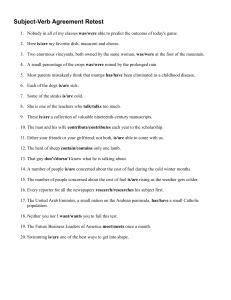

CESSNA GRAND CARAVAN C208B QUICK REFERENCE HANDBOOK Original COPY # __ Page 1 Table of Contents Page Title Page Title 1 Table of Contents 29 Normal Checklist 2 Distribution List/Revision and Use Policy 30 Briefing Card 3 List of Effective Pages 31 DG Hazard and Handling Labels 4 Emergency and Abnormal Index 32 DG Hazard and Handling Labels 5 Emergency and Abnormal Index 33 DG Carried by Passengers or Crew 6 Emergency and Abnormal Index 34 DG Carried by Passengers or Crew 7 Airspeeds for Emergency Operation 35 DG Emergency Response Guide 8 Maximum Glide 36 DG Emergency Response Guide 9 Emergency Procedures 37 Annunciator Panel 10 Emergency Procedures 11 Emergency Procedures 12 Emergency Procedures 13 Emergency Procedures 14 Emergency Procedures 15 Emergency Procedures 16 Abnormal Procedures 17 Abnormal Procedures 18 Abnormal Procedures 19 Abnormal Procedures 20 Abnormal Procedures 21 Abnormal Procedures 22 Maximum Takeoff and Climb Torque 23 Takeoff Performance 24 Takeoff Performance 25 Cruise Performance 26 Landing Performance 27 Landing Performance 28 Intercept Procedures Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook Page 2 Distribution List Two copies of the QRH have been issued by Air Serv Limited and Approved by the Civil Aviation Authority as indicated below: COPY NO. ISSUED TO COPY TYPE 01 Air Serv Limited Hardcopy 02 CAA - Uganda Hardcopy The Chief Pilot shall be responsible for issuing and controlling certified true copies of the QRH Copy No.1, for use/reference by Air Serv, see listing below: CERTIFIED COPY NO. ISSUED TO COPY TYPE 01 Operations Library Hardcopy 02 5X-ASI Hardcopy 03 5X-ASA Hardcopy 04 5X-ASB Hardcopy 05 5X-ASC Hardcopy 06 5X-ACE Hardcopy e-Copy Director of Operations Electronic copy held on server available to all staff Revision Policy The Operations Manual indicates that the Chief Pilot issues additions to and revision for any pages in this document. Upon receipt of any amendments, they are to be incorporated into the manual immediately and the revision sheet completed and signed. If any error is found by a user it should be brought to the attention of the Chief Pilot as soon as possible. If the error is a safety issue, they are to inform the base as soon as practical. Use Policy This document is for use by Air Serv operations staff and flight crew and it is used in conjunction with other Air Serv documents. All performance charts are based on the approved Pilots Operating Handbook, for the Cessna Grand Caravan (C208B) and have incorporated additional safety margins as prescribed by Air Serv. It is the PIC’s ultimate responsibility to ensure the aircraft is operated within the limitations of the Pilots Operating Handbook and appropriate CAR’s. Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook Page 3 Revision List Revision Date Pages Amended Added By Original All Incorporated List of Effective Pages Page Revision Date Page Revision Date 1 Original 21 Original 2 Original 22 Original 3 Original 23 Original 4 Original 24 Original 5 Original 25 Original 6 Original 26 Original 7 Original 27 Original 8 Original 28 Original 9 Original 29 Original 10 Original 30 Original 11 Original 31 Original 12 Original 32 Original 13 Original 33 Original 14 Original 34 Original 15 Original 35 Original 16 Original 36 Original 17 Original 37 Original 18 Original 19 Original 20 Original Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook Page 4 EMERGENCY AND ABNORMAL INDEX AIRSPEEDS FOR EMERGENCY OPERATION ...................................... 7 MAXIMUM GLIDE CHART ....................................................................... 8 EMERGENCY EVACUATION .............................................................. 15A EMERGENCY DESCENT PROCEDURE ............................................ 14B ENGINE START MALFUNCTIONS Hung Start or Hot Start ............................................................. 15B Ignition Failure .......................................................................... 15B SMOKE AND FIRE Engine Fire In Flight (Red ENGINE FIRE Annunciator ON or OFF) ............................ 9A Electrical Fire In Flight ................................................................ 9B Cabin Fire ................................................................................... 9B Wing Fire .................................................................................. 10A Cabin Fire During Ground Operations ...................................... 10B Engine Fire During Ground Start (Red ENGINE FIRE Annunciator ON Or OFF)..........................10C ENGINE FAILURES Engine Failure During Takeoff Roll ...........................................10D Engine Failure Immediately After Takeoff ................................. 10E Engine Failure During Flight ..................................................... 11A Engine Flameout During Flight ................................................. 11B AIRSTART Starter Assist (Preferred Procedure) ......................................... 16A No Starter Assist ...................................................................... 16B FORCED LANDINGS Emergency Landing Without Engine Power ..............................16C Precautionary Landing With Engine Power ............................... 17A Ditching .................................................................................... 17B Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook Page 5 ICING Weather Conditions That May Be Conductive To Severe Inflight Icing (As Required By AD 96-09-15) ............19D Procedures For Exiting Severe Icing Conditions (As Required By AD 96-09-15) ................................................. 19E Inadvertent Icing Encounter ...................................................... 20A Static Source Blockage (Erroneous Instrument Reading Suspected) ............................. 20B ENGINE MALFUNCTIONS Loss Of Oil Pressure (Red OIL PRESSURE LOW Annunciator ON).......................... 12A Fuel Control Unit Malfunction In The Pneumatic Or Govern or Sections (Engine Power Falls Back To Idle) ......................... 12B Gear Box Contamination (Amber Chip Detector Annunciator ON) ..................................17C FUEL SYSTEM MALFUNCTIONS Loss Of Fuel Pressure (Amber FUEL PRESS LOW Annunciator ON) ..........................17D Fuel Flow Interruption To Fuel Reservoir (Red RESERVOIR FUEL LOW Annunciator ON) .....................12C Fuel Tank Selector Off During Engine Start (Red FUEL SELECT OFF Annunciator ON And Both Fuel Selector Warning Horns Activated) ...........................12D Fuel Level Low With Single Tank Selected (Red FUEL SELECT OFF And Amber LEFT Or RIGHT FUEL LOW Annunciator ON And Fuel Selector Warning Horn Activated)............................................. 12E FLAP SYSTEM MALFUNCTIONS Asymmetric Flap Extension Or Sudden Flap Retraction On One Side ........................................................... 12F Flaps Fail To Extend Or Retract ............................................... 18A LANDING GEAR MALFUNCTIONS Landing With A Flat Main Tire .................................................. 18B Landing With A Flat Nose Tire ..................................................18C Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook Page 6 ELECTRICAL MALFUNCTIONS Battery Temperature High (Amber BATTERY HOT Annunciator On)................................. 19A Battery Overheated (Red BATTERY OVERHEAT Annunciator On) ........................ 13A Voltage Low (Red VOLTAGE LOW Annunciator On) ............... 13B Generator Malfunction with Standby power (Red VOLTAGE LOW And/Or Red GENERATOR OFF Annunciators ON) .................. 13B Inverter Failure (Amber INVERTER INOP Annunciator ON) ..... 19B Starter Contactor Does Not Disengage After Engine Start (Amber STARTER ENERGIZED Annunciator ON) ...................19C Standby Power Malfunction (STB PWR INOP Annunciator ON)...........................................13C Electric Trim Malfunction .......................................................... 14A INADVERTENT OPENING OF AIRPLANE DOORS IN FLIGHT Upper Half Of Cargo Door Of Upper Half Of Passenger Airstair Door Open (Red DOOR WARNING Annunciator ON) ..14C Lowe Half Of Passenger Airstair Door Open.............................14D Right Or Left Crew Doors Open ................................................ 14E Cargo Pod Door(S) Open ......................................................... 14F VACUUM SYSTEM Vacuum Failure (Red VACUUM LOW annunciator ON) ...........15C Rev: Or iginal Date: 06-Nov-2014 C208B Quick Reference Handbook C-208B EMERGENCY AIRSPEEDS C208B CESSNA GRAND CARAVAN (675 SHP) WITH PAYLOAD EXTENDER MOD. Engine Failure After Takeoff: Wing Flaps Up 100 KIAS Wing Flaps Down 80 KIAS Maneuvering Speed: 9000 Pounds 143 KIAS 8750 Pounds 148 KIAS 7500 Pounds 137 KIAS 6250 Pounds 125 KIAS 5000 Pounds 112 KIAS Maximum Glide: With Cargo Pod Without Cargo Pod 9000 Pounds 97 KIAS 99 KIAS 8750 Pounds 95 KIAS 97 KIAS 7500 Pounds 87 KIAS 90 KIAS 6250 Pounds 79 KIAS 82 KIAS 5000 Pounds 71 KIAS 74 KIAS Precautionary Landing with Engine Power Flaps Down 80 KIAS Landing Without Engine Power: Wing Flaps Up 100 KIAS Wing Flaps Down 80 KIAS Rev: Or iginal Date: 06-Nov-2014 C208B Quick Reference Handbook Page 7 C-208B EMERGENCY AIRSPEEDS Page Maximum Glide Chart SECTION 3 EMERGENCY PROCEDURES CESSNA MODEL 208B G1000 ENGINE FAILURE (Continued) MAXIMUM GLIDE Rev: Or iginal Figure 3-1 Propeller feathering is dependent on circumstances and is at the discretion of the pilot. However, if engine oil pressure drops below 15 psi, the propeller should be feathered. If an airstart is to be attempted, follow the checklist procedures. The Starter Assist procedure is preferred since it results in cooler engine starts. Successful airstarts (with starter assist) can be achieved at all airspeeds normally flown and up to an altitude of 14,000 feet. However, Date: 06-Nov-2014 C208B Quick Reference Handbook above 14,000 feet, or with the gas generator RPM below 10%, starting temperatures tend to be higher and caution is required. 8 C-208B EMERGENCY PROCEDURES Continued… SMOKE AND FIRE WARNING Without electrical power, A ENGINE FIRE IN FLIGHT Red ENGINE FIRE annuciator light ON or OFF 1. Skytrac and ELT Switch..................….ACTIVATE 2. Power Lever ................................................... IDLE 3. Propeller Control Lever ........................ FEATHER 4. Fuel Condition Lever ...............................CUTOFF 5. Fuel Shutoff ..................................................... OFF 6. Cabin Heat Firewall Shutoff Control ....PULL OFF 7. Forward Side Vents ..................................... CLOSE 8. Overhead Vents ............................................. OPEN 9. Ventilation Fans (if installed) ..............................ON 10.Wing Flaps ....................................................20°- 30° 11.Airspeed ................................................ 