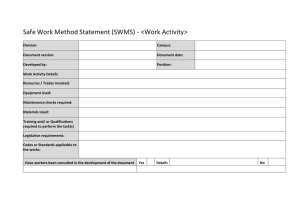

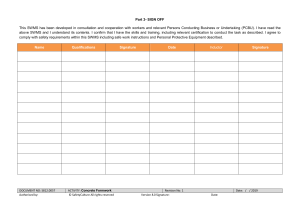

Safe Work Method Statement (SWMS) ACTIVITY: Friable / Non-Friable Asbestos Removal Company Name: Client Company: ACMA Group ABN: FDC Construction 86 445 769 563 Mick Dalby - 0410637313 Client Contact: Job Number: Job Address: Scope of works: Project Manager: Works Commencing: 09/05/22 Completion Date: 16/05/22 30-32 Wentworth Ave Surry Hills NSW 2010 - Remove top layer of corrugated iron roof sheeting. - Remove timber battons and sarking. - Remove bottom layer of currugated iron sheeting ( asbestos mastik located on joins ) - Decontaminate timber roof joists and complete site tidy. Alex Lowe ACMA Supervisor: Alex Lowe SWMS Developed by: Alex Lowe Signature: Position: Director Date: 26/04/22 SWMS Approved by: Alex Lowe Signature Position: Director Date: 26/04/22 Documents, Qualifications, Permits required to Complete Task Safely: þ Regulator Notification ARCP / LRCP Blue & Yellow Site Folders Site Induction Company Insurances Asbestos Removal Licence EPA Licence (3rd Party transport) Industry OHS Induction or White Card Asbestos Certificates (Supervisor, Friable, Non-Friable) First Aid Training RPE fit tests Health Monitoring Safe Work Method Statement (SWMS) Personal Protective Equipment Personal protective equipment required to be available on the site þ þ Other: Equipment to be used for Task/s: H-Type Vacuum PPE / RPE Airless sprayer (PVA) Wetting agent (Dust suppression) Wet Decontamination Facilities Dry Decontamination Facilities Negative Air Units Hand Tools Risk Assessment Matrix Power Tools Mobile scaffold Large Plant Other: Consequence Disaster Very Serious Serious Substantial Minor Almost certain 1 1 1 2 2 Likely 1 1 2 2 2 Possible 1 2 2 2 3 Remotely Possible 2 2 2 3 3 Practically impossible 2 3 3 3 3 Safe Work Method Statement (SWMS) Risk Class Likelihood / Consequence 1 Permanently disable or kill Cause major damage to the structure Have significant impact on the surrounding population and environment 2 Temporarily disable or seriously injure Cause minor damage to the structure Breach the site boundary and pollute local environment 3 Cause minor injury Be contained within the site boundary Hierarchy of Control Eliminate (E) Removal of the risk; e.g. Risk of falling from height, risk is eliminated if work is undertaken from ground Substitute (S) Replacing the plant or substance with another with a lower risk e.g. Risk of inhaling fumes from oil based paints – substitute by using water based paints Isolate (I) Removing or separating people from the hazard; Risk of injury from falling objects or moving plant, isolate by setting up barricades, fence protection, hoarding Engineering Control (EC) Changing the physical characteristics of plant or workplace to remove or reduce risk; e.g. Risk of boom on excavator dropping due to hydraulic hoses bursting when lifting, engineering control by fitting anti drop/burst valves Administrative (A) Using policies, procedures, SWMS and training; e.g. workers not aware of site hazards, administrate by providing on site induction Personal Protective Equipment (P) Equipment or clothing designed to provide protection. E.g. risk of being hit from falling objects –control by using hard hat Safe Work Method Statement (SWMS) Legislation & Compliance Codes / Codes of Practice Commonwealth Work Health and Safety Regulation 2011 Safe Work Australia Work Health and Safety Regulation 2017 WorkSafe Victorian Occupational Health and Safety Regulations 2017 WA OHS Regulation 2001 WorkSafe ACT Dangerous Substances (General) Regulation 2004 Safe Work Australia How to Manage Asbestos in the Workplace Code of Practice 2016 ACT How to Manage Asbestos in the Workplace Code of Practice 2014 WorkSafe Victoria Compliance Code Managing Asbestos in Workplaces, 2008 WA Code of Practice for the Management and Control of Asbestos in Workplaces [NOHSC:2018(2005)] Safe Work Australia How to Safely Remove Asbestos Code of Practice 2016 ACT How to Safely Remove Asbestos Code of Practice 2014 WorkSafe Victoria Compliance Code Removing asbestos in workplaces 2008 WA Code of Practice for the Safe Removal of Asbestos 2nd Edition [NOHSC:2002(2005) Code of Practice for the Safe Use of Synthetic Mineral Fibres [NOHSC:2006(1990)] AS/NZS 4361.2 – 2017 Guide to Hazardous Paint Management – Part 2: Lead Paint in Residential, Public and Commercial Buildings Code of Practice for the Control and Safe Use of Inorganic Lead at Work [NOHSC:2015(1994)] Protection of the Environment Operations (Waste) Regulation 2014 QLD Environmental Protection Act 194 QLD Environmental Protection