 36.7 38.6 42.3 44.6 43.1 39.3 42.3 10 11 12 13 14 15 16 17 18 19 20 44.7 42.6 40.5 45.3 36.4 40.5 39.5 37.6 41.0 40.9 37.6 36.5 43.5 40.4 42.0 37.5 34.3 38.2 40.6 34.3 42.3 39.2 37.3 35.4 39.1 43.1 36.2 36.2 37.6 40.3 39.1 37.6 39.3 35.3 36.1 37.2 44.7 38.9 35.1 34.1 39.7 45.2 35.4 41.2 41.1 38.2 41.6 39.5 40.1 36.8 38.7 41.2 43.7 34.8 37.6 a. Construct an R-chart based on these data using 3𝜎 limits, and plot the 20 sample range values. b. Does it appear that the temperature is in control according to the criteria established by management? 16. Valtec Electronics fills orders for its electronic components and parts by truck to customers through several distribution centers. A measure of its supply chain responsiveness is order fulfillment lead time, which is the number of days from when a company receives an order to when it is delivered to the customer. A distribution center manager has taken 20 samples of 5 orders each during the month and recorded the lead time for each as follows: Samples 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1.3 2.1 4.2 1.6 2.6 0.8 2.6 3.4 3.1 2.4 1.9 6.1 1.2 2.4 3.7 3.6 2.4 1.2 3.3 2.1 3.0 2.7 3.5 6.1 2.5 4.8 2.7 4.9 3.4 2.9 7.0 2.7 Load Time (Days) 0.7 3.0 1.0 2.5 2.6 1.5 2.8 0.9 1.4 4.6 5.8 3.7 3.1 3.6 1.5 2.5 2.2 2.9 5.9 3.2 3.4 2.2 2.1 3.6 2.8 2.3 3.4 2.3 1.4 2.4 4.8 2.0 1.8 3.6 3.0 1.5 1.9 4.5 1.4 2.8 1.8 4.4 0.4 5.2 4.5 2.5 3.3 1.7 17 18 19 20 0.4 5.3 2.7 4.7 1.8 2.9 3.6 2.0 6.5 3.4 2.9 2.0 3.2 4.8 4.1 3.1 4.8 4.4 5.2 1.8 Construct an X - chart to be used in conjunction with an R-chart using 3𝜎 limits for this data and indicate if the process is in control.