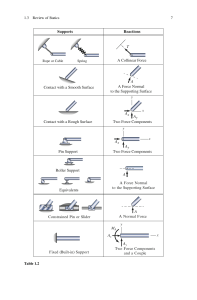

Wear 261 (2006) 785–791 The effect of various surface treatments on piston pin scuffing resistance I. Etsion a,∗ , G. Halperin a , E. Becker b a b Department of Mechanical Engineering, Technion, Haifa 32000, Israel General Motors Corporation, Mail Code 483-710-251, 895 Joslyn Ave., Pontiac, MI 48340, USA Received 26 July 2005; received in revised form 22 January 2006; accepted 24 January 2006 Available online 3 March 2006 Abstract A new test rig that was specially designed to evaluate the effect of various surface engineering methods on the tribological performance of piston pins is described. The test rig was used to study scuffing resistance provided by CrN and diamond-like carbon (DLC) coatings and by laser surface texturing in comparison with a base line standard pin. Scuffing inception could be obtained only with low viscosity base oil. In this case, all the treated pins performed better than the standard one, with the laser surface texturing offering the best performance. With formulated 20W50 engine oil, all the four types of piston pins performed satisfactorily until the load limit of the test rig, without scuffing. © 2006 Elsevier B.V. All rights reserved. Keywords: Piston pin; Scuffing; Surface treatment; Surface texturing; Engine 1. Introduction The internal combustion engine is the powerplant of choice for automotive transportation worldwide, and will likely remain so for the foreseeable future [1]. One trend that has continued unabated in the century-long development of engines is the increase in specific power, that is, the power output divided by the displacement of the engine [2]. A fundamental consequence of increasing the specific power is increased temperature and stress in all parts of the engine that transmit the force from the combustion gasses. As engine pistons run hotter, the interface between the piston and piston pin can become susceptible to wear. Therefore, an inexpensive and efficient way to evaluate the effect of changes in these components on wear behavior is needed. A literature search regarding friction and wear of piston pin revealed that very little has been published so far on this subject. Ravan et al. [3] dealt theoretically with the problem of joint clearances under dry or lubricated conditions. They provided an example analysis of a slider-crank mechanism having a clearance in the piston pin. Beside the obvious observation that lubrication will result in smoother operation this paper does not provide practical detailed design information. Two more papers [4,5] deal with the problems of scuffing and fretting wear of Al–Si alloys with potential application in the automotive industry including bearing materials such as in the piston pin case. In both papers experiments were performed on standard tribometers such as block-on-ring for the scuffing test and a pin-on-flat for the fretting wear test. Although standard tribometers may be helpful in fundamental studies they do not necessarily simulate real life situation in a specific application. Hence, a more realistic test rig is needed to better simulate the piston pin operating conditions. Very recently, Zhang et al. [6] described an elaborate test rig to simulate as close as possible the operating conditions of a piston pin and to study its scuffing behavior. Such an elaborate test rig is quite expensive and would not be possible to construct without the massive support of industrial companies. Indeed, the work described in [6] was supported by Karl Schmidt Unisia Inc. (a manufacturer of a wide range of pistons and assemblies for leading engine manufacturers), and by the Ford Motor Co. The present report describes a test rig that was built in order to perform tests that will still simulate the piston pin much better than the tests described in [4,5] and yet will be simple enough compared to the far more elaborate test rig of [6]. This concept is similar to the one described in [7] for testing of piston rings. 2. The test rig ∗ Corresponding author. Tel.: +972 4 829 2096; fax: +972 4 829 5711. E-mail address: Etsion@tx.technion.ac.il (I. Etsion). 