Regulation 2008 Assessment & Classification of Liquid & Non-liquid Wastes, 2002 The Waste Management and Pollution Control Act 2009 Environmental Management and Pollution Control Act 1994 AS 1319-1994 Safety signs for the Occupational Environment AS 4260 – 1997 High efficiency particulate air filters (HEPA) classification, construction and performance AS/NZS 1716 – 2012 Respiratory Protective Devices AS/NZS 1715 – 2009 Selection, use and maintenance of respiratory equipment Australian Standard AS4801 Work Health Safety Management System Applicable þ Safe Work Method Statement (SWMS) Task Activity Driving to site Entering site Hazard/Risk Injury from car / driving Collisions with others Road closures Fatigue Weather Traffic Electrical Poisonous or dangerous fauna or flora Potential exposure to asbestos and other construction hazards Not adhering to procedures or paying attention / lack of awareness Failure to set up site correctly as roles / tasks are not understood Daily Pre-Start Checks Working near public areas Equipment failure Poor operational performance / practice resulting in injury Equipment not maintained or damaged Equipment not tagged ‘out of service’ Potential exposure to asbestos and other construction related hazards Public being aware of the project Incorrect controls or containment PRERISK Control Measure 2 2 2 1 Contact your State main roads for updated road closures or visit the website Check weather report / status Obey road safety rules Site management to identify all essential services and ensure arrangement have been made for isolation services Inspect building and surrounding area before commencing works Remove vegetation and / or materials from the work area that could attract dangerous fauna or flora All workers to be site inducted OHS Construction cards to be held in blue site folder Review of SWMS, ARCP & other site documents before commencing Site documents signed and completed before work commences Ensure all workers have correct PPE Maintain good communication skills Allocate roles and responsibilities to ensure workers understand the requirements and roles Use the daily site and equipment checklist to ensure all pre-start checks have been completed All equipment to be checked prior to use Out of service tags to be attached to non-functional or non-safe equipment Isolate work site, ensure exclusion zones are demarcated and appropriate signage is set up Access to the removal site is restricted Keep gates / access wats locks where possible Provide information to workers, clients and neighbouring areas to ensure they know about the project Emergency action taken in the event of unauthorised entry into work areas POST RISK Person Responsible Operative Management Site supervisor Operative Supervisor Operative Supervisor Operative 3 3 3 3 Safe Work Method Statement (SWMS) Task Activity Working in and around the site Working outdoors Hazard/Risk Emergency Incident Accident Inadequate first aid supplies Reduced hearing within work area Exposure to bites and stings PRERISK Control Measure 2 2 Emergency response Poor response or no response resulting in injuries or death Fire installations isolated Persons not aware of emergency Manual Handling (Lifting, carrying tools & heavy loads) Sprains Injuries to back, muscles, joints etc. Incorrect manual handling techniques Use of hand tools Cuts lacerations Eye injury Manual handling Damaged or unsafe tools Vibration 1 1 1 Call 000 or 112 in an emergency Report all dangerous situations to the site supervisor Emergency plan and contacts are to be contacted as per client and or company emergency procedures Outside person to periodically check on operatives inside working area at all times Long pants Clear vegetation and debris from work area prior to any operatives entering removal area Ensure any workers with allergic reactions insect bites are identified and monitored Inspect areas for indication that animals may be present Call 000 or 112 in an emergency Directions given by emergency forces are to be followed Prior to commencing work on site all fire installation isolations are to be identified and communicated to all stakeholders Ensure training in manual handling procedures Avoid twisting the body, lifting above head height and turn using your feet Assess the weight of the objects prior to lifting Ensure a clear transit path is free from obstruction Prior to each use; inspect all tools for defects and damage Set exclusion zones when working above ground level Rotate workers around various tasks All workers training in the correct use of equipment as per manufactures instructions and safe operating