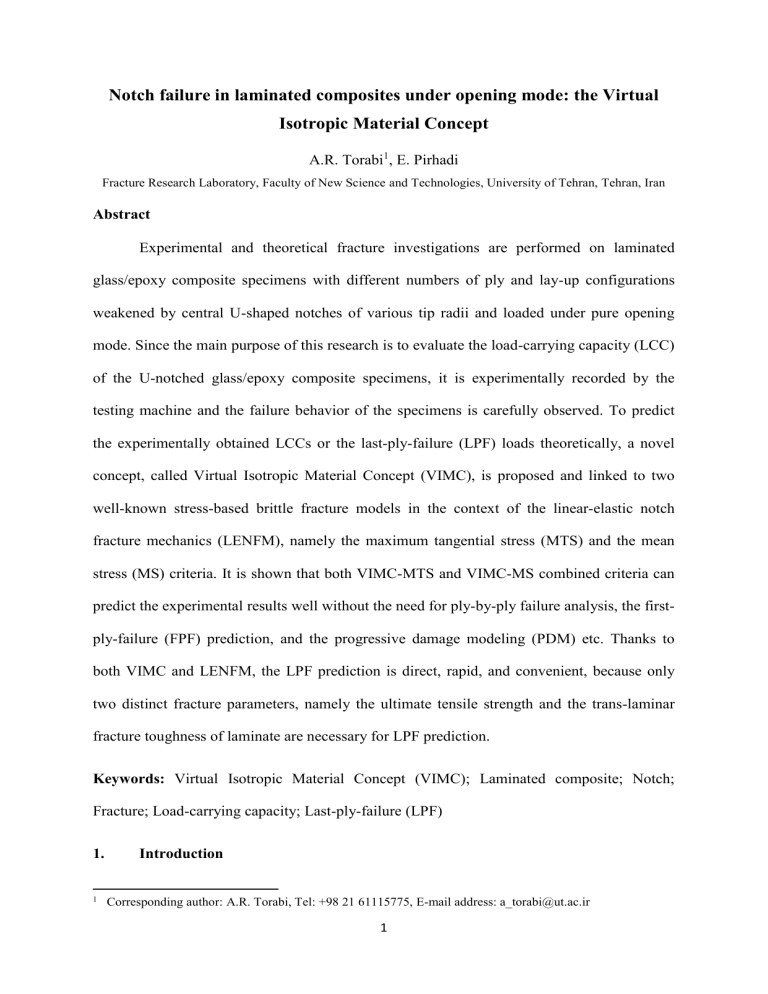

Notch failure in laminated composites under opening mode: the Virtual Isotropic Material Concept A.R. Torabi1, E. Pirhadi Fracture Research Laboratory, Faculty of New Science and Technologies, University of Tehran, Tehran, Iran Abstract Experimental and theoretical fracture investigations are performed on laminated glass/epoxy composite specimens with different numbers of ply and lay-up configurations weakened by central U-shaped notches of various tip radii and loaded under pure opening mode. Since the main purpose of this research is to evaluate the load-carrying capacity (LCC) of the U-notched glass/epoxy composite specimens, it is experimentally recorded by the testing machine and the failure behavior of the specimens is carefully observed. To predict the experimentally obtained LCCs or the last-ply-failure (LPF) loads theoretically, a novel concept, called Virtual Isotropic Material Concept (VIMC), is proposed and linked to two well-known stress-based brittle fracture models in the context of the linear-elastic notch fracture mechanics (LENFM), namely the maximum tangential stress (MTS) and the mean stress (MS) criteria. It is shown that both VIMC-MTS and VIMC-MS combined criteria can predict the experimental results well without the need for ply-by-ply failure analysis, the firstply-failure (FPF) prediction, and the progressive damage modeling (PDM) etc. Thanks to both VIMC and LENFM, the LPF prediction is direct, rapid, and convenient, because only two distinct fracture parameters, namely the ultimate tensile strength and the trans-laminar fracture toughness of laminate are necessary for LPF prediction. Keywords: Virtual Isotropic Material Concept (VIMC); Laminated composite; Notch; Fracture; Load-carrying capacity; Last-ply-failure (LPF) 1. 1 Introduction Corresponding author: A.R. Torabi, Tel: +98 21 61115775, E-mail address: a_torabi@ut.ac.ir 1 In the past five decades, many experimental and numerical research works have been performed to evaluate failure in laminated composite specimens under different loading conditions. However, most of them have dealt with cracked samples and not with notched ones. In practical applications of composite laminates, drilling holes for mechanical fastenings or cut-outs for access are usually inevitable. These holes and cut-outs with various shapes, such as circular holes, rectangular cut-outs with round corners and bean-shaped holes with two U-ends etc., concentrate stresses at their neighborhood and increase the risk of initiation of damage from their borders. The damage initiated may grow and lead to final fracture depending on the loading and service conditions. Increasing of the application of laminated composites in aerospace structures, particularly in the primary structures, makes it necessary to have reliable criteria for predicting failure in laminated composite components weakened by notches and ensuring the structural integrity. A careful literature survey on fracture prediction of laminated composites indicates that there are generally three different approaches for this purpose; i) the models based on fracture mechanics [1-5], ii) the stress-fracture models [6-17], and iii) the progressive damage models [18-25]. One of the well-known failure models based on the linear elastic fracture mechanics (LEFM) for composite materials in macroscopic level is the WEK-fracture model, known as the inherent flaw model (IFM). This model was presented by Waddoups et al. [2], which is known by two parameters, namely the un-notched strength and the characteristic dimension (the inherent flaw length). Whitney and Nuismer [6] suggested two stress-based fracture criteria known as the point stress (PS) criterion and the average stress (AS) criterion. Additionally, Pipes et al. [16] and Kim et al. [17] modified the PS criterion and proposed a three-parameter model with an exponential relationship between the characteristic dimension and the notch size. Another criterion, called Mar-Lin criterion, was presented by Mar and Lin 2 [13], in which failure in multi-layer composites occurs through the propagation of a crack lying on matrix material. Some other researchers have focused on damage zone, which is less attractive from the practical viewpoint than other closed-form criteria. Backlund and Aronsson [3, 4] have proposed the damage zone model (DZM) to evaluate the residual strength of composite laminates. Eriksson and Aronsson [26] have developed a new criterion, called the damage zone criterion (DZC), based on the assumption that a damage zone is present in the maximum stress region of the laminate; the maximum strength region represents the point in which the tensile stress of the notched laminate reaches the tensile strength of the un-notched laminate. Khatibi et al. [27-29] have also evaluated the residual strength of composite laminates weakened by a sharp notch using an effective crack growth model (ECGM). In completion of damage mechanism and complying with damage zone model, the progressive damage models have been employed to take into account the damage and resulting changes in the stress distributions that occur throughout the loading process [23– 29]. Another criterion based on damage mechanisms, is the continuum damage mechanics (CDM) proposed originally by Ladeveze [30] for characterizing and analyzing the produced damage by material stiffness loss. Mohammadi et al. [31-33] have frequently analyzed the laminated composites in wide range of failure modes, loadings, and layups by using the CDM to estimate the residual stiffness. Moreover, Mohammadi and co-workers [33] have conducted a parametric study on the influence of diameter of hole and characterized the initiation and growth of damage parameters in the Ladeveze model. As conclusions about important damage models it should be added that the DZM requires some properties such as the un-notched strength, apparent fracture energy, and stiffness parameters needing more experimental works. The ECGM criterion is based on the global equilibrium condition with the aid of an iterative technique on the results of large 3 variation of apparent fracture energy (𝐺𝑐 ) values to evaluate the residual strength of composite laminates. So, taking average 𝐺𝑐 values as the basic input parameter in ECGM analyses will be erroneous. At last, in the CDM criterion two complicacies exist; first, the dependency of it on damage and inelastic strains to estimate residual stiffness, second, this model requires different user-defined subroutines for various lay-up configurations, stacking sequences, failure modes, and loading conditions. To the best of authors’ knowledge, no paper or technical report is available in the literature dealing with fracture analysis of U-notched composite laminates. Most of the fracture investigations on notched composite laminates or laminas have been performed on O-notched (open hole) and cracked (slit) specimens. In order to simplify the procedure of the last-ply-failure (LPF) prediction in U-notched laminated composites, it is tried in the present study to use directly the linear elastic notch fracture mechanics (LENFM). For this purpose, the composite laminate is equated with a virtual isotropic plate of the same thickness and some brittle fracture criteria in the context of LENFM are utilized for failure prediction. Hence, in next paragraph, some papers already published on brittle fracture of U-notched components made of isotropic materials are reviewed. Generally, several main failure theories, namely the cohesive zone model (CZM), the strain energy density (SED), the J-integral, the maximum tangential stress (MTS), and the mean stress (MS) criteria, based on stress or energy equations have been suggested and utilized for evaluating fracture in notched brittle specimens. The cohesive zone model (CZM) has been successfully employed by proposing suitable softening curves for some engineering materials, such as steel, aluminum, polymethyl-methacrylate (PMMA), and PVC [34-36]. Also the strain