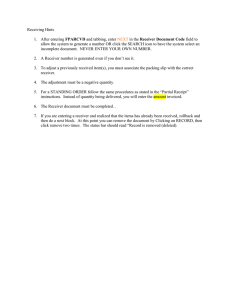

Executive summary: A compressed air receiver was required to hold compressed air to power a roller coaster carriage. For safety reasons the pressure vessel was to conform to British Standard 5169 – Fusion welded air receivers. The British Standards: BS 470 – Inspection, access and entry openings for pressure vessels, BS 10: Flange dimensions, BS 5276: Supports for Pressure Vessels, BS 4504: Flanges and BS5500: Annex C: Fatigue in pressure vessels, were also used to inform the design. The estimated cost for the air receiver, supports and flanges is $29486 (NZD) including labour, consultancy and inspection costs, but excluding GST. A heat exchanger for cooling the inlet temperature of the air from the compressor was sized. A counter-flow two pass heat exchanger arrangement was selected to make the exchanger as compact as possible. It was found that the heat exchanger needed to have 0.09 m2 of air pipe surface area to dissipate the 1 [kW] of heat from the air. Design issues: Several constraints on the design of the air receiver were stated in the design brief. Most of the stated constraints had only minor implications for the design of the vessel. The major design constraints presented by the design brief were: a maximum operating pressure of 10 [bar], a capacity of 2.5 [m3], and a 10,000-hour service life over ten years. Naturally, costs were also to be kept as low as possible. The implications of these constraints respectively were that: the receiver needed to be of 2.5 m3 volume, with a wall thickness to resist 10 [bar] of pressure with a sufficient safety factors on yielding and fatigue life. The volume constraint was met by selecting the ends of the pressure vessel first and deducting their combined volume from the required 2.5 m3 to find the volume required by the cylindrical section of the pressure vessel. With this, an appropriate combination of length and radius was selected. The pressure constraint was met by calculating the axial and radial stress and selecting a wall thickness that would provide a suitable safety factor against yielding. The fatigue constraint was met by performing fatigue analysis of the vessel and using the results to ensure the selected material would have a sufficient service life. Concept Sketches: During the initial design stage, several concepts were considered for the air receiver. Only variations on welded cylindrical concepts were considered due to the practicality and industry familiarity of cylindrical designs. However, different end designs were considered including toroidal, hemispherical and semi-elliptical. The final chosen design will be subject to development and changes after consultation with the standard. The first concept considered consisted of a cylindrical tank with two hemispherical ends with the outlet/inlet flange on one of the ends. A second hand-hole would be situated on the cylindrical portion of the tank to allow inspection of the area that could not be seen from the end. Figure 1: Concept 1 - Hemispherical Ends This concept was rejected because it was considered overly complex and expensive compared to the others. Since spherical ends are more expensive than elliptical ends, this concept would cost more than the other two and the structural advantages of the hemi-spherical ends would likely be negated by the flange and pipe attachments. Thus, this concept would probably be more expensive than the other two for little advantage. The second concept involved a mixed end tank, with one spherical end and one elliptical end. The inlet/outlet would protrude from the spherical end and a flange opening would be present in the elliptic end. Figure 2: Concept 2 - Mixed Ends This concept was rejected because it had the disadvantages of both the first and third concepts. Namely, that it would have the more expensive and cumbersome spherical end, with its structural properties undermined by the manhole, whilst also possessing a structurally weaker elliptical end. This concept would also have added logistical difficulties of sourcing two different ends, potentially from different suppliers. This could make the manufacturing of the ten tanks required unnecessarily difficult compared to the other designs. It would also be more expensive than just using two elliptical ends. The final considered concept consisted of the first concept but with semi-elliptical ends rather than hemi-spherical. Although the semi-elliptical ends are will have higher stress levels than hemi-spherical ends, they will make the tank easier to transport and store due to their more convenient shape. Also, since both tank ends are the same, there will be less potential for logistical difficulties when sourcing the ends during manufacturing. Elliptical ends are also usually less expensive than spherical ends because they are easier to manufacture. Figure 3: Concept 3 - Elliptical Ends with closed flange This concept was selected because it would be the least expensive and the most practical to manufacture in the numbers required (10). The elliptical ends will be cheaper and potentially easier to source than a mixture of ends. Although the elliptical ends are less effective at withstanding pressure, any increase in stress can be compensated for with a slightly higher wall thickness. Scope of standard BS5169: The primary standard used for this study was BS5169 – fusion welded steel air receivers. This standard covers the design and manufacture of unfired fusion-welded pressure vessels which are to contain compressed air. The design brief specifies an unfired pressure vessel for holding compressed air, therefore BS5169 should be appropriate. It should be noted however, that BS5169 does not specify fatigue requirements for pressure vessels a fatigue analysis will need to be performed using BS 5500 in lieu of a specification from BS5169. The design of the vessel supports will need to be taken from BS 5276, and the