procedures All workers trained in the identification and warning signs of manual handling related injury and illness POST RISK Person Responsible All Supervisor All All Supervisor Operative Supervisor Operative 3 3 2 2 2 Safe Work Method Statement (SWMS) Task Activity PPE / RPE Hazard/Risk PRERISK Exposure to asbestos Exposure to chemicals Local irritation Sensory effects Physiologic effects Body temperature Sunburn Contaminated PPE Worn incorrectly Use of inadequate filters Battery pack not charged Control Measure 2 If scope of works changes or hazards identified PPE / RPE is to be changed (P2 to P3 respirators) All PPE / RPE is to be inspected for damage and filters changed as required Any person identified as being non-compliant is to be removed immediately from the work area A pre check of all batteries is to be conducted prior to demobilisation from the shed Replace PPE / RPE immediately when it is identified as inappropriate, ineffective, damaged or other immediate cease work RPE brand is chosen based on risk assessments Spare battery packs are made available Only safety shoes that are cleanable, have no laces are to be worn at any time on site Coveralls to be worn over head covering hair and zipped up at all times. Use a different suit colour for removal work areas and transit routes for easy identification All workers are to be clean shaven with no facial hair that may potentially interfere with the seal of RPE Pre-checks of PPE / RPE is to be completed for EACH use Work systemically and plan reducing the risk of any missed or unseen items Pre-filters should be changed as required P3 main filters should have date of first use written on them and changed as necessary Fit checks should be conducted for each use of RPE Maintenance schedule as provided by supplier is to be followed Sunscreen should be regularly applied to the entire body when working outdoors PPE / RPE specific for non-friable and friable works is set out within the ARCP for various stages of works Policies and procedures on the selection use, limitations, maintenance of PPE / RPE is given to all operatives at induction and throughout the year Training in correct procedures for use maintenance and wearing PPE / RPE Training in the limitations of respiratory protection and filters Training in the physical and psychological effects of wearing RPE RPE is the last item to be removed when decontaminating in EVERY instance POST RISK Person Responsible 3 Supervisor Operative Safe Work Method Statement (SWMS) Task Activity Use of power tools Hazard/Risk Electric shock High risk Use of powered electrical tools and equipment Live electrical services PRERISK Control Measure 1 Use of a Utility Knife Use of dust suppressant Working in high voltage areas Cuts to the non-knife hand or arm (most common) Cuts to the hand holding the knife which occur when the hand slips off the handle Cuts which occur with a reverse grip and pulling back towards the body Cuts to another person, inadvertently, where people are too close together when working Sprains or strains (e.g. from the extra effort required when using a dull knife) Excessive runoff Electrocution Excessive application of dust suppressant Electrocution Death Never take your eyes off the cutting path of the knife, if you must look away, stop cutting Never cut towards yourself or towards another individual Always be aware of the movements of people around you Do not apply too much pressure on the blade Follow manufacturer’s instructions when changing blades Don’t use utility knives to pry loose objects Dispose of dull or broken blades in a puncture resistant container Wear appropriate PPE e.g. cut proof gloves Use self-retracting knives Always use a sharp blade Dust suppressant to be monitored Water sprays to be used to suppress dust Tack rags to be used on all electrical equipment Water is not to be used on or near electrical equipment Test before you touch Identify tasks and appoint competent personnel for work Qualified licensed electrician Instructed persons under supervision Appropriately trained Working within safe working distances to live equipment Comply with the Electrical Company procedures 2 2 1 Ensure client provides confirmation of isolation for all electrical fittings and equipment to be disturbed during removal works Connect all electrical tools to RCD box Remove equipment and leads from the work area prior to commencement where practicable Ensure all leads and equipment used during removal process are serviced, tag and tested Ensure good housekeeping skills are maintained POST RISK Person Responsible Client Supervisor Operative All All All 