CP Interference

January 2008

©NACE International, 2006

IMPORTANT NOTICE

Neither the NACE International, its officers, directors, nor members thereof accept

any responsibility for the use of the methods and materials discussed herein. No

authorization is implied concerning the use of patented or copyrighted material.

The information is advisory only and the use of the materials and methods is

solely at the risk of the user.

It is the responsibility of the each person to be aware of current local, state and

federal regulations. This course is not intended to provide comprehensive

coverage of regulations.

Printed in the United States. All rights reserved. Reproduction of contents in

whole or part or transfer into electronic or photographic storage without

permission of copyright owner is expressly forbidden.

Acknowledgements

The scope, desired learning outcomes and performance criteria of this course were

developed by the CP Task Group under the auspices of the NACE Education

Administrative Committee.

The time and expertise of several members of NACE International have gone into the

development of this course—and its task analysis, course outline, student manual,

classroom lab manual, presentation slides, and examinations. Their dedication and efforts

are greatly appreciated.

On behalf of NACE, we would like to thank the task group for its work. Their efforts

were extraordinary and their goal was in the best interest of public service—to develop

and provide a much needed training program that would help improve corrosion control

efforts industry-wide. We also wish to thank their employers for being generously

supportive of the substantial work and personal time that the members dedicated to this

program.

CP Interference Course Development Task Group

Paul Nichols, Task Group Chairman

Brian Holtsbaum

Kevin Parker

David A. Schramm

Steven R. Zurbuchen

Steven Nelson

Donald R. Mayfield

Shell Global Solutions, Houston, Texas

CC Technologies Canada, Ltd., Calgary,

Alberta

CC Technologies, Mt. Pleasant, Michigan

EN Engineering, Woodridge, Illinois

EN Engineering, Topeka, Kansas

Columbia Gas Transmission, Charleston,

West Virginia

Dominion

Transmission,

Delmont,

Pennsylvania

CP Interference

Daily Course Outline

DAY ONE

Introduction, Welcome, Overview

Chapter 1

Stray Current Interference

DAY TWO

Chapter 2

DC Interference

(Includes Experiment 2-1)

DAY THREE

MORNING

Chapter 2

DC Interference

AFTERNOON

Chapter 3

AC Interference

(Includes experiments 3-1, 3-2, and 3-3)

DAY FOUR

Chapter 3

AC Interference

DAY FIVE

MORNING

Chapter 3

AC Interference

AFTERNOON

Chapter 4

Telluric Current Interference

DAY SIX

MORNING

Exam

CP Interference Course Manual

© NACE International, 2006

January 2007

Introduction

Introduction

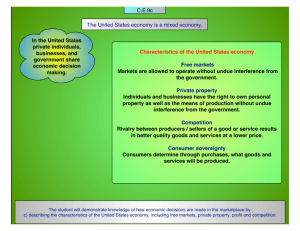

The Cathodic Protection (CP) Interference course is a six-day course

focusing on alternating current (AC) and direct current (DC)

interference. The course includes in-depth coverage of both the

theoretical concepts and the practical application of identifying

interference and interference mitigation techniques. Students will

learn to identify the causes and effects of interference as well as

conduct tests to determine if an interference condition exists and

perform calculations required to predict AC interference. The course

is presented in a format of lecture, discussion and hands-on, in-class

experiments, case studies and group exercises. There is a written

examination at the conclusion of the course.

Who Should Attend

This course is designed for persons who have extensive CP field

experience, a strong background in mathematics, and a strong

technical background in CP.

Prerequisites

• CP 3–Cathodic Protection Technologist certification

recommended

• Minimum of 3 years CP work experience

Length

The course begins at 1 p.m. on Sunday and concludes Friday

afternoon.

Daily class hours: 8 a.m. to 6:30 p.m. Monday through Thursday and

8 a.m. to 3 p.m. Friday.

Reference Book

Students will receive the CP Interference Course Manual prior to the

start of the course. A course manual on CD-ROM will be provided

to students on-site.

CP Interference Course Manual

© NACE International, 2006

July 2007

1

Introduction

Quizzes and Examinations

There will be four (4) quizzes distributed during the week and

reviewed in class by the instructors.

This course has a written final examination. The final examinations

will be given on Friday.

The written final examination is open-book and students may bring

reference materials and notes into the examination room.

Non-communicating,

battery-operated,

silent,

non-printing

calculators, including calculators with alphanumeric keypads, are

permitted for use during the examination. Calculating and computing

devices having a QWERTY keypad arrangement similar to a

typewriter or keyboard are not permitted. Such devices include but are

not limited to palmtop, laptop, handheld, and desktop computers,

calculators, databanks, data collectors, and organizers. Also excluded

for use during the examination are communication devices such as

pagers and cell phones along with cameras and recorders.

A score of 70% or greater on the examination is required for

successful completion of the course. All questions are from the

concepts discussed in this training manual.

You will receive written notification of your exam results as quickly

as possible. Your results will not be available on Friday.

Introductions

We would like for each of you to stand, one at a time and introduce

yourself to the class. Tell us:

•

Your name

•

Your company’s name and location

•

Your job function

•

Your experience related to CP Interference.

CP Interference Course Manual

© NACE International, 2006

July 2007

2

CP Interference

Course Manual

Table of Contents

General Course Information

Daily Course Outline

Introduction

Chapter 1–Stray Current Interference

1.1 Historical Background ...........................................................

1:1

1.2 Typical Stray Current Circuit Arising from a Transit

System Operation .................................................................

1:5

1.3 Stray Current Charge Transfer Reactions on a.....................

Metallic Structure

1:6

1.4 Effects of Stray Current on Metallic Structures .....................

1:9

1.4.1

1.4.2

1.4.3

At the Current Discharge Location......................................

At Area of Current Pick-Up .................................................

Along the Structure .............................................................

1:9

1:15

1:19

1.5 Summary ..............................................................................

1:21

Summary of Equations..................................................................

1:22

Figures

Fig. 1-1

Fig. 1-2

Fig. 1-3

Fig. 1-4

Fig. 1-5

Fig. 1-6

Early Electric Trolley..............................................................

Pipe-to-soil Potential Changes due to Transit System

Stray Current Activity were Recorded on Smoked Charts..

Co-efficient of Corrosion at Different Frequencies for

Iron Electrode Denoted as Average Electrode Loss...........

Typical Stray Current Paths Around a DC Transit System ....

Typical Stray Current Interference on a Metallic

Underground Structure .......................................................

Simplified pH Pourbaix Diagram For Iron in Water at 25ºC

Showing Potential Shift Direction for Current Pick-up

and Discharge at Low pH ...................................................

CP Interference Course Manual

© NACE International, 2006

June 2007

1:1

1:3

1:4

1:6

1:6

1:8

Fig. 1-7

Fig. 1-8

Fig. 1-9

Fig. 1-10

Fig. 1-11

Fig. 1-12

Fig. 1-13

Fig. 1-14

Fig. 1-15a

Fig. 1-15b

Fig. 1-16

Simplified pH Pourbaix Diagram For Iron in Water at 25ºC

Showing Potential Shift Direction for Current Pick-up

and Discharge at High pH...................................................

Current Discharge from a Metal Structure to Earth via

an Oxidation Reaction ........................................................

Superposition of a Stray Current and a Cathodic Protection

Current at a Metal/Electrolyte Interface ..............................

Randle’s Electrical Circuit Model of a Metal/Electrolyte

Interface..............................................................................

Theoretical Conditions of Corrosion, Immunity and

Passivation of (a) Aluminum at 25ºC and

(b) Lead at 25ºC .................................................................

Comparison of Zn and Al Coatings for Corrosion

Resistance as Functions of pH ...........................................

Typical Section Through a Joint in Two Types of PCCP .......

