Metalurgia Produkcji: Obliczenia Wsadu Stali i Węglika Krzemu

advertisement

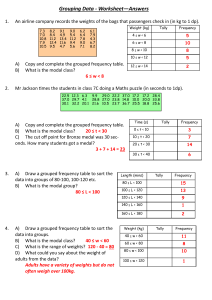

Dainty Monica Orate 2018-09906 PS4 MetE 136: Production Metallurgy April 20, 2022 A. Determine the amount of steel scrap and silicon carbide that needs to be charged with 500 kg of hot metal and 10 kg of cast iron. Account for all the input and output items. Heat loss is 7000 kcal/MT. Input Fuel/ Coolant Weight, kg Weight in MT kg 31.5 Burnt Dolomite Multiplier 20 Burnt Lime 99.5% O2 Total Hot Metal 500 0.5 Multiplier 63 Steel Scrap 680 0.68 0 0 0 0 3 2.04 682.04 Cast Iron 10 0.01 158 1.58 49 0.49 92 0.92 12.99 Silicon Carbide 62.4 0.0624 5298 330.5952 1648 102.8352 1900 118.56 614.3904 164.52 1893.9204 1252.4 363.6752 kg 10 Multiplier 86 kg 43 584.5 113.3252 Output Item Weight, kg Weight in MT kg 70.5 Gas and Fumes Multiplier 116 Hot Metal 500 0.5 Multiplier 912 kg 456 Multiplier 141 kg 58 584.5 Steel Scrap 680 0.68 981 667.08 13 8.84 9 6.12 682.04 Cast Iron 10 0.01 877 8.77 340 3.4 82 0.82 12.99 Silicon Carbide 62.4 0.0624 -2081 -129.8544 11070 690.768 857 53.4768 614.3904 118.4168 1893.9204 Steel Slag 1001.9956 773.508 Total B. Determine the amount of iron ore and calcium carbide need for the following conditions. Prepare the Input and Output tables for each case and rationalize any differences observed. Heat loss is 7000 kcal/MT. 1. 500 kg hot metal + 100 kg steel scrap Equation 1 W,hm(0.912) + W,ss(0.981) + W,io(0.599) + W,cc(0.014) = 1 Equation 2 W,hm(-131552) + W,ss(315801) + W,io(1484527) + W,cc(-2325126) + 7000 = 0 Weight of hot metal W,hm 500 kg Equation 1 Equation 2 Weight of steel scrap W,ss 100 kg c 0.4459 27195.9 734 0.599 1484527 Weight of iron ore W,io kg a coeff Weight of calcium carbide Input Fuel/ Coolant Weight, kg W,cc Weight in MT 457.00 kg b coeff Multiplier kg Burnt Dolomite Multiplier Burnt Lime 0.014 a 0.734 -2325126 b 0.457 99.5% O2 Total kg Multiplier kg Hot Metal 500 0.5 63 31.5 20 10 86 43 584.5 Steel Scrap 100 0.1 0 0 0 0 3 0.3 100.3 Iron ore 734 0.734 149 109.366 33 24.222 -265 -194.51 673.078 Calcium carbide 457.00 0.457 -937 -428.209 12 5.484 655 299.335 333.61 148.125 1691.488 1791 -287.343 39.706 Output Item Weight, kg Weight in MT kg Gas and Fumes Multiplier Multiplier kg Multiplier Hot Metal 500 0.5 912 456 141 kg 70.5 116 58 584.5 Steel Scrap 100 0.1 981 98.1 13 1.3 9 0.9 100.3 Iron ore 734 0.734 599 439.666 313 229.742 5 3.67 673.078 Calcium carbide 457 0.457 14 6.398 -32 -14.624 748 341.836 333.61 404.406 1691.488 Steel Slag 1000.164 286.918 Total 2. 500 kg hot metal + 100 kg cast iron scrap Equation 1 W,hm(0.912) + W,ci(0.877) + W,io(0.599) + W,cc(0.014) = 1 Equation 2 W,hm(-131552) + W,ci(122947) + W,io(1484527) + W,cc(-2325126) + 7000 = 0 Weight of hot metal W,hm 500 kg Equation 1 Equation 2 Weight of cast iron W,ci 100 kg c 0.4563 46481.3 Weight of iron ore W,io 75.1 kg a coeff 0.599 1484527 Weight of calcium carbide W,cc 46 kg b coeff 0.014 -2325126 a b 0.751 0.46 Input Fuel/ Coolant Weight, kg Weight in MT kg 31.5 Burnt Dolomite Multiplier 20 Burnt Lime 99.5% O2 Total Hot Metal 500 0.5 Multiplier 63 Cast Iron 100 0.1 158 15.8 49 4.9 92 9.2 129.9 Iron ore 75.1 0.0751 149 11.1899 33 2.4783 -265 -19.9015 68.8667 Calcium carbide 46.00 0.046 -937 -43.102 12 0.552 655 30.13 33.58 62.4285 816.8467 721.1 15.3879 kg 10 Multiplier 86 kg 43 584.5 17.9303 Output Item Weight, kg Weight in MT kg 70.5 Gas and Fumes Multiplier 116 Hot Metal 500 0.5 Multiplier 912 kg 456 Multiplier 141 kg 58 584.5 Cast iron 100 0.1 877 87.7 340 34 82 8.2 129.9 Iron ore 75.1 0.0751 599 44.9849 313 23.5063 5 0.3755 68.8667 Calcium carbide 46 0.046 14 0.644 -32 -1.472 748 34.408 33.58 100.9835 816.8467 Steel Slag 589.3289 126.5343 Total Conclusion: When using steel scrap instead of cast iron scrap, the burnt lime needed became negative due to the largely negative value of lime needed for calcium carbide. When steel scrap is used, the calcium carbide needed to supply heat is almost ten times more that when using cast iron. This is because cast iron contains more carbon (around 4%) than steel (less than 2%).