3 3 3 3 Safe Work Method Statement (SWMS) Task Activity Use of chemicals or hazardous substances Hazard/Risk PRERISK Skin irritation, eye irritation and illness from handling and inhalation or ingestion of hazardous substances / chemicals Manual handling risks from using / applying hazardous substances or chemicals causing back and muscle strain Control Measure 1 H-type vacuums Wet wiping Electric shock Exposure to asbestos Manual handling Equipment not maintained Inadequate filters Inadequate air flow Uncontrolled maintenance Damaged equipment Electrocution 2 2 Plant and Equipment Electrocution Water leak 1 The manufacturer’s instructions and safety precautions should always be followed when using hazardous materials and chemicals. These are to be found in the material safety data sheet (MSDS) for the product Provide training / awareness in the first aid measures for treating an exposure Train employees in the safety precautions and PPE to be used when using hazardous substances or chemicals, as per the material safety data sheet (MSDS) Ensure containers are properly labelled Ensure materials are properly stored Use quantities that are easily handled Train employees in the correct selection and use of any handling equipment Train employees in manual handling techniques appropriate to the chemical or material being used Where tools / equipment are identified as damaged or broken immediately remove from the work area and tag accordingly Ensure all equipment is maintained and tested as per maintenance schedule Install containment measures prior to carrying our any maintenance Connect electrical equipment to RCD boxes Inspect all equipment prior to each use and during operation All workers training in the correct use of equipment as per manufactures instructions and safe operating procedures No use of wet wiping on electrical components Maintain safe working distances from live electrical equipment Ensure all equipment (including power leads, RCD boxes) has up-to-date tagging (At least every 3 months) Ensure all water supply is adequately controlled POST RISK Person Responsible Supervisor Operative Supervisor Operative Operative Supervisor Operative 3 3 3 3 Safe Work Method Statement (SWMS) Task Activity Installation of enclosures and containment measures Hazard/Risk Slips, trips and falls Polythene installed to floor Exposure to Asbestos fibres Poor housekeeping Insufficient seal Gaps in containment PRERISK Control Measure 2 Dry Decontamination Wet multistage decontamination facilities Exposure to asbestos fibres Operatives not following correct decontamination procedures Decontamination facilities not set up Airlocks flaps not secured Exposure to asbestos fibres Operatives not following correct decontamination procedures Failure of essential services to decontamination unit Decontamination facilities not set up correctly or turned off prior to work completion 2 2 All care to be taken when walking over slippery surfaces Polythene sheeting is not to be installed over steps Practice good housekeeping skills Seal all apertures, windows, penetrations, doorways prior to works commencing All transit routes to be clearly demarcated and no person detour from path All workers are trained in the design and building process for installation of containment measures Decontamination facilities to be clearly demarcated Site supervisor to conduct inspection and ensure appropriate decontamination facilities are in place prior to any works commencing All personnel are training in the correct procedures for decontamination A mobile self-sufficient wet multistage decontamination unit to be established and connected to main services Decontamination unit to be fully operational prior to works commencing Decontamination facilities are to remain fully operational for duration of works Transit routes from decontamination units to enclosure are to be clearly demarcated Site hygienist is to conduct air monitoring within the clean end of the decontamination unit Sit supervisor to conduct inspection and ensure appropriate decontamination facilities are in place prior to any works commencing All personnel are training in the correct procedures for decontamination POST RISK Person Responsible All Supervisor Operative All 3 3 3 Safe Work Method Statement (SWMS) Task Activity Work in or areas with extreme of temperature Hazard/Risk PRERISK Working in tropical weather conditions over 35 degrees PPE is not breathable Dehydration 2 UV / Heat UV exposure sunburn / heat exhaustion Lack of protection or cover Exposure to sun Dehydration Control Measure 2 Work with noise and vibration Hearing damage