Cathodic Blistering/Disbondment of Protective Coating ........

Stray Current Discharge and Pick-Up Around an

Electrically Discontinuous Joint Though the Earth..............

Stray Current Discharge and Pick-Up Through the

Internal Aqueous Medium Around an Electrically

Discontinuous Bell and Spigot Joint on Cast Iron Piping....

Stray Current Circuit in an AC Electrical Distribution

System................................................................................

1:9

1:10

1:10

1:14

1:16

1:17

1:18

1:19

1:19

1:20

1:20

Tables

Table 1-1 Theoretical Consumption Rates of Various Metals and

Substances ..................................................................

1:12

Table 1-2 Electrochemical and Current Density Equivalence with

Corrosion Rate....................................................................

1:13

Chapter 2–DC Interference

2.1 Introduction ...........................................................................

2:1

2.2 Detecting Stray Current ........................................................

2:23

2.2.1 Mitigation of Interference Effects from Impressed Current

Cathodic Protection Systems .....................................

2:24

a. Source Removal or Output Reduction ..........................

2:25

b. Installation of Isolating Fittings......................................

2:26

c. Burying a Metallic Shield Next to the Interfered-with

Structure ....................................................................

2:27

d. Installation of Galvanic Anodes on Interfered-with

Structure at Point of Stray Current Discharge............

2:28

e. Installation of an Impressed Current Distribution System

on the Interfered-with Structure at Point of Stray Current

Discharge...................................................................

2:33

f. i. Installing a Bond Between the Interfered-with and

CP Interference Course Manual

© NACE International, 2006

June 2007

Interfering Structures................................................

ii. Calculation of Bond Resistance ...............................

g. Use of Coatings in the Mitigation of Interference Effects

2.2.2

2:33

2:35

2:40

Other Sources of DC Stray Current ....................................

2:41

a. DC Transit Systems ......................................................

2:42

i. Analysis of Transit System Stray Currents ...............

2:44

ii. Mitigation of Transit System Stray Currents .............

2:51

b. High Voltage Direct Current (HVDC) Electrical Transmission

Systems .....................................................................

2:55

c. DC Welding Operations ................................................

2:57

Experiment 2-1:

To Demonstrate DC Interference

and Its Mitigation........................................................

2:59

………………………………………………………. …..

2.64

Summary of Equations ............................................................................

2:65

Case Study

Figures

Fig. 2-1

Fig. 2-2

Fig. 2-3

Fig. 2-4

Fig. 2-5

Fig. 2-6

Fig. 2-7a

Fig. 2-7b

Fig. 2-8

Fig. 2-9

Fig. 2-10

Fig. 2-11

Fig. 2-12

Fig. 2-13

Fig. 2-14

Fig. 2-15

Fig. 2-16

Parallel Current Paths in the Earth ....................................

Parallel Current Paths in a Pipeline Cathodic Protection

Section................................................................................

Parallel Current Paths in Vertically Stratified Soil Conditions

Parallel Current Paths in Horizontally Stratified Soil

Conditions...........................................................................

Polarization Test Results.......................................................

Stray Current in a Metallic Structure Parallel to a

Cathodically Protected Structure ........................................

Voltage vs. Distance from a Vertically Oriented Anode .........

Multiple Vertical Anodes Connected to a Common

Header Cable .....................................................................

Multiple Horizontal Anodes Connected to a Common

Header Cable .....................................................................

Hemispherical Electrode........................................................

Cathodic Protection Circuit Model with Foreign Structure

Intercepting the Anode Gradient.........................................

Potential Profile along the Interfered-with Structure ..............

Electrical Model for Interfered-with Pipe ................................

Attenuation Model..................................................................

Voltage Gradient in the Earth Around a Cathodically

Protected Bare Pipeline ......................................................

Cathodic Protection Circuit Model .........................................

Cathodic Protection Circuit Model with Foreign Structure

Intercepting the Anode Gradient.........................................

Stray Current in a Foreign Metallic Structure that Intercepts

both the Anodic and Cathodic Voltage Gradient.................

CP Interference Course Manual

© NACE International, 2006

June 2007

2:1

2:2

2:3

2:3

4:5

2:5

2:6

2:7

2:8

2:9

2:11

2:14

2:14

2:15

2:18

2:18

2:19

2:20

Fig. 2-17 Cathodic Protection Circuit Model with Foreign Structure

Intercepting both Anodic and Cathodic Voltage Gradient...

Fig. 2-18 Stray Current in a Foreign Metallic Structure that Intercepts

the Cathodic Protection Gradient........................................

Fig. 2-19 Cathodic Protection Circuit Model for Foreign Structure

Intercepting the Cathodic Voltage Gradient........................

Fig. 2:20 Typical Potential Profile on an Interfered-with Structure

that Intersects both Anodic and Cathodic Voltage

Gradient with the Current Source Interrupted.....................

Fig. 2-21 Current Changes In and Near an Interfered-with Structure ...

Fig. 2-22 Stray Current Arising from Installation of Isolating Fittings ....

Fig. 2-23 Using a Buried Metallic Cable or Pipe as a Shield to

Reduce Stray Current Interference.....................................

Fig. 2-24 Cathodic Protection Current Model for a Buried Metallic

Shield Connected to the Negative Terminal of the

Transformer-Rectifier..........................................................

Fig. 2-25 Interference Mitigation using Galvanic Anodes at Stray

Current Discharge Location ................................................

Fig. 2-26 Electrical Circuit Model for Mitigating Stray Current

Interference at a Stray Current Discharge Site Using

Galvanic Anodes.................................................................

Fig. 2-27 Potential Profile Changes on a Pipeline where Stray

Current is Discharging in an End-Wise Pattern ..................

Fig. 2-28 Interference Mitigation Using a Resistance Bond..................

Fig. 2-29 Measurements Required to Determine Size of Resistance

Bond Re ..............................................................................

Fig. 2-30 Use of a Dielectric Coating to Mitigate Interference ..............

Fig. 2-31 Typical Stray Current Paths Around a DC Transit System ....

Fig. 2-32 Typical Structure-to-Soil Potential Recording with Time

Caused by Interference from a DC Transit System ............

Fig. 2-33 Current Clamp Used to Measure Pipeline Currents ..............

Fig. 2-34 Line Current Survey to Locate Source of Interference

Using IR-Drop Test Stations ...............................................

Fig. 2-35 Line Current Plots for Example in Figure 2-34 ......................

Fig. 2-36 Exposure Survey to Locate Point of Maximum Exposure......

Fig. 2-37 Exposure Survey Plots for Example in Figure 2-36 ...............

Fig. 2-38 Mutual Survey to Confirm Source of Interference..................

Fig. 2-39 Pipe-to-Soil Potential Versus Pipe-to-Rail Potential for

Example in Figure 2-38.......................................................

Fig. 2-40 Exposure Survey Conducted Without the Measurement

Of Pipeline Currents ...........................................................

Fig. 2-41 Exposure Survey Plots for Example in Figure 2-40 ...............

Fig. 2-42a Typical Embedded Track Installation.....................................

Fig. 2-42b Typical Direct-Fixation Isolating Fastener .............................

Fig. 2-43 Typical Utilities Drainage System at a Transit Substation .....

Fig. 2-44 Schematic Showing Circulating Current between Transit

Substations Through Direct Bonds to Utilities ....................

Fig. 2-45 Forced Drainage Bonds Using a Potential Controlled

Rectifier...............................................................................

Fig. 2-46 Electrical Schematic for a HVDC System ..............................

