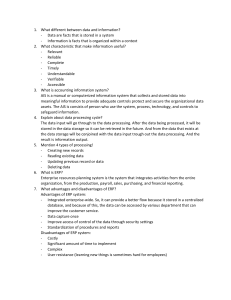

1 Individual Report on Strategic Analysis and Supply Chains 3M Author Institute Date Page | 2 Table of Contents 1. Introduction ........................................................................................................................................... 3 2. Overview of 3M Company ................................................................................................................... 3 3. Overview of the Product ....................................................................................................................... 3 3.1. Stethoscope Anatomy ................................................................................................................... 4 Supply Chain Information for 3M ........................................................................................................ 4 4. 4.1. Overview of 3M Supply Chain and Littman Stethoscope ............................................................ 4 4.1.1. 4.2. Description of Rich Picture ........................................................................................................... 6 4.2.1. 4.3. Supply Chain Diagram of the 3M Company......................................................................... 5 Rich Picture: 3M Company................................................................................................... 7 Table of Information ..................................................................................................................... 7 5. Macro Issues Affecting the 3M – PESTEL Analysis............................................................................ 9 6. A Supply Chain Information Management for 3M ............................................................................. 10 6.1. The Implementation of ERP System ........................................................................................... 10 6.2. The Method of Manipulating Decision-Making Information with ERP System ........................ 10 6.3. The Method of Delivering Information to the 3M Management with the Use of ERP System .. 10 Supply Chain Visibility................................................................................................................... 11 6.4. 7. Discussion ........................................................................................................................................... 12 7.1. 8. The Benefits and Drawbacks of Implementing ERP System to 3M Company .......................... 12 Conclusion & Recommendations........................................................................................................ 13 References ................................................................................................................................................... 14 Page | 3 1. Introduction This report aims to explore essential practices associated with the delivery of information concerning the supply chain management (SCM) of stethoscope product manufactured by 3M. Also, to provide a validation description on the suggested system that can be implemented in the SCM in order to improve the efficiency of distributing information to various levels of management at 3M and as well as the benefit of enhancing their decision-making. This report describes an overview of theoretical SCM of Littman stethoscope manufactured by 3M, graphic interpretation of information relevant to the supply chain of 3M and analysis of Enterprise Resource Planning (ERP) system which is recommended to be used to enhance analysing, managing, storing information within the business that provides the base for generating forecast reports to help determine business trends. This report will also include some of the possible success factors and drawbacks that 3M will have when incorporating the ERP system to their day-to-day business operations. 2. Overview of 3M Company The 3M company is a multi-billion technology corporation with significant standings in electronics, health care, telecommunications, safety, consumer and office, and industrial (Forbes, 2018). 3M has been ranked as 103 in Fortune 500 and has been featured in the Fortune’s magazine as one of the “ten most admired corporations” in the last decade (Fortune, 2020). The main growth strategy that 3M uses is to sell more current stock of goods into new markets and to present recently made products into the market that already exist or are new. 3M ensures that customers are guaranteed satisfaction by providing outstanding service, quality and value. 3. Overview of the Product Stethoscope is an instrument used in the medical field through which sounds produced in the body especially those producing from heart and lungs are listened (Elhilali and West, 2019). Stethoscope is made up of two plastic rubber tubes the covers between the valve and the earpiece. Also, the tubes are joined to the chest piece through the valve, which can be either a piece with a bell shape to detect minimal sounds or a horizontal disk for greater frequencies (Cain, Ahroon and Greenburg, 2002). The stethoscope is utilised primarily for the observation Page | 4 of any sound in the heart such as asymmetrical heart rhythms, abnormal sound of the heart called murmurs and heart’s abnormal pulsation sound. Along with these, the instrument is used as well to examine any sound related to movement of the air within the lungs so that irregularities in the air pipes and sacs located in the lung walls can be identified. 