from use of plant and equipment such as excavators, vibratory plate, vibrators, saws, nail guns etc. 2 If a person is suspected of suffering a heat related illness at any time, emergency procedures are to be immediately implemented and medical assistance sought. Symptoms of a heat related illness may include: Rash, Cramps, Red, hot, dry skin, although the person may have been sweating earlier, nausea, Fatigue, dizziness (DIAL 000 AMBULANCE – FIRE – POLICE) IF person displays these symptoms: Confusion, disorientation, high body temperature, rapid respiratory and pulse rate; unconsciousness or collapse Ensure all workers have PPE, including wide brimmed hats, long sleeve shirts and sunglasses where possible Wear sunscreen SP30+ or SP50+ Ensure water is constantly made available to all workers and take breaks as required Ensure certified first aid kit is onsite and personnel trained in heat related injuries/illness Where practicable, provide engineered solution for high noise level, e.g. quieter or muffled equipment, temporary sound absorption screen or barrier to protect other persons in the area Check that regular plant and equipment maintenance to minimize noise has been carried out and that noise suppression mufflers etc. are fitted to prior to use Identify noisy work areas Ensure appropriate hearing protection is worn POST RISK Person Responsible All Supervisor Operative All 3 3 3 Safe Work Method Statement (SWMS) Task Activity Working with reduced visibility Hazard/Risk PRERISK Not visible hazards within work area ACM not removed or missed Reduced or poor visibility Insufficient lighting to the work area Control Measure Virgin clean polythene sheeting to be used on wall and ceilings surfaces Installation of suitable portable lighting equipment 2 Working within a restricted space Restricted access to removal work area Penetration to PPE / RPE Exposure to asbestos PPE / RPE penetrated or disturbed due to catch on object within the work area Working within a confined space Electrical shock or electrocution Body injury from moving equipment if inadvertently activated or from falling or slipping Body injury from direct contact with corrosive materials Suffocation, asphyxiation or poisoning Fire or explosion Scalding or burning Hypothermia, drowning Burial 1 Person Responsible All All Supervisor Operative 3 2 POST RISK Inspect areas before and during works commencing and identifies all potential hazards that may interfere with PPE All movements within the enclosure are to be slow maintaining awareness of restricted work space In the event of PPE damage immediately leave removal works area and follow full decontamination procedures. Immediately notify site supervisor should RPE be disturbed or seal broken Ensure all persons onsite have been consulted with the procedures to undertake in the event of penetration to suits All operatives are to wear gloves and hard hats The concentration of oxygen in the atmosphere within a confined space and the increase in the level of flammable gases must be in accordance with Australian Standard AS 28652001 The work in the confined space must be carried out as specified in the permit and all the required precautions must be strictly followed The stand-by person shall follow the instructions for his duties and not leave his position while person(s) are in the confined space. In the event of an injury or collapse of the person in the confined space, the stand-by person's primary duty is to summon help and if possible, provide assistance, first aid, resuscitation, etc. The Stand-by person must not enter the confined space 3 2 Safe Work Method Statement (SWMS) Task Activity Working at Heights Hazard/Risk PRERISK Fall from height Struck by falling objects Collapse Working from above ground level Platforms / ladders not locked into place or setup correctly Overloading of SWL Control Measure 1 Use Scaffolding Collapse of scaffold Fall from height Electrocution 1 Work from a scaffold Slips trips and falls Sprains and strains Crush injury 1 Ensure no personnel working below Take care when erecting platforms / removing asbestos Platform ladders to setup on firm level ground Only platform ladders back railing can be worked off Ensure 3 points of contact on ladders at all times Ensure mobile platforms are correctly setup to manufacturer’s specifications and brakes applied at all times Crawl boards are to be used within the ceiling activity Operatives to only stand on supported beams if any structural beams are identified as unsafe hey are to be marked Inspect all equipment (steps and scaffold) prior to each use Ensure max load on equipment is