80-85 KIAS EMERGENCY LANDING WITHOUT ENGINE POWER 1. Seats, Seat Belts, Shoulder Harness SECURE 2. Airspeed: Flaps UP.............................. 100 KIAS Flaps DOWN ..........................80 KIAS 3. PowerLever .............................................. IDLE 4. Propeller Control Lever ................... FEATHER 5. Fuel Condition Lever ..........................CUTOFF 6. Fuel Boost Switch ..................................... OFF 7. Ignition Switch ....................................... NORM 8. Standby Power Switch (if installed) ........... OFF 9. Nonessential Equipment (if installed) ....... OFF 10. Fuel Shutoff ...............................................OFF 11. Fuel Tank Selectors ......(horn will sound) OFF 12. Wing Flaps(full recommended)AS REQUIRED 13. Crew Doors ................. UNLATCH PRIOR TO TOUCHCHDOWN 14.Battery Switch (when landing is assured) OFF 15. Touchdown ................... SLIGHTLY TAIL LOW 16. Brakes .................................APPLY HEAVILY ELECTRICAL or CABIN FIRE IN FLIGHT Rev: 1. 2. 3. 4. 5. 6. 7. Orignal Skytrac and ELT Warning Switch….ACTIVATE Battery Switch ............................................ OFF Generator Switch ............ TRIP and RELEASE Standby Power Switch (if installed) ............ OFF Vents ..................................................... CLOSE Bleed Air Heat Switch ................................ OFF Fire Extinguisher ............................. ACTIVATE Date: 06-Nov214 9 all electricallyoperated gyros and engine instruments, fuel boost pump, annunciator lights, wing flaps and all avionics will be inoperative Vacuum-driven gyros will still be operative (For airplanes with a KFC-150 autopilot, vacuum-driven gyros are the pilot’s horizon gyro and right-hand directional gyro For airplanes with a KFC250 autopilot, vacuum-driven gyros are the right-hand horizon and directional gyros) WARNING Occupants should use oxygen masks until smoke clears After discharging an extinguisher within a closed cabin, ventilate the cabin IF ELECTRICAL FIRE: 8. Avionics Power Switches ........................... OFF 9. All Other Electrical Switches ...................... OFF If fire appears out and electrical power is necessary for continuance of flight: 10. Battery Switch and STBY Power Switch......ON 11. Generator Switch ........ RESET and RELEASE 12. 13. 14. 15. 16. CB ..... CHECK for faulty circuit; do not reset Inverter Switch (if installed) ...................... 1 or 2 Radio Switches .......................................... OFF Avionics Power Switches ............................. ON Radio and Electrical Switches (one at a time, with delay after each until short circuit is localized) ...................................................... ON 17. Vents (when it is ascertained that fire is completely extinguished)......................... OPEN 18. Bleed Air Heat ........................... ON as desired If Cabin Fire: EMERGENCY LANDING WITH ENGINE POWER 1. 2. 3. 4. 5. B Page 6. 7. 8. 9. 10. 11. 12. 13. 14. Seats, Seat Belts, Shoulder Harness.SECURE. Wing Flaps .................................................. 10°. Airspeed ..............................................90 KIAS. Selected Field ............................... FLY OVER, *NOTE TERRAIN AND OBSTRUCTIONS All Electrical Switches (except Battery and Generator) .................................................. OFF Wing Flaps . FULL DOWN (on final approach) Airspeed ...............................................80 KIAS Crew Doors UNLATCH PRIOR TO TCHDOWN Skytrac and ELT………………… . ...ACTIVATE Generator Switch ............ TRIP and RELEASE Battery Switch ............................................ OFF Touchdown .................... SLIGHTLY TAIL LOW Fuel Condition Lever ...........................CUTOFF Brakes ...................................APPLY HEAVILY C208B Quick Reference Handbook 10 C-208B EMERGENCY PROCEDURES Page ENGINE MALFUNCTIONS A D WING FIRE 1. 2. 3. 4. 5. 6. 7. 8. Skytrac and ELT Warning Switch….ACTIVATE Pitot/Static Heat Switch .............................. OFF Stall Heat Switch ........................................ OFF Strobe Lights Switch .................................. OFF Navigation Lights Switch ............................ OFF Landing and Taxi Light Switches ............... OFF Radar.......................................................... OFF Ventilation Fans (if installed) ...................... OFF WARNING Perform a sideslip as required to keep flames away from the fuel tank and cabin Land the airplane B CABIN FIRE DURING GROUND OPERATIONS 1. 2. 3. 4. 5. 6. 7. 8. Power Lever .............................................. IDLE Brakes ...................................... AS REQUIRED Propeller Control Lever .................... FEATHER Fuel Condition Lever ...........................CUTOFF Skytrac and ELT Warning Switch….ACTIVATE Battery Switch ............................................ OFF Airplane ......................................... EVACUATE Fire .............................................. EXTINGUISH C ENGINE FAILURE DURING TAKEOFF ROLL 1. Power Lever ............................................ BETA 2. Brakes ................................................... APPLY 3. Wing Flaps. ...................................... RETRACT If airplane cannot be stopped on remaining runway: 4. 5. 6. 7. 8. Fuel Condition Lever ...........................CUTOFF Fuel Shutoff ...............................OFF (pull out) Fuel Tank Selectors ..... OFF (horn will sound) ISAT and ELT Warning Switch ....... ACTIVATE Battery Switch ............................................ OFF E ENGINE FAILURE IMMEDIATELY AFTER TAKEOFF 1. 2. 3. 4. 5. 6. 7. 8. Airspeed ...................... 85 KIAS with 20° flaps Skytrac and ELT Warning Switch….ACTIVATE Propeller ........................................... FEATHER Wing Flaps ...................................FULL DOWN Fuel Condition Lever ...........................CUTOFF Fuel Shutoff ................................OFF (pull out) Fuel Tank Selectors ..... OFF (horn will sound) Battery ........................................................ OFF ENGINE FIRE DURING START ON GROUND (Red ENGINE IFIRE Annunciator On or Off) 1. Fuel Condition Lever ...........................CUTOFF 2. Fuel Boost Switch ...................................... OFF 3. Starter Switch ....................................... MOTOR CAUTION Do not exceed the starting cycle limitations; refer to Section 2 Should the fire persist, as indicated by sustained inter-turbine temperature, Immediately close the fuel shutoff and continue motoring. Rev: 4. 5. 6. 7. 8. 9. Orignal Starter Switch ............................................. OFF Fuel Shutoff ................................OFF (pull out) ISAT and ELT Alert Switch.............. ACTIVATE Battery Switch ............................................ OFF Airplane ......................................... EVACUATE Fire .............................................. EXTINGUISH Date: 06-Nov214 C208B Quick Reference Handbook C-208B EMERGENCY PROCEDURES A ENGINE FAILURE DURING FLIGHT 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Skytrac and ELT Alert Switch…. ..... ACTIVATE Airspeed ...............................................95 KIAS Power Lever .............................................. IDLE Propeller Control Lever .................... FEATHER Fuel Condition Lever ...........................CUTOFF Wing Flaps ................................................... UP Fuel Boost Switch ...................................... OFF Fuel Shutoff ................................OFF (pull out) Ignition Switch ........................................ NORM Standby Power Switch (if installed) ............ OFF Electrical Load .................................... REDUCE EMERGENCY LANDING WITHOUT ENGINE POWER 12. Seats, Seat Belts, Shoulder Harness SECURE. 13. Airspeed: ........................................100 KIAS (Flaps UP) ................................... 80 KIAS (Flaps DOWN) 14. PowerLever .............................................. IDLE. 15. Propeller Control Lever ................... FEATHER. 16. Fuel Condition Lever ..........................CUTOFF. 17. Fuel Boost Switch ..................................... OFF. 18. Ignition Switch ....................................... NORM. 19. Standby Power Switch (if installed) ........... OFF. 20. Nonessential Equipment (if installed) ........ OFF. 21. Fuel Shutoff ...............................OFF (pull out). 22. Fuel Tank Selectors ..... OFF (horn will sound) 23. Skytrac and ELT Switch…… .. .….…ACTIVATE 24. Wing Flaps AS REQD (FULL recommended). Continued on next page………… 25. Crew Doors .................. UNLATCH PRIOR TO TOUCHCHDOWN 26. Battery Switch OFF when landing is assured. 27. Touchdown ................... SLIGHTLY TAIL LOW. 28. Brakes .................................. APPLY HEAVILY Page 11 AIRSTART (STARTER ASSIST) FOR NO STARTER ASSIST REF 15-B 1. Electrical Load .................................... REDUCE 2. Standby Power Switch (if installed) ............ OFF 3. Avionics Power Switches ........................... OFF 4. Ignition Switch ........................................ NORM 5. Air Conditioner (if installed) ........................ OFF 6. Bleed Air Heat Switch ................................ OFF 7. Emergency Power Lever ................... NORMAL 8. Power Lever .............................................. IDLE 9. Propeller Control Lever ......................MIN RPM 10. Fuel Condition Lever ...........................CUTOFF 11. Fuel Shutoff ..................................ON (push in) 12. Fuel Tank Selectors ....... LEFT ON, RIGHT ON 13. Battery Switch .............................................. ON 14. Fuel Boost Switch – .................................... ON 15. AUX FUEL PUMP ON Annunciator .... CHK ON 16. FUEL PRESS LOW Annunciator ...... CHK OFF 17. Altitude .......................... 20,000 feet maximum 18. Starter Switch .............. START and OBSERVE a. IGNITION ON Annunciator CHECK ON b. Engine Oil Pressure ...........CHECK for indication c. Ng ................................. 12% MINIMUM 19. Fuel Condition Lever ................ LOW IDLE and OBSERVE a. ITT ..... MONITOR (1 090°C maximum) b. Ng ................................. 52% MINIMUM 20. Starter Switch ............................................. OFF WARNING If conditions exist, such as heavy precipitation or nearly empty fuel tanks, turn the ignition switch ON. 21. Fuel Boost Switch .................................. NORM (unless it cycles on and off; then leave ON) 22. Fuel Condition Lever ....................... HIGH IDLE 23. Propeller Control Lever ............... AS DESIRED 24. Power Lever ................................ AS DESIRED 25. Electrical Equipment ................ AS REQUIRED B ENGINE FLAMEOUT DURING FLIGHT If Gas Generator Speed (Ng) Is Above 50% 1. Power Lever .............................................. IDLE 2. Fuel Selectors ...................................BOTH ON 3. Fuel Boost Pump ……………………………..ON 4. Ignition Switch .............................................. ON 5. Skytrac and ELT Warning Switch….ACTIVATE 6. Power Lever ................................ AS DESIRED 7. Ignition Switch ............................................ OFF If Gas Generator Speed (Ng) is Below 50%: 1. Fuel Condition Lever ........................CUTOFF Rev: Continued…. Orignal Date: 06-Nov214 C208B Quick Reference Handbook C-208B EMERGENCY PROCEDURES Page 12 A D LOSS OF OIL PRESSURE FUEL TANK SELECTOR OFF DURING ENGINE START (Red FUEL SELECT OFF Annunciator On And Both Fuel Selector Warning Horns Activated) (Red OIL PRESS LOW Annunciator On) 1. Oil Pressure Gage ........... CHECK oil pressure indication If oil pressure gage confirms annunciator warning, proceed in accordance with Engine Failures checklists or at the discretion of the pilot and consistent with safety, continue engine operation in preparation for an emergency landing as soon as possible. B (Engine Power Falls Back To Idle) 1. Power Lever .............................................. IDLE 2. Emergency Power Lever .......... AS REQUIRED (maintain 65 Ng minimum during flight) CAUTION The emergency power lever overrides normal fuel control functions and results in the direct operation of the fuel metering valve Utilize slow and smooth movement of the emergency power lever to avoid engine surges, and/or exceeding lTT, Ng, and torque limits FUEL SYSTEM MALFUNCTIONS C FUEL FLOW INTERRUPTION TO FUEL RESERVOIR (Red RESERVOIR FUEL LOW Annunciator On) 1. 2. 3. 4. 5. Fuel Tank Selectors ....... LEFT ON, RIGHT ON Fuel Boost Switch ........................................ ON Ignition Switch .............................................. ON Skytrac and ELT Warning Switch….ACTIVATE If RESERVOIR FUEL LOW annunciator remains illuminated and there is usable fuel in the wing tanks: a. Carefully monitor engine gages and FUEL PRESS LOW annunciator for signs of fuel starvation b. Land as soon as possible and determine cause of RESERVOIR ~ FUEL LOW warning Continued… WARNING If there are signs of fuel starvation, prepare for a forced landing (as described in Emergency Landing Without Engine Power) Orignal E FUEL LEVEL LOW WITH SINGLE TANK SELECTED (Red FUEL SELECT OFF And Amber FCU MALFUNCTION IN THE PNEUMATIC OR GOVERNOR SECTIONS Rev: 1. Left and Right Fuel Tank Selectors .............. ON Date: 06-Nov214 LEFT Or RIGHT FUEL LOW Annunciators On And Fuel Selector Warning Horn Activated) 1. Left and Right Fuel Tank Selectors .............. ON (turning both fuel tank selectors ON will extingush the red FUEL SELECT OFF annunciator and silence the warning horn) FLAP SYSTEM MALFUNCTION PROCEDURES F ASYMMETRIC FLAP EXTENSION OR SUDDEN FLAP RETRACTION ON ONE SIDE 1. Apply aileron and rudder to stop the roll 2. Flap Selector ................................................ UP 3. Airspeed ................SLOW to 100 KIAS or less 4. If both flaps retract to a symmetrical setting: a. Plan a flaps up landing b. Refer to Section 5 (notes above landing performance tables) for increase in approach speed and landing distance 6. If both flaps cannot be retracted to a symmetrical setting: a. Land as soon as practical b. Maintain a minimum airspeed of 90 KIAS on the approach and avoid a nose high flare on landing C208B Quick Reference Handbook 13 C-208B EMERGENCY PROCEDURES Page If GENERATOR OFF annunciator is extinguished ELECTRICAL POWER and STBY ELECT PWR ON annunciator is illuminated: SUPPLY SYSTEM 3. Perform steps 4, 5, and 6 above MALFUNCTIONS If GENERATOR OFF annunciator is extinguished and STBY ELECT PWR INOP annunciator is illuminated: A BATTERY OVERHEATED (Red BATTERY OVERHEAT Annunciator On) (NiCad Battery Equipped Airplanes Only) 1. 2. 3. 4. 5. Battery Switch ..................................... CHECK OFF Generator Switch ..................................................... Standby Power Switch (if installed) ......................... All Electrical System Switches ................................. Bus 1 Pwr and Bus 2 Pwr CBs ................................ (total of 6 circuit breakers) 6. Avionics Switches .................................................... 7. 8. Standby Power Switch (if installed) .................................. Avionics Standby Power Switch ………...Lift Switch, TURN ON 9. Avionics Bus tie Switch ............ LIFT GUARD, TURN ON 10. Reinstate essential electrical systems, exercising caution not to exceed capacity of standby electrical system (if installed) 11. ISAT and ELT Alert Switch ............................ CONSIDER 12. As Soon as Practical .............................................. LAND B 3. STBY PWR Switch ....................... Off, then ON 4. STBY ELECT PWR INOP Annunciator ..................... Check Extinguished If STBY ELECT PWR INOP annunciator remains illuminated: 5. Go to 13C, STNDBY ELECT PWR INOP ANNUNCIATOR ILLUMINATED C STDBY ELECT PWR INOP ANNUNCIATOR ILLUMINATED: 1. STBY PWR Switch ....................... Off, then ON 2. STBY ELECT PWR INOP Annunciator ..................... Check Extinguished If STBY ELECT PWR INOP annunciator remains illuminated: GENERATOR FAILURE (GENERATOR OFF, Red VOLTAGE LOW and/or STBY ELECT PWR Annunciators On) 1. Generator Switch ....................... TRIP, then RESET If primary power is not restored: 2. GEN CONT and GEN FIELD CBs ........ RESET (If tripped) and repeat step 1. If GENERATOR OFF annunciator remains illuminated and STBY ELECT PWR INOP annunciator is illuminated: 3. STBY PWR Switch .................................... OFF 4. Oil Pressure Gauge................................ Check CAUTION An Indication of less than normal or 0 may indicate failure of the scavenge oil system, closely monitor engine gauges and oil pressure for signs of engine failure. Land as soon as possible 5. Flight......... COMPLETE utilizing primary power 6. ISAT and ELT Alert Switch ........... CONSIDER 3. STBY PWR Switch .................... OFF, then ON. Check STBY ELECT PWR INOP annunciator extinguished and STBY ELECT PWR ON annunciator illuminated. 4. AVIONICS STBY PWR and AVIONICS BUS TIE Switches ................................................ ON 5. AVIONICS 1 and 2 Switches...................... OFF 6. Volt/Ammeter ............. SELECT ALT and verify alternator load is 75 amperes or less. REDUCE LOAD as required to prevent batty discharge. Continued…. Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook 14 C-208B EMERGENCY PROCEDURES Page INADVERTENT OPENING OF AIRPLANE DOORS IN ELECTRIC TRIM MALFUNCTION FLIGHT 1. A/P DISC/TRIM INTER Switch…PRESS AND A HOLD 2. Elevator Trim Circuit Breaker(7:10)……...........................PULL OFF 3. Retrim aircraft manually WARNING When disconnecting the autopilot after an electric trim malfunction, hole the control wheel firmly; up to 45 pounds of force on the control wheel may be necessary to hold the aircraft level. EMERGENCY DESCENT PROCEDURES UPPER HALF OF CARGO DOOR OR UPPER HALF OF PASSENGER AIRSTAIR DOOR OPEN (Red DOOR WARNING Annunciator On) 1. Airspeed .... MAINTAIN LESS THAN 100 KIAS 2. Wing Flaps ............................................... FULL (wing downwash with flaps extended will move the doors near their normally closed position) 3. If available or practical, have a second crew member go aft to close and latch door 4. If landing is required with door open: a. Approach and Landing ............... NORMAL D B LOWER HALF OF PASSENGER AIRSTAIR DOOR OPEN ROUGH AIR 1. Seats, Seat Belts, Shoulder Harnesses ........................................................... SECURE 2. Power Lever .............................................. IDLE 3. Propeller Control Lever ...... MAX (full forward) 4. Wing Flaps ................................................... UP 5. Weights and Airspeed: 9062 Pounds .......................................143KIAS 8750 Pounds ......................................148 KIAS 7500 Pounds ......................................137 KIAS 6250 Pounds .......................................125KIAS 5000 Pounds .......................................112KIAS 1. Airspeed .... MAINTAIN LESS THAN 100 KIAS 2. Flight Controls ....... MANEUVER for return for landing 3. Wing Flaps ............................................... FULL 4. Approach ........................................... NORMAL 5. Landing ......................... SLIGHTLY TAIL LOW avoid nose high flare E RIGHT OR LEFT CREW DOORS OPEN SMOOTH AIR 1. 2. 3. 4. 5. C Seats, Seat Belts, Shoulder Harnesses ..... SECURE Power Lever ...................................................... IDLE Propeller Control Lever ................ MAX (full forward) Wing Flaps ...........................................................10° Airspeed ..................................................... 175 KIAS 1. Airspeed .... MAINTAIN LESS THAN 125 KIAS 2. Door..................... PULL CLOSED and LATCH F CARGO POD DOOR(S) OPEN Rev: 1. Airspeed .... MAINTAIN LESS THAN 125 KIAS 2. Land ......................AS SOON AS PRACTICAL a. Approach .................................... NORMAL b. Landing ...... AVOID A NOSE HIGH FLARE Orignal Date: 06-Nov214 C208B Quick Reference Handbook C-208B EMERGENCY PROCEDURES AIRCRAFT EVACUATION Page 15 A AIRCRAFT EVACUATION CHECKLIST 1. 2. 3. 4. 5. 6. 7. 8. Park Brake.................................................. SET Power Lever .............................................. IDLE Propeller ........................................... FEATHER Condition Lever ..................................CUT OFF Standby Power ........................................... OFF ISAT and ELT Alert Switch............ACTIVATED Battery Switch ............................................ OFF All People ...................................... EVACUATE ABNORMAL STARTS B HOT START or HUNG START or IGNITION FAILURE 1. Condition Lever ..................................CUT OFF 2. Starter Switch ....................................... MOTOR CAUTION: Should the fire persist, as possibly indicated by sustained inter-turbine (ITT) temperature, continue motoring CAUTION: DO NOT exceed starter cycle limitations. 3. Starter Switch ............................................. OFF 4. Battery Switch ............................................ OFF VACUUM FAILURE C VACUUM FAILURE (Red VACUUM LOW Annunciator ON) Rev: 1. Vacuum Pressure Gauge ..................... VERIFY a. If gauge indicates sufficient vacuum, then continue to monitor situation b. If gauge indicates no vacuum, then proceed with partial panel procedures Note: For airplanes with KFC-150 or KFC-225 autopilot, vacuum driven gyros are the pilots horizon gyro and right hand directional gyro Original Date: 06-Nov-2014 C208B Quick Reference Handbook 16 C-208B ABNORMAL PROCEDURES Page 13. Fuel Boost Switch -- ON (check AUX FUEL AIRSTART PUMP ON annunciator ON, FUEL PRESS A STARTER ASSIST (Preferred Procedure) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. Electrical Load ....................................... REDUCE Standby Power Switch (if installed) ............... OFF Avionics Power Switches .............................. OFF Ignition Switch ........................................... NORM Air Conditioner (if installed) ........................... OFF Bleed Air Heat Switch .................................... OFF Emergency Power Lever ...................... NORMAL Power Lever ................................................. IDLE Propeller Control Lever .........................MIN RPM Fuel Condition Lever ..............................CUTOFF Fuel Shutoff .....................................ON (push in) Fuel Tank Selectors .......... LEFT ON, RIGHT ON Battery Switch.................................................. ON Fuel Boost Switch – ........................................ ON AUX FUEL PUMP ON Annunciator ........ CHK ON FUEL PRESS LOW Annunciator.......... CHK OFF Altitude .............................. 