0043-1648/$ – see front matter © 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.wear.2006.01.032 A test rig employing reciprocating angular motion was designed and built to allow simulation of the relative rotational 786 I. Etsion et al. / Wear 261 (2006) 785–791 Fig. 1. Schematic diagram of the piston pin test rig. (1) Torque meter; (2) loading frame; (3) specimen (pin); (4) mating part (piston pin bearing); (5) holder; (6) lever; (7) connecting rod; (8) load cell; (9) lever; (10) crank drive; (11) electrical motor. sliding motion between a piston pin and its bearing(s). The test rig allows control of normal load, angular amplitude, frequency and number of reciprocating cycles, and lubricant flow rate. The rig provides means for measuring friction torque and friction coefficient, face temperature, seizure resistance and wear. A schematic description of the test rig is presented in Fig. 1. It consist of three main parts; a drive system, an adjustable crank mechanism to provide controlled reciprocating angular motion of a tested piston pin, and a loading and torque measuring system. This latter system allows pure pin/bearing friction torque measurement by utilizing an internal pin/bearing loading system and, hence, completely eliminating the loading system friction from affecting the torque measurement. Fig. 2 is a general view of the piston pin test machine showing all the mechanical systems, and Fig. 3 is a close up of the test zone. The tested specimens consist of actual piston pins and counter face specimens that are prepared from actual pistons by cutting out the pin bearings and manufacturing from each bearing two circular segments with two contacting pads on each segment as shown in Fig. 4. Since the centers of the pads on each segment Fig. 2. A photograph of the piston pin test rig showing the drive motor, reciprocating crank mechanism and pin test zone. Fig. 3. Piston pin test zone showing the loading mechanism, friction torque sensor and lubricant supply. Fig. 4. Bearing specimen showing the two segments with four contact pads. I. Etsion et al. / Wear 261 (2006) 785–791 787 the pressure on the piston pin to piston surface is usually less than 10 MPa during most of the combustion cycle, but can rise to peak values approaching 100 MPa in a running engine. 3. Preliminary tests Fig. 5. Photographs of a piston (a), and piston pin and piston bearing segments (b). are 120◦ apart, and the load clamping the two segments to the pin acts at mid point between the pads, it turns out that the normal load on each pad equals the external clamping load. The contact area of each pad constitutes the original bore surface and has a total area of 60 mm2 . Special self-alignment holders assure full contact between the four pads and the pin. Photographs of a piston, two piston bearing segments, and a piston pin are shown in Fig. 5. The test rig can operate at speed range from 170 to 2000 rpm and up to a maximum load of 1950 N. It is fully computerized for controlling the test conditions and for data acquisition and processing. A sample data sheet showing various controlled and measured test parameters is presented in Fig. 6. The temperature shown in the data sheet is indicative of the face temperature of the contact pads. The temperature of each of the four pads was measured by means of thermocouples attached to the back of the bearing pad specimen (about 4 mm below the contact interface) and the differences from pad to pad were found to be less than 1 ◦ C indicating uniform loading and operating conditions in all four pads. For comparison purposes, Ligier and Ragot [8] calculated the force on a typical piston pin in a gasoline engine over the entire combustion cycle and found the force to be below 500 N over most of the cycle. Only during the combustion event was the force higher than 2000 N, peaking near 3000 N. Therefore Prior to the main test that was aimed at studying scuffing of piston pins, several preliminary tests were performed. This was done to verify the test rig concept and study its behavior over the range of operating conditions. The main purpose of these preliminary tests was to select proper operating conditions that will provide scuffing inception. This turned out to be a difficult task with a laboratory test rig. A first preliminary test was performed at speeds from 750 to 2000 rpm and normal loads from 100 to 500 N. SAE 40 oil (having viscosity of 89 mPa s at 40 ◦ C and 12.5 mPa s at 100 ◦ C) was used as the lubricant and its flow rate, by drip lubrication, was fixed at 50 s between consecutive drops. Cooling was provided by blowing air through the central bore of the piston pin. It was found that at 1500 rpm the face temperature is maintained below 100 ◦ C provided the load is below 450 N. At 2000 rpm and 500 N the face temperature reached 120 ◦ C. The second preliminary test was performed at three speed levels of 750, 1000, and 1450 rpm where at each speed level the normal load was increased in steps as shown in Fig. 6. This figure shows the time variation of the friction torque during the reciprocating angular motion at a given set of load and speed as well as the average