not exceeded All operatives to have completed working at heights training Handrails and mid rails are to be installed on every deck level. No –one is to be on scaffold during re-positioning At no time should a ladder or other be used to gain additional height from scaffold deck Internal ladder access is for all travel; at no time should any person climb on the inside or outside of scaffold Caster breaks are to be applied at all times Prior to each days use scaffold is to be inspected for stability Install and tag scaffold as safe prior to any works (ACMA has a qualified scaffolder) Site supervisor is to conduct an inspection of scaffolding: Before its first use As soon as practicable before next use After an occurrence that might reasonably be expected to have affected its stability POST RISK Person Responsible Supervisor Operative Supervisor Operative Supervisor 2 2 2 Safe Work Method Statement (SWMS) Task Activity Use of a mobile work platform (boom lift) Hazard/Risk PRERISK Fall from platform Tip machine Collision Operated by unauthorized / unqualified person(s) Control Measure 1 Working near suspended loads Traffic Management Crane falling Load falling Being hit by moving load Personnel being struck by moving vehicles and plant 1 1 Carry out daily inspections / checks as per manufacturers operating manual and Operator Daily Safety Checks on the cover of the log book and give to team leader Check and familiarize yourself with the operation of platform emergency descent and/or operator retrieval system at ground controls Read all manufacturers safety decals/stickers on machine Record in the log book and sign off by person making entry Report any defects or damage to supervisor immediately. Do not use machine until these are repaired / fixed Place “Danger do not use” tag on machine to prevent use by others Take instructions from Dogman on site Stay well clear of suspended loads Do not walk under suspended loads Ensure all workers are aware of site traffic safety requirements; designated safe access points and walkways; designated plant/vehicle movement zones; designated parking areas and designated delivery areas Where in doubt consult the builder or site supervisor Ensure reflective vests are worn as required POST RISK Person Responsible All All All 2 2 2 Safe Work Method Statement (SWMS) Task Activity Excavations for footings / stock piling spoil / cutting piles * Check for existing services Hazard/Risk PRERISK Contact with underground services (gas, electricity, pipelines, sewer) and contaminated soil Crushing injury from collapse of undermined nearby structures Crushing injury from collapse of the sides of the excavation Falling into excavations Injuries to the head from materials, rock or spoil falling onto people working in excavations or from collision with fixed objects Carbon monoxide poisoning from fumes given off by fuelled plant and equipment such as generators, cutting saws etc. Accidents to members of the public Control Measure 1 Inspect all relevant site drawings and where necessary contact the Dial-before-you-dig-service prior to digging Ensure that all underground services and any other contamination are identified and that all relevant safety issues are addressed Ensure that any potential undermining of nearby structures has been assessed by a competent person (such as a GeoTechnical Engineer) and that any necessary supports are in place No person to enter any unsupported section of an excavation unless it has been assessed for stability and has adequate ground support Ensure that sides of excavations are protected by a trench shield or by shoring, battering or stepped as detailed in the Code of Practice Safety Precautions in Trenching Operations Do not allow plant close to the sides of an excavation No person to work alone within excavations The sides of the excavation to be protected by barriers to prevent falling, particularly where access is required within 2 metres of unprotected edges Provide adequate access ramp, stairs or ladder to prevent falls Ensure construction and excavated materials are kept at least 0.5 metres away from the edges of excavations Ensure hard hats are worn when working in excavations Do not operate fuel driven plant or equipment inside trenches, holes, or shafts unless adequate exhaust ventilation is provided, or use electric powered equipment instead Keep fuel driven equipment well away from excavations prevent build-up of exhaust fumes Where practicable, fill in or cover up any excavations that may be accessed by members of the public Protect after hours by barriers and illuminated signage to prevent falling