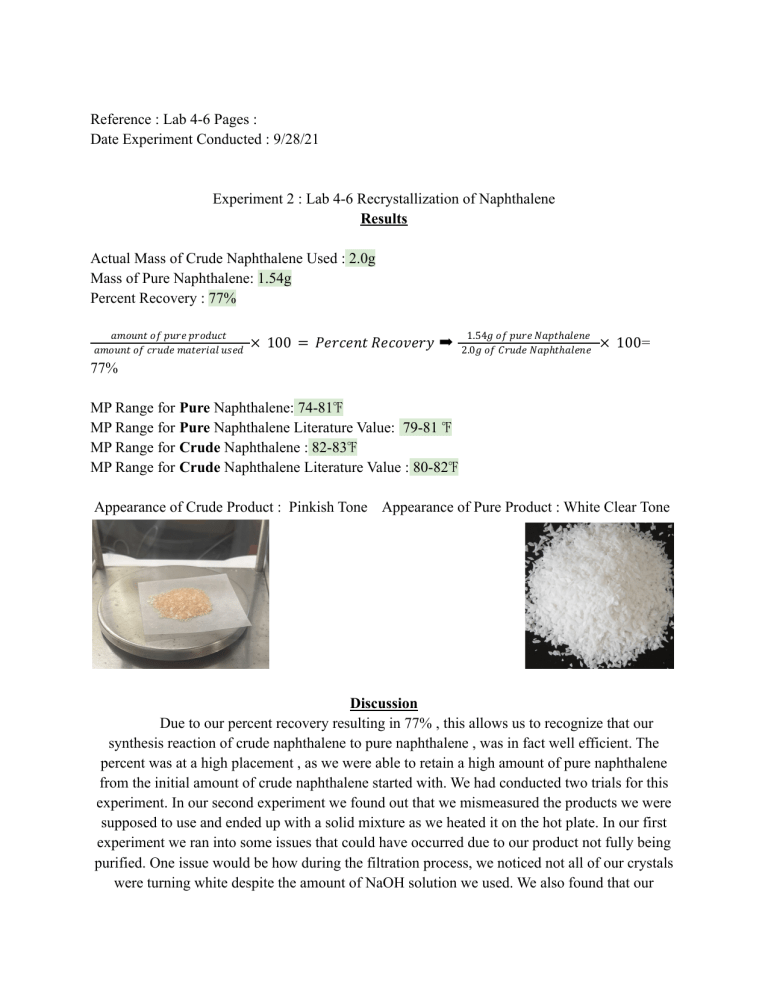

Reference : Lab 4-6 Pages : Date Experiment Conducted : 9/28/21 Experiment 2 : Lab 4-6 Recrystallization of Naphthalene Results Actual Mass of Crude Naphthalene Used : 2.0g Mass of Pure Naphthalene: 1.54g Percent Recovery : 77% 𝑎𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑝𝑢𝑟𝑒 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑎𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑐𝑟𝑢𝑑𝑒 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 𝑢𝑠𝑒𝑑 × 100 = 𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝑅𝑒𝑐𝑜𝑣𝑒𝑟𝑦 ➡ 1.54𝑔 𝑜𝑓 𝑝𝑢𝑟𝑒 𝑁𝑎𝑝𝑡ℎ𝑎𝑙𝑒𝑛𝑒 2.0𝑔 𝑜𝑓 𝐶𝑟𝑢𝑑𝑒 𝑁𝑎𝑝ℎ𝑡ℎ𝑎𝑙𝑒𝑛𝑒 × 100= 77% MP Range for Pure Naphthalene: 74-81℉ MP Range for Pure Naphthalene Literature Value: 79-81 ℉ MP Range for Crude Naphthalene : 82-83℉ MP Range for Crude Naphthalene Literature Value : 80-82℉ Appearance of Crude Product : Pinkish Tone Appearance of Pure Product : White Clear Tone Discussion Due to our percent recovery resulting in 77% , this allows us to recognize that our synthesis reaction of crude naphthalene to pure naphthalene , was in fact well efficient. The percent was at a high placement , as we were able to retain a high amount of pure naphthalene from the initial amount of crude naphthalene started with. We had conducted two trials for this experiment. In our second experiment we found out that we mismeasured the products we were supposed to use and ended up with a solid mixture as we heated it on the hot plate. In our first experiment we ran into some issues that could have occurred due to our product not fully being purified. One issue would be how during the filtration process, we noticed not all of our crystals were turning white despite the amount of NaOH solution we used. We also found that our melting point range occurred earlier than the literature melting point range. While this is not so much of an issue, it is still important to note. Some errors within the experiment that might have occurred was 1. We did not wait long enough or we waited too long for our products to be cooled 2. Our product was not dry enough after the filtration step These two errors can affect things such as the amount of crystals that formed and our melting points which is stated above. Despite these errors, our percent recovery is very reasonable and all procedures were followed carefully and monitored closely.