values (time average) of the friction torque, friction coefficient, and face temperature for all the different combinations of load and speed. The lubricant flow rate in this test was maintained fixed at 50 s/drop. The results are summarized in Table 1 and presented in Fig. 7 in the form of Stribeck curves. From this figure it is clear that the piston pin operates in the boundary or mixed lubrication regime as is also indicated in Ref. [9]. The linear velocity, V, in Table 1 and in Fig. 7 is the average linear velocity over one reciprocating cycle corresponding to the appropriate rpm value. The Stribeck number is given by: S = ηV/P where η is the lubricant viscosity at the measured face temperature, and P is the contact pressure over one contact Table 1 Second preliminary test operating conditions and test results Average velocity (m/s) Contact pressure (MPa) Friction coefficient Face temperature (◦ C) 0.19 0.19 0.19 0.19 0.27 0.27 0.27 0.27 0.38 0.38 0.38 0.38 1.67 3.33 5.00 6.67 1.67 3.33 5.00 6.67 1.67 3.33 5.00 6.67 0.055 0.042 0.053 0.063 0.031 0.029 0.048 0.064 0.032 0.024 0.048 0.067 29 33 43 53 31 35 47 61 34 37 53 75 788 I. Etsion et al. / Wear 261 (2006) 785–791 Fig. 6. A sample data sheet showing various controlled and measured test parameters. pad. The unit of the Stribeck number expressed in this way is meters. It should be noted that the actual face temperature may be somewhat higher than that measured by the thermocouples at the back of the bearing pads. However, since the aluminum pads have excellent heat conductivity this difference may be very small and negligibly affect the actual value of the viscosity at the contact interface. The fact that the Stribeck curves in Fig. 7 do not coincide may be attributed to the reciprocating nature of the motion which is different from the case of unidirectional sliding with a constant sliding velocity. The last preliminary test was aimed at studying the effect of lubricant supply on the friction and on scuffing inception of the piston pin. This test was performed at a constant load and speed of 200 N and 1000 rpm, respectively, but with a gradually reduced lubricant flow rate. This was achieved by increas- ing the time between consecutive drops in the drip lubrication system in the range from 30 to 500 s/drop. This upper limit was determined by a significant increase of the friction torque short of the inception of piston pin scuffing. Fig. 8 presents the results of this test showing very little increase in the friction torque up to about 300 s/drop. The friction torque obtained in the range of flow rate between 30 and 300 s/drop is only about 0.24 N m but at 500 s/drop it increases more rapidly to 0.36 N m. Based on the experiences from the preliminary tests it was concluded to run the main test at the lowest possible Stribeck number in order to increase the chances for scuffing inception. This means operating at low reciprocating speed combined with high load and low viscosity lubricant without commercial additives. I. Etsion et al. / Wear 261 (2006) 785–791 Fig. 7. Stribeck curve showing piston pin operation regimes that are mainly mixed and boundary lubrication. 789 low spherical shape dimples having diameter of about 100 m, depth of 3 m and area density of about 10%. The LST pins were lapped by a special soft pad lapping (SPL) technology to remove bulges that are formed around the dimples during the laser texturing. The treated pins had a measured surface roughness of Ra 0.02 m while the standard pins had Ra of 0.04 m. The piston pin was subjected to a reciprocating angular motion with amplitude of 20◦ . The friction torque and the temperature of the bearing pads were measured while the loading on the bearing segments was gradually increased, and the average friction coefficient was calculated on-line for each load step. Two different lubricants were used in the course of the main test: (i) base oil SN 90 (having viscosity of 17 cSt at 40 ◦ C and 3.75 cSt at 100 ◦ C) and (ii) a formulated SAE 20W50 engine oil (198 cSt at 40 ◦ C and 21.3 cSt at 100 ◦ C). The lubricant was supplied by drip lubrication with a controlled flow rate. Three different types of tests were performed as follows. 