20,000 feet maximum Starter Switch ................. START and OBSERVE a. IGNITION ON Annunciator ...... CHECK ON b. Engine Oil Pressure CHECK for indication c. Ng ....................................... 12% MINIMUM 19. Fuel Condition Lever LOW IDLE and OBSERVE a. ITT ........... MONITOR (1 090°C maximum) b. Ng ....................................... 52% MINIMUM 20. Starter Switch ................................................ OFF WARNING If conditions exist, such as heavy precipitation or nearly empty fuel tanks, turn the ignition switch ON. 21. Fuel Boost Switch ...................................... NORM .... (Unless it cycles on and off; then leave ON) 22. Fuel Condition Lever .......................... HIGH IDLE 23. Propeller Control Lever .................. AS DESIRED 24. Power Lever ................................... AS DESIRED 25. Electrical Equipment .................... AS REQUIRED B NO STARTER ASSIST Rev: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Original Generator Switch ................ TRIP and Release Standby Power Switch (if installed) ............ OFF Avionics Power Switches ........................... OFF Air Conditioner (if installed) ........................ OFF Bleed Air Heat Switch ................................ OFF Emergency Power Lever ................... NORMAL Power Lever .............................................. IDLE Propeller Control Lever ......................MIN RPM Fuel Condition Lever ...........................CUTOFF Fuel Shutoff ..................................ON (push in) Fuel Tank Selectors ....... LEFT ON, RIGHT ON Battery Switch .............................................. ON Date: 06-Nov-2014 LOW annunciator OFF). 14. Ignition Switch -- .......................................... ON Check IGNITION ON annunciator ON 15. Airspeed ........................... 100 KIAS minimum (140 KIAS if propeller is feathered) 16. Altitude .......................... 20,000 feet maximum (15,000 feet if propeller is feathered). CAUTION Do not attempt a restart without starter assist if Ng tachometer indicates zero RPM. 17. Ng Indicator ........................... CHECK STABLE 18. Fuel Condition Lever ................ LOW IDLE and OBSERVE. a. ITT ........... MONITOR (1 090°C maximum) b. Ng ....................................... 52% MINIMUM 19. Ignition Switch -- NORM (Ng 52% or above) unless conditions warrant leaving ON. WARNING If conditions exist, such as heavy precipitation or nearly empty fuel tanks, turn the ignition switch ON. 20. Fuel Boost Switch -- NORM (unless it cycles on and off); then leave ON 21. Fuel Condition Lever ....................... HIGH IDLE 22. Propeller Control Lever ............... AS DESIRED 23. Power Lever ................................ AS DESIRED 24. Generator Switch ......... RESET and RELEASE 25. Electrical and Avionics Equipment ............... AS REQUIRED FORCED LANDINGS C EMERGENCY LANDING WITHOUT ENGINE POWER 1. Seats, Seat Belts, Shoulder Harness . SECURE. 2. Airspeed: ........................................ 100 KIAS (Flaps UP) ................................... 80 KIAS (Flaps DOWN) 3. Power Lever ............................................... IDLE. 4. Propeller Control Lever ..................... FEATHER. 5. Fuel Condition Lever ............................CUTOFF. 6. Fuel Boost Switch ....................................... OFF. 7. Ignition Switch ......................................... NORM. 8. Standby Power Switch (if installed) ............ OFF. 9. Nonessential Equipment (if installed) ......... OFF. 10. Fuel Shutoff ................................OFF (pull out). 11. Fuel Tank Selectors ....... OFF (horn will sound) 12. Skytrac and ELT Switch…… ... .….…ACTIVATE 13. Wing Flaps .. AS REQD (FULL recommended). Continued on next page………… 14. Crew Doors .................... UNLATCH PRIOR TO TOUCHCHDOWN 15. Battery Switch .. OFF when landing is assured. 16. Touchdown .................... SLIGHTLY TAIL LOW. 17. Brakes ....................................APPLY HEAVILY. C208B Quick Reference Handbook 17 C-208B ABNORMAL PROCEDURES Page ENGINE MALFUNCTIONS A PRECAUTIONARY LANDING WITH ENGINE POWER 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Seats, Seat Belts, Shoulder Harness.SECURE. Wing Flaps .................................................. 10°. Airspeed ..............................................90 KIAS. Selected Field ............................... FLY OVER, (Note terrain and obstructions). All Electrical Switches (except Battery and Generator) .................................................. OFF Wing Flaps . FULL DOWN (on final approach) Airspeed ...............................................80 KIAS Crew Doors UNLATCH PRIOR TO TCHDOWN Skytrac and ELT………………… . ...ACTIVATE Generator Switch ............ TRIP and RELEASE Battery Switch ............................................ OFF Touchdown .................... SLIGHTLY TAIL LOW Fuel Condition Lever ...........................CUTOFF Brakes .................................. APPLY HEAVILY C GEAR BOX CONTAMINATION (Amber CHIP DETECTOR Annunciator On) 1. Engine Gages CAREFULLY MONITOR engine gages for abnormal oil pressure, oil temperature or power indications 2. If engine gages are normal, proceed to destination and determine cause of chip detector annunciator warning prior to next flight 3. If engine gages confirm chip detector annunciator warning, proceed in accordance with Engine Failures checklists or at the discretion of the pilot and consistent with safety, continue engine operation in preparation for an emergency landing as soon as possible FUEL SYSTEM MALFUNCTIONS B DITCHING Rev: 1. Radio--TRANSMIT MAYDAY on 121.5 MHz, giving location and intentions and SQUAWK 7700 if transponder is installed. Select Emergency Position on Skyrac and ELT. 2. Heavy Objects in Cabin -- SECURE if passenger is available to assist. 3. Seats, Seat Belts, Shoulder Harnesses .......................................................... SECURE. 4. Wing Flaps ..................................FULL DOWN. 5. Power -- ESTABLISH 300 FT/MIN DESCENT AT 80 KIAS. 6. Approach ........... High Winds INTO THE WIND. 7. Light Winds, Heavy Swells -- PARALLEL TO SWELLS. 8. Skytrac and ELT Switch………………….ACTIVATE 9. Face -- CUSHION at touchdown with folded coat or similar object. 10. Touchdown ........ NO FLARE, maintain descent attitude. 11. Airplane ........................................ EVACUATE. 12. Life Vests and Raft ....... INFLATE when outside cabin. WARNING The airplane has not been flight tested in actual ditching, thus the above recommended procedure is based entirely on the best judgment of Cessna Aircraft Company. Original Date: 06-Nov-2014 D LOSS OF FUEL PRESSURE (Amber FUEL PRESS LOW Annunciator On) 1. Fuel Boost Switch ........................................ ON 2. If FUEL PRESS LOW annunciator extinguishes: a. Carefully monitor fuel quantity and cabin odor for evidence of a fuel leak b. Land as soon as practical and determine cause for motive flow failure before next flight 3. If FUEL PRESS LOW annunciator and AUX FUEL PUMP ON annunciator are illuminated: a. Carefully monitor engine gages for sign of fuel starvation b. Land as soon as possible C208B Quick Reference Handbook 18 C-208B ABNORMAL PROCEDURES Page FLAP SYSTEM LANDING GEAR MALFUNCTION MALFUNCTION PROCEDURES PROCEDURES A FLAPS FAIL TO EXTEND OR RETRACT B LANDING WITH FLAT MAIN TIRE 1. Flap Motor and STBY Flap Motor CBs CHECK IN 2. If flaps still fail to extend or retract: Earlier Airplanes: a. Guarded Standby Flap Motor Switch (Overhead) MOVE GUARD, and POSITION SWITCH TO STBY b. Standby Flap Motor Up/Down Switch (Overhead) UP or DOWN (hold switch until flaps reach desired position, except release switch before flaps reach full up or full down travel) Later Airplanes: a. Guarded and Safety-tied Standby Flap Motor Switch (Overhead) MOVE GUARD, breaking safety wire, and POSITION SWITCH TO STBY b. Guarded and Safety-tied Standby Flap Motor Up/Down Switch (Overhead) ....... MOVE GUARD, breaking safety wire, and position switch UP or DOWN (hold switch until flaps reach desired position, except release switch before flaps reach full up or full down travel) 1. Airplane ............................ CONTINUE FLIGHT (As desired to lighten fuel load). 1. Fuel Selectors ................................................... ............ POSITION ONE SELECTOR OFF TO LIGHTEN LOAD ON SIDE OF FLAT TIRE (maximum fuel unbalance of 200 pounds) 2. Approach ................... NORMAL FULL FLAPS) 3. Touchdown ................. INFLATED TIRE FIRST Hold airplane off flat tire as long as possible with aileron control 4. Directional Control ...........................MAINTAIN (Using brake on wheel with inflated tire as required). C LANDING WITH FLAT NOSE TIRE 1. Pax and Bags .......... MOVE AFT (if practical). Remain within approved CG envelope. 2. Approach ........................................... NORMAL WITH FULL FLAPS 3. Touchdown ................................... NOSE HIGH HOLD NOSE-WHEEL OFF LANDING ROLL 4. Brakes ......................... MINIMUM AS NEEDED CAUTION: With the standby flap system in use, limit swItches, which normally shut off the primary flap motor when reaching the flap travel limits, are electrically inactivated Therefore, the pilot must release the standby flap motor up/down switch before the flaps reach their travel limit to prevent overloading and damage to the flap system Rev: 3. Guarded Standby Flap Motor Switch Leave in STBY position until after landing when maintenance action can be accomplished Original Date: 06-Nov-2014 C208B Quick Reference Handbook 19 C-208B ABNORMAL PROCEDURES Page STARTER CONTACTOR DOES NOT ELECTRICAL POWER DISENGAGE AFTER ENGINE START (Amber STARTER ENERGIZED Annunciator On) SUPPLY SYSTEM 1. Battery Switch ............................................ OFF MALFUNCTIONS 2. Auxiliary Power Unit ... OFF, then DISENGAGE A 3. Fuel Condition Lever ...........................CUTOFF ICING BATTERY TEMPERATURE HIGH (Amber BATTERY HOT Annunciator On) (Ni-Cad Battery Equipped Airplanes Only) 1. Battery Switch ............................................ OFF 2. Ammeter .............................................. CHECK With selector switch in BATT position If ammeter shows zero indication: (1) Annunciator light should extinguish If ammeter shows charge indication: (2) Generator Switch .............. TRIP AND RELEASE (3) Standby Power Switch (if installed) .................................................... OFF (4) All Electrical System Switches ... OFF (5) Bus 1 Pwr and Bus 2 Pwr Circuit Breakers ...........................PULL OFF (total of 6 circuit breakers) (6) Avionics Switches ....................... OFF (7) Standby Power Switch (if installed) ...................................................... ON (8) Avionics Standby Power Switch LIFT GUARD, TURN ON (9) Avionics Bus Tie Switch ............LIFT GUARD, TURN ON (10) Essential electrical systems ............. ....................................... REINSTATE (Exercise caution not to exceed capacity of standby electrical system). B INVERTER FAILURE (Amber INVERTER INOP Annunciator On) (Airplanes Equipped with KFC-250 Autopilot Only) 1. Inverter Switch ............SELECT other inverter 2. Failed Inverter ....... REPAIR before next flight If INVERTER INOP Annunciator remains on: 3. Inverter 1 and 2 Circuit Breakers ..... CHECK IN 4. If the left-hand gyros are flagged, the INVERTER INOP annunciator is correct 5. Disregard left-hand gyros, land as soon as practical, and repair inverters C Rev: Original Date: 06-Nov-2014 D THE FOLLOWING WEATHER CONDITIONS MAY BE CONDUCIVE TO SEVERE IN-FLIGHT ICING - As Required by AD 96-09-15, Paragraph (a) (2): 1. Visible rain at temperatures below 0 degrees Celsius ambient air temperature. 