energy density (SED) criterion has been proposed by Yosibash et al. [37] showing very good correlation to a large amount of experimental data regarding brittle failure of Alumina-7% Zirconia and PMMA specimens. More recent developments in this context 4 have also been published (see for instance [38-40]). A criterion based on the J-integral has been proposed by Matvienko and Morozov [41] for a body with a U-notch considering linear elastic and elastic–plastic behavior of material. Gomez et al. [42] have published a paper dealing with various criteria that exist for investigating fracture initiation at U-notches under mode I loading. Moreover, the SED model has been frequently used by several investigators to assess brittle fracture of U-notched components made of different engineering materials under mode I (i.e. opening mode) and mixed mode I/II (i.e. combined tension-shear mode) loading conditions [43-46]. Beside SED failure criterion, two other well-known brittle fracture models are the maximum tangential stress (MTS) and the mean stress (MS) criteria. The MTS criterion, proposed originally by Erdogan and Sih [47] for predicting mixed mode brittle fracture in sharp cracked bodies, has been extended by Ayatollahi and Torabi [48] to U-notched domains and frequently used for predicting the onset of mixed mode brittle fracture in different notched brittle members. The MS criterion in its mixed mode format has been previously formulated by Seweryn and Lukaszewicz [49] for V-notched components and presented as a closed-form expression. Recently, Torabi [50] has successfully made use of the point stress (PS) and the mean stress (MS) fracture criteria for predicting mode I failure of U-notched graphite plates tested and reported by Berto et al. [51]. Additionally, Torabi [52] has utilized the MTS fracture curves to predict theoretically the fracture loads of several U-notched graphite specimens reported in [51] under mixed mode I/II loading conditions and found very good agreement between the theoretical and experimental results. Another research work has been published by Torabi et al. [53] in which the load-carrying capacity (LCC) of U-notched Brazilian disc (UNBD) specimens made of graphite has been successfully predicted by using the mean stress (MS) and point stress (PS) criteria under mode I loading conditions. 5 Considering the absence of the LPF prediction of the U-notched laminated composite specimens in the literature and also the fact that such a prediction by means of any mentioned failure models is very complex and time-consuming (because they need several material properties, ply-by-ply analysis, and the first-ply-failure (FPF) prediction etc.), a novel concept, called the Virtual Isotropic Material Concept (VIMC), is proposed by which a laminated composite specimen is equated with a virtual isotropic specimen of exactly the same dimensions. The VIMC allows to utilize brittle fracture criteria, which are valid for isotropic materials, to predict LPF of notched laminated composite specimens. To verify the validity of the proposed concept, numerous experiments are carried out on laminated glass/epoxy composite specimens with different numbers of ply and various lay-up configurations weakened by U-notches under pure mode I loading (i.e. the opening mode). It is revealed that VIMC combined with MTS and MS brittle fracture models can predict the experimentally obtained LCCs well, easily, and rapidly. At last, it should be noted that the proposed novel concept permits to engineers predicting failure of laminated composite components weakened by conventional notches (i.e. V and U-notches) without regarding lay-up configurations, fibers, and epoxy-based resins used in fabrication of laminated composite specimens. Also, the engineers always accept warmly the simple ways in which any complicated subroutines have not been used. 2. Experiments 2.1. Material characterization First, for manufacturing the composite plates, an epoxy resin with its hardener, namely Epon 828 and Siclo-Aliphatic-Amin, respectively, and a type of unidirectional Eglass cloth fiber are chosen. The composite plates are fabricated by using the vacuum bagautoclave molding technique including bleeders located on top and bottom surfaces in order 6 to ensure that the processing technique is similar to fabrication of glass fiber reinforced polymer (GFRP) composites, which are widely used in many industries, such as aerospace industries. In this study, three lay-up configurations, namely unidirectional ([0]8 ), cross-ply ([0⁄90 /0⁄90]𝑠 ), and quasi-isotropic ([0 ∕ 90 ∕ ±45]𝑠 ) are considered. The fiber volume fraction of the composite plates is determined to be between 56% and 59% for the three layup configurations. The thickness of each lamina is approximately equal to 0.28 mm and the total thickness of each laminate configuration is about 2.9-3.1 mm for 8 layers. In order to examine if the novel concept proposed in the present contribution is independent of the number of layers, the composite plates of the three different layups with 16 layers and total thickness of 5.6-5.8 mm are also considered in the experiments. Two major parameters, namely the ultimate tensile strength (𝜎𝑢 ) and the trans-laminar fracture toughness (𝐾𝑇𝐿 ), which are necessary for failure prediction by the novel concept, are determined using the standard procedures described in ASTM D3039 [54] and ASTM E1922 [55], respectively. Three standard tests are carried out according to ASTM D3039 [54] to determine the material properties for each lay-up configuration, such as the ultimate tensile strength in the test direction, the ultimate tensile strain, the modulus of elasticity in the test direction, and the Poisson’s ratio. The dimensions of the coupons for various lay-up configurations can be easily realized by referring to ASTM D3039 [54]. The tensile tests are performed using a universal tension-compression testing machine under displacement-control condition at the loading rate of 2 mm/min, as recommended in ASTM D3039 [54] for establishing the ultimate tensile strength (𝜎𝑢 ) of the laminate in the desired loading direction. It should be noted that the novel combined criteria proposed in this research are independent of 𝐸𝑥 , 𝐸𝑦 , 𝜈𝑥 and 𝜈𝑦 , which are the elastic moduli and the Poisson’s ratios in X and Y directions, but solely dependent on 𝜎𝑢 and 𝐾𝑇𝐿 . Hence, there is no need to perform two 7 distinct tensile tests along X and Y directions which are done normally in most of the experimental composite researches. Three fracture tests are performed for each lay-up configuration with the aim to measure the trans-laminar fracture toughness (𝐾𝑇𝐿 ) explained in ASTM E1922 [55]. This code has permitted to have various configurations for test specimens, such as the planar size, the thickness, the single-edge-notch length, and the stacking sequence with eccentric loading conditions, providing that the notch-mouth displacement (NMD) values at maximum load satisfy the criterion ∆𝑉𝑛 𝑉𝑛−0 ≤ 0.3, where 𝑉𝑛−0 = 𝑉𝑛 is the NMD of the initial linear portion of the plot at the maximum load 𝑃 = 𝑃𝑚𝑎𝑥 (see Fig. 1) and ∆𝑉𝑛 is the additional NMD up to the maximum load 𝑃𝑚𝑎𝑥 . The single-edge notches (i.e. the pre-cracks) in the modified compacttension (CT) specimens suggested by ASTM E1922 [55] are introduced by using a diamond wheel cutter with a thickness of 0.3 mm. Note that the maximum allowable size of the precrack mouth based on ASTM E1922 [55] is equal to 0.015W, where W is the specimen width. Considering that W is equal to 50 mm in the present specimens, the limiting value is obtained equal to 0.75 mm and hence, the introduced pre-crack mouth size (i.e. 0.3 mm) is valid. Fig. 1. Typical load versus notch-mouth-displacement plot in ASTM E1922 [55]. The trans-laminar fracture toughness 𝐾𝑇𝐿 is calculated from the maximum load recorded by the tensile testing machine by using the equations established on the basis of the 8 linear elastic stress analysis of the modified single-edge notched specimens. To verify the validity of the trans-laminar tests, the important criterion mentioned in ASTM E1922 [55] is checked and it is found that the trans-laminar tests for all of the lay-up configurations satisfy that criterion. For more clarity, with consideration of the values of the two parameters 𝑉𝑛−0 and ∆𝑉𝑛 equal to 1.8 mm and 0.3 mm, respectively for the quasi-isotropic laminate [0/90/ ±45]𝑠 , it is evident that the ratio ∆𝑉𝑛 / 𝑉𝑛−0 is calculated to be 0.16, which is adequately lower than the limiting value 0.3 (see Fig. 2b). Two samples of the stress–strain and load–notch-mouth-displacement curves obtained from the standard tests according to ASTM D3039 [54] and ASTM E1922 [55], respectively on the laminated composite specimens are represented in Fig. 2. The bulk mechanical properties of each lay-up configuration are also presented in Table 1. 