4.1. Test 1 In this test the reciprocating rotational velocity of the piston pin was 173 rpm. The load was increased from 200 N in steps of 100 N up to 700 N and then in smaller steps of 50 N. The time length at each load step was determined by stabilization of the average friction torque and the temperature of the bearing pads. The test was terminated if the friction coefficient µ exceeded the value 0.05 or if the load reached 1200 N. Base oil SN 90 was used as the lubricant and was supplied at a rate of one drop every 340 s. 4.2. Test 2 Fig. 8. Friction torque vs. lubricant flow rate. 4. The main test The piston pin bore segments used in these tests were taken from production pistons which are cast from Aluminum Alloy 390. The pin bore surface was machined to a maximum surface roughness of Ra 0.3 m. Piston pins of 65 mm length and 24 mm diameter with three different surface treatments were obtained for testing. These include standard pins that were used as a reference, CrN coated pins and diamond-like carbon (DLC) coated pins. The standard pins were carburized steel with a minimum case depth of 0.4 mm and a minimum surface hardness of Rockwell 15 N 89. The CrN and DLC coatings were applied to standard pins directly over the carburized surface using physical vapor deposition by closed field unbalanced magnetron sputtering. The CrN coating was 1.4 m thick, had a modulus of 235 GPa and a hardness of 16 GPa. The DLC coating contained 11 at.% chromium, was 2.2 m thick, had a modulus of 70 GPa and a hardness of 8 GPa. Several of the standard pins were treated by laser surface texturing (LST) as another surface treatment candidate for enhanced tribological performance [10]. The texture consisted of shal- This test was conducted under the same conditions as Test 1 with only two changes. The time length at each load step was fixed at 500 s., and the test was terminated at scuffing inception that was detected by noticeable substantial change in the noise level, or if the load reached 1500 N. 4.3. Test 3 This test was performed with a reciprocating rotational velocity of 187 rpm and with formulated SAE 20W50 oil. The lubrication rate was one drop of oil every 90 s, and the time between load steps was 500 s. The test was terminated at scuffing inception (as in Test 2) or if the load reached the test rig limitation of 1950 N. It should be noted that with lower oil flow rate the friction torque was not stable and exhibited a saw tooth form with a reduction in its value corresponding to the application of each drop. For this reason the flow rate was selected to be the smallest one which still provides stable friction torque. 5. Results and discussion The results of Test 1 are presented in Fig. 9 showing the effect of the different surface treatments on the behavior of the average friction coefficient with increasing load. As can be seen in Fig. 9, all the three treated pins gave lower friction compared to the ref- 790 I. Etsion et al. / Wear 261 (2006) 785–791 Table 3 Performance of the different pins under load of 1950 N with formulated 20W50 engine oil Fig. 9. Average friction coefficient vs. load for the different piston pins in Test 1. erence pin. Up to about 800 N load these three differently treated pins behave very similar with an average friction coefficient that decreased monotonically from about 0.005 at 200 N to about 0.002 at 800 N. The reference pin friction coefficient decreased from 0.012 at 200 N to about 0.003 at 600 N. Thereafter the friction coefficient of the reference pin started to increase slightly and then much more rapidly above a load of 700 N. At a load of about 900 N, the friction coefficient of the reference pin was 0.05 and the test was terminated at 950 N. The three treated pins showed sharp increase of the friction coefficient above 900 N. The CrN and DLC coated pins friction coefficient reached the value of 0.05 under load of 1000 N when the test was terminated. Only the LST pin reached the limit load of 1200 N with a friction coefficient of 0.04, thus showing a substantial better performance in this load range. The results obtained in Test 2 are summarized in Table 2. These include the critical load at scuffing inception with the corresponding bearing pads temperature and average friction coefficient for the four various pins. As can be seen in this test the DLC coated and LST pins performance exceeded that of the reference and the CrN coated pins. Scuffing inception as indicated by increased noise level occurred with the reference and CrN coated pins under 1050 N when the pads face temperature was about 66 ◦ C and the friction coefficient was about 0.06. The Table 2 Results of Test 2 critical load along with corresponding bearing pads temperature and average friction coefficient at scuffing inception with SN 90 base oil Pin type Critical load (N) Temperature (◦ C) Friction coefficient Reference CrN coating DLC coating LST 1050 1050 1200 1450 66.5 65.4 73.5 85.3 0.060 0.062 0.053 0.051 Pin type Temperature (◦ C) Friction coefficient Reference CrN coating DLC coating LST 115.7 117.0 112.2 109.5 0.050 