2. Droplets that splash or splatter on impact at temperatures below 0 degrees Celsius ambient air temperature. E PROCEDURES FOR EXITING THE SEVERE ICING ENVIRONMENT ............ As Required by AD 96-09-15, Paragraph (a) (2): These procedures are applicable to all flight phases from takeoff to landing. Monitor the ambient air temperature. While severe icing may form at temperatures as cold as -18 degrees Celsius, increased vigilance is warranted at temperatures around freezing with visible moisture present. If the visual cues specified in Section 2 Limitations for identifying severe icing conditions are observed, accomplish the following: 1. Immediately request priority handling from Air Traffic Control to facilitate a route or an altitude change to exit the severe icing conditions in order to avoid extended exposure to flight conditions more severe than those for which the airplane has been certificated. 2. Avoid abrupt and excessive maneuvering that may exacerbate control difficulties. 3. Do not engage the autopilot. 4. If the autopilot is engaged, hold the control wheel firmly and disengage the autopilot. 5. If an unusual roll response or uncommanded roll control movement is observed, reduce the angle-of-attack. CONTINUED ON NEXT PAGE…… 6. Do not extend flaps during extended operation in icing conditions. Operation with flaps extended can result in a reduced wing angle-ofattack, with the possibility of ice forming on the C208B Quick Reference Handbook C-208B ABNORMAL PROCEDURES upper surface further aft on the wing than normal, possibly aft of the protected area. 7. If the flaps are extended, do not retract them until the airframe is clear of ice. 8. Report these weather conditions to Air Traffic Control. A INADVERTENT ICING ENCOUNTER 1. 2. 3. 4. 5. 6. 7. Ignition Switch .............................................. ON Inertial Separator ............................... BYPASS Pitot-Static Heat Switch................................ ON Stall Warning Heat Switch............................ ON Windshield Anti-ice Switch(es) ............... AUTO Prop Anti-Ice Switch ................................ AUTO If Above 20,000 feet .......................................... a. Airspeed: 160 KIAS or less b. Altitude: DESCEND to 20,000 feet or below as soon as practical 8. Flight Path ... Turn back or change altitude to obtain an OAT that is less conducive to icing. 9. Ignition Switch ................................................... .......... OFF- AFTER 5 MINUTES OPERATION 10. Bleed Air Heat Switch and Temp Control ......... .............................................. ON and ADJUST 11. Push Fwd Cabin Heat Contol ............. FULL IN. 12. Defrost Control ............................... FULL OUT (to obtain max windshield defrost effect). 13. Propeller RPM .......... INCREASE to 1900 RPM (to minimize ice build-up). Page 20 WARNING With heavy ice accumulations on the horizontal stabilizer leading edge, do not extend flaps while enroute or holding. When landing is assured, select the minimum flap setting required, not to exceed 20°, and maintain extra airspeed consistent with available field length. Do not retract the flaps once they have been extended, unless required for go-around. Then retract flaps in increments while maintaining 5 to 10 knots extra airspeed. 18. Land on the main wheels first, avoiding a slow and high flare-out. 19. Missed approaches should be avoided whenever possible because of severely reduced climb capability. However, if a goaround is mandatory, make the decision much earlier in the approach than normal. Apply takeoff power and maintain 90 to 105 KIAS while retracting the flaps slowly in small increments. B STATIC SOURCE BLOCKAGE (Erroneous Instrument Reading Suspected) 1. Static Pressure Alternate Source Valve...PULL FULL ON NOTE The alternate static source is connected to the left-hand flight panel instruments only. 2. Refer to Section 5 for airspeed and altimeter corrections. 3. Autopilot ................... DISENGAGE altitude hold mode Rev: CAUTION If excessive vibration is noted, momentarily reduce propeller RPM to 1600 with the propeller control, then rapidly move the control full forward. Cycling the RPM flexes the propeller blades and high RPM increases centrifugal force, causing ice to shed more readily . 14. If icing conditions are unavoidable, plan a landing at the nearest airport. With an extremely rapid ice build-up, select a suitable off airport’ landing site. 15. With an ice accumulation of 1/4 inch or more on the wing leading edges, be prepared for a significantly higher power requirement, approach speed and stall speed and longer landing roll. 16. If necessary, set up a forward slip for visibility through the left portion of the windshield during the landing approach. 17. Use a minimum approach speed of 105 KIAS, select the minimum flap setting required, and maintain extra airspeed consistent with available field length. With ice suspected on the airframe, or operating at 4°C or less in visible moisture, Do Not Extend Flaps Beyond 20° for Landing. Original Date: 06-Nov-2014 C208B Quick Reference Handbook C-208B ABNORMAL PROCEDURES Page 21 STARTING ENGINE (Auxiliary Power Start) (24-28 Volt, Minimum 800 Amp and Maximum 1700 Amp Capacity) 1. Battery Switch - ON. 2. External Power Switch - OFF. 3. Volt/Ammeter - CHECK (20 volts minimum). 4. Battery Switch - OFF. 5. Auxiliary Power Unit - ENGAGE; then ON. 6. External Power Switch - BUS. 7. Volt/Ammeter - CHECK 24 -28.5 Volts. CAUTION MAKE SURE THAT THE EMERGENCY POWER LEVER IS IN THE NORMAL POSITION OR AN OVER TEMPERATURE CONDITION WILL RESULT DURING ENGINE START. 8. Battery Switch - ON. 9. External Power Switch - STARTER. 10. Emergency Power Lever - NORMAL (check EMERGENCY POWER LEVER annunciator OFF). 11. Propeller - CLEAR. 12. Fuel Boost Switch - ON and OBSERVE. A. AUX FUEL PUMP ON Annunciator - ON. B. FUEL PRESS LOW Annunciator - OFF. C. No fuel flow. CAUTION IF THE AUXILIARY POWER UNIT DROPS OFF THE LINE, INIITIATE ENGINE SHUTDOWN 13. Starter Switch- START and OBSERVE A. IGNITION ON Annunciator – CHECK ON. B. Engine Oil Pressure – CHECK ON. C. Ng – STABLE (12% minimum). 14. Fuel Condition Lever – LOW IDLE and OBSERVE. A. Fuel Flow – CHECK for 90 to 140 pph. B. ITT – MONITOR (1090 C° maximum, limited to 2 seconds). CAUTION • IF ITT CLIMBS RAPIDLY TOWARDS 1090°C, BE PREPARED TO RETURN THE FUEL CONDITION LEVER TO CUTOFF. • UNDER HOT OAT AND/OR HIGH GROUND ELEVATION CONDITIONS, IDLE ITT MAY EXCEED MAXIMUM IDLE ITT LIMITATION OF 685°C. INCREASE Ng AND/OR REDUCE ACCESSORY LOAD TO MAINTAIN ITT WITHIN LIMITS. Rev: C. Ng - 52% MINIMUM. 15. Starter Switch - OFF (check STARTER ENERGIZED annunciator OFF). 16. Inverter Switch (if installed) - 1 or 2. 17. Engine Instruments - CHECK. 18. External Power Switch - OFF. 19. Auxiliary Power Unit - OFF, then DISENGAGE. 20. Generator - CHECK GENERATOR OFF annunciator OFF and battery charging. 21. Fuel Boost Switch - NORM (check AUX FUEL PUMP ON annunciator OFF). 22. Avionics No.1 and No.2 Power Switches - ON. 23. Navigation Lights and Flashing Beacon - ON as required. 24. Suction Gage - CHECK. 25. Cabin Heating, Ventilating and Defrosting Controls – AS DESIRED. 26. Radios - AS REQUIRED. Original Date: 06-Nov-2014 C208B Quick Reference Handbook Page 22 Air Serv Limited Takeoff & Climb Torque for C208B (675 SHP) with Cargp Pod Installed Directions: 1.) First number is max takeoff torque (Inerial Seperator in BYPASS, Cabin Heat OFF) 2.) Second number is max climb torque at 1000 ft. AGL assuming 2° C decrease in temperature (Inertial Seperator NORMAL, Cabin Heat OFF) 5° C 10° C 12° C 14° C 16° C 18° C 20° C 22° C 24° C 26° C 28° C 30° C 32° C 34° C 36° C 38° C 40° C 42° C 44° C 46° C 48° C MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX 1850 1835 1795 1760 1720 1685 MAX MAX MAX MAX MAX MAX MAX MAX 1850 1800 1760 1725 1685 1645 1600 1555 1515 1475 1435 1400 1360 MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX 1835 1815 1780 1745 1715 1680 ----- MAX MAX MAX MAX MAX 1850 1835 1805 1780 1730 1695 1660 1620 1585 1545 1495 1455 1415 1380 1335 ----- MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX 1835 1795 1770 1735 1705 1680 ----- ----- MAX MAX MAX 1840 1820 1785 1770 1740 1710 1665 1635 1595 1560 1525 1490 1435 1400 1360 1325 ----- ----- MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX MAX 1835 1810 1775 1755 1725 1695 1665 ----- ----- ----- MAX MAX 1820 1760 1740 1770 1705 1675 1640 1600 1570 1530 1495 1465 1425 1375 1340 ----- ----- ----- ----- MAX MAX MAX MAX MAX MAX MAX MAX MAX 1845 1810 1780 1755 1725 1695 1670 1645 ----- ----- ----- ----- MAX 1790 1745 1705 1680 1640 1640 1610 1575 1535 1505 1465 1435 1405 1360 1320 1280 ----- ----- ----- ----- MAX MAX MAX MAX MAX MAX MAX 1825 1805 1775 1745 1715 1695 1675 1645 1615 ----- ----- ----- ----- ----- MAX 1700 1660 1610 1600 1580 1560 1520 1480 1440 1400 1370 1340 1300 1260 ----- ----- ----- ----- ----- ----- 7,000 MAX MAX MAX MAX 1825 1795 1775 1755 1725 1700 1680 1645 1625 1590 1585 ----- ----- ----- ----- ----- ----- 8,000 1700 1610 1600 1570 1530 1500 1490 1440 1415 1395 1340 1310 1290 1245 ----- ----- ----- ----- ----- ----- ----- 9,000 1620 1560 1520 1500 1460 1440 1410 1380 1350 1320 1290 1260 1240 ----- ----- ----- ----- ----- ----- ----- ----- 10,000 1550 1500 1480 1460 1430 1400 1360 1330 1300 1280 1250 1220 ----- ----- ----- ----- ----- ----- ----- ----- ----- 11,000 1520 1450 1420 1390 1350 1320 1290 1270 1240 1220 1200 ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- 12,000 1430 1360 1340 1310 1280 1260 1230 1210 1180 ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- 13,000 1360 1310 1280 1260 1240 1220 1180 1150 1130 ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- 1,000 2,000 3,000 4,000 5,000 Climb Torque Only 6,000 Notes: Takeoff: 1. Takeoff torque on this chart shall be achieved without exceeding 805°C ITT or 101.6% Ng. When ITT exceeds 765°C this power setting is time limited to 5 minutes 2. With cabin heater ON, where altitude and temperature do not permit 1865 ft-lbs for takeoff, decrease torque setting by 65 ft-lbs. 3. With the inertial separator in NORMAL increase torque by 15 ft-lbs Climb: 4. Climb torque on this chart shall be achieved without exceeding 765°C ITT or 101.6 Ng. 5. With cabin heater ON, decrease torque setting by 80 ft-lbs 6. With the inertial separtor in BYPASS decrease torque by 100 ft-lbs Rev: Original 06 Nov 2014 Air Serv Limited C-208B Payload Extender Takeoff Performance Chart (Distances in Meters) WT Tkof Speed LBS Vlof V50 Alt Roll 50 ft Roll 50 ft Roll 50 ft Roll 50 ft Roll 9062 71 86 0 797 891 822 918 846 945 871 971 1000 853 951 879 979 905 1007 940 2000 909 1010 937 1040 964 1069 3000 973 1079 1003 1112 1033 1146 