1000 (a) stress (MPa) 800 600 400 200 0 0.000 0.005 0.010 0.015 strain 9 0.020 0.025 ∆𝑉𝑛 =0.3 mm 𝑉𝑛−0 = 1.8 mm 10 𝑃𝑚𝑎𝑥 (b) Load (kN) 8 6 4 2 0 0.0 0.5 1.0 1.5 2.0 2.5 Notch-mouth-displacement (mm) Fig. 2. Stress˗strain and Load˗notch-mouth-displacement curves according to (a): ASTM D-3039 and (b): ASTM E-1922 corresponding to unidirectional ([0]16 ) and quasi-isotropic ([0/90/±45]𝑠 ) laminates. Table 1. Mechanical properties of various lay-up configurations tested. Material property Unidirectional Cross-ply Quasi-isotropic 8-ply 16-ply 8-ply 16-ply 8-ply 16ply Ultimate tensile strength (𝝈𝒖 ) [MPa] 858 876 489 498 425 442 Trans-laminar fracture toughness (𝑲𝑻𝑳 ) [MPa√𝒎] 51.2 47.8 39.2 36.5 42.6 40.2 To check the repeatability of the experiments, three tests are conducted for each layup configuration. Also, to ensure the accuracy and reliability of the experimental results and also, to check the likely dependence of the Virtual Isotropic Material Concept (VIMC) on the laminate thickness, all of the ultimate tensile strength and the trans-laminar fracture toughness tests are repeated for 16-ply laminated specimens. Totally, 36 tests of laminate characterization are performed; 18 tests for 8-ply and 18 for 16-ply specimens. The average values of 𝜎𝑢 and 𝐾𝑇𝐿 are summarized in Table 1 for various lay-up configurations and different ply numbers. As can be seen in Table 1, the values for 8-ply laminates are different from those for 16-ply laminates. The reason for this behavior is discussed in Section 6. The obvious fully linear curve up to the peak point in Fig. 2a and the negligible nonlinear portion in Fig. 2b until the peak point prove that the laminates exhibit brittle 10 manner in the presence and absence of pre-existing defects. Hence, the measured 𝜎𝑢 and 𝐾𝑇𝐿 values are valid and they can be used in various brittle fracture criteria for predicting failure in glass/epoxy laminated composites. In order to compute the value of the trans-laminar fracture toughness 𝐾𝑇𝐿 for each lay-up configuration, the maximum load recorded in the load−notch-mouth-displacement curve (see Fig. 2b) can be substituted into the closed-form expression of the mode I stress intensity factor (SIF) 𝐾𝐼 given by ASTM E1922 [55] and the corresponding critical value can be computed. If the laboratory-scaled pre-cracked specimen geometry does not meet ASTM E1922 exactly, the value of 𝐾𝑇𝐿 can be calculated by directly applying the maximum load to the finite element (FE) model of pre-cracked specimen and computing the mode I SIF under the linear-elastic conditions. 2.2. Fracture testing of glass/epoxy laminates weakened by U-notches The specimen used in this study to perform the fracture tests on U-notched composite laminates is a rectangular plate with a central bean-shaped slit with two U-ends as shown in Fig. 3. The specimen length (L) and width (W) are constant and equal to 160 mm and 50 mm, respectively. The total slit length (i.e. the tip-to-tip distance) 2a is also kept constant and equal to 25 mm. The specimen thickness depends trivially on the number of layers in the laminated composite tested. With the aim to investigate the effects of the notch tip radius 𝜌 on the load-carrying capacity (LCC) of the U-notched specimens, various notch tip radii 𝜌 = 1, 2, 4 𝑚𝑚 are considered in the experiments. Fig. 3 represents the U-notched test specimen with its geometrical parameters schematically. A high-precision water-jet cutting machine is utilized to fabricate the U-notched specimens from the composite plates. To polish the notches as the cut surfaces, brass rods are utilized. These rods are used in a drill press with 25 𝜇𝑚 lapping compound followed by 9 𝜇𝑚 diamond suspension compound that provide smooth and defect-free notches. The parameters 𝜌, 2a, L, W, and P in Fig. 3 are the notch tip 11 radius, twice the notch length (i.e. the total bean-shaped slit length), the specimen length, the specimen width, and the remotely applied tensile load, respectively. Some of the U-notched composite specimens are shown in Fig. 4. As shown in Fig. 4, the bean-shaped slits are cut from the center of the specimens such that the bisector line of the U-ends is perpendicular to the applied load direction. Fig. 3. Schematic of the U-notched rectangular specimen with its geometrical parameters. Fig. 4. Some U-notched rectangular laminated composite specimens with various notch tip radii. The experimentally obtained last-ply-failure (LPF) loads of the U-notched laminated specimens for the three lay-up configurations are summarized in Tables 2-4. Considering the three notch tip radii, three lay-up configurations, repeating each test three times, and two 12 numbers of ply, 54 fracture tests are totally carried out on the U-notched composite specimens. As is evident in the three Tables, the averaged LPF load increases as the notch tip radius increases from 𝜌=1 mm to 𝜌=4 mm, because of the decrease of the stress concentration in the notch tip vicinity. Moreover, it can be seen in Tables 2-4 that for a specific notch tip radius 𝜌, as the number of plies changes from 8 to 16 (i.e. the laminate thickness becomes larger by approximately a factor of 2), the LPF load does not grow by a factor of 2. The reason for this phenomenon is discussed in Section 6. Fig. 5 shows three U-notched laminated specimens with 𝜌=1 mm during loading (a) and 𝜌=2 mm and 𝜌=4 mm after failure (b, c). Two sample load-displacement curves obtained from testing the U-notched glass/epoxy laminated specimens under pure mode I loading conditions are also depicted in Fig. 6. As can be seen in Fig. 6, the load-displacement curves are linear up to the LPF and fracture occurs abruptly. Table 2. The experimentally obtained LCCs of the U-notched laminated specimens for the unidirectional laminates [0]8 and [0]16 . Number of layers 𝝆 (𝒎𝒎) 𝑷𝟏 (𝑵) 𝑷𝟐 (𝑵) 𝑷𝟑 (𝑵) 𝑷𝒂𝒗𝒈 (𝑵) 1 8-ply 21800 22900 26400 23700 2 8-ply 25800 28200 24900 26300 4 8-ply 26500 27100 28600 27400 1 16-ply 41100 38900 45100 41700 2 16-ply 42500 44300 44900 43900 4 16-ply 45100 44800 42700 44200 Table 3. The experimentally obtained LCCs of the U-notched laminated specimens for the quasi-isotropic laminates [0/90/+45/−45/]s and [0/90/+45/−45/]2s . Number of layers 𝝆 (𝒎𝒎) 𝑷𝟏 (𝑵) 𝑷𝟐 (𝑵) 𝑷𝟑 (𝑵) 𝑷𝒂𝒗𝒈 (𝑵) 1 8-ply 12600 13800 16500 14300 2 8-ply 15700 17300 17700 16900 4 8-ply 16800 17900 17300 17200 1 16-ply 25900 27300 27200 26800 2 16-ply 28800 28400 30100 29100 4 16-ply 29100 29500 30950 29850 13 Table 4. The experimentally obtained LCCs of the U-notched laminated specimens for the cross-ply laminates [0/90/0/90]s and [0/90/0/90]2s . Number of layers 𝝆 (𝒎𝒎) 𝑷𝟏 (𝑵) 𝑷𝟐 (𝑵) 𝑷𝟑 (𝑵) 𝑷𝒂𝒗𝒈 (𝑵) 1 8-ply 15800 16100 17600 16500 2 8-ply 18900 19300 16700 18300 4 8-ply 19400 19000 18300 18900 1 16-ply 25800 26900 26800 26500 2 16-ply 29700 31200 31800 29800 4 16-ply 30400 31200 29900 30900 (a) 𝜌 = 1 𝑚𝑚 (b) 𝜌 = 2 𝑚𝑚 (c) 𝜌 = 4 𝑚𝑚 Fig. 5. The U-notched laminated specimens; (a) during loading and (b, c) after failure. 