3.1.Stethoscope Anatomy 4. Supply Chain Information for 3M 4.1.Overview of 3M Supply Chain and Littman Stethoscope The Littman stethoscope is a product of the company 3M which is based in Maplewood, Minnesota, United States of America. The major part of the stethoscope is manufactured in USA, china, and other Asian countries. The metal components such as the chest piece and plastic parts of stethoscopes are manufactured at separate locations. This process involves the insertion of pressured molten aluminium into a hollow container, giving a shape and creating a slug in the shape of a basic chest piece or binaural piece. Once those components are made they are transported to the manufacturing facilities in USA for assembly. The components that make up stethoscope are put together and transformed into a usable product. Once assembled, the product is packaged and transported in bulks to the warehouses where they are stored. The major distribution is done through direct sales, retail and online store, direct sales and wholesale retailers. Additionally, 3M Company also has a policy of warranty return, trade in programme, recycle/reuse programme. (3M, 2021). Page | 5 The company’s manufacturing facility, before shipment delivery, conducts a tug tests for stethoscopes by placing on an especially designed machine through which the force at a specified level is stretched to examine whether routine use of the instrument will break it, leading to separate pieces of it. The entire raw materials are examined, and every component manufactured in an area besides the assembly plant is thoroughly tested for quality. Inspection of the aspects of tolerance and procedures is performed at every phase of the manufacturing and assembling. The examination contains visually inspecting the stethoscope and testing the mechanical components for appropriate function and, also inspected its reliability for acoustic. Maintenance and appropriate use of stethoscope has similar significance as the quality of production. The product must be sporadically inspected for any issues involving air leaks and defective parts in which requires replacement. 4.1.1. Supply Chain Diagram of the 3M Company Page | 6 4.2.Description of Rich Picture The Rich Picture is an information elicitation technique utilised mostly in businesses to recognise the scope of issues within information systems (ISs) that are complex. It is applied in socio-technical model in which the people that uses the system are just appropriately suitable as the technology that delivers the solution (Uden, Hadzima and Ting, 2018). The rich picture is one of the soft systems technique which provides a beneficial way of evaluating interactions of technical systems and human (Uden, Hadzima and Ting, 2018). It is crucial that the rich picture Page | 7 necessitates minor description and can be simply understood. The rich picture can act as a communication tool that stimulates systems and users involved to depict their specific perspective of the environment regarding systems. The use of rich picture, in this context, is to provide an analysis of information that provides an enhancement to the decision-making of the management in 3M Company, in relation to the optimisation of strategic, management and operation decisions. 4.2.1. Rich Picture: 3M Company 4.3.Table of Information Page | 8 Page | 9 5. Macro Issues Affecting the 3M – PESTEL Analysis By applying the PESTEL analytical framework, business entities can analyse various macroenvironmental factors affecting its business operations including supply chain. These factors include political, economic, social, technological, environmental and legal factors. The target business sector of 3M Company is the healthcare and consumer goods industry, and it means that this framework can be used to analyse the industry. The political factors affecting the 3M’s industry include legislation about tax, consumer protection, tariffs, trade regulations, insurance policy, and so on, whereas the insurance policy and tax legislation are keys to the health industry (Kiesha Frue, 2018). The consumer goods industry is affected by the trade regulations. The key economic factors include unemployment in the society, inflation, and competition practices of market players. These are major factors affecting to a greater extent the aggregate market demand for goods and the company’s financial and investment decisions. The main sociological factors relevant to 3M include changes in people’s demographics and their attitude and values. The aspect of attitude of people can have major impact on the kind of goods they prefer. As an instance, the preference for being healthy has been increased and more and more people eat healthy and are concerned about food safety. The technological development is one of the main factors in the PESTLE’s technological category. This factor is greatly understood by 3M Company and thus it produces products including Littman stethoscope, healthcare software, electronic materials, and so on. 3M Company, regarding environmental factors, needs to take issues into consideration, including climate change, waste management, and so on. The company experienced the environmental pollution issue by use of perfluorooctanesulfonic acid (PFOS). However, measures were also put to prevent these issues. The company should also consider legal factors including laws related to health and safety, antitrust, copyrights and patents, and others. It is important for 3M to evaluate to what extent these factors have the potential to protect its intellectual property (IP) rights. Page | 10 6. A Supply Chain Information Management for 3M 6.1.The Implementation of ERP System As a software solution, ERP system provides business entities with the important information, supporting the management to effectively manage all the business processes (Parker, 2008). By incorporating ERP system into the business, they will gain agility by linking information gathered from all the departments and every process occurring throughout the enterprise (Gratch, 2015). ERP equips the company with the ability to rapidly track orders and oversee the procurement of raw materials and other components. ERP converts sales orders into specific work orders defining each phase of assembling a company’s product. ERP will cater a company’s sales force of with a translucent view of fruitful chances to better aid assistance to new and existing customers in the market where challenges are always present. All this information grants the company to generate comprehensive reports and statistics that shows the overview knowledge of the company’s activities. 