4000 1036 1147 1069 1185 1103 5000 1111 1230 1169 1304 1227 6000 1187 1313 1269 1422 7000 1335 1502 1431 8000 1482 1692 1594 8950 8850 8750 8600 71 70 70 69 85 84 83 82 Press 20 C Rev: Original Page 23 Tkof Speed 50 ft LBS Vlof V50 Alt Roll 50 ft Roll 50 ft Roll 50 ft Roll 50 ft Roll 896 998 8500 68 81 0 676 745 696 766 717 788 738 809 759 831 1049 976 1091 1000 722 793 744 816 766 839 796 873 826 907 1009 1127 1055 1185 2000 768 840 791 865 814 890 853 936 892 982 1098 1231 1162 1317 3000 822 896 847 924 873 952 926 1019 979 1086 1222 1187 1336 1270 1449 4000 876 952 904 983 932 1014 999 1102 1066 1189 1377 1321 1509 1415 1641 5000 938 1020 985 1078 1033 1135 1109 1236 1185 1337 1351 1532 1456 1683 1560 1833 6000 1000 1087 1067 1172 1134 1257 1219 1371 1303 1485 1640 1528 1778 1652 1974 1775 2171 7000 1121 1234 1200 1339 1278 1444 1378 1588 1477 1732 1857 1705 2023 1848 2266 1990 2509 8000 1242 1382 1333 1506 1423 1630 1537 1805 1651 1979 30 C 35 C 40 C 8400 25 C 30 C 35 C 40 C 50 ft 0 774 863 798 889 822 915 846 940 870 965 0 655 720 675 741 695 761 715 782 736 803 828 920 853 947 879 975 913 1015 947 1056 1000 700 766 721 788 742 810 771 843 800 876 2000 882 978 909 1006 935 1034 980 1090 1024 1146 2000 744 812 766 836 789 859 826 903 864 948 3000 944 1044 973 1076 1003 1108 1065 1190 1127 1272 3000 796 866 821 892 846 919 897 983 948 1047 4000 1005 1110 1038 1146 1070 1182 1151 1290 1231 1398 4000 848 920 875 949 903 979 967 1062 1032 1146 5000 1078 1189 1134 1260 1190 1330 1280 1456 1371 1582 5000 908 984 954 1040 1000 1095 1073 1191 1146 1286 6000 1151 1269 1230 1374 1309 1479 1410 1622 1511 1766 6000 968 1049 1033 1130 1097 1211 1178 1319 1260 1427 7000 1294 1450 1387 1582 1480 1713 1599 1899 1718 2086 7000 1085 1189 1160 1289 1236 1388 1331 1524 1427 1659 8000 1436 1632 1544 1789 1651 1947 1788 2176 1925 2406 8000 1201 1330 1288 1447 1375 1565 1484 1728 1593 1892 67 81 20 C 1000 8300 68 Press 06 Nov.2014 WT 25 C 0 751 835 774 860 797 884 821 909 844 933 0 634 695 653 715 672 735 692 755 712 775 1000 803 890 828 916 852 942 885 981 919 1020 80 1000 677 739 697 761 718 782 746 813 774 845 2000 855 945 881 972 907 1000 950 1053 993 1107 2000 720 783 741 806 763 829 799 871 836 914 3000 915 1008 944 1040 972 1071 1032 1149 1092 1227 3000 770 835 794 861 818 886 867 947 916 1008 4000 975 1072 1006 1107 1037 1142 1115 1245 1192 1348 4000 821 887 847 915 874 943 935 1023 997 1102 5000 1045 1149 1099 1216 1153 1284 1240 1404 1327 1523 5000 879 949 923 1001 967 1054 1037 1145 1107 1235 6000 1116 1226 1192 1325 1268 1425 1365 1562 1462 1698 6000 937 1011 998 1088 1060 1165 1138 1267 1216 1369 7000 1253 1399 1343 1523 1433 1648 1547 1824 1661 2000 7000 1049 1144 1121 1238 1193 1332 1285 1459 1376 1586 8000 1390 1572 1494 1721 1597 1870 1729 2087 1860 2303 8000 1161 1278 1244 1388 1327 1499 1431 1651 1536 1804 0 728 807 750 830 773 854 796 877 818 901 0 616 674 634 693 653 712 672 731 691 751 1000 778 859 802 885 826 910 858 947 890 984 8200 1000 657 716 677 737 696 757 724 787 751 818 2000 828 912 853 939 879 965 920 1016 962 1067 2000 698 759 719 781 740 803 775 843 811 884 3000 886 973 914 1003 942 1034 1000 1108 1057 1183 3000 747 809 770 833 794 858 841 916 888 975 4000 944 1034 974 1068 1005 1102 1079 1200 1153 1298 4000 796 859 822 886 847 913 907 989 966 1065 5000 1012 1108 1064 1173 1115 1237 1199 1351 1283 1465 5000 852 918 895 969 937 1019 1004 1106 1072 1193 6000 1080 1182 1153 1277 1226 1372 1319 1501 1412 1631 6000 908 978 968 1052 1027 1125 1102 1223 1177 1321 7000 1212 1347 1298 1465 1385 1583 1494 1749 1604 1915 7000 1016 1106 1086 1196 1156 1285 1244 1407 1331 1528 8000 1344 1512 1444 1653 1543 1794 1669 1997 1795 2199 8000 1124 1234 1204 1340 1285 1445 1385 1590 1485 1735 0 697 770 718 792 739 814 761 837 783 859 0 597 653 615 671 633 689 652 708 670 726 1000 744 819 767 843 790 867 821 902 851 938 1000 637 694 656 713 675 733 702 762 728 791 8100 66 66 79 78 2000 792 869 816 894 840 920 880 968 920 1016 2000 677 734 697 756 718 777 752 816 786 855 3000 848 927 874 956 900 984 955 1054 1010 1124 3000 724 782 746 806 769 830 815 886 861 942 4000 903 985 932 1017 961 1049 1031 1141 1101 1233 4000 771 830 796 857 820 883 878 956 936 1028 5000 968 1055 1017 1116 1066 1176 1145 1282 1224 1388 5000 826 888 867 936 907 985 972 1068 1037 1151 6000 1032 1125 1101 1214 1171 1303 1259 1423 1347 1544 6000 880 946 937 1016 994 1086 1066 1179 1138 1273 7000 1158 1279 1239 1389 1321 1499 1424 1652 1528 1805 7000 984 1068 1051 1154 1118 1239 1203 1354 1287 1469 8000 1283 1434 1377 1565 1471 1696 1590 1882 1709 2067 8000 1088 1190 1165 1291 1242 1392 1339 1529 1435 1665 Air Serv Limited C-208B Payload Extender Takeoff Performance Chart (Distances in Meters) WT Tkof Speed LBS Vlof V50 Alt Roll 50 ft Roll 50 ft Roll 50 ft Roll 50 ft Roll 8000 65 78 0 579 631 596 649 613 666 631 684 1000 617 671 635 689 654 708 679 2000 655 710 675 730 695 751 3000 701 756 723 779 744 802 4000 747 802 770 828 794 5000 799 858 839 904 6000 852 913 907 980 7900 7800 7700 65 64 63 77 76 75 Press 20 C 25 C Rev: Original Page 24 Tkof Speed 50 ft LBS Vlof V50 Alt Roll 50 ft Roll 50 ft Roll 50 ft Roll 50 ft Roll 649 702 7500 62 74 0 491 533 506 547 520 562 534 577 549 592 736 705 764 1000 523 566 538 581 554 597 575 619 596 642 728 788 760 825 2000 554 599 571 615 588 632 615 662 642 692 788 855 833 908 3000 593 636 611 655 629 674 666 716 702 759 853 849 922 905 992 4000 631 674 651 695 671 715 716 771 762 826 878 950 940 1029 1002 1108 5000 675 719 708 756 740 793 791 856 841 918 962 1047 1031 1136 1100 1225 6000 720 765 765 818 810 872 866 941 921 1010 35 C 40 C Press 06 Nov.2014 WT 30 C 20 C 25 C 30 C 35 C 63 75 50 ft 7000 952 1030 1016 1111 1081 1193 1162 1302 1242 1411 7000 802 858 854 922 907 986 972 1069 1037 1153 8000 1052 1147 1126 1242 1200 1338 1292 1467 1385 1596 8000 884 951 944 1025 1004 1100 1078 1198 1153 1295 0 560 610 577 626 594 643 611 660 628 677 0 475 515 488 528 502 542 516 557 530 571 1000 597 648 615 666 633 684 657 710 682 737 7400 62 1000 505 546 520 561 534 576 555 597 575 619 2000 633 685 653 705 672 725 704 760 735 796 2000 535 578 551 594 567 609 593 638 619 667 3000 678 730 699 752 720 774 762 824 805 875 3000 572 614 590 632 607 650 642 690 677 731 4000 722 774 744 798 767 823 821 889 874 955 4000 609 650 628 670 648 690 691 742 735 795 5000 773 827 810 871 848 915 908 991 968 1066 5000 652 694 683 729 715 764 763 824 811 883 6000 824 880 876 944 929 1008 995 1092 1061 1177 6000 695 737 738 788 781 839 834 905 887 970 7000 920 992 982 1069 1043 1146 1120 1249 1198 1352 7000 774 826 824 887 874 948 936 1027 998 1106 8000 1016 1103 1087 1194 1158 1284 1246 1406 1334 1527 8000 852 915 909 986 966 1056 1038 1149 1109 1241 7300 61 74 0 541 589 558 604 574 620 590 637 607 653 0 458 496 471 509 483 523 497 537 511 551 1000 577 625 594 642 612 659 635 684 658 710 1000 487 527 501 541 515 555 534 576 554 596 2000 612 661 631 680 650 699 680 732 710 766 2000 516 557 531 572 546 587 572 615 597 642 3000 655 703 675 724 695 746 736 794 777 842 3000 551 592 568 609 585 626 619 664 652 703 4000 697 746 719 769 740 793 792 855 843 918 4000 587 626 605 645 624 664 666 714 707 764 5000 746 797 782 839 818 881 876 952 933 1023 5000 628 668 658 702 689 735 735 792 780 848 6000 796 848 846 908 896 969 959 1049 1022 1129 6000 670 710 711 758 753 807 803 869 853 931 7000 887 954 947 1027 1006 1100 1079 1197 1153 1293 7000 745 794 793 852 841 910 900 984 959 1059 8000 979 1060 1047 1145 1115 1231 1200 1344 1284 1458 8000 821 879 875 946 929 1012 997 1100 1065 1187 CONDITIONS: 73 0 525 570 540 585 556 601 572 617 588 633 Flaps 20 Torque Set Per Figure 5-8 1000 559 605 576 622 592 638 615 663 637 687 1900 RPM Dry, Grass Runway 2000 593 640 611 658 629 676 658 709 687 741 Intertial Separator - BYPASS Zero Wind 3000 634 681 653 701 673 722 712 768 752 814 Cabin Heat - OFF ASI Ground Roll x 1.4 4000 675 722 696 744 717 767 767 827 816 888 5000 723 771 758 811 792 852 847 920 902 988 6000 770 820 819 878 868 936 928 1013 988 1089 1 Short Field Takeoff Technique as specified in Section 4 7000 859 922 916 992 973 1062 1044 1154 1114 1247 2 Decrease distances 10% for each 11 knots headwind. 8000 948 1023 1013 1105 1078 1187 1159 1295 1240 1404 0 508 552 523 566 538 581 553 597 568 612 3 Ground roll figures include 15% penalty due to operation on dry, grass runway 1000 541 586 557 602 573 618 595 641 617 664 4 Ground roll & Total distance figures include 3% penalty for inertial separator in bypass 2000 574 619 591 637 608 654 636 685 665 716 5 For operations above 40C and below the temperature operating limitations, 3000 613 659 632 678 651 698 689 742 727 787 4000 653 698 673 720 694 741 741 799 789 857 5000 699 745 733 784 766 823 819 888 872 953 6000 745 792 792 848 839 904 897 977 955 1050 7000 831 890 885 957 940 1024 1008 1112 1076 1200 8000 916 987 978 1065 1041 1143 1119 1247 1196 1350 NOTES: For operations with tailwinds up to 10 knots, increase distances by 10% for each 2 knots 7600 40 C multiply takeoff distances at 40C by 1.2 6 Ground Roll distances include ASL OM specified adjustment of +40% Air Serv Limited Cruise Performance Charts For C208B with Cargo Pod Installed Notes: Page 25 From Section 5 Performance CESSNA MODEL 208B (675 SHP) Rev 23, Figure 5-17 Cruise Performance. o 1. The highes torque shown for each temperature and RPM corresonds to the max allowable cruise power. Do not exceed this torque, 740 C ITT or 101.6% Ng, whichever occurs first. 2. The lowest torque shown for each temperature and RPM corresponds to the recommended torque setting for best range in zero wind conditions. 3. With the inertial separator in BY-PASS and the power set below the torque limit (1865 ft-lbs), decrease the max cruise torque by 100 ft-lbs. Do not exceed 740oC ITT. Fuel flow for a given torque setting will increase 15 pph . 