50 Load (kN) 40 30 20 10 0 0.0 0.5 1.0 1.5 Displacement (mm) (a) 14 2.0 2.5 50 Load (kN) 40 30 20 10 0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Displacement (mm) (b) Fig. 6. The load-displacement curves for 16-ply unidirectional laminated composite specimens; (a) 𝜌 = 1 𝑚𝑚 and (b) 𝜌 = 4 𝑚𝑚. In Section 6, a full discussion is provided regarding the experimental observations on failure of U-notched composite specimens (see for instance Fig. 5 (b, c)). Moreover, some pictures captured from the damage zone near the notch tip by means of the scanning electron microscope (SEM) are presented and discussed. 3. The Virtual Isotropic Material Concept As widely reported in literature and with paying a careful attention to the overall behavior of the tested U-notched composite specimens, the linearity of the load-displacement curves is confirmed. This important manner is a basis to develop a novel concept, called the Virtual Isotropic Material Concept (VIMC). In this new concept, an equivalent brittle material, which is a virtual isotropic material, is defined and employed for simulating the bulk behavior of the tested laminated composites. This means that the real laminated composite material having generally orthotropic behavior is equated with a virtual brittle material having isotropic behavior for predicting the last-ply-failure (LPF) load of the Unotched laminated composite specimens by means of using directly the linear elastic notch fracture mechanics (LENFM) principles. It is noteworthy that the VIMC does not require 15 performing experiments for measuring the longitudinal (𝐸𝑥 ), lateral (𝐸𝑦 ) and shear (𝐺𝑥𝑦 ) moduli, consuming time and cost. Only, two important characteristics of the composite laminate, namely the ultimate tensile strength (𝜎𝑢 ) and the trans-laminar fracture toughness (𝐾𝑇𝐿 ), are essential in VIMC. As mentioned before, 𝜎𝑢 and 𝐾𝑇𝐿 can be obtained from two distinct tests according to ASTM D3039 [54] and ASTM E1922 [55], respectively. Fig. 7 represents the VIMC schematically. As seen in Fig. 7, a laminated composite material with orthotropic behavior having several material parameters, e.g. 𝐸𝑥 , 𝐸𝑦 , 𝐺𝑥𝑦 , 𝜈𝑥𝑦 , 𝐾𝑇𝐿 , 𝜎𝑓 (fracture stress) etc., is equated with a virtual material with isotropic behavior having the elastic modulus E equal to 𝐸𝑥 or 𝐸𝑦 , depending on the direction of loading on the composite laminate, the fracture toughness 𝐾𝐼𝐶 or 𝐾𝐶 , and the ultimate tensile strength 𝜎𝑢 . It has been well established in literature that in all of brittle fracture criteria in the context of LENFM, 𝜎𝑢 and 𝐾𝐼𝐶 are the two significant material properties for failure prediction of notched components. ≅ (a) Orthotropic laminated composite with (b) 𝐸𝑥 , 𝐸𝑦 , 𝐺𝑥𝑦 , 𝜈𝑥𝑦 ,𝐾𝑇𝐿 , 𝜎𝑓 etc. Linear elastic isotropic brittle material with E, 𝜈, 𝐾𝐼𝐶 (𝑜𝑟 𝐾𝐶 ) , 𝜎𝑢 Fig. 7. The Virtual Isotropic Material Concept (VIMC) schematically. Now, the U-notched laminated composite specimens tested in Section 2 are virtually considered as the isotropic homogeneous specimens with exactly the same geometries, 16 making it possible to avoid the first-ply-failure (FPF) analysis and the progressive damage modeling (PDM) for the LPF prediction and instead, to predict the LPF directly and simply by linking VIMC to LENFM criteria. It should be necessary to note that approximately all of the presented failure or damage models for predicting the strength of the laminated composite specimens have utilized layer-by-layer analyses so far. But this new concept does not need to perform conventional procedures for prediction of strength of laminated composite specimens especially containing stress raisers. The first significant parameter, i.e. the ultimate tensile strength, is normally defined for both isotropic and orthotropic materials as a material property or an inherent property with the difference that this parameter for orthotropic materials is dependent on the applied load direction. So, for correct prediction of LPF of U-notched laminated specimens, the direction along which the tensile strength of un-notched laminate is measured should be perpendicular to the notch bisector line in the U-notched laminate. Moreover, by introducing the pre-crack in the composite laminate along a direction the same as the direction of the Unotch bisector line, the trans-laminar fracture toughness (𝐾𝑇𝐿 ) obtained from ASTM E1922 [55] can be utilized instead of the fracture toughness (𝐾𝐼𝐶 ) in LENFM brittle fracture criteria. It should be noted that the fracture mechanics related failure modes in laminated composites are delamination, intra-laminar fracture, and trans-laminar fracture. Delamination and intra-laminar fracture have been under extensive investigations for several years [56-63]. In spite of the fact that the importance of trans-laminar fracture toughness measurement was recognized many years ago, it has received relatively little attention from the scientific community until now. Laffan [64] has stated that this little attention is at least partially due to a lack of confidence in composites, resulting in them not being used in primary structures. The latest failure mode corresponding to the ultimate tensile strength in laminated composites is the fiber breakage; thus, conducting the trans-laminar fracture toughness test for measuring 17 the capacity of the laminated composite weakened by a crack to withstand against breakage is necessary. In next section, two well-known brittle fracture criteria in the context of LENFM, namely the maximum tangential stress (MTS) and mean stress (MS) criteria, are briefly described and linked to VIMC to form two novel combined criteria to predict the experimentally obtained LCCs of the U-notched laminated composite specimens reported in Tables 2-4. 4. Brittle fracture criteria 4.1. Maximum tangential stress criterion The maximum tangential stress (MTS) criterion is a well-known brittle fracture criterion originally developed by Erdogan and Sih [47] for estimating mixed mode I/II failure of cracked members. This criterion has been extended to U-notched domains by Ayatollahi and Torabi in 2009 [48] and its effectiveness has been well demonstrated. According to Unotch MTS (U-MTS) criterion, brittle fracture occurs in a U-notched component under pure mode I loading, when the value of tangential stress at a specified critical distance 𝑟𝑐 ahead of the notch tip attains the material critical stress 𝜎𝑐 . The first expression for 𝑟𝑐 has been proposed by Ritchie et al. [65] as follows 𝑟𝑐 = 1 𝐾𝐼𝑐 2 ( ) 2𝜋 𝜎𝑐 (1) where 𝐾𝐼𝑐 is the plain-strain fracture toughness of material. The critical stress 𝜎𝑐 has also been known in literature as the inherent strength 𝜎0 , proposed by Taylor [66]. It has been stated in [66] that for most of brittle materials, 𝜎0 can be considered equal to the ultimate tensile strength 𝜎𝑢 and for some materials like polymers, it can be larger than 𝜎𝑢 , even several times. 18 4.2. Mean stress criterion The U-notch mean stress (UMS) criterion suggests that brittle fracture occurs under mode I loading, when the average value of tangential stress over a particular critical distance 𝑑𝑐 ahead of the notch tip reaches 𝜎𝑐 [40]. The critical distance has been originally suggested by Seweryn [67] which has been frequently used by many researchers to predict brittle failure in notched members. The 𝑑𝑐 expression is [67] 𝑑𝑐 = 2 𝐾𝐼𝑐 2 ( ) 𝜋 𝜎𝑐 (2) Comparing Eqs. 1 and 2, it is evident that 𝑑𝑐 is four times 𝑟𝑐 . In order to employ UMTS and UMS criteria for predicting LCC of the U-notched laminated composite specimens (i.e. the LPF prediction), they should be combined with the VIMC. Hence, the VIMC-MTS and VIMC-MS combined criteria are utilized in forthcoming sections for predicting the experimentally obtained LCCs. The most important point is that the critical distances 𝑟𝑐 and 𝑑𝑐 are equal to 𝑟𝑐 = 1 2𝜋 ( 𝜎𝑇𝐿 )2 𝐾 𝑑𝑐 = 2 𝜋 ( 𝜎𝑇𝐿 )2 𝑢 𝐾 𝑢 for VIMC-MTS (3) for VIMC-MS (4) where 𝐾𝑇𝐿 and 𝜎𝑢 are the trans-laminar fracture toughness and the ultimate tensile strength of the laminated composite material. The values of 𝑟𝑐 and 𝑑𝑐 for different lay-up configurations tested are presented in Table 5. These values are simply calculated by using the data provided in Table 1. 