CP Interference Course Manual

© NACE International, 2006

June 2007

2:20

2:21

2:22

2:23

2:24

2:26

2:27

2:28

2:29

2:30

2:33

2:34

2:36

2:41

2:42

2:43

2:44

2:45

2:46

2:47

2:48

2:48

2:49

2:50

2:50

2:52

2:52

2:52

2:53

2:54

2:55

Fig. 2-47 Potential-Time Plot for a Metallic Structure being

Interfered-with by a HVDC System.....................................

Fig. 2-48 Stray Current Caused by DC Welding Operations ................

2:57

2:58

Experiment Schematic No. 1...................................................................

Experiment Schematic No. 2...................................................................

Experiment Schematic No. 3...................................................................

2:59

2:60

2:61

Table 2-1 Specific Leakage Resistances and Conductances in

1000 Ω-cm Soil or Water .......................................................

Table 2-2 Types of Reverse Current Switches ......................................

2:13

2:54

Tables

Chapter 3–AC Interference

3.1 Introduction ...........................................................................

3.1.1

3.1.2

3.1.3

Experiment 3-1:

3:1

Electrostatic (Capacitive) Coupling.....................................

3:2

Electromagnetic (Inductive) Coupling .................................

3:11

Conductive Coupling (Resistive Coupling) During Powerline Fault

Conditions...........................................................................

3:14

To Demonstrate the Effects of Electrostatic

Induction .............................................................................

3:16

3.2 Basic Theory of Electromagnetically Induced Voltages ........

3:19

3.2.1

3.2.2

Experiment 3-2:

AC Circuit Theory ...............................................................

The Nature of Induced AC Pipeline Voltages .....................

3:19

3:34

To Demonstrate the Effects of Electromagnetic

Induction .............................................................................

3:42

3.3 Induced AC Voltages ............................................................

3:44

3.3.1

3.3.2

Experiment 3-3:

Factors that Affect the Longitudinal Electric Field...............

Factors that Affect the Pipeline Voltages............................

3:44

3:48

To Further Investigate the Effects of Electromagnetic

Induction .............................................................................

3:57

3.4 Deleterious Effects of AC Interference..................................

3:60

3.4.1

3.4.2

3.4.3

Electric Shock Hazards.......................................................

AC Corrosion ......................................................................

.1 Theory...........................................................................

.2 AC Corrosion Case Histories........................................

.3 AC Corrosion Field Test Procedures ............................

Fault Current Effects...........................................................

CP Interference Course Manual

© NACE International, 2006

June 2007

3:60

3:67

3:67

3:75

3:90

3:93

3.5 Induced AC Voltage Prediction and Mitigation Calculations .

3.5.1

3.5.2

3.5.3

3:95

Data Gathering ...................................................................

Field Estimation of LEF.......................................................

Measurement and Interpretation of Soil Resistivity Data....

3:95

3:97

3:98

3.6 Prediction of Steady-State Induced AC Voltages..................

3:102

3.6.1

3.6.2

3.6.3

3.6.4

3.6.5

Introduction .........................................................................

Calculation of Pipeline Electrical Characteristics................

Sectionalization of Pipeline-Powerline Route .....................

Determination of Longitudinal Electric Field (LEF) .............

Calculation of Induced Pipeline Voltages ...........................

3:102

3:102

3:106

3:107

3:110

3.7 Prediction of Fault Voltages ..................................................

3:115

3.7.1

3.7.2

3.7.3

3.7.4

Introduction .........................................................................

Conductive Coupling Due to Fault Currents .......................

Inductive Coupling Due to Fault Currents...........................

Other Related Calculations.................................................

(a) Ground Electrode Resistance ....................................

(b) Step and Touch Potential ..........................................

(c) Conductor Size ..........................................................

3:115

3:115

3:122

3:123

3:123

3:125

3:126

3.8 Equipment for AC Mitigation .................................................

3:126

3.8.1

3.8.2

3.8.3

DC Decoupling Devices......................................................

Test Stations.......................................................................

Sacrificial Anodes ...............................................................

3:126

3:138

3:139

Group Activity – AC Mitigation System Design .......................................

3:142

Summary of Equations ............................................................................

3:145

Figures

Fig. 3-1a Single Horizontal 3φ Circuit with Shield Wires.......................

Fig. 3-1b Distribution System (1φ 4kV Primary and 2φ 240V Secondary

with Neutral)........................................................................

Fig. 3-2

AC Voltage Waveforms in a 3φ Circuit ..................................

Fig. 3-3

Elements of a Capacitor ........................................................

Fig. 3-4

Electrostatic Coupling during Pipeline Construction ..............

Fig. 3-5

Voltage Divider Circuits – Resistive (left) and Capacitive

(right) ..................................................................................

Fig. 3-6

Calculation of Typical Capacitance Values for a Pipe

on Skids ..............................................................................

Fig. 3-7

Calculation of Typical Electrostatically Induced Voltage

for a Pipe on Skids..............................................................

Fig. 3-8

Calculation of Typical Shock Current Resulting from

Electrostatic Coupling .........................................................

Fig. 3-9

Calculation of Typical Electrostatically Induced Voltage

CP Interference Course Manual

© NACE International, 2006

June 2007

3:2

3:2

3:2

3:3

3:4

3:5

3:6

3:7

3:8

for an Automobile................................................................

Fig. 3-10 Calculation of Typical Electrostatically Induced Voltage

for a Buried Pipe .................................................................

Fig. 3-11 Electromagnetic Field Created by Current Flow in a Wire.....

Fig. 3-12 Electromagnetic Induction in a Multiple-Turn, Iron-Core

Transformer ........................................................................

Fig. 3-13 Electromagnetic Induction in a Single-Turn, Air-Core

Transformer ........................................................................

Fig. 3-14 Electromagnetic Coupling Between a Pipeline and an

Overhead AC Powerline .....................................................

Fig. 3-15 Conductive Coupling During Line-to-Ground Fault

Conditions...........................................................................

Fig. 3-16 Determination of Voltage on a Transformer Secondary ........

Fig. 3-17 Effect of Interconnecting the Secondary Windings ................

Fig. 3-18 Effect on Polarity on a Series Combination of DC Voltage

Sources ..............................................................................

Fig. 3-19 Effect of “Polarity” on a Series Combination of AC Voltage

Sources ..............................................................................

Fig. 3-20 In-Phase 60 Hz AC Waveform ..............................................

Fig. 3-21 Typical Electrical Distribution Transformer ............................

Fig. 3-22 Typical Residential Electrical Service ....................................

Fig. 3-23 AC Waveforms on a Residential Electrical Service ...............

Fig. 3-24 Plot of General Equation for Sinusoidal AC Waveforms........

Fig. 3-25 Typical Phasor Diagram ........................................................

Fig. 3-26 Series Combination of AC Voltage Sources ..........................

Fig. 3-27 Phasor Diagram for Problem in Figure 3-26 ..........................

Fig. 3-28 Determination of Current through a Capacitor.......................

Fig. 3-29 Voltage and Current Waveforms for a Purely Capacitive

Circuit..................................................................................

Fig. 3-30 Determination of Current through an Inductor .......................

Fig. 3-31 Voltage and Current Waveforms for a Purely Inductive

Circuit..................................................................................

Fig. 3-32 Phasor Representation of a Three-Phase Circuit ..................

Fig. 3-33 Electric Model of Single Pipe Section ....................................

Fig. 3-34 Simplified Electrical Model of Single Pipe Section.................

Fig. 3-35 Simplified Electrical Model of Single Pipe Section.................

Fig. 3-36 Series Combination of Multiple Pipe Sections .......................

Fig. 3-37 Series Combination of Two Pipe Sections ............................

Fig. 3-38 Series Combination of Two Pipe Sections (Simplified)..........

Fig. 3-39 Circuit Analysis Using Kirchhoff’s Law...................................

Fig. 3-40 Circuit Analysis Using Kirchhoff’s Law...................................