4. The propeller setting for cruise shall be 1750 RPM. 5. With the cabin heat on and power wet below the torque limit (1865ft-lbs). Decrease maximum cruise torque by 80 ft-lbs. Do not exceed 740oC ITT. Fuel flow for a given torque setting will be 7 pph higher. Altitude Torque Temp 'C ft-lbs 2000ft 4000ft 6000ft 8000ft 10000ft 12000ft Fuel Flow PPH KTAS Torque ft-lbs Fuel Flow PPH KTAS Torque ft-lbs Fuel Flow PPH KTAS Torque ft-lbs Fuel Flow PPH KTAS Torque ft-lbs Fuel Flow PPH KTAS Torque ft-lbs Fuel Flow PPH 14000ft KTAS Torque ft-lbs Fuel Flow PPH KTAS 45 1336 346 145 40 1457 362 151 1335 335 147 35 1573 362 151 1447 335 147 1326 324 149 30 1689 1500 1465 393 365 360 160 151 150 1558 1420 1355 365 341 335 157 151 151 1430 1380 338 330 154 151 1291 311 149 25 1800 1600 1465 369 409 378 163 163 155 1631 1460 1355 375 375 347 161 161 154 1531 1440 1604 338 353 338 156 158 154 1386 1393 320 325 154 152 1254 298 148 20 1910 1700 1465 424 391 356 166 158 148 1704 1500 1355 385 353 331 165 157 150 1632 1500 1360 367 346 325 162 156 149 1481 1325 1255 338 314 302 158 150 150 1342 1320 310 307 154 152 1207 284 147 1285 288 154 11552 269 143 1362 1310 306 298 156 153 1225 280 149 15 10 5 1940 384 156 1837 357 156 1730 345 156 1572 332 162 1426 315 160 1700 427 167 1600 405 168 1550 382 166 1413 351 162 1360 288 150 1458 390 158 1380 367 159 1360 352 158 1290 326 154 1970 1700 1450 430 388 351 167 157 146 1970 1700 1405 425 381 336 170 160 147 1828 1600 1360 396 358 322 169 159 148 1663 1500 1325 364 338 310 165 158 149 1510 1400 1305 334 317 302 161 156 150 1970 388 157 1970 373 159 1899 357 159 1754 335 157 1594 335 166 1441 310 162 1299 283 157 1700 429 166 1700 424 169 1650 409 171 1600 380 168 1450 315 159 1355 279 150 1190 273 153 164 157 151 1372 1295 304 283 158 153 1443 387 156 1398 379 159 1360 363 161 1328 344 159 1300 285 149 0 1970 1700 1435 427 385 345 165 155 144 1970 1700 1390 422 376 331 168 158 145 1970 1700 1360 421 367 319 172 162 146 1844 1700 1330 396 350 308 171 160 148 1678 1500 1295 364 330 298 168 159 148 1520 1400 1295 333 310 293 -5 1970 385 155 1970 377 158 1970 364 161 1907 343 158 1763 307 154 1598 155 78 1444 456 238 1700 425 164 1700 421 168 1700 420 171 1600 407 173 1500 379 171 1400 347 167 1348 317 162 1430 384 154 1385 376 158 1345 366 161 1323 341 157 1295 329 159 1288 310 156 1290 304 159 Rev: Original 06 Nov 2014 Air Serv Limited WT LBS 9000 Ldg Speed V50 80 C-208B Payload Extender Landing Performance Chart (Distances in Meters) 20 C 25 C 30 C 35 C 40 C Press Alt Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft 0 604 806 616 817 629 828 636 838 644 848 1000 625 829 638 840 650 850 660 861 670 872 2000 647 852 659 862 671 872 683 884 696 896 3000 673 874 683 884 694 895 707 908 720 921 4000 699 896 708 907 717 917 731 932 744 946 5000 723 922 735 934 746 946 759 959 772 972 6000 748 948 761 961 775 974 787 986 799 998 7000 780 980 792 991 804 1002 818 1016 831 1030 8000 812 1011 822 1021 833 1031 848 1046 863 1061 WT LBS 8500 Ldg Speed V50 78 Rev: Original 06 Nov 2014 Page 26 20 C 25 C 35 C Press 30 C 40 C Alt Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft 0 567 769 578 779 589 789 598 799 607 809 1000 589 791 600 801 610 811 620 821 630 831 2000 610 813 621 823 632 833 642 843 653 854 3000 635 836 645 846 656 856 667 868 677 879 4000 659 859 670 870 680 880 691 892 702 904 5000 683 884 695 895 706 907 718 919 729 931 6000 708 909 720 921 732 933 744 945 757 957 7000 737 937 749 949 761 961 774 974 787 986 8000 766 965 778 977 790 989 804 1002 818 1016 8900 80 0 1000 2000 3000 4000 5000 6000 7000 8000 597 618 639 665 691 715 739 771 803 799 822 844 866 889 914 940 971 1002 608 630 652 676 701 727 753 783 814 810 832 854 877 900 926 953 983 1012 620 642 664 687 710 738 766 795 824 820 842 864 887 911 938 966 995 1023 628 652 676 699 723 751 779 809 839 830 853 876 900 924 951 978 1008 1037 636 662 687 712 736 763 791 822 854 840 864 888 913 938 964 990 1021 1052 8400 77 0 1000 2000 3000 4000 5000 6000 7000 8000 561 582 603 627 651 676 700 728 757 762 784 805 828 851 876 901 929 957 571 592 614 638 662 687 712 740 769 772 794 815 839 862 887 913 941 969 582 603 624 648 672 698 724 752 781 782 804 825 849 873 899 924 953 981 591 613 635 659 683 710 736 765 794 792 814 836 860 884 910 936 965 994 600 622 645 669 694 721 748 778 808 801 824 846 871 896 922 948 977 1006 8800 79 0 1000 2000 3000 4000 5000 6000 7000 8000 589 611 632 658 684 707 730 762 794 792 814 836 859 882 907 932 962 992 600 622 644 669 693 719 744 775 805 802 824 846 869 893 919 945 974 1004 611 634 657 679 702 730 758 787 816 812 834 856 880 904 931 958 987 1015 620 644 668 691 715 742 770 800 830 822 845 868 892 917 944 970 1000 1029 629 654 679 703 727 755 782 813 844 832 856 880 905 930 956 982 1012 1042 8300 77 0 1000 2000 3000 4000 5000 6000 7000 8000 554 575 596 619 643 668 692 720 748 755 777 798 821 844 868 893 921 948 564 585 606 630 654 679 704 732 760 765 787 808 831 854 879 905 932 960 574 596 617 641 665 690 715 744 772 775 796 818 841 865 890 916 944 972 583 605 627 651 675 701 727 756 785 784 806 828 852 876 902 928 956 985 593 615 637 661 686 713 740 769 798 794 816 839 863 888 914 940 969 997 8700 79 0 1000 2000 3000 4000 5000 6000 7000 8000 586 607 629 654 680 703 726 758 790 789 811 833 855 878 903 928 958 987 596 619 641 665 690 715 740 770 801 799 821 842 866 889 915 941 970 999 607 630 653 676 699 726 754 783 812 809 830 852 876 900 927 955 983 1011 616 640 664 687 711 738 766 796 825 818 841 864 889 913 940 967 995 1024 625 650 674 699 723 751 778 809 839 828 852 876 901 926 952 979 1008 1037 8200 76 0 1000 2000 3000 4000 5000 6000 7000 8000 547 568 588 612 635 660 684 711 738 748 770 791 814 836 861 885 912 939 557 578 599 622 646 671 695 723 751 758 779 800 824 847 872 897 924 951 567 588 610 633 657 682 707 735 763 768 789 810 834 857 882 908 936 963 576 598 619 643 667 693 719 747 776 777 799 821 844 868 894 920 948 976 585 607 629 654 678 704 731 760 788 786 809 831 855 880 906 932 960 988 8600 78 0 1000 2000 3000 4000 5000 6000 7000 8000 582 603 625 650 676 699 722 754 785 785 807 829 851 874 899 924 954 983 593 615 637 661 686 711 736 766 796 795 817 838 862 885 911 937 966 995 603 626 649 672 695 722 749 778 807 805 826 848 872 896 923 950 979 1007 613 636 659 683 707 734 762 791 821 814 837 860 884 909 936 962 991 1020 622 646 670 694 719 746 774 804 835 824 848 872 897 922 948 974 1004 1033 8100 76 0 1000 2000 3000 4000 5000 6000 7000 8000 541 561 581 604 627 652 676 703 729 741 762 783 806 829 853 877 904 931 550 571 592 615 638 663 687 714 741 751 772 793 816 839 864 889 916 943 560 581 602 625 649 673 698 726 754 761 782 803 826 849 874 900 927 955 569 590 612 636 659 685 710 738 766 770 791 813 837 860 886 912 939 967 578 600 621 646 670 696 722 751 779 779 801 823 847 871 897 924 951 979 Air Serv Limited WT LBS 8000 Ldg Speed V50 75 C-208B Payload Extender Landing Performance Chart (Distances in Meters) 20 C 25 C 30 C 35 C 40 C Press Alt Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft 0 534 734 543 744 552 754 561 763 571 771 1000 554 755 564 765 574 775 583 784 592 793 2000 574 776 584 786 595 795 604 805 613 815 3000 596 799 607 809 618 818 628 829 638 839 4000 619 822 630 831 641 841 651 852 662 863 5000 644 846 654 856 665 866 677 878 688 889 6000 668 870 679 880 690 891 702 903 714 915 7000 694 896 706 907 717 919 729 931 741 943 8000 720 922 732 934 744 946 757 958 769 970 WT LBS 7500 Ldg Speed V50 73 Rev: Original 06 Nov 2014 Page 27 35 C 20 C 25 C 30 C 40 C Press Alt Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft Gd Roll 50 ft 0 500 700 510 708 519 717 528 726 537 734 1000 520 719 529 728 539 738 548 746 557 755 2000 540 739 549 749 558 758 567 767 577 776 3000 560 759 570 770 580 780 589 789 598 799 4000 580 780 590 791 601 802 610 812 619 822 5000 603 803 613 814 624 825 634 835 644 846 6000 625 826 636 837 647 848 658 859 668 870 7000 650 851 661 862 673 874 684 885 696 896 8000 674 876 686 888 699 900 711 911 723 922 7900 75 0 1000 2000 3000 4000 5000 6000 7000 8000 527 547 567 589 611 636 660 685 711 727 748 768 791 813 837 861 887 913 536 557 577 600 622 646 670 697 723 737 758 778 801 823 848 872 898 925 546 567 588 610 633 657 681 708 735 747 767 788 811 833 858 883 910 937 555 576 597 620 643 668 693 720 748 755 776 798 821 844 869 894 921 948 564 585 606 630 654 679 705 732 760 764 786 807 831 855 880 906 933 960 7400 73 0 1000 2000 3000 4000 5000 6000 7000 8000 494 513 533 552 572 594 617 641 665 693 712 731 752 772 795 818 843 867 503 522 542 562 582 605 628 652 677 701 721 741 762 783 806 828 854 879 511 531 550 571 593 615 638 664 689 710 730 751 772 794 816 839 865 890 521 540 560 581 602 625 649 675 701 719 739 759 781 804 827 850 876 901 530 549 569 590 611 635 659 686 713 727 748 768 791 813 837 861 887 912 7800 74 0 1000 2000 3000 4000 5000 6000 7000 8000 521 540 560 582 603 627 651 676 702 720 741 761 783 805 829 852 878 904 530 550 570 592 614 638 662 688 714 730 750 771 793 815 839 863 889 916 539 560 580 603 625 649 672 699 726 739 760 781 803 826 850 874 901 928 548 569 589 612 635 659 684 711 738 748 769 790 813 836 861 885 912 939 557 578 599 622 645 670 696 723 751 757 778 799 823 846 872 897 924 951 7300 72 0 1000 2000 3000 4000 5000 6000 7000 8000 487 506 525 545 564 586 608 632 656 686 705 724 744 765 787 809 834 859 495 515 534 554 574 596 619 643 668 694 714 733 754 775 797 820 845 870 504 523 542 563 584 607 630 654 679 703 723 743 764 785 808 830 856 881 513 532 552 573 594 617 640 665 691 711 731 751 773 795 818 841 866 892 522 542 561 582 603 627 650 676 702 720 740 760 783 805 829 852 877 903 7700 74 0 1000 2000 3000 4000 5000 6000 7000 8000 514 534 553 575 596 619 643 668 693 714 734 754 775 797 820 843 869 894 523 543 563 585 606 630 653 679 705 723 743 763 785 807 831 854 880 906 532 553 573 595 617 640 664 690 717 732 753 773 795 818 841 865 892 918 541 562 582 604 627 651 675 702 729 741 761 782 805 828 852 877 903 930 550 571 591 614 636 661 686 714 741 749 770 792 815 838 863 888 914 941 7200 72 0 1000 2000 3000 4000 5000 6000 7000 8000 480 499 518 537 556 578 600 623 647 679 698 717 737 757 779 801 826 850 488 507 526 546 566 588 611 634 658 687 707 726 746 767 789 811 836 861 497 516 535 555 575 598 621 645 669 696 715 735 756 777 799 822 846 871 506 525 544 565 585 608 631 656 681 704 724 744 765 787 810 833 857 882 515 534 553 574 596 618 641 666 692 712 732 752 775 797 820 843 868 893 7600 73 0 1000 2000 3000 4000 5000 6000 7000 8000 507 527 547 567 588 611 634 659 683 707 726 746 767 788 812 835 860 885 516 536 556 577 598 621 645 670 696 715 736 756 778 799 822 846 871 897 525 546 566 587 609 632 655 682 708 724 745 766 788 810 833 856 883 909 535 555 575 597 618 642 666 693 720 733 754 775 797 820 844 868 894 920 544 564 584 606 628 653 677 705 732 742 763 784 807 830 854 879 905 931 7100 71 0 1000 2000 3000 4000 5000 6000 7000 8000 474 492 511 529 548 570 591 614 638 672 690 709 729 749 771 793 817 841 481 500 519 538 557 580 602 625 649 680 699 718 738 759 781 803 827 851 489 508 527 547 567 590 613 636 660 689 708 727 748 769 791 813 837 862 499 517 536 557 577 600 622 646 671 697 716 736 757 779 801 824 848 873 508 526 545 566 588 610 632 657 682 705 725 744 766 788 812 835 859 883 CONDITIONS: Flaps 30° Power Lever - BETA Prop Lever - MAX Max Braking NOTES: Dry, Grass Runway Zero Wind ASL Ground Roll and 50' Distance +30% 1 Short Field Landing Technique as specified in Section 4 2 Decrease distances 10% for each 11 knots headwind. For operations with tailwinds up to 10 knots, increase distances by 10% for each 2 knots. 3 Ground roll figures include 40% penalty due to operation on dry, grass runway 4 For wet or slippery runways, multiple Landing Roll by 1.75 to calculate 115% distance requirement. 5 The total calculated ground roll lengths in this chart are increased 70% over Cessna performance fiugres from POH Section 5. Page 28 Intercept Procedures Excerpt from Ugandan Civil Aviation (Rules of the Air and Air Traffic Control) Regulations 2006. 40. (1) When intercepted by a military or government aircraft, the PIC shall comply with, by interpreting and responding to visual signals as shown in Table 2. (2) The intercepting aircraft shall interpret visual signals from an intercepted aircraft as shown in Table 3. Table 2 - SIGNALS INITIATED BY INTERCEPTING AIRCRAFT Meaning INTERCEPTED Aircraft Responds Meaning Series INTERCEPTING Aircraft Signals You have been intercepted Follow me. DAY or NIGHT - Rocking aircraft. Flashing Navigational lights at irregular intervals and following. Understood, will comply. 