19 Table 5. The values of the critical distances 𝑟𝑐 and 𝑑𝑐 for various lay-up configurations. Unidirectional Critical distances Cross-ply Quasi-isotropic 8-ply 16-ply 8-ply 16-ply 8-ply 16-ply 𝒓𝒄 (𝒎𝒎) 0.5 0.4 1 0.8 1.5 1.3 𝒅𝒄 (𝒎𝒎) 2 1.6 4 3.2 6 5.2 At the first glance, the presented new equations have been utilized in the past for similar brittle criterions whereas the new developed equations for critical distances have been modified by appropriate parameters which have more influence in strength prediction correctly. In next section, the finite element (FE) analysis is performed and the failure concepts of the VIMC-MTS and VIMC-MS criteria are directly applied to the stress distributions resulted from the FE analysis for predicting the LPF of the U-notched composite specimens. 5. Finite element analysis In order to implement the VIMC-MS and VIMC-MTS criteria for LPF prediction of U-notched composite specimens, two-dimensional (2D) finite element (FE) models of the Unotched specimens are created and analyzed under pure mode I loading conditions. It is necessary to note that one of the advantages of VIMC is the independency of the LPF prediction from the layer-by-layer modeling and failure analysis of the notched laminated composite. Hence, the FE models are considered to be virtually made of the isotropic material. The analyses are performed under the plane-stress assumption due to small thickness of the specimens compared to the length and width of them. The specimens are simulated and meshed in the well-known commercial FE software ABAQUS 6.14. Moreover, the models are meshed with the eight-node plane-stress quadratic elements. In Fig. 8a, a structured mesh pattern produced with careful partitioning for the whole model is shown. 20 Also, as seen in Fig. 8 (b, c), refined meshes with the minimum size of about 0.006 mm are used at the notch neighborhood due to the high level of stress gradient. About 118074 elements are totally utilized in each FE model. As mentioned in Section 4, the tangential stress distribution on the notch bisector line is needed for LCC prediction, which can be obtained directly from the FE analysis. Now, the critical loads of the U-notched laminated composite specimens can be theoretically predicted by using the VIMC-MTS and VIMC-MS criteria. For this purpose, first, an arbitrary load equal to 2000 N is applied to the FE model and the tangential stress distribution on the notch bisector line is obtained. Now, the value of tangential stress at the critical distance 𝑟𝑐 reported in Table 5 (called 𝜎𝜃𝜃 ) is computed. According to VIMC-MTS criterion, fracture occurs when the tangential stress at 𝑟𝑐 attains the ultimate tensile strength of the un-notched laminated composite 𝜎𝑢 reported in Table 1. Therefore, because of the linearity of the analyses, the fracture load predicted by VIMC-MTS criterion can be easily given as 𝑃𝑉𝐼𝑀𝐶−𝑀𝑇𝑆 = 𝜎𝑢 ∗ 2000 𝑁 𝜎𝜃𝜃 (5) The procedure of LCC prediction for the U-notched composite specimens in accordance with VIMC-MS criterion is the same as that described above for VIMC-MTS criterion with the main difference that, the average of the tangential stresses over the specified critical distance 𝑑𝑐 (called ̅̅̅̅̅) 𝜎𝜃𝜃 should reach the ultimate tensile strength of the laminate (𝜎𝑢 ). Therefore, LPF load of the U-notched composite samples can be predicted by VIMC-MS criterion as 𝑃𝑉𝐼𝑀𝐶−𝑀𝑆 = 𝜎𝑢 ∗ 2000 𝑁 𝜎𝜃𝜃 ̅̅̅̅̅ (6) The failure concepts of VIMC-MTS and VIMC-MS criteria are schematically represented in Fig. 9. Additionally, the distribution of the tangential stress contours in the vicinity of Unotches in the tested specimens with 3 mm thickness is depicted in Fig. 10 for a constant 21 tensile load equal to 20 kN for two different notch tip radii. The butterfly wing shape in Fig. 10a is quiet symmetric, showing that the U-notched specimen is under pure mode I loading. (b) (a) (c) Fig. 8. A sample mesh pattern for the tested U-notched specimens; (a) the whole specimen, (b) the vicinity of notch border, and (c) very close to the notch round border. 𝒓𝒄 A B C (a) VIMC-MTS concept 𝒅𝒄 A B D (b) VIMC-MS concept Fig. 9. The failure concepts of VIMC-MTS (a) and VIMC-MS (b) criteria. The points A and B denote the center of curvature of notch and the notch tip, respectively. The point C specifies the point at which the tangential stress is monitored. The line BD is also the distance over which the tangential stress is monitored. 22 (a) (b) Fig. 10. Contours of the tangential stress in the vicinity U-notches in the tested specimens with 3 mm thickness for a load equal to 20 kN; (a) 𝜌 = 1 𝑚𝑚 and (b) 𝜌 = 2 𝑚𝑚. 6. Results and discussion The variations of the last-ply-failure (LPF) load of the U-notched laminated specimens versus the notch tip radius are presented in Figs. 11-16 for the three lay-up configurations and two numbers of ply. The discrepancies between the experimental and theoretical results for 8-ply and 16-ply specimens are also presented in Tables 6 and 7, respectively. It is obvious from Figs. 11-16 and Tables 6 and 7 that both VIMC-MTS and VIMC-MS criteria can successfully predict the experimentally obtained LCCs of the Unotched laminated composite specimens under pure mode I loading conditions. Considering all the notch tip radii, the lay-up configurations, and the numbers of ply, the average discrepancies of VIMC-MTS and VIMC-MS criteria are obtained equal to approximately 8.7% and 9.8%, respectively, indicating that both criteria are generally 23 successful in predicting LCCs of the U-notched glass/epoxy composite laminates tested. Since the predictions by the new concept are good for various lay-up configurations and different numbers of ply, it seems that the two combined criteria based on the LENFM are independent of the glass/epoxy laminate properties. Remembering that the LPF prediction in notched laminated composites by the existing models, like the progressive damage models, are very complicated, time-consuming, and not user-friendly, the easy, fast, and user-friendly aspects of VIMC-MTS and VIMC-MS criteria shine. Table 6. The discrepancies between the theoretical and experimental results for the U-notched 8-ply laminated composite specimens. Discrepancy for VIMC-MTS criterion (%) Discrepancy for VIMC-MS criterion (%) 𝝆 (𝒎𝒎) Unidirectional Cross-ply Quasi-isotropic Unidirectional Cross-ply Quasi-isotropic 1 9.1 11.4 13.5 10.2 12.3 14.7 2 8.9 9.8 12.4 7.6 9.8 13.2 4 7.3 8.4 6.9 8.6 9.2 10.6 Table 7. The discrepancies between the theoretical and experimental results for the U-notched 16-ply laminated composite specimens. Discrepancy for VIMC-MTS criterion (%) Discrepancy for VIMC-MS criterion (%) 𝝆 (𝒎𝒎) Unidirectional Cross-ply Quasi-isotropic Unidirectional Cross-ply Quasi-isotropic 1 8.5 8.8 9.7 9.3 7.2 12.4 2 6.7 4.3 10.3 9.1 6.8 11.3 4 5.1 6.7 7.6 7.4 6.3 8.6 24 Last-ply-failure load (kN) 40 30 20 10 VIMC-MTS criterion VIMC-MS criterion Experiments 0 0 1 2 3 4 5 Notch tip radius (mm) Fig. 11. Variations of the last-ply-failure (LPF) load of the U-notched 8-ply unidirectional laminated specimen versus the notch tip radius for the two combined criteria and the experimental data. Last-ply-failure load (kN) 30 25 20 15 10 VIMC-MTS criterion VIMC-MS criterion Experiments 5 0 0 1 2 3 4 5 Notch tip radius (mm) Fig. 12. Variations of the last-ply-failure (LPF) load of the U-notched 8-ply quasi-isotropic laminated specimen versus the notch tip radius for the two combined criteria and the experimental data. 25 Last-ply-failure load (kN) 25 20 15 10 VIMC-MTS criterion VIMC-MS criterion Experiments 5 0 0 1 2 3 4 5 Notch tip radius (mm) Fig. 13. Variations of the last-ply-failure (LPF) load of the U-notched 8-ply cross-ply laminated specimen versus the notch tip radius for the two combined criteria and the experimental data. Last-ply-failure load (kN) 60 50 40 30 20 VIMC-MTS criterion VIMC-MS criterion Experiments 10 0 0 1 2 3 4 5 Notch tip radius (mm) Fig. 14. Variations of the last-ply-failure load (LPF) of the U-notched 16-ply unidirectional laminated specimen versus the notch tip radius for the two combined criteria and the experimental data. 26 Last-ply-failure load (kN) 50 40 30 20 VIMC-MTS criterion VIMC-MS criterion Experiments 10 0 0 1 2 3 4 5 Notch tip radius (mm) Fig. 15. Variations of the last-ply-failure load (LPF) of the U-notched 16-ply cross-ply laminated specimen versus the notch Last-ply-failure load (kN) tip radius for the two combined criteria and the experimental data. 40 30 20 10 VIMC-MTS criterion VIMC-MS criterion Experiments 0 0 1 2 3 4 5 Notch tip radius (mm) Fig. 16. Variations of the last-ply-failure load (LPF) of the U-notched 16-ply quasi-isotropic laminated specimen versus the notch tip radius for the two combined criteria and the experimental data. It is obvious from Tables 6 and 7 that in both quasi-isotropic laminated composite members fabricated with 8-ply and 16-ply, the average discrepancies are more than other layup configurations. One of the main important reasons is maybe that the quasi-isotropic laminated composite specimens have various fiber directions encountering U-notch border. 