POST RISK Person Responsible 3 All Safe Work Method Statement (SWMS) Task Activity Identification of previously undetected hazards (soil contamination, ground asbestos) Hazard/Risk PRERISK Exposure to hazardous substances Control Measure 2 Contaminated Material Unloading, plant, equipment & tools Plant & vehicles exposed to contaminated materials Employees struck by mobile plant Plant, vehicles, tools, equipment, persons obstructing work areas, road ways and public areas 2 At any time, odorous or oily material is identified, works are to stop and site management is to be contacted for advice. No works are permitted to recommence in the area until such time approval has been provided by the site supervisor If any debris or building rubble is identified, works are to stop and site management is to be notified for instruction At any time suspected asbestos containing materials are identified, works are to stop and site management notified for instruction NO works are permitted to recommence in the area until such time approval has been provided by the site supervisor On arrival to site, delivery vehicles must be parked in specified area & contact is to be made with site management and instruction obtained as to the appropriate area to unload If plant and equipment cannot be unloaded within the site boundary, traffic management (as per site TMP) must be in place prior to unloading Any delivery vehicles unloading in contaminated areas must have the driver inducted into the relevant contractor SWMS site prior to unloading if they are required to exit the truck cab The contaminated area may need to be scraped level prior to vehicle entry if the ground conditions are poor Vehicles must proceed through the wheel wash / plant decontamination area prior to leaving site Roadways, public areas, haul roads and access routes must not be obstructed by any plant and equipment unloaded on site, unless under management instruction Once equipment has been unloaded, it needs to be relocated to the required work area or stored in the nominated area so it does not obstruct the roadways, public areas, haul roads and access routes POST RISK Person Responsible All All 3 3 Safe Work Method Statement (SWMS) Task Activity Contaminated Material Prepare for work Hazard/Risk PRERISK Exposure to contaminated materials Struck by mobile plant Slips, trips & falls Trucks being bogged Control Measure 2 Prior to works starting contact to be made with management to discuss scope of work and required work area / exclusion zone for tasks to take place The site contamination plan is to be reviewed to inform the contractor of suspected contaminates in work zone environmental to be contacted if required Only trained and authorized personal to operate earthmoving plant All earthmoving plant to be inducted to site prior to operation. Exclusion zones, barricade’s and signage to be erected if required prior to works starting Access for trucks etc to be set up prior to work starting. Agreed communication to be place (2 – way, UHF etc ) if required Dust control is to be arranged prior to works starting and maintained at all times If operators intend to be working in a sealed cabin, then no additional PPE will be required to be worn, however if they intend to handling contaminated soils then overalls, PVC gloves, half face respirator will be required if dust or odour is present (with a P2 particulate filter for dust) or (with organic vapour filters for potential presence of organic volatiles POST RISK Person Responsible 3 All Safe Work Method Statement (SWMS) Task Activity Contaminated Material Bulk excavation, stockpiling, trenching and loading soil Hazard/Risk PRERISK Being struck by delivery trucks or passing vehicles Falls & trips when moving around wet and slippery site Contact with o/head or U/ground assets Plant overturning Persons struck by moving vehicles Truck Drivers injured by plant Dust contamination of the area Exposure to contaminated soil Exposure to asbestos containing materials Control Measure 2 Site traffic management plan to be in place prior to works starting Appropriate access to be provided for contractor access to work area and for truck / trailer movement Pre-start checks to be completed prior to works commencing Agreed communication to be place (2 ways, UHF etc.) if required Site service plan to be reviewed, all overhead and underground services in work area that have not been de-energized or made safe, are required to be clearly marked and no go zones implemented / spotter to be in place if required Pedestrians are to be kept out of work zone Truck drivers are required to stay inside