Fig. 3-41 Induced AC Voltage Profile Along Two-Section Pipe

Method of Figure 3-39 ........................................................

Fig. 3-42 Profile of Induced AC Voltages and their Phase Angles

along any Pipeline having Uniform Electrical

Characteristics ....................................................................

Fig. 3-43 Effect of Electrical Length of Pipeline on AC Voltage Profile.

Fig. 3-44 Double Vertical Circuit ...........................................................

Fig. 3-45 Quadruple Vertical Circuit......................................................

Fig. 3-46 Single Delta Circuit ................................................................

CP Interference Course Manual

© NACE International, 2006

June 2007

3:9

3:10

3:11

3:12

3:13

3:13

3:14

3:20

3:20

3:21

3:21

3:22

3:23

3:23

3:24

3:25

3:26

3:27

3:27

3:30

3:31

3:32

3:33

3:33

3:35

3:36

3:36

3:36

3:37

3:37

3:37

3:38

3:39

3:39

3:40

3:44

3:44

3:45

Fig. 3-47 Effect of Phase Conductor Separation ..................................

Fig. 3-48 Phase Arrangements for a Double Vertical Circuit ................

Fig. 3-49 Effect of Phase Arrangement on LEF Magnitude for

Variation of d/s Ratios (and for the specific case

Where ρ/s2 = 1Ω/m, s/h=0.3, and I=1000A) .......................

Fig. 3-50 Simple Pipeline-Powerline Corridor (Plan View)....................

Fig. 3-51 AC Voltage Profile Along an Electrically Short Pipeline

(Uniform Conditions – No Grounding) ................................

Fig. 3-52 Electrical Service Analogy for Pipeline-Powerline Corridor

In Figure 3-50 .....................................................................

Fig. 3-53 AC Voltage Profile Along an Electrically Short Pipeline

(Non-Uniform Conditions – No Grounding).........................

Fig. 3-54 Effect of Grounding One End of Electrical Service

Secondary...........................................................................

Fig. 3-55 Effect of Grounding One End of Pipeline in Figure 3-50 .......

Fig. 3-56 Effect of Grounding Both Ends of Pipeline or Adding

Distributed Grounds............................................................

Fig. 3-57 Effect of an Insulator at the Midpoint of the Pipeline .............

Fig. 3-58 AC Voltage Profile Along an Electrically Long or Lossy

Pipeline (Uniform Conditions – No Grounding)...................

Fig. 3-59 AC Voltage Profile Along an Electrically Long or Lossy

Pipeline (Zero Resistance Ground at Distance = 0) ...........

Fig. 3-60 Effect of an Insulator at the Midpoint of an Electrically

Long Pipeline ......................................................................

Fig. 3-61 Fibrillating Current vs. Body Weight (Various animals – 3

second shock duration).......................................................

Fig. 3-62 Possible Body Current Paths.................................................

Fig. 3-63 Example of Typical Touch and Step Potentials at an

Energized Structure ............................................................

Fig. 3-64a Coefficient of Corrosion at Different Frequencies for

Iron Electrode Denoted as Average Electrode Loss...........

Fig. 3-64b Maximum Penetration Depth as a Function of Test

Duration at Constant Cathode DC Current Density

(2A/m2) and Differing AC Current Density ..........................

Fig. 3-65a Effect of CP Potential on AC Corrosion Rate ........................

Fig. 3-65b Effect of CP Potential on AC Current Density........................

Fig. 3-65c Pit Cluster and Pinhole Perforation (Case History No. 1) ......

Fig. 3-65d Hemispherical Shell of Hardened Soil Surrounding

Anomaly (Case History No. 3) ............................................

Fig. 3-65e Hemisphere of Hardened Soil and Corrosion Pit

(Case History No. 3) ...........................................................

Fig. 3-65f Pinhole Corrosion Failure Following Removal of Repair

Clamp (Case History No. 4)................................................

Fig. 3-65g Pipeline-Powerline Route (Case History No. 4).....................

Fig. 3-65h Nodule of Corrosion Products Protruding Through

Coating (Case History No. 4)..............................................

Fig. 3-65i Corrosion Pit After Removal of Coating and Corrosion

Products (Case History No. 4) ............................................

Fig. 3-65j Effects of Installing Ground Electrodes at Sites A and B

(Case History No. 4) ...........................................................

CP Interference Course Manual

© NACE International, 2006

June 2007

3:46

3:46

3:47

3:49

3:49

3:50

3:50

3:51

3:52

3:52

3:53

3:54

3:55

3:56

3:61

3:63

3:64

3:68

3:71

3:73

3:74

3:76

3:80

3:81

3:82

3:83

3:85

3:85

3:88

Fig. 3-65k Effects of Installing Ground Electrodes on AC Current

Densities (Case History No. 4) ...........................................

Fig. 3-66 Fault Damage to CP Bond.....................................................

Fig. 3-67 Field Estimation of LEF Magnitude Using Horizontal

Wire Method .......................................................................

Fig. 3-68 Soil Resistivity Measurement Using the Wenner Four-Pin

Method................................................................................

Fig. 3-69 Determination of Pipeline Coating Resistance ......................

Fig. 3-70 Determination of Pipeline Internal Impedance.......................

Fig. 3-71 Sectionalization of Pipeline-Powerline Route ........................

Fig. 3-72 Pipeline-Powerline Geometry for Calculation of LEF.............

Fig. 3-73 Typical Series of Curves for Determining LEF.......................

Fig. 3-74 Simple Pipeline-Powerline Corridor (Plan View)....................

Fig. 3-75 Simple Pipeline-Powerline Model ..........................................

Fig. 3-76 Equivalent Circuit for Line-to-Ground Fault ...........................

Fig. 3-77 Distribution of Fault Current Along Powerline........................

Fig. 3-78 Distribution of Fault Current Along Powerline........................

Fig. 3-79 Calculation of Earth Voltage at Pipe due to Faulted Tower ...

Fig. 3-80 Approximate Length of Pipeline Affected by Faulted Tower..

Fig. 3-81 Resistance of Coating Holiday to Earth .................................

Fig. 3-82 Modified Resistance of Coating Holiday to Earth due

to Localized Soil Ionization Effects .....................................

Fig. 3-83 AC Pipeline Voltages Induced by Overhead Faulted

Powerline (Per 1000 A of Fault Current).............................

Fig. 3-84 Motor Operated Valve – Effects of Grounding on Induced

AC and CP Currents ...........................................................

Fig. 3-85 Electrical Isolation of Motor Operated Valve from Pipeline....

Fig. 3-86 Electrical Grounding Schematic of Motor Operated Valve

Showing Two Alternative Locations for a DC Decoupling

Device.................................................................................

Fig. 3-87 Decoupling Device Installed by Electrical Utility Between

Primary and Secondary Grounds .......................................

Fig. 3-88 Isolation-Surge Protector Installed across Isolating Flange...

Fig. 3-89 Electrical Schematic of One Model of Solid-State DC

Decoupling Device..............................................................

Fig. 3-90 DC Decoupling Device Installed Across Insulating Flange

for Lightning Protection.......................................................

Fig. 3-91 AC Current Being Measured Through a Polarization Cell .....

Fig. 3-92 Polarization Cell Construction ...............................................

Fig. 3-93 Corrosion of Plates Within a Polarization Cell .......................

Fig. 3-94 Grounding Cell.......................................................................

Fig. 3-95 Electrolytic Capacitor.............................................................

Fig. 3-96 Failure of Electrolytic Capacitors in Stray Current Area ........

Fig. 3-97 Metal-Oxide Varistors (MOVs)...............................................

Fig. 3-98 Explosion-Proof Surge Protection Device Installed

Across Insulator ..................................................................

