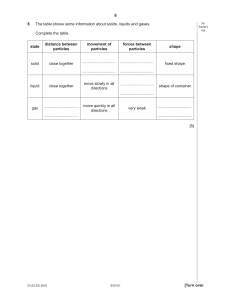

A NEW LASER FAST PYROLYSIS DEVICE WITH IMAGING OF PARTICLES AND ON-LINE ANALYSIS OF VOLATILES A. Dufour*a, S. Beckerb, H. Le Galla, M. Weberb, O. Dufauda, Y. Le Brecha, G. Mauviela, G. Parentb b a LRGP, CNRS, Université de Lorraine, ENSIC, Nancy, France LEMTA, CNRS, Université de Lorraine, Vandoeuvre les Nancy, France *anthony.dufour@univ-lorraine.fr What is the real temperature of particles during their fast pyrolysis? The real temperature of particles during their fast pyrolysis remains unknown due to the lack of real-time imaging of the temperature during the reaction. Most of the fast pyrolysis micro-reactors present huge thermal lags of several dozens of degrees [1,2]. Indeed the true heating rate and temperature of reacting particles can be different than the heating rate and temperatures of the heating source [3,4]. Furthermore the temperature given by thin thermocouples may not be accurate under fast conditions (thermal lag between the reacting particles and the thermocouple). A novel device is under development at CNRS Nancy The global concept of the set-up is based on 4 main features: 1) a well-controlled laser heating system combined with : 2) the imaging of the real temperature of particles; 3) the visual imaging of the shape of particles (bubbles, aerosols, etc.); 4) on-line analysis of volatiles by photoionisation mass spectrometry [5]. Filters on a wheel Mirror Sampling to PI-MS Reactor in inox with various windows in quartz (for visible camera) & ZnSe (for pyrometry) Particles N2+ pyro vapors N2 Silica lamella (20mm, 100µm) ZnSe window CO2 Laser (180W, 10.2-10.8µm) MCT pyrometer Control of the laser Dichroic beam splitter Beam homogeniser Mirror The set-up is composed of: - a high power (180W) CO2 laser emitting an IR light at 10.6µm; - thin film (or particles) of solids/liquids are deposited over a silica lamella (20mm, 100µm) absorbing the CO2 laser IR light; - the laser heats the silica lamella and the temperature heating program of this support is controlled by an advanced monitoring system based on the analysis of lamella temperature with a MCT pyrometer; - the real-time temperature of particles undergoing pyrolysis is measured by a multispectral IR camera (& pyrometer); - the shape of particles (bubbles formation, aerosols ejection) is analyzed by a fast visible camera; - volatiles are sampled by a custom probe from the surface of particles and are analyzed on-line by laser photoionisation mass spectrometry (SPI and REMPI-MS) [5]. Preliminary results 500 Homogeneous heating of the lamella Control of the lamella temperature Good homogenity of heating on the surface due to special laser beam homogeniser Fast monitoring (response time of the pyrometer: 30ms) with a custom FPGA National Instrument system and custom control interface of the laser (triggered with the mass spectrometer). Heating time Excellent homogeneity of temperature on ~10mm diameter of the silica lamella (total diam. 20mm) Temperature of the lamella (°C) Multispectral pyrometer + camera InSb (1.5-5µm) Thermal imaging of real temperature of particles during pyrolysis On-line mass spectrometry Visible fast imaging of Material to be the shape of pyrolysed particles deposited over a silica lamella Heating by CO2 laser Set temperature Measured temperature 400 300 410 405 400 200 400 395 390 350 100 6 300 3.5 4 4.5 6.5 7 7.5 8 5 0 0 Snapshot of the custom interface for controlling the laser 2 4 6 Time (sec) 8 10 Good control of heating (up to 500K/s) and good stability (5K variation at 400°C) Future work Visible image (movie) of lignin pyrolysis Triggering all the signals (laser, pyrometers, cameras, mass spectrometer) (1s to 400°C then 10sec. at 400°C) Improving the resolution of images Other analysis under-development Temperature (°C) References [1] [2] [3] [4] [5] Energy Fuels, 25 (1), 370-378, 2011. Energy Fuels 23 (2), 993-1006, 2009. JAAP, 113, 1-14, 2015. Energies 3(4), 886-898, 2010. Energy Fuels, 30 (3), 1555–1563