27 This variety causes that the portion of maximum tangential stress to be distributed along ±45° fiber directions. Since the global approach of novel concept (VIMC) is equality at the macroscopic level and also the presented lay-up configurations are symmetric, the maximum tangential stresses taken from FE analyses are synchronized with desired critical distances. Another important point is that the discrepancies of 8-ply in all of lay-up configurations are obviously more than 16-ply ones. As the engineers know, many researches have been done about size and scale effects of experimental specimens on theoretical predictions. The investigators try to reach a comprehensive approach about independency of presented criteria from size and scale of tested components either orthotropic or isotropic materials. The almost all of the comparisons between experimental and theoretical observations have shown that the important source of errors is related to the various thicknesses of the test specimens. As the thickness of test specimens increases the discrepancies between theoretical and experimental criteria would be decreased. This fact has been proved in this paper correctly. Although, different limiting values exist for various materials beyond which the increase of thickness does not influence on final results. Although the prediction of the LPF load of the U-notched laminated composite specimens is the important aim of this study at the macroscopic level, the microscopic investigation of the damage zone at the notch neighborhood is essential to better recognize the failure modes. To this end, several micrographs are taken from the damage zone by means of the scanning electron microscope (SEM) and interpreted. Visual observations during the fracture tests are also reported and discussed. As previously mentioned, the three fracture mechanics related modes of failure in laminated composites are delamination, intra-laminar fracture, and trans-laminar fracture. According to [68] in which the techniques for measuring the trans-laminar fracture toughness 28 experimentally associated with trans-laminar (fiber-breaking) failure modes of laminated composites have been reviewed, the critical damages due to trans-laminar fracture tests are the fiber-matrix damages and consequently, the fiber pull out or fiber breakage. The fibermatrix damages can occur longitudinally or transversely depending on the position of the initial crack or cracks. Also, Liu et al. [68] have stated that in the presence of notches in laminated composites, the conventional damages in un-notched laminated composites such as the longitudinal cracks (splits) and free-edge delaminations change to the notch-induced splits (NISs) and the notch-induced delaminations (NIDs). Moreover, they have stated that the global damages are localized due to the notch presence in laminates and the subcritical damage states depend on the type of lay-up configuration and the notch size. With this prelude, according to Fig. 17, the small damages are localized at the periphery of the U-notch and the clear differences in the shape of bulk damage between the three lay-up configurations are seen. As can be seen in Fig. 17, two vertical lines form in the vicinity of the U-notch round border in both sides of the central bean-shaped slit for all of the three lay-up configurations. However, this phenomenon in the unidirectional and cross-ply laminates is more visible than that in the quasi-isotropic laminate. In the quasi-isotropic laminates, the lines are oblique as depicted in Fig. 17b. As shown in Fig. 17, the initial longitudinal crack is observed in the notch tip vicinity without exception in the lay-up configuration and consequently, the damage zone propagates across the width of specimens (i.e. the horizontal axis). Because of the pure mode I loading conditions, as expected, the first micro-cracks or splits initiate at 𝜃 = 5° − 10° (𝜃 = 0° specifies the notch bisector line) as represented in Fig.17. The meaning of the initial longitudinal crack is the matrix-cracking propagation along the fiber due to resin brittleness which occurs suddenly after the first fiber breakage. If the test continues, considering that the last-ply-failure (LPF) corresponds to failure of 0° ply aligned with the loading direction, another longitudinal crack propagation 29 smaller than the initial one forms in matrix in the first step after the maximum load record. It should be explained that during the fracture test, the monotonic load increases until it suddenly drops from the peak to a significantly lower load, via a loud sound relating to the fiber breakage. After the fiber breakage, micro-cracks or notch-induced splits (NISs) bond together and propagate vertically between fiber/matrix bonding. It should be noted that the NIS and notch-induced delamination (NID) are two kinds of damage previously introduced by Liu et al. [68] for notched laminated composite specimens, especially for notched crossply laminates. The NID is significantly visible at the notch neighborhood for unidirectional and cross-ply laminates, while the NIS for quasi-isotropic laminates. These failure evidences with their locations in the tested U-notched composite specimens are depicted in Fig. 17. Vertical line Notch induced splits Oblique line Notch induced delamination Fiber Notch induced splits breakage Notch induced delamination (a) (b) Vertical line Notch induced delamination (c) Fig. 17. The close view of damage zone near the notch tip for the three lay-up configurations tested; (a) unidirectional, (b) quasi-isotropic, and (c) cross-ply laminates. 30 Now, for more clarity, two SEM photographs taken in different scales from the damage zone of the composite specimens tested are depicted in Fig. 18. According to Fig. 18a, the U-notched laminated specimen is broken like a bamboo. The notch domain is divided into several strips, for which the locations of the fracture surface are different. Under such a situation, the strips are broken at their weak portions, leading to different locations of the fracture surface of the strips. The primary damages in the notched laminated composites are located at the periphery of the notch blunt border and constricted in a small zone. On the other hand, if the damage zone ahead of the notch tip in laminated composites is not large with respect to the ligament size, the fracture mechanics criteria can be applied for LPF prediction. As can be seen in Fig. 18a for the unidirectional laminate, the individual shapes of bamboo have many fibers bundle that some of which indicate the fiber pull-out mode arising from the weak fiber/matrix interface and subsequently, interfacial de-bonding would happen. Generally, in laminated composites with brittle fiber and matrix, three various failure modes, namely the matrix cracking, the shear crack initiation, and the fiber breakage are seen in most of experimental investigations. As seen in Fig. 18b for the cross-ply laminate, the longitudinal matrix cracking is resulted from the coupling of splitting and micro-cracks in 90° ply failure and subsequently in 0° ply failure. It is also seen in Fig. 18b that the two