0.050 0.049 0.046 best performance was obtained with the LST pin that reached 1450 N at scuffing inception. At this high load the pads temperature reached 85.3 ◦ C which is about 19 ◦ C higher than the reference case but the friction coefficient was only 0.051 that is 15% lower than in the reference case. Note that none of the pins could sustain the limit load of 1500 N. Finally in Test 3 with the SAE 20W50 formulated oil none of the pins scuffed even at the maximum test rig loading capability of 1950 N. It should be noted that at this high load with a bearing pad area of 60 mm2 , the contact pressure at each pad was 32.5 MPa which is of the same order of magnitude as in real application of piston pins. The friction coefficient remained at its lower level without showing the sharp increase that was observed with the SN 90 oil as shown in Fig. 9. A comparison of the various pins performance at the maximum load of 1950 N is presented in Table 3. The performance of all the four pins is similar (like the behavior at 600 N, for example, in Fig. 9) with slightly lower, between 3 and 6 ◦ C, pads temperature in the case of the LST pin that also showed between 5% and 10% lower friction coefficient. Unfortunately, with the current test rig it was impossible to obtain higher loads that would initiate the scuffing of the pins. 6. Conclusion A piston pin test rig was designed and built to allow investigation of the effect of different surface engineering techniques on the tribological performance of piston pins. The piston pin test rig allows tests of actual pins and piston bearing bores in a reciprocating angular motion to better simulate real operating conditions. Preliminary tests proved the concept and demonstrated the capabilities of the rig in terms of loads, speeds and lubricant supply. Three different surface treatments for piston pins namely, CrN coating, DLC coating and LST were tested in comparison with a standard reference pin. All three treatments gave, with SN90 base oil, similar lower friction compared to the reference pin up to a normal load of 900 N. The LST performed best at loads above 1000 N. Scuffing load with the LST pin and with SN90 base oil was 1450 N, representing 38% improvement over the reference pin and CrN coating, and 20% improvement over the DLC coating. With formulated 20W50 engine oil all the four pins reached the 1950 N load limit of the test rig without scuffing. At this maximum load, which corresponds to a contact pressure of 32.5 MPa, the LST performed only slightly better resulting in about 10% lower friction than both the reference and CrN coated pins, and I. Etsion et al. / Wear 261 (2006) 785–791 about 5% lower friction than the DLC coated pin. The LST also resulted in 3–6 ◦ C lower temperature than the other pins. Acknowledgements The authors would like to thank Michael Lukitsch, GM Research and Development Center, for providing the coated piston pins and analysis of the coatings. Partial support by General Motors Corporation, Argonne National Lab, the Israel Ministry of National Infrastructure, and the Japan Technion Society Research Fund is gratefully acknowledged. References [1] C.F. Taylor, The Internal Combustion Engine in Theory and Practice, vol. 2, MIT Press, Cambridge, MA, 1985, pp. 576–604. [2] K.H. Hellman, R.M. Heavenrich, Light-duty automotive technology and fuel economy trends: 1975 through 2003. US Environmental Protection Agency Report EPA420-R-03-006 (2003) pp. 12–13. 791 [3] P. Ravan, S. Shivaswamy, B.J. Alshaer, H.M. Lankarani, Joint clearances with lubricated long bearings in multibody mechanical systems, ASME J. Mech. Des. 122 (2000) 484–488. [4] A.R. Riahi, T. Perry, A.T. Alpas, Scuffing resistance of Al–Si alloys: effects of etching conditions, surface roughness and particle morphology, Mater. Sci. Eng. A 343 (2003) 76–81. [5] G. Timmermans, L. Froyen, Fretting wear behavior of hyperutectic P/M Al–Si in oil environment, Wear 230 (1999) 105–117. [6] C. Zhang, H.S. Cheng, L. Qiu, K.W. Knipstein, J. Bolyard, Scuffing behavior of piston–pin/bore bearing in mixed lubrication. Part I. Experimental studies, Tribol. Trans. 46 (2003) 193–199. [7] G. Ryk, Y. Kligerman, I. Etsion, Experimental investigation of laser surface texturing for reciprocating automotive components, Tribol. Trans. 45 (2002) 444–449. [8] J.-L. Ligier, P. Ragot, Piston pin: wear and rotating motion, SAE Paper 2005-01-1651 (2005) p. 3. [9] E. Becker, Trends in tribological materials and engine technology, Tribol. Int. 37 (2004) 569–575. [10] I. Etsion, Improving tribological performance of mechanical components by laser surface texturing, Tribol. Lett. 17 (2004) 733–737.