6.2.The Method of Manipulating Decision-Making Information with ERP System A company such as 3M is repetitively challenged with critical decisions regarding the supply chain. This can mean determining on such issues as where to place a manufacturing plant, or whether to benefit from the entities of wholesale or retail distributors. The company’s decisionmaking information indicated in the diagram can be incorporated in the ERP systems, as it provides assistance and can accelerate the entire process to fulfil orders, comprising product distribution. ERP systems, by recording adjustments in computer storage, comprehensively observes and manages human resources, facilities, materials typically used in the making process, financial management and distribution. Along with these, the information of business processes related to 3M company comprising acquirement of raw materials, process of manufacturing, and shipment of the final product are gathered and embedded in the ERP system thoroughly in order to provide accurate data, allow quicker decision making, assure lesser operations cost, generate systematic financial reports for Bureau of Internal Revenue (BIR) compliance and guarantee efficient and smooth business operations. 6.3.The Method of Delivering Information to the 3M Management with the Use of ERP System Page | 11 With the implementation of ERP systems in 3M company, the tools needed for storing and processing data is provided in which supports Management Information System (MIS) to gather information which can be utilised furthermore in forecasting, analysis, application, controlling and monitoring of numerous resources so that more improved decisions can be made regarding the optimisation of operational, strategic and management decisions. These managements can formulate strategies that will be effective in planning and business decisions through the use of Management Information System as it translate data that is stored in the database by ERP into information that is necessary for decision-making. For example, the operational management deals with various information such as the delivery of goods to customers, the supply of materials, and status of machinery and equipment in which used on a daily operation which are then required to take a decision in regard to the inventory level of the company. With the use of ERP allows the management to generate a report from all the information accumulated in the database to form the base of this decision. Also, other information such as the cost of materials bought, the cost of the finished product and the amount of profit gain from sold products, can be compiled using MIS enhanced by ERP tools into a management report that can be analysed by the strategic managers in making decisions such as eradicating the production volume to decrease financial problems to allow business growth and prosperity. 6.4.Supply Chain Visibility The visibility is a prerequisite to provide agility and responsiveness of the chain. If a company has the appropriate tools and know how to use the data obtained, the knowledge that is extracted about a global vision of the supply chain allows it to reduce inventory, save costs and maximise profits; without the efficiency of processes or customer satisfaction being affected (Green and Zueger, 2014). The visibility of the supply chain can be adapted by 3M to form dynamic to changes that occur in markets a flexibility that multiplies its potential sustainability resulting in hundreds of different ways to generate value, inward and the outside of the organisation (McDowell, 2017). There are many examples of how visibility can help the company improve the supply chain. Having end-to-end supply chain visibility will enable 3M acquire greater control over supplier orders and be able to know if they shipped the merchandise on time, if the transport is expected Page | 12 to deliver it within the established period, and if the agreed goods movement conditions are met based on the type of product (Allen, 2017). The company will develop its ability to solve a stock shortage in time and know in which areas it needs to increase knowledge, such as establishing new indicators, collecting metrics that improve visibility, adjusting this selection of KPIs periodically based on the needs of the supply chain that arise, and facilitating the selection of the appropriate tools (Green and Zueger, 2014). The traceability of goods can also be optimised to a greater extent by minimising risk and increasing security, ensuring transport in optimal conditions, improving quality and clarity in customer service, and increasing the rate of punctual deliveries (Bordner, 2017). The visibility, the ability to capture and integrate data, create intelligence based on the knowledge that they generate and modify decisions based on the three main flows in the supply chain (materials, capital and information) is becoming increasingly important in management (McDowell, 2017). Without the global perspective of visibility, decision-making would be deprived of one of its most powerful weapons and the future of the supply chain would lose its sharpness, being reduced to the shadow of what it could have become. 