Fig. 3-99 Test Station Varieties (left to right): a) Terminals Exposed

To Public; b) Terminals Covered by a Plastic Cap (Locking

or Non-Locking); c) Dead-Front Terminals; d) Aluminum

Test Station with Padlocked Cover.....................................

CP Interference Course Manual

© NACE International, 2006

June 2007

3:89

3:95

3:98

3:99

3:103

3:104

3:107

3:109

3:110

3:111

3:111

3:115

3:116

3:117

3:118

3:119

3:120

3:121

3:123

3:127

3:128

3:129

3:130

3:131

3:131

3:132

3:133

3:133

3:134

3:135

3:135

3:136

3:137

3:138

3:139

Fig. 3-100 a) Zinc Ribbon Anode of Various Sizes; b) Zinc Ribbon

Being Installed in Pipe Trench ............................................

Fig. 3-101 Effect of Gypsum on Restoration of Zinc Potential in

Bicarbonate-Rich Soil .........................................................

Fig. 3-102 Potential of Magnesium Versus AC Current Density

in a Fe-Mg Cell ...................................................................

3:140

3:140

3:141

Tables

Table 3-1

Table 3-2

Table 3-3

Table 3-4

Table 3-5

Effects of 60 Hz AC Body Currents on Humans ....................

Let-Go Currents from Dalziel’s Experiments .........................

Let-Go Currents from Dalziel’s Experiments .........................

Voltage Puncture Levels for Various Holiday-Free Coatings.

Specific Leakage Resistances and Conductances................

CP Interference Course Manual

© NACE International, 2006

June 2007

3:60

3:62

3:63

3:94

3:103

Chapter 4–Telluric Current Interference

4.1 Background Theory ..............................................................

4.1.1

4.1.2

4:1

Distributed Source Transmission Line Equations ...............

Factors that Affect the Induced Electric Field .....................

(a) Solar Cycle Variations................................................

(b) Sun’s Rotational Frequency.......................................

(c) Earth’s Rotation .........................................................

(d) Plasma Magnetic Field Direction ...............................

(e) Proximity of Pipeline to a Sea Coast..........................

(f)

Pipeline Latitude ........................................................

Factors that Affect the Pipeline Lineal Impedance (Z) and

Shunt Admittance (Y)..........................................................

(a) Effect of Coating Quality ............................................

(b) Effect of Isolating Fittings...........................................

(c) Effect of Pipeline Directional Change ........................

4:13

4:13

4:14

4:15

4.2 Measuring the Geomagnetic Intensity and Determining

the Electric Field (E)..............................................................

4:16

4.3 Interference Effects of Telluric Current on Pipelines .............

4:18

4.1.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

General Considerations ......................................................

Corrosion ............................................................................

(a) Theoretical Considerations ........................................

(b) Calculating the Corrosion Rate ..................................

(c) Telluric Corrosion Case Studies on Cathodically

Protected Piping......................................................

Impact on Accuracy of Current and Potential Measurements

...................................................................................

Impact of Telluric Current on Pipeline Coatings .................

Impact on Output of a CP Rectifier .....................................

4.4 Mitigating the Effects of Telluric Current ...............................

4.4.1

4:6

4:8

4:8

4:9

4:9

4:9

4:10

4:12

4:18

4:18

4:18

4:22

4:27

4:29

4:31

4:32

4:33

Mitigating Corrosion Impact ................................................

(a) Making the Pipeline Electrically Continuous and

Grounded ................................................................

(b) Using CP....................................................................

(i) Sacrificial Anodes ................................................

(ii) Impressed Current Systems ................................

Compensating for Measurement Error Caused by ............

Telluric Current ..........................................................

4:33

4:34

4:35

4:39

4.5 Summary ..............................................................................

4:49

Summary of Equations..................................................................

4:51

4.4.2

CP Interference Course Manual

© NACE International, 2006

June 2007

4:33

4:42

Figures

Fig. 4-1

Interaction of Solar Particles on the Earth’s Magnetic Field ..

Fig. 4-2a Plasma Charge Distribution around the Earth during

Quiescent Period ................................................................

Fig. 4-2b Plasma Charge Distribution around the Earth during

a Magnetic Storm................................................................

Fig. 4-3

This Plot Shows the Current Extent and Position of the

Auroral Oval in the Northern Hemisphere, Extrapolated

From Measurements Taken During the Most Recent

Polar Pass of the NOAA POES Satellite for September

16, 2004 at 14:22 UT ..........................................................

Fig. 4-4

Schematic of Geomagnetic Induction Directly into a Pipeline

and the Resulting Change in Pipeline Potential that is

Produced ............................................................................

Fig. 4-5

Quiet Day Variation in the Geomagnetic Field and the

Associated Change in the Electric Field and the Pipe-toSoil Potential.......................................................................

Fig. 4-6

P/S Potential and Telluric Current in a Long Pipeline

Exposed to an Induced Electric Field of 1 V/km,

Having an Impedance of 0.1 Ω /km and an

Admittance of 0.15 Ω /km...................................................

Fig. 4-7

Equivalent Circuit for a Short Section of Pipeline ..................

Fig. 4-8

History of Geomagnetic Effects on Ground Technology........

Fig. 4-9

Pipe-to-soil Potential Variations with Time ............................

Fig. 4-10 Charge Accumulation at the Coast Resulting from Larger

Induced Currents in the Sea Compared to in the Land.

The Charge Accumulation Increases the Electrical

Potential of the Earth’s Surface Near the Coast .................

Fig. 4-11 Electric Field, E, Generated by Seawater Moving with

Velocity, v, Through the Earth’s Magnetic Field, B .............

Fig. 4-12 Geomagnetic Hazard Percentage of Probability of

Occurrence .........................................................................

Fig. 4-13 Telluric Induced Voltage Profile vs Distance for a

Pipeline with Different Attenuation Constants.....................

Fig. 4-14 Calculated Telluric Induced Voltage at the End of a Long

Pipeline as a Function of Coating Conductance for

an East-West Electric Field of 0.1V/km ..............................

Fig. 4-15 Effect of Isolating Fittings on the Telluric Induced Voltage

Profile on an Electrically Short Pipeline ..............................

Fig. 4-16 Effect of Pipeline Directional Change on the Telluric

Induced Voltage..................................................................

Fig. 4-17 Average Occurrence of 3-Hour Intervals with the Magnetic

Activity Index Kp Equal to or Greater than a Specified

Value. Kp=9 Corresponds to a Severe Magnetic Storm ....

Fig. 4-18 Peak Electric Field Magnitudes as a Function of Kp .............

Fig. 4-19 Oxidation Reaction at Pipe Surface During Telluric

Current Discharge in the Absence of CP............................

Fig. 4-20 Reduction Reactions During Negative Cycle Telluric

CP Interference Course Manual

© NACE International, 2006

June 2007

4:1

4:2

4:2

4:3

4:3

4:4

4:5

4:6

4:8

4:9

4:10

4:11

4:12

4:13

4:14

4:14

4:15

4:16

4:17

4:18

and CP Current Pick-up......................................................

4:19

Fig. 4-21 Steel Surface pH versus Applied CP Current Density ...........

4:20

Fig. 4-22 Polarization Curves after Several Days of Potentiostatic

Polarization .........................................................................

4:20

Fig. 4-23 Experimental Anodic Polarization Curve of Steel in

Hydroxide (pH 12.0)............................................................

4:21

Fig. 4-24 Telluric Current Discharge from a Cathodically Protected

Pipe ....................................................................................

4:22

Fig. 4-25 Coefficient of Corrosion at Different Frequencies for

Iron Electrodes Denoted as Average Electrode Loss .........

4:23

Fig. 4-26 Effect on Corrosion Rate of Reversing Direction of

Current Compared to Steady State DC and Length of Time

Between Reversals.............................................................