1 DAY or NIGHT - Rocking aircraft and flashing navigational lights at irregular intervals (and landing lights in the case of a helicopter) from a position slightly above and ahead of, and normally to the left of, the intercepted aircraft (or to the right if the intercepted aircraft is a helicopter) and, after acknowledgement, a slow level turn, normally to the left, (or to the right in the case of a helicopter) on the desired heading. Note 1 Meteorological conditions or terrain may require the intercepting aircraft to reverse the positions and direction of turn given above in Series 1. Note 2 If the intercepted aircraft is not able to keep pace with the intercepting aircraft, the latter is expected to fly a series of race-track patterns and to rock the aircraft each time it passes the intercepted aircraft. DAY or NIGHT - An abrupt break-away maneuver from the intercepted aircraft consisting of a climbing turn of 90 degrees or more without crossing the line of flight of the intercepted aircraft. You may proceed. DAY or NIGHT - Rocking the aircraft. Understood, Will comply. DAY or NIGHT - Lowering landing gear (if fitted), showing steady landing lights and overflying runway in use or, if the intercepted aircraft is a helicopter, overflying the helicopter landing area. In the case of helicopters, the intercepting helicopter makes a landing approach, coming to hover near to the landing area. Land at This aerodrome. DAY or NIGHT - Lowering landing gear (if fitted), showing steady landing lights and following the intercepting aircraft and, if, after overflying the runway in use or helicopter landing area, landing is considered safe, proceeding to land. Understood, will comply. DAY or NIGHT - Raising landing gear (if fitted) and flashing landing lights while passing over runway in use or helicopter landing area at a height exceeding 300 m (1,000 ft) but not exceeding 600 m (2,000 ft) (in the case of a helicopter, at a height exceeding 50 m (170 ft) but not exceeding 100 m (330 ft) above the aerodrome level, and continuing to circle runway in use or helicopter landing area. If unable to flash landing lights, flash any other lights available. Aerodrome you have designated is inadequate. DAY or NIGHT - If it is desired that the intercepted aircraft follow the intercepting aircraft to an alternate aerodrome, the intercepting aircraft raises its landing gear (if fitted) and uses he Series 1 signals prescribed for intercepting aircraft. If it is decided to release the incepted aircraft. The intercepting aircraft uses the Series 2 signals prescribed for intercepting aircraft. Understood, follow DAY or NIGHT - Regular switching on and off of all available lights but in such a manner as to be distinct from flashing lights. Cannot comply DAY or NIGHT - Use Series 2 signals prescribed for intercepting aircraft. Understood. DAY or NIGHT - Irregular flashing of all available lights. In distress DAY or NIGHT - Use Series 2 signals prescribed for intercepting aircraft. Understood 2 3 Table 3 - SIGNALS INITIATED BY INTERCEPTED AIRCRAFT 4 5 6 Rev: Original Date: 06-Nov-2014 C208B Quick Reference Handbook C208B Normal Checklist Original C208B Normal Checklist Original Climb Before Start After Start *External Inspection ......... Complete (C) *Documents ....................... Checked (C) *Cabin Ht FW Cutoff ......... Open (IN) (C) *Fuel Firewall Cutoff ......... Open (IN) (C) Annunciator Panel ................. Checked (C) Flaps ................. Set___°,Indic,Verified (C) Trims ........................................... 3 Set (C) Avionics/TAWS/TCAS .................... Set (F) Engine Instruments ................ Checked (F) Trims ............................... Checked/Set (C) Flaps ............................... Checked/Set (C) Emergency Power Lever ......... Stowed (C) PWR, PROP, FUEL Lever............. Set (C) Bleed Air......................................... Off (C) Radar ............................................. Off (C) Inertial Separator ................... As Req’d (C) Control Lock ......................... Removed (C) Park Brake ..................................... Set (C) Lights (FSB,NS,Position)................ Set (C) Circuit Breakers..................... Checked (C) Brakes ................................... Checked (B) Flight Controls ........................ Checked (F) Flight Instruments ........ Set/X-Checked (F) Taxi/Recog Lights ..........................Off (C) Altimeters ....................... 1013 Set L/R(C/F) Before Take-Off Cruise *Autopilot ........................... Checked (C) *Fuel Boost Pump ....... Norm/On/Off (C) *Avionics Fan / Xtie ..... Checked/Off (C) *Alt Static Source .................... Norm (C) *Fire Extinguisher .............. Checked (C) *Fire Warning ......................... Tested (C) *Annunciator Panel Lights.... Tested (C) *Annunciator Day/Night Switch ..Set (C) *Standby Flaps ........................ Norm (C) Seat, seat belt, shoulder harness .. SET(B) Fuel Selectors ................................ On (C) Passenger Briefing ............... Complete (C) Chocks/ Tail Stand ............... Removed (C) Beacon ........................................... On (C) Battery Switch ............................... On (C) Voltage ......................... >24V/Set Batt (C) Door Light...................................... Off (C) Fuel .................... Lbs Req’d. Lbs Indic (C) Prop Area ................................... Clear (B) Fuel Boost Pump ............................ On (C) Taxi Crew Briefing ..................... Complete (PF) *Feather/Unfeather ............ Checked (C) *Beta/Reverse .................... Checked (C) *Over-speed Gov ............... Checked (C) *Inertial Separator ............. Checked (C) *Suction.............................. Checked (C) *Standby Power ................. Checked (C) *Voltmeter ...................Checked/Batt (C) Entering the Active Transponder .....................................Alt (F) Strobes.......................................... .On (C) Radar .................................... As Req’d (F) Environmentals (Bleed/HEAT/FLTFANS/OFF)Set (F) Stdby Power ....................................On (C) Annunc Panel ................... As Indicated (C) Fuel Condition Lever ............. High Idle (C) Compass/Rwy Hdg .............. Checked (B) Passengers ............................ Checked (F) Transfer of Controls Lights (when cleared for takeoff)........................................ On (C) ( * Denotes First-Flight Items) Page 29 Inertial Separator .................. As Req’d (C) Landing Lights ................... As Req’d (PM) Power......................................... Set (PM) Flaps ........................................... Up (PM) Annunciator Panel ........... Considered (PM) Engine Instruments .............. Checked (PM) Environmentals ................... .As Req’d (PM) Transition Altitude After Landing Flaps ......................................... Set (F) Radar ......................................... Off (F) Transponder (clear of active) ................ Standby (F) Lights ......................................... Set (C) Ignition Switch ....................... Norm (C) Stdby Power .............................. Off (C) Fuel Cond Lever ........................ Set (C) Shut Down Cruise Power ................................ Set (PF) Engine Instruments .............. Checked (PM) Fuel Selectors ...................... As Req’d (PM) *Trend Monitor ........................Complete (PM) Descent Seat, seat belt, shoulder harness ............. Set(B) Cabin Signs/FSB/NS...............................On App & Landing Data .......... .Reviewed (PF) Navaids ........................... Set/Tune/ID (PM) Fuel Selectors ..................... As ReQ’d (PM) Transition Level Taxi/Recog Lights .........................On (C) Altimeters ........................... ____Set L/R (B) TAWS .................................. As Req’d (PM) Power Lever ............................ Idle (C) Park Brake ............................... Set (C) Avionics ................................... Off (C) Standby Power ........................ Off (C) Fuel Boost Pump ..................... Off (C) Lights ....................................... Off (C) Environmentals ........................ Off (C) ITT ....................................... Stable (C) Prop Lever .......................... Feather (C) Fuel Condition Lever .......... Cut Off (C) Fuel Selectors........................... Off (C) Battery Switch........................... Off (C) Control Lock .......................... Install (C) Post Flight Duties .............Assigned (C) Before Landing Brakes.................................... Checked (B) Bleed Air .............................. As Req’d (PM) Radar ................................... As Req’d (PM) Fuel Selectors .................... Qty/Bal/On(PM) Passengers .................. Seated/Secured (PM) Ignition ....................................... On (PM) Inertial Separator .............. As Req’d (PM) Flaps .............. Set__° / Ind / Vref____ (PM) Prop ...................................... Full Fwd (PM) Landing Lights ................................On (C) Revision: .............................. ...Original Date Revised: ...........................6-Nov-2014 Page 30 DEPARTURE BRIEF IFR ARRIVAL BRIEF Runway Departing RWY Initial Turn (L/ R) Initial Course Initial Altitude Emergency Landing Plan Chart Name Approach Chart Number Jeppesen Briefing Strip Minimums Vis Requirements (If A Factor) Missed Approach Initial Actions Terrain Relevant Terrain And Obstacles Minimum Safe IFR Altitude Weather – Relevant Weather Wind – Wind/ X Wind/ Tailwind Terrain Relevant MSA And Highest MSA Relevant Terrain And Obstacles Weather Relevant Weather Wind – Wind/ X Wind/ Tailwind Operational Type Of Takeoff (If Non Standard) Weight Restrictions (If Applicable) Any Other Non Standard Items Operational Notams Chart Notes And Warnings Lateral Management Vertical Management Speed Control Configuration Braking, Use Of Beta/ Reverse Diversion Plan, Holding Time Non Standard Items THREATS VFR ARRIVAL BRIEF Runway – Expected, Inspection/ Joining Procedure Terrain – Relevant Terrain And Obstacles Weather – Relevant Weather Wind – Wind/ X Wind/ Tailwind Operational Notams Type Of Landing (If Non Standard) Speed Control Configuration Braking/ Use Of Beta Reverse Any Other Non Standard Items (Key Points, Slope, Specific Rwy Characteristics) THREATS Rev: Original Date: 06-Nov-2014 THREATS Setup 1. Gps/ Vnav Setup 2. Nav Radio Setup 3. PM Crosscheck 4. Briefing C208B Quick Reference Handbook Rev: Original 06-Nov-2014 Rev: Original 06-Nov-2014 Rev: Original 06-Nov-2014 Rev: Original 06-Nov-2014 Rev: Original 06-Nov-2014 Rev: Original 06-Nov-2014 Page C208B ANNUNCIATOR PANEL ENGINE FIRE Ground – 10C Flight – 9A VOLTAGE LOW 13B Rev: Original 12A VACUUM LOW 15C DOOR WARNING 14C/D OIL PRESS LOW ------------------- N/A Date: 06-Nov-2014 GENERATOR OFF 13B RESERVOIR FUEL LOW 12C BATTERY OVERHEAT 13A EMERGENCY POWER LEVER AUX FUEL PUMP ON FUEL PRESS LOW 17D STARTER ENERGIZED 12B 17D LEFT FUEL LOW RIGHT FUEL LOW 12E 12E BATTERY HOT CHIP DETECTOR STBY ELEC PWR INOP WINDSHIELD ANTI-ICE 19A 17C 13C 20A STBY ELEC PWR ON 19C ------------------- 13B IGNITION ON 20A FUEL SELECT OFF 12D/12E C208B Quick Reference Handbook DE-ICE PRESSURE 20A 37