7. Discussion 7.1.The Benefits and Drawbacks of Implementing ERP System to 3M Company The ERP systems support the integration of every single sector within the organisation of the company functions into one specific software application. The integration ensures that ERP systems provides backbone where all business units are in unity and any actions taken in any unit impacts the other due to the sharing and usage of mutual data. The use of ERP systems is to provide effortless tracking of the workflow across various departments (Pylypenko and Redko, 2019). It can decrease the operational costs regarding the non-automatic tracking and the replication of the raw information using specific and diverse systems. ERP systems can be extended to a point in which is able to provide business intelligence functionalities, that is able to provide a general understanding on processes regarding businesses and recognise possible areas of complications/improvements (Sheldon, 2014). By doing so, the decision makers at 3M will find their jobs with much ease and improves their business decisions in which is imperative to the future of the company. The management is empowered by data appropriateness and precision to make well-informed and immediate decisions with reduced risks. The procurement and Page | 13 incorporation of an ERP system to the business contains numerous advantages, but it does not secure the overall success of the business. The culture of an organisation with the business, knowledge on ensuring the involvement of employees and predict changes that will suffer the organisation using this system of management, are vital elements for the achievement of the implementation. For this very reason, enactment of ERP system is terrifically challenging as it involves restructuring of the whole business processes, changing process of the perception in the ways in which human resources perform their tasks, and incorporating numerous types of ISs. Primarily assessing the existing inefficiencies of existing processes would be good practice, along with bring improvement to or significantly shortening the processes (Turban, 2014). 8. Conclusion & Recommendations In conclusion, the SCM of the 3M company acts a network of activities where operations from the purchasing of raw materials is converted into the valuable goods and then the delivery to the customers is concluded through the systems of distribution. The 3M Company should implement the ERP (ERP) system as it is a very important tool for organisation to consistently manage the business with precision. ERP is necessary in almost every company and their departments. In the future, every company will incorporate some type of ERP application set up within the organisation of their company. Although, the implementation of an ERP system can be relatively difficult in terms of cost to be accustomed with, but the benefits exceed the disadvantages which makes the implementation of ERP system to be feasible even for small businesses. An ERP system can provide a seamless integration of entire departments and operates throughout a company onto an individual computer system in which delivers improvement in production, communication, and running operations for further competency. Page | 14 References 3M, 2021. Warranty And Repairs For Your Stethoscope. [online] 3M. Available at: <https://www.3m.co.uk/3M/en_GB/Littmann-UK/my-stethoscope/warranty/> [Accessed 17 January 2021]. Allen, A., 2017. Just 6% of firms have achieved supply chain visibility - Supply Management. [online] Cips.org. Available at: <https://www.cips.org/supplymanagement/news/2017/may/just-6-of-firms-have-achieved-supply-chain-visibility/> [Accessed 27 February 2021]. Bordner, T., 2017. Achieving Greater Visibility and Agility - Inbound Logistics. [online] Inboundlogistics.com. Available at: <http://www.inboundlogistics.com/cms/article/achievinggreater-visibility-and-agility/> [Accessed 27 February 2021]. Cain, P., Ahroon, W. and Greenburg, D., 2002. An Assessment Of Acoustic And Electronic Stethoscope Performance In The UH-60 Noise Environment. Ft. Belvoir: Defense Technical Information Center. Elhilali, M. and West, J., 2019. The Stethoscope Gets Smart: Engineers from Johns Hopkins are giving the humble stethoscope an AI upgrade. IEEE Spectrum, 56(2), pp.36-41. Forbes, 2018. 3M (MMM). [online] Forbes. Available at: <https://www.forbes.com/companies/3m/?sh=6806b3c74aec> [Accessed 17 January 2021]. Fortune, 2020. 3M | 2020 Fortune 500. [online] Fortune. Available at: <https://fortune.com/company/3m/fortune500/> [Accessed 17 January 2021]. Gratch, O., 2015. To ERP Or Not To ERP: Should SMB's Invest In Enterprise Resource Planning?. [online] Business.com. Available at: <https://www.business.com/articles/erpwhat-it-means-for-you-and-your-small-business/> [Accessed 17 January 2021]. Green, W. and Zueger, S., 2014. Supply Chain Visibility. [online] Supply and Demand Chain Executive. Available at: <https://www.sdcexec.com/riskcompliance/article/10210894/supply-chain-visibility> [Accessed 27 February 2021]. Kiesha Frue., 2018. PEST Analysis of the Healthcare Industry. pestleanalysis.com McDowell, J., 2017. Supply Chain Visibility: Closer Than You Think - Inbound Logistics. [online] Inboundlogistics.com. Available at: Page | 15 <http://www.inboundlogistics.com/cms/article/supply-chain-visibility-closer-than-you-think/> [Accessed 27 February 2021]. Parker, P., 2008. The 2009-2014 World Outlook For Enterprise Resource Planning (ERP) Applications. [San Diego, Calif.]: Icon Group International. Pylypenko, L. and Redko, M., 2019. ANALYSIS OF THE ADVANTAGES AND DISADVANTAGES OF ERP SYSTEM IMPLEMENTATION IN ENTERPRISES. Pryazovskyi Economic Herald, (6(17). Sheldon, D., 2014. Class A ERP Implementation. Boca Raton: J. Ross Publishing, Incorporated. TURBAN, E., 2014. INFORMATION TECHNOLOGY FOR MANAGEMENT + WILEYPLUS LEARNING SPACE. [Place of publication not identified]: JOHN WILEY. Uden, L., Hadzima, B. and Ting, I., 2018. Knowledge Management In Organizations: 13Th International Conference, KMO 2018, Žilina, Slovakia, August 6–10, 2018, Proceedings. Cham: Springer International Publishing. Zoellner, D., 2020. The 8 Best Stethoscopes For Nurses Of 2021. [online] Verywell Health. Available at: <https://www.verywellhealth.com/best-stethoscopes-for-nurses-4174854> [Accessed 17 January 2021].