fibers of the 90° ply located at the left of the picture are pulled out and then broken. Fiber pull out Fiber pull out Bamboo effects Bamboo effects (a) Unidirectional laminate 31 Fibers pull out Matrix cracking (b) Cross-ply laminate Fig. 18. Two SEM photographs taken from the damage zone of the U-notched laminated specimens; (a) unidirectional laminate and (b) cross-ply laminate. As mentioned in subsection 2.1, the values of the ultimate tensile strength 𝜎𝑢 and the trans-laminar fracture toughness 𝐾𝑇𝐿 for 8-ply laminates are different from those for 16-ply laminates. Regarding 𝜎𝑢 , it is seen in Table 1 that for all the three lay-up configurations, the discrepancy between the values for 8-ply and 16-ply laminates is approximately equal to 1.5 %, which is quite acceptable compared to usual error bands defined for similar experiments. This discrepancy could be due to the small difference in specimen width and thickness, and also due to natural errors that happen during the experiments (e.g. human errors, machine errors etc.). Dealing with 𝐾𝑇𝐿 , however, considerable differences are seen between the values for 8-ply and 16-ply laminates which may not be attributed to natural testing errors. It has been reported in ASTM E399 [69] for metallic materials that the thickness-independent plane-strain fracture toughness of material (𝐾𝐼𝑐 ) can be obtained from the standard test 𝐾 method if the pre-cracked specimen thickness becomes larger than 2.5( 𝜎𝐼𝑐)2 where 𝜎𝑦 is the 𝑦 yield strength of material. Analogous to metallic materials, a critical thickness has also been proposed in some papers published in literature [70, 71] beyond which the trans-laminar fracture toughness of material (𝐾𝑇𝐿 ) is independent of thickness. This means that as the laminate thickness increases, the value of 𝐾𝑇𝐿 obtained from the test decreases until the thickness reaches the critical thickness. In [70], for graphite/epoxy laminates, it has been 32 reported that 𝐾𝑇𝐿 value does not change when the number of plies is greater than 64. Similar statements have also been reported in other references, e.g. [72]. Considering 64 as a critical ply number, in the present glass/epoxy composite laminates, it means a laminate with approximately 20 mm thickness. Noting that the thicknesses of both 8-ply and 16-ply laminates tested in the present study are significantly below 20 mm, it is expected that the values of 𝐾𝑇𝐿 for 8-ply laminates become larger than those for 16-ply laminates, as truly obtained and presented in Table 1. It was mentioned in subsection 2.2 that for U-notched laminated composite specimens, the value of the LPF load does not grow by a factor of 2, as the specimen changes from 8-ply to 16-ply. It should be noted that the failure behaviors of notched and un-notched specimens are fundamentally different. In an un-notched rectangular tensile test specimen, the whole cross-sectional area participates in load-carrying process and failure usually happens uniformly over the cross-section. For such a specimen, it is truly expected that by increasing the specimen thickness by a factor of 2, the failure load also increases by the same factor. However, in a notched rectangular specimen, the stress is concentrated in the notch vicinity and only a specific part of the cross-sectional area, called the fracture process zone (FPZ), participates in load-carrying process and hence in the failure of the notched specimen. As explained in the paragraph above, the fracture phenomenon in pre-cracked laminated composite specimens is significantly dependent on the laminate thickness. On the other hand, the fracture behaviors of cracked and notched laminates are very similar and the only difference is the level of stress concentration and hence, the size of the FPZ. As a consequence, the notch fracture toughness (NFT) is also dependent on the laminate thickness. For the U-notched composite specimens tested, by increasing the specimen thickness (i.e. changing 8-ply to 16-ply) the FPZ size decreases, meaning that lower amount of energy is absorbed by the notched laminate until LPF. Obviously, this means that the U-notched 16-ply 33 laminate fails at an ultimate tensile load considerably lower than twice the failure load of the 8-ply laminate weakened by the same notch. 7. Conclusions The U-notched laminated glass/epoxy composite specimens with three various notch tip radii, three types of lay-up configuration, and two numbers of ply were fabricated and tested for failure under pure mode I loading conditions, and the last-ply-failure (LPF) loads were experimentally recorded. With the aim to avoid using complex, time-consuming, and not user-friendly models of LPF load prediction, e.g. the progressive damage models that need ply-by-ply failure analysis, a novel concept, called the Virtual Isotropic Material Concept (VIMC) was proposed and combined with two brittle fracture criteria, namely the maximum tangential stress (MTS) and mean stress (MS) criteria for predicting the experimentally obtained LPF loads. It was demonstrated that both VIMC-MTS and VIMCMS criteria could estimate the experimental results well. In general, the VIMC-MS criterion could predict the experimental results a bit better than the VIMC-MTS criterion, but no meaningful difference was seen between the accuracies of the two criteria. By using the scanning electron microscope (SEM) micrographs and some close-up pictures taken from the periphery of the damaged U-notches, the major failure modes were specified. As expected, the matrix cracking mode due to shear and transverse stresses concentration and subsequently the fiber breakage mode occurred. By using the VIMC-MTS and the VIMC-MS criteria, one can accurately predict the LPF load of Unotched laminated glass/epoxy composites under pure mode I loading conditions with using only two distinct laminate parameters, namely the trans-laminar fracture toughness and the ultimate tensile strength. 34 References [1] Beaumont P. The failure of fiber composites: An overview. J Strain Anal 1989;24:189– 205. [2] Waddoups ME, Eisenman JR, Kaminski BE. Macroscopic fracture mechanics of advanced composite materials. J Compos Mater 1971;5:446–451. [3] Backlund J, Aronsson CG. Tensile Fracture of Laminates with Holes and Cracks. J Compos Mater 1986;20:259–285. [4] Aronsson CG, Backlund J. Tensile fracture of laminates with cracks. J Compos Mater 1986;20:287–307. [5] Eriksson I, Aronsson CG. Strength of tensile loaded graphite/epoxy laminates containing cracks, open and filled holes. J Compos Mater 1990;24:456–482. [6] Whitney J, Nuismer R. Stress fracture criteria for laminated composites containing stress concentration. J Compos Mater 1974;8:253–265. [7] Tan SC. Notched strength prediction and design of laminated composites under in-plane loadings. J Compos Mater 1987;21:925–948. [8] Tan SC. Laminated composites containing an elliptical opening-II. experiment and model modification. J Compos Mater 1987;21:949–968. [9] Tan SC. Effective stress fracture models for un-notched and notched multidirectional laminates. J Compos Mater 1988;22:322–340. [10] Tan SC. Finite width correction factors for anisotropic plate containing a central opening. J Compos Mater 1988;22:1080–1097. [11] Tan SC. and Nuismer, R.J. A theory for progressive matrix cracking in composite laminates. J Compos Mater 1989;23:1029–47. [12] Lagace PA. Notch sensitivity of graphite/epoxy fabric laminates. Compos Sci Tech 1986;26:95–117. [13] Mar JW, Lin KY. Fracture mechanics correlation for tensile failure of filamentary composites with holes. J Aircraft 1977;14:703–704. 