the cabin until the truck has been loaded and they can drive to the designated area to tarp up At any stage any person is observed within the excavators’ work area the machine is to immediately stop working and the operator is required to wait until the area is clear of personal The operator is required to ensure that the working stockpile is safe to access and left in a safe condition The operator will communicate with water cart to ensure the soil remains damp and dust is controlled at all times No eating, drinking or smoking is allowed within the work site including within the machines cabin At any time odorous, or oily material is identified, works are to stop and site management is to be contacted for advice. The SWMS for odour monitoring is to be followed. No works are permitted to recommence in the area until such time approval has been provided by the site supervisor If any debris or building rubble is identified, works are to stop and site management is to be notified for instruction At any time suspected asbestos containing materials are identified, works are to stop and site management notified for instruction The SWMS for suspect material in soil is to be followed NO works are permitted to recommence in the area until such time approval has been provided by the site supervisor POST RISK Person Responsible 3 All Safe Work Method Statement (SWMS) Task Activity Contaminated Material Clean-up & leave site Hazard/Risk PRERISK Being struck by delivery trucks or passing vehicles Falls & trips when moving around wet and slippery site Trips and falls into open excavations Contact with o/head or u/ground assets Plant overturning Persons struck by moving vehicles Truck drivers injured by plant Dust contamination of the area Exposure to contaminated soil Exposure to asbestos containing materials Drains contaminated with soil runoff Roads soiled by contaminated soil Passing public struck by vehicles entering / leaving site Contamination of clean areas Control Measure 2 Operators only to exit trucks in nominated area Site ground conditions to be monitored and maintained in an acceptable condition by mechanical sweeping, scraping with earthmoving plant, washing down, hardstands to be used if possible All pedestrians, excavation to be backfilled if possible, if not possible barricades are required to be installed at the angle of repose It is the responsibility of the contractor who excavated the area to install and maintain the barricades Tippers must ensure that the body is fully lowered prior to moving Stockpiles are required to be maintained in a safe condition Stockpiles are to be located away from drainage points Dust must be suppressed at all times If soils loads on trucks cannot be kept damp, then they are required to be tarped up or covered during transportation. Wheel wash to be used on all vehicles that have had contact with contaminated soil prior to leaving site Use active traffic control at site entry points Personnel leaving the work site MUST leave through the site change area. This includes all meal break’s, toilet break’s etc. All boots must go through the boot washes Hard hats, high vis vests and boots that cannot be cleaned or decontaminated must be left in the change area and not taken into the clean zone If gloves are worn they need to be washed as per procedure. Coveralls that are not soiled may be left in change area for reuse. Soiled coveralls are to be left in the laundry container or Tyvex suits disposed of in nominated area Disposable mask’s to be disposed of in nominated area Half face respirator to be cleaned as per procedure and cartridges inspected as per procedure Hands, face are to be washed thoroughly. If persons have had significant direct contact with contaminated soil, has occurred was in shower provided If normal clothing has been contaminated the clothing should be bagged for professional cleaning. Temporary clothing such as clean disposable coveralls will be supplied to the person POST RISK Person Responsible 3 All Safe Work Method Statement (SWMS) Additional SWMS items; if not listed above. Task Activity Hazard/Risk PRERISK Changes made by: All team members have read and understood the above updates: Control Measure Date: (please initial below) POST RISK Person Responsible Safe Work Method Statement (SWMS) This SWMS has been developed through consultation with ACMA employees and has been read, understood and signed by all employees undertaking the works. I understand that I must comply with all steps, if changes are required or task changes. I will STOP works and review the process. Print Names: Notes: Signatures: Day & Date: