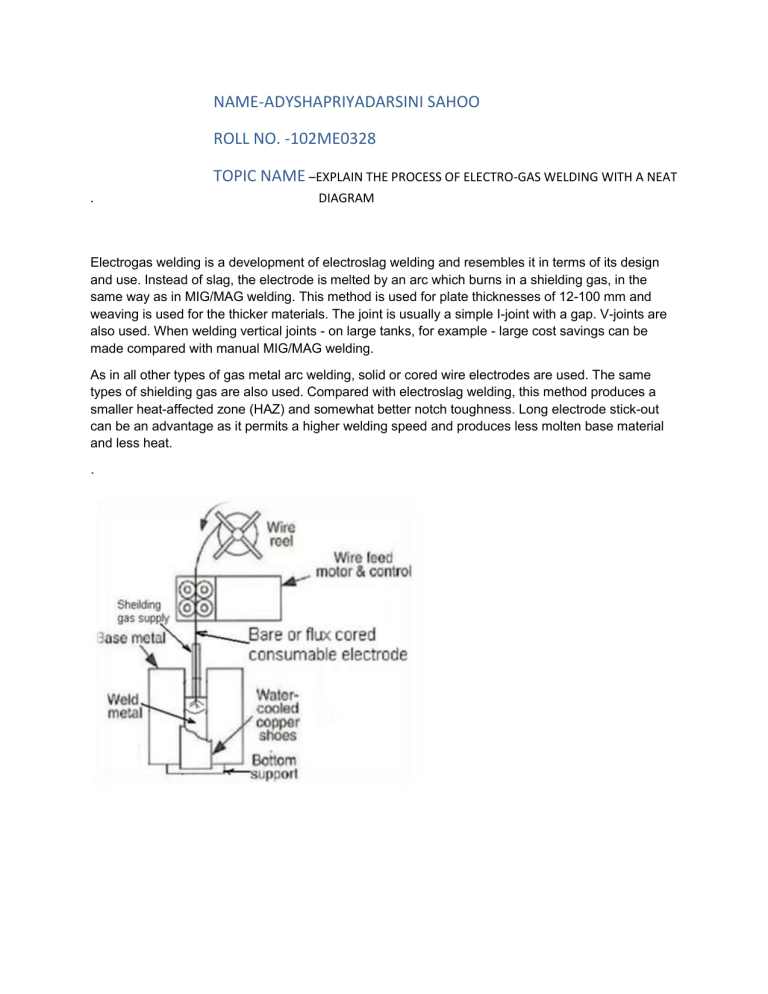

NAME-ADYSHAPRIYADARSINI SAHOO ROLL NO. -102ME0328 TOPIC NAME –EXPLAIN THE PROCESS OF ELECTRO-GAS WELDING WITH A NEAT . DIAGRAM Electrogas welding is a development of electroslag welding and resembles it in terms of its design and use. Instead of slag, the electrode is melted by an arc which burns in a shielding gas, in the same way as in MIG/MAG welding. This method is used for plate thicknesses of 12-100 mm and weaving is used for the thicker materials. The joint is usually a simple I-joint with a gap. V-joints are also used. When welding vertical joints - on large tanks, for example - large cost savings can be made compared with manual MIG/MAG welding. As in all other types of gas metal arc welding, solid or cored wire electrodes are used. The same types of shielding gas are also used. Compared with electroslag welding, this method produces a smaller heat-affected zone (HAZ) and somewhat better notch toughness. Long electrode stick-out can be an advantage as it permits a higher welding speed and produces less molten base material and less heat. .