35 [14] Mar JW, Lin KY. Fracture of boron/aluminum composites with discontinuities. J Compos Mater 1977;11:405–421. [15] Nuismer RJ, Labor JD. Applications of the average stress failure criterion: Part I– Tension. J Compos Mater 1978;12:238–249. [16] Pipes RB, Wetherhold RC, Gillespie JW. Macroscopic fracture of fibrous composites. Mater Sci Eng 1980;45:247–253. [17] Kim JK, Kim DS, Takeda N. Notched strength and effective crack growth in woven fabric laminates. J Compos Mater 1995;29:982–998. [18] Yeow YT, Morris DH, Brinson HF. A correlative study between analysis and experiment on the fracture behavior of graphite/epoxy composites. J Test Evaluation 1979;7:117–125. [19] Naik NK, Shembekar PS. Elastic behavior of woven fabric composites: I-lamina analysis. J Compos Mater 1992;26:2196–2225. [20] Tan SC. A progressive failure model for composite laminates containing openings. J Compos Mater 1991;25:536–577. [21] Chang FK, Chang KY. A progressive damage model for laminated composite containing stress concentration. J Compos Mater 1987;21:834–855. [22] Chang KY, Sheng L, Chang FK. Damage tolerance of laminated composites containing an open hole and subjected to tensile loading. J Compos Mater 1991;25:274–301. [23] Nguyen BN. Three-dimensional modeling of damage in laminated composites containing a central hole. J Compos Mater 1997;31:1672–1693. [24] Lawcock G, Ye L, Mai YW. Progressive damage and residual strength of a carbon fiber reinforced metal laminate. J Compos Mater 1997;31:762–787. [25] Coats TW, Harris CE. A progressive damage methodology for residual strength predictions of notched composite panels. J Compos Mater 1999;33:2193–2224. [26] Erikson I, Aronsson CG. Strength of tensile loaded graphite/epoxy laminates containing cracks, open and filled holes. J Compos Mater 1990;24:456–82. [27] Afaghi-Khatibi A, Ye L, Mai YW. An effective crack growth model for residual strength evaluation of composite laminates with circular holes. J Compos Mater 1996;30:142– 163. [28] Afaghi-Khatibi A, Ye L, Mai YW. Effective crack growth and residual strength of composite laminates with a sharp notch. J Compos Mater 1996;30:333–357. [29] Afaghi-Khatibi A, Ye L. Residual strength simulation of fiber reinforced metal laminates containing a circular hole. J Compos Mater 1997;31:1884–1904. 36 [30] Ladeveze P. A damage computational method for composite structures. Comput Struct 1992;44:79–87. [31] Mohammadi B, Hosseini-Toudeshky H, Sadr-Lahidjani MH. Damage evolution of laminated composites using continuum damage mechanics incorporate with interface element. Key Eng Mater 2008;385:277–280. [32] Mohammadi B, Hosseini-Toudeshky H, Sadr-Lahidjani MH, Aivazzadeh S. Prediction of inelastic behavior of composite laminates using multi-surface continuum damageplasticity. Adv Mater Res 2008;47:773–776. [33] Mohammadi B, Kazemi A, Ghasemi R. (In Persian) [34] Gómez FJ, Elices M, Valiente A. Cracking in PMMA containing U‐shaped notches. Fatigue Fract Eng Mater Struct 2000;23:795–803. [35] Gómez FJ, Elices M. A fracture criterion for sharp V-notched samples. Int J Fract 2003;123:163–75. [36] Gómez FJ, Elices M. and Planas, J. The cohesive crack concept: application to PMMA at -60° C. Eng Fract Mech 2005;72:1268–85. [37] Yosibash Z, Bussiba A, Gilad I. Failure criteria for brittle elastic materials. Int J Fract 2004;125:307–33. [38] Barati E, Aghazadeh Mohandesi J, Alizadeh Y. The effect of notch depth on J-integral and critical fracture load in plates made of functionally graded aluminum–silicone carbide composite with U-notches under bending. Mater Des 2010;31:4686–4692. [39] Barati E, Alizadeh Y, Aghazadeh J, Berto F. Some new practical equations for rapid calculation of J-integral in plates weakened by U-notches under bending. Mater Des 2010;31:2964–71. [40] Ayatollahi MR, Torabi AR. Brittle fracture in rounded-tip V-shaped notches. Mater Des 2010;31:60-67. [41] Matvienko YG, Morozov EM. Calculation of the energy J-integral for bodies with notches and cracks. Int J Fract 2004;125:249–61. [42] Gomez FJ, Guinea GV, Elices M. Failure criteria for linear elastic materials with Unotches. Int J Fract 2006;141:95–109. [43] Berto F, Barati E. Fracture assessment of U-notches under three point bending by means of local energy density. Mater Design 2011;32:822–830. [44] Berto F, Lazzarin P. A review of the volume-based strain energy density approach applied to V-notches and welded structures. Theor Appl Fract Mech 2009;52:183–194. 37 [45] Berto F, Lazzarin P, Gomez FJ, Elices M. Fracture assessment of U-notches under mixed mode loading: two procedures based on the equivalent local mode I concept. Int J Fract 2007;148:415–433. [46] Berto F, Lazzarin P, Ayatollahi MR. Brittle fracture of sharp and blunt V-notches in isostatic graphite under torsion loading. Carbon 2012;50:1942–1952. [47] Erdogan F, Sih G. On the crack extension in plates under plane loading and transverse shear. J Basic Eng Trans 1963;85:528–534. [48] Ayatollahi MR, Torabi AR. A criterion for brittle fracture in U-notched components under mixed-mode loading. Eng Fract Mech 2009;76:1883–1896. [49] Seweryn A, Lukaszewicz A. Verification of brittle fracture criteria for elements with Vshaped notches. Eng Fract Mech 2002;69:1487–1510. [50] Torabi AR. Fracture assessment of U-notched graphite plates under tension. Int J Fract 2013;81:285–292. [51] Berto F, Lazzarin P, Elices M, Zappalorto M. Fracture behavior of notched round bars made of PMMA subjected to torsion at room temperature. Eng Fract Mech 2012;90:143–160. [52] Torabi A.R. Ultimate bending strength evaluation of U-notched ductile steel samples under large-scale yielding conditions. Int J Fract 2013;180:261–8. [53] Torabi AR, Fakoor M, Pirhadi E. Tensile fracture in coarse-grained polycrystalline graphite weakened by a U-shaped notch. Eng Fract Mech 2013;111:77-85. [54] ASTM, D3039/D3039M. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. Annual Book of ASTM Standard. [55] ASTM, E1922-04. Standard Test Method for Trans-laminar Fracture Toughness of Laminated Polymer Matrix Composite Materials. Annual Book of ASTM Standard. [56] Davies P. Round Robin analysis of GIc inter-laminar fracture test. App Comp Mat 1996;3:135–140. [57] ASTM, D5528. Standard Test method for Mode I Inter-laminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. Annual Book of ASTM Standard. [58] ISO, 15024. Determination of Mode I Inter-laminar Fracture Toughness, GIc , for unidirectional Reinforced Materials 2001. [59] JIS, K 7086. Testing Methods for Inter-laminar Fracture Toughness of Carbon Fibre Reinforced Plastics 1993. 38 [60] ASTM, D 6671/D 6671M-06. Standard Test Method for Mixed Mode I-Mode II Interlaminar Fracture Toughness of Unidirectional Fiber Reinforced Polymer Matrix Composites. Annual Book of ASTM Standard. [61] Martin RH. Inter-laminar fracture characterization: a current review. NASA Contractor Report 1991;187573. [62] Sela N, Ishai O. Inter-laminar fracture toughness and toughening of laminated composite materials: a review. Composites 1989;20:423–435. [63] O’Brien TK. Inter-laminar fracture toughness: the long and winding road to standardization. Compos Part B: Eng 1998;29:57–62. [64] Laffan MJ, Pinho ST, Robinson P, McMillan AJ. Trans-laminar fracture toughness testing of composites: A review. Poly Test 2012;31:481–489. [65] Ritchie RO, Knott JF, Rice JR. On the relationship between critical stress and fracture toughness in mild steel. J Mech Phys Solids 1973;21:395–410. [66] Taylor D. Predicting the fracture strength of ceramic materials using the theory of critical distances. Eng Fract Mech 2004;71:2407-2416. [67] Seweryn A. Brittle fracture criterion for structures with sharp notches. Eng Fract Mech 1994;47:673–681. [68] Liu CJ, sterk JC, Nijhof AHJ, Marissen R. Matrix-dominated damage in notched cross-ply composite laminates: experimental observations. Appl Comp Mater 2002;9:155–168. [69] ASTM, E399–06. Standard Test Method for Linear-elastic Plane strain Fracture Toughness of Metallic Materials. Annual Book of ASTM Standard. [70] Harris CE, Morris DH. Fracture behavior of thick, laminated graphite/epoxy composites. NASA Contractor Report 1984;3784. [71] Harris CE, Morris DH. A comparison of the fracture behavior of thick laminated composites utilizing compact tension, three- point bend, and center-cracked tension specimens. J Fract Mech 1986;905:124–135. [72] El-Hajjar R, Haj-Ali R. Mode-I fracture toughness testing of thick section FRP composites using the ESE(T) specimen. Eng Fract Mech 2005;72:631–643. 39