4:24

Fig. 4-27 Corrosion Current Density at a Coating Defect having an

Applied Voltage of 1.0V in 1000 Ω-cm Soil for

Various Coating Thicknesses .............................................

4:25

Fig. 4-28 Chart Showing the Influence of Anodic Transient Time with

Respect to Corrosion Experienced by Probe in Sandy and

Clay Soil. Line (a) Represents the Corrosion Rate

Expected from Faraday’s Law for the Clay Soil, and

Line (B) for the Sandy Soil, Respectively ...........................

4:26

Fig. 4-29 Corrosion Pit at 112+307 (60 mils/497mils 07:30).................

4:28

Fig. 4-30 Magnetic Field Intensity and Pipe-to-Soil Potential

Superimposed.....................................................................

4:29

Fig. 4-31 Schematic of Potentially Controlled CP System Used to Mitigate

Telluric Current Effects .......................................................

4:30

Fig. 4-32 Current Flow and Calculated OFF Potentials during a

GIC Incident........................................................................

4:31

Fig. 4-33 Telluric Current Through a Bridge Rectifying Element

During a Discharge Cycle ...................................................

4:32

Fig. 4-34 Schematic of a Telluric Bond Switch .....................................

4:34

Fig. 4-35 Mitigation of Telluric Current Discharge Effects Using

Galvanic Anodes.................................................................

4:35

Fig. 4-36 Effect of Connecting and Disconnecting Groups of

Galvanic Anodes to a Pipeline Subjected to Telluric

Current................................................................................

4:36

Fig. 4-37 Maritimes DSTL Results Without Flanges .............................

4:38

Fig. 4-38 Electrical Schematic at a Constant Voltage Transformer

Rectifier During a Positive Telluric Voltage Fluctuation ......

4:40

Fig. 4-39 Pipe Potential and Rectifier Current Output vs Time for

An Impressed Current System Operating in Potential

Control ................................................................................

4:41

Fig. 4-40 Typical Pipe-to-Soil Potential Measurements at Test

Station Having a Steel Coupon and Soil Tube ...................

4:42

Fig. 4-41 Typical Pipe-to-Soil Potential Recording at a Test

Station Using a Coupon/Reference Probe..........................

4:43

Fig. 4-42 Comparison Between Pipe/Coupon Potential with Time

Recorded with Respect to a Copper-Copper Sulfate

Reference on Grade and to a Coupon/Reference Probe

Located at Pipe Depth ........................................................

4:44

CP Interference Course Manual

© NACE International, 2006

June 2007

Fig. 4-43 Pipe-to-Soil Potential Measurement Method to Compensate

For Telluric Current Effects During a Close Interval

CP Survey...........................................................................

Fig. 4-44 CIPS Method Using One Moving and Two Stationary

Data Loggers ......................................................................

Fig. 4-45 Pipe-to-Soil Potential Measurement Method to Compensate

for Telluric Current Effects During a Close Interval

CP Survey...........................................................................

Fig. 4-46 Pipe Potential/Telluric Current Relationship at a Coupon

Test Station.........................................................................

Fig. 4-47 Four Wire Test Lead Arrangement for Measuring

Pipe Current........................................................................

Appendices

Appendix A – Curve Matching

Appendix B – Pipe Data Table

Appendix C – Anode Tables

Appendix D – Wire Size Table

Appendix E – Metric Conversion Table

Appendix F – Dabkowski Paper

NACE RP0177

NACE SP0169

NACE Glossary of Corrosion-related Terms

Course Evaluation

Instructor Evaluation

CP Interference Course Manual

© NACE International, 2006

June 2007

4:45

4:46

4:47

4:48

4:49

CHAPTER 1

STRAY CURRENT INTERFERENCE

1.1

Historical Background

The term “interference” is understood in the pipeline industry as electrical

interference and is defined as “any detectable electrical disturbance on a

structure caused by a stray current where a ‘stray current’ is defined as a current

in an unintended path”.1 This broad definition suggests that the structure,

although often a pipeline, could be any metallic network such as electrical power

grids and communication systems. Furthermore, although the interfering current

is often a direct current (DC) from a cathodic protection (CP) impressed current

source, the current can also originate from any electrical system that uses the

earth either intentionally or inadvertently as a current path. Thus alternating

current (AC) can also be included in the definition.

Electrical interference concerns preceded the use of CP for corrosion control of

pipelines. Telegraph systems were reported2 to interfere with the operation of the

early telephone systems. Lighting systems, first introduced in about 1880,

comprised arcs and incandescent lamps also interfered with the telephone

systems, primarily because both the

telephone system and the lighting

systems used the earth as a current

path. Then, in the late 1800s and

early 1900s, street railways

throughout North America were

electrified.3 They ultimately led to

the corrosion of cast iron

watermains.

Figure 1-1: Early Electric Trolley

(courtesy of East Bay Municipal Utility District, Oakland, CA)4

1

CP3 – Cathodic Protection Technologist Course, NACE International, June 1, 2004, p.3-1.

Anderson, John M., The Fight Over the Highways, IEEE Power Engineering Review, December 1997,

p.45.

3

Anderson, John M., First Electric Street Car, IEEE Power Engineering Review, Oct. 1999, p.32.

4

Lewis, Mark, Once Vagrant Current, Now Impressed Current Cathodic Protection, MP, Vol 36,

July1997.

2

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:2

Corrosion on watermains as a result of interference from a DC transit system was

first reported by Stone & Forbes in 18945, just 6 years after a New England transit

system began operation. In 1901, damage to water and gas mains in Toronto,

Ontario, was reported6 as being due “to railway currents.” The currents

reportedly affected the watermains for two reasons: deterioration of the rail joint

bonds and the practice of bonding the watermains to the rails at certain locations.

The U.S. Bureau of Standards began studying the stray current traction problem

in 1910. The bureau would issue 15 reports by 1921. Many of the investigations

involved field studies, during which temporary electrolysis committees were formed

consisting of interested utility representatives. The corrosion resulting from stray

current was initially referred to as “electrolysis,” a term defined as “the

decomposition of a substance by the application of a current”.7 The widespread

corrosion of iron watermains by stray transit system currents led to the formation

in 1913 of the American Committee on Electrolysis.8

Stray current activity on underground structures arising from transit system

operation is not steady-state but dynamic in terms of current and potential

amplitude. It often reverses direction. Typical structure potential activity was

recorded on smoked charts. These charts collect data as a stylus moving in

response to a changing potential input removes the smoke from the chart, which

is rotated by a clock drive. The dynamic nature of the stray current effect on pipe

potential is shown in Figure 1-2.

5

Stone, C.A. and Forbes, H.C., Electrolysis of Water Pipes, New England Water Works Association, Vol.

9, pp.1894-5.

6

Knudson, A.A., Report on the Joint Investigation and Survey for Electrolysis on the Water and Gas

Mains in the City of Toronto, Ontario, July 1, 1906.

7

The Oxford Encyclopedic English Dictionary, Oxford University Press, 1991.

8

Meany, J.J., A History of Stray Traction Current Corrosion in the United States, NACE, Corrosion’74,

Paper 152, p.3.

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:3

Figure 1-2: Pipe-to-Soil Potential Changes due to Transit System Stray Current Activity

were Recorded on Smoked Charts

Because of the variable nature of the stray current activity, it is difficult to predict

how much corrosion would occur. The Bureau of Standards conducted a study9 in

which iron samples where subjected to AC discharge and current pick-up for

different periods of time. The resulting corrosion was compared to corrosion

produced by a steady-state DC of the same current density and discharge period.

The results of this study, reported in 1916, are summarized in Figure 1-3.

9

McCollum, B. and Ahlborn, G.H., Influence of Frequency of Alternating and Infrequently Reversed

Current on Electrolytic Corrosion, Technologic Papers of the Bureau of Standards, U.S. Dept. of

Commerce, No. 72, 1916.

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:4

100

90

80

LEGEND:

Soil

Soil + Na2CO3

70

60

50

40

30

20

10

0

-10

1/60S 1/15S

1S

5S

1M 5M 10M 1Hr.

2Days 2Weeks

D.C.

Logarithm of Length of Time of One Cycle

Figure 1-3: Coefficient of Corrosion at Different Frequencies for Iron Electrode

Denoted as Average Electrode Loss

For short periods of reversals, the corrosion was only a small fraction of the

corrosion at steady state. For equal periods of pick-up and discharge, the

corrosion coefficient remained below 20% when the cycle remained below one

hour. This meant that the corrosion occurring from dynamic stray currents was a

function of the frequency. At 60hz the corrosion rate was less than approximately

2% of the steady state value.

R.J. Kuhn, who investigated the effects of transit system stray current activity on

iron water mains in New Orleans, Louisiana, is credited with the discovery of CP.

It occurred to him in 1928 that “ordinary corrosion could be prevented by

reversing these currents”.10 Sir Humphrey Davy11 was the first person on record

to use CP by applying zinc castings to protect the copper sheathing on British

warships in 1824. Although a technical success, Davy’s application was a

10

Kuhn, R.J., Cathodic Protection of Underground Pipe lines from Soil Corrosion, API Proceedings, Nov.

1933, Vol. 14, p.164.

11

Davy, H., Philosophical Transactions of the Royal Society, London, 1824-1825.

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:5

practical failure because the copper biofouled when the corrosion was stopped—

thus reducing the speed of these sailing ships. It appears that neither Kuhn nor

any other corrosion practitioner had knowledge of this. Hence, Kuhn is

considered by one source12 as the “father” of CP (certainly as it applies to

pipelines).

Against this backdrop, stray current interference and its corrosion consequences

for underground metallic structures were first evaluated. Today electrolysis

committees exist throughout North America, and methods of mitigation that have

subsequently been developed are commonly utilized. Sources of stray current

interference are not confined to DC transit systems. They now include any

electrical source that uses the earth either intentionally or inadvertently as a

current path. This course addresses these sources and the mitigation methods that

have been developed to mitigate not only the corrosion effects, but other

deleterious consequences of stray current activity.

1.2

Typical Stray Current Circuit Arising from a

Transit System Operation

Figure 1-4 depicts stray current paths originating from the operation of an electric

transit system. Although it is the intent that the DC operating current returns to

the substation via the running rails (IR), some of the load current (IL) will pass

through the earth (Ie) if the rail is in electrolytic contact with the earth. If there is a

metallic structure in the earth, it, too, will carry some of the load current (IS).

Therefore, the load current (IL)—after passing through the locomotive—divides

into parallel paths. The amount of current in each path is inversely proportional to

the resistance of each path relative to the total circuit resistance, as Equation 1-1

indicates.

I path =

where:

12

Ipath

RT

Rpath

IL

=

=

=

=

R T • IL

R path

current in a path

total resistance of parallel paths

resistance of current path

load current

von Baeckmann, W., Schwenk, W., and Prinz, W., Handbook of Cathodic Corrosion Protection, 3rd

edition, Gulf Publishing Co., Houston, TX, 1997, p.16.

CP Interference Course Manual

© NACE International, 2006

January 2008

[1-1]

Stray Current Interference

1:6

DC

substation

O/H power conductor

IL

IR

ground

Is

running

rails

Is

Is

p ic k - u p

metallic structure

(e.g.,watermain)

d is c h a r g e

Ie

Ie

Figure 1-4: Typical Stray Current Paths Around a DC Transit System

Hence, as the resistance of the rail path increases or the resistance of the

alternative stray current path(s) decreases, a greater percentage of the load current

will appear in the stray current path(s).

1.3

Stray Current Charge Transfer Reactions on a

Metallic Structure

Figure 1-5 illustrates the typical stray current situation on an underground

metallic structure that is not electrically connected to the source of stray current.

The stray current pattern consists of a pick-up of stray current from the earth at

one or more locations and the subsequent discharge of stray current to the earth at

one or more locations.

Is

Is

stray current

pick-up

Is

stray current

discharge

Is

Figure 1-5: Typical Stray Current Interference on a Metallic Underground Structure

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:7

The principal charge carriers in the earth are ions. They are electrons in the

metallic structure. For these reasons, electrochemical reactions must transfer the

charge between the structure and earth at both the pick-up and discharge

locations.

At the pick-up location(s), it is through reduction reactions that the electrical

charges are transferred. Depending on the nature of the electrolytic environment,

the reduction reactions can be one or more of the following:

H3O+ + e–

Æ

HO + H2O

[a]

O2 + 2H2O + 4 e–

Æ

4OH–

[b]

2H2O + 2e–

Æ

H2↑ + 2OH–

[c]

Reaction [b] is favored in well-aerated soils and waters; reduction reaction [a] is

favored in acidic soils or waters. Reduction reaction [c], which involves the

breakdown of water molecules to hydrogen gas and hydroxyl ions, can occur

under all conditions if there is sufficient over-voltage applied.

At the discharge location, one or more of the following oxidation reactions

transfers the electrical charge.

M0

Æ

Mn+ + ne–

[d]

4OH–

Æ

O2 + 2H2O + 4e–

[e]

2H2O

Æ

O2 + 4H+ +

[f]

4e–

Reaction [d] tends to occur on most basic metals such as iron, copper, zinc, and

aluminum when the electrolyte has an acid or neutral pH. Reaction [e] is more

likely in electrolytes with a high pH. Reaction [f] is more likely to occur when

the over-voltage reaches the oxygen line. The oxygen line is line “b” on the

Pourbaix diagram for iron (Figure 1-6).

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

-2

1:8

0

2

4

6

8

10

12

14

2

2

1.6

1.6

1.2

b

1.2

0.8

0.4

0

current

pick-up

a

0.8

current

discharge

0.4

3

passivation

0

corrosion

-0.4

-0.4

-0.8

1

-1.2

immunity

-0.8

2

corrosion

-1.2

-1.6

-1.6

-2

16

0

2

4

6

8

10

12

14

16

pH

(assuming passivation by a film of Fe2O3)

Figure 1-6: Simplified pH Pourbaix Diagram for Iron in Water at 25ºC Showing

Potential Shift Direction for Current Pick-up and Discharge at Low pH

The Pourbaix diagram for iron in pure water represents three zones of

thermodynamic stability: corrosion, immunity, and passivity based on a potential

(SHE) vs pH relationship. Line (a) is the hydrogen line and line (b) is the oxygen

line. Water is stable between these two lines. If the potential of iron is shifted to

either of these lines, then oxygen is generated at line (b) and hydrogen gas at line

(a).

For an iron structure without CP that is exposed to a neutral or low-pH water, a

current pick-up will cause the potential to shift in the negative direction toward

the immunity zone and afford the structure some CP. Conversely, at the

discharge location, the potential is shifted in the electropositive direction into the

passive region if not at a low pH—where it would otherwise remain in the

corrosion zone.

On a cathodically protected structure as illustrated in Figure 1-7, where the

electrolyte at the iron surface normally has a high pH, a current discharge

resulting in a positive shift can produce a passive film given by the following

reaction:

Fe + 2H2O Æ Fe(OH)2 + 2H+ + 2e–

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

-2

1:9

0

2

4

6

8

10

12

14

2

2

1.6

1.6

1.2

b

1.2

0.8

0.8

0.4

0

0.4

3

a

passivation

0

corrosion

current

discharge

-0.4

-0.8

1

-1.2

immunity

corrosion

current

pick-up

0

2

4

6

8

-0.4

-0.8

2

-1.2

-1.6

-1.6

-2

16

10

12

14

16

pH

(assuming passivation by a film of Fe2O3)

Figure 1-7: Simplified pH Pourbaix Diagram for Iron in Water at 25ºC Showing

Potential Shift Direction for Current Pick-up and Discharge at High pH

The ferrous hydroxide formed is relatively stable at high pH. Because this

reaction also produces hydrogen ions, the pH will decrease with time.

1.4

Effects of Stray Current on Metallic Structures

It is apparent that the effect of a stray current pick-up and a stray current

discharge from an iron structure from a thermodynamic perspective can cause

corrosion, passivation, or immunity, depending upon the direction of current and

the pH of the aqueous electrolyte at the charge transfer location.

1.4.1 At the Current Discharge Location

Identification of the current discharge site receives considerable attention in stray

current investigations because it is the location where corrosion damage is most

likely to occur on all metallic structures. When a current transfers from a metallic

structure to earth (Figure 1-8), it must do so via an oxidation reaction that

converts electronic current to ionic current.

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:10

metal

structure

(electrons)

Is

O

X

I

D

A

T

I

O

N

Is

earth

(ions)

Is

Figure 1-8: Current Discharge from a Metal Structure to Earth via an Oxidation Reaction

The generic oxidation reaction is the corrosion of the metal as in Equation 1-2.

Mo Æ Mn+ + ne–

[1-2]

For steel, the oxidation reaction is:

Feo Æ Fe++ + 2e–

[1-3]

A stray current discharge from a metallic structure may not cause corrosion attack

if the structure is receiving CP (Figure 1-9). Whether the superposition of a stray

current discharge and a CP current pick-up at a metal/electrolyte interface causes

corrosion will depend on time and the relative magnitudes of these two currents.

metal

structure

O

X

I

D

A

T

I

O

N

R

E

D

U

C

T

I

O

N

Is

Is

Is

Icp

Icp

earth

Icp

Icp

Figure 1-9: Superposition of a Stray Current and a Cathodic Protection Current at a

Metal/Electrolyte Interface

CP current transfers across the metal/earth interface via a reduction reaction,

which produces hydroxyl ions in either of the three following reactions:

H3O+ + e– Æ HO + H2O

[1-4]

O2 + 2H2O + 4e– Æ 4OH–

[1-5]

2H2O + 2e– Æ H2Ç + 2OH–

[1-6]

In the presence of a high concentration of hydroxyl ions, a possible oxidation

reaction is given in Equation 1-7. The reaction involves the oxidation of hydroxyl

ions to oxygen and water.

4OH– Æ O2 + 2H2O + 4e–

[1-7]

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:11

This latter reaction does not consume metal atoms; therefore, there is no corrosion

damage. Hence, as long as the polarized potential at the structure electrolyte

interface is not driven more electropositive than the CP criterion (e.g.,

–850mVcse for iron or steel), significant corrosion would not be expected.

If the metal has a surface passive film or is a relatively inert material (such as some

of the materials used for impressed current anodes), then not all of the stray current

need transfer through a corrosion reaction. If the stray current polarizes the metal

surface electropositively to the oxygen line on the Pourbaix diagram, then the

hydrolysis[13] of water molecules by the following reaction 1-8 is likely.

2H2O Æ 4H+ + O2Ç + 4e–

[1-8]

This oxidation reaction does not result in the consumption of the metal surface, but it

does produce an acidic pH from the generation of hydrogen ions.

On an iron or steel structure without CP, the oxidation reaction is usually the

dissolution of the metal according to Equation 1-9

Feo

Æ

Fe++ + 2e–

[1-9]

The severity of corrosion depends on the magnitude of the stray current and time

as related by Faraday’s Law:

Wt =

M

t I corr

nF

[1-10]

where:

Wt = total weight loss at anode or weight of material produced

at the cathode (g)

n = number of charges transferred in the oxidation or

reduction reaction

Icorr = the corrosion current (A)

F = Faraday’s constant of approximately 96,500 coulombs per

equivalent weight of material (where equivalent weight =

M

)

n

M = the atomic weight of the metal that is corroding or the

substance being produced at the cathode (g)

t = the total time in which the corrosion cell has operated (s)

13

Hydrolysis is defined as a double decomposition reaction involving the splitting of water into its ions

and the formation of a weak acid or base or both. CRC Handbook of Chemistry and Physics, CRC

Press, 53rd Edition, 1972-1973, PF-83.

CP Interference Course Manual

© NACE International, 2006

January 2008

Stray Current Interference

1:12

Given the atomic weight of pure iron as 55.85 g and assuming 100% efficiency

and pure DC, the consumption rate of iron as illustrated in Table 1-1 is 9.13

kg/A-y.

Table 1-1: Theoretical Consumption Rates of Various Metals and Substances

Reduced

Species

Oxidized

Species

Al

Cd

Be

Ca

Cr

Cu

H2

Fe

Pb

Mg

Ni

OHZn

Al+++

Cd++

Be++

Ca++

Cr+++

Cu++

H+

Fe++

Pb++

Mg++

Ni++

O2

Zn++

Molecular

Weight, M

(g)

26.98

112.4

9.01

40.08

52.00

63.54

2.00

55.85

207.19

24.31

58.71

32.00

65.37

Electrons

Transferred

(n)

3

2

2

2

3

2

2

2

2

2

2

4

2

Equivalent

Weight, M/n

(g)

8.99

56.2

4.51

20.04

17.3

31.77

1.00

27.93

103.6

12.16

29.36

8.00

32.69

Theoretical

Consumption Rate

(Kg/A-y)

2.94

18.4

1.47

6.55

5.65

10.38

0.33

9.13

33.9

3.97

9.59

2.61

10.7

On pipelines, the total weight loss is usually less important than the penetration

rate. By re-arranging Faraday’s Law, the weight loss per unit time per unit area is

shown to be directly proportional to current density (i = I/A) as in Equation 1-11.

Wt

A tt

=

M

i

nF

[1-11]

Dividing this equation by the density (d) of the metal or alloy produces the

corrosion rate (rcorr), which can be expressed in mm/y (Equation 1-12).

rcorr

=

k M is

nF d

where:

M

n

i

k

d

rcorr

=

=

=

=

=

=

CP Interference Course Manual

© NACE International, 2006

January 2008

atomic weight (g)

number of charges transferred in corrosion reaction

current density (μA/cm2)

unit correction term ≈ 3.156 x 108 mm s/cm yr

density (g/cm3)

penetration rate in (mm/yr)

[1-12]

Stray Current Interference

1:13

Example: Using Equation 1-12 to calculate the penetration rate based on a current

density of 1 A/m2 (10-4 A/cm2):

where:

i = 10-4 A/cm2

d = 7.87 g/cm3

M = 55.85 g

n = 2

F = 96,500 coulombs

then:

rcorr =

3.156 × 10 8 mm s/ cm yr × 55.85g × 10 -4 A/cm 2

2 × 96,500 coulombs × 7.87 g/cm 3

= 1.16 mm/y

Table 1-2 gives the penetration rate, in mpy and 10-3 mm/y, equivalent to a

current density of 1μA/cm2 for a number of common pure metals.

Table 1-2: Electrochemical and Current Density Equivalence with Corrosion Rate

for Some Common Pure Metals

Metal/Alloy

Pure Metals

Iron

Nickel

Copper

Aluminum

Lead

Zinc

Tin

Titanium

Zirconium

Element/

Oxidation

State

Density

(g/cm3)

Equivalent

Weight

(g)

Fe/2

Ni/2

Cu/2

Al/3

Pb/2

Zn/2

Sn/2

Ti/2

Zr/4

7.87

8.90

8.96

2.70