access hole design from BS 470 as these topics are not covered by BS 5169. Class of air receiver according to BS5169: From an examination of BS5169, it was decided that the most appropriate class of air receiver was Class II. Class II was considered the most appropriate because the pressure vessel design meet the criteria of having a design pressure below the 35 [bar] limit and the product of the internal diameter and design pressure less than 37000 [bar-millimetres]. The air receiver cannot be classed as Class III because the product of the internal diameter and design pressure is more than 8800 [barmillimetres]. This means that the testing protocol will be slightly more stringent than a Class III vessel, but less severe than a Class I vessel. Although Class I is very broad and could potentially be applied to the design, it would require needlessly stringent inspection and testing protocols which would make the design more expensive than it would need to be. The costs saved from reducing the rigor of the testing and inspection could be used in additional material to strengthen the vessel. Identification of materials: The chosen material for the cylindrical portion of the vessel is 1800 [mm] width by 5800 [mm] length, 10 [mm] thick mild steel plate from BS5169 Table 2. This steel was chosen due to its availability from easysteel in New Zealand. 10 [mm] thick plate needed to be used because the next smallest size (8 [mm]) would have been below the required thickness. This steel complies with BS4360 and has material properties matching that 40B carbon Steel from Table 2 of BS5169. The plate steel will have to be cut into the required rectangular shape (1.8m by 3.754 m) and then rolled into a cylindrical shape using a cylindrical rolling machine. Identification of Joint Factor: From BS5169 Table 1, the “Joint Factor” J is determined to be 0.75. The material chosen for the cylindrical section of the air receiver is plate steel, Table 2 of BS5169 states that the Joint factor for Class II vessels with plate steel should be 0.75. Diameter and End choice: An internal diameter of 1.195 [m] was chosen. It was thought that a small diameter with a relatively long length would be preferable to the opposite situation of a flat, disk-like container that may be harder to transport. This internal diameter allows the use of Dispatch and Garlick Ltd 1195 [mm] internal diameter elliptical dished ends at both ends. Determine the length of the cylindrical section: The volume of the chosen ends are 0.242 m3 each. Since there are two ends, this means that the cylindrical volume needs to occupy 2.016 m3 of space. Using this volume value means a cylindrical length of 1.8 [m]. Since the length of each is 300 [mm], the total length of the pressure vessel is 2.4 [m]. The total length to diameter ratio is almost exactly 2, this seems like a reasonable compromise between length and diameter. Figure 4: Cylindrical Section Length calculation Decide on four pressures: Table 1: Pressures used in the design of the air receiver Safety Valve pressure Design pressure Hydrostatic test pressure Working pressure 10.5 bar 11 bar 16.5 bar 10 bar Table 1 shows the four pressures involved in the design of the air receiver. The safety valve pressure specifies the pressure at which the safety valve will open to relive the pressure and prevent failure. The design pressure is the pressure used in the calculation of the stresses in the pressure vessel. The hydrostatic test pressure corresponds to the pressure specified by BS5169 with which the air receiver is formally tested using water, it is 1.5 times the design pressure. The working pressure is the pressure at which the air receiver operates at in practice, in this case it is the same as the design pressure. Determine thickness of shell: Using Equation 2 from BS5169, the thickness of the shell of the cylindrical component of the air receiver was determined: Figure 5: Cylindrical Shell Thickness Calculation Since the required steel plate is only manufactured in increments of 2 [mm], plate with a thickness of 10 [mm] must be used. Calculation of end thickness and Determine what to do if they are different thicknesses: The calculated thickness of the cylindrical shell is 10 [mm]. The thickness of the chosen dished elliptical ends, given by the manufacturer is 12 [mm]. Figure 6: Figure 8 (b) of BS5169 regarding the mating of the dished ends to the cylindrical section Figure 6 demonstrates the procedure that is required to mate the elliptical ends to the cylindrical shell. The edges of the end will be ground down from 12 [mm] to 10 [mm] over at least 10 [mm] length. This will result in a more even stress distribution at the mating point that will not create weak points where the cylindrical shell meets the ends. Determine weld specifications from the standard: As according to BS5169, the longitudinal and circumferential welds of the air receiver will be double sided butt welds, with the weld metal built up to 10% more than the plate thickness, or 11 [mm] in this specific situation. Before welding, the metal around the seams should be clean, dry and free of slag, scale and irregularities. The longitudinal and circumferential welds should be C grade welds with removable backing plates on one side, as according to BS 5169 Table 1. The branch pipes at the air inlet/outlet and manhole are to be attached to the shell of the receiver with fillet welds whose dimensions are listed on the weld detail drawing. The flanges are likewise welded to the branch pipes using filet welds whose dimensions are also listed on the weld specification drawing. Decide on branch connections and flanges; determine branch pipe wall thickness: The brief stipulates that the air entry pipe (presumably from an air compressor) must be at least 80 [mm] internal diameter, and the air exit pipe must be at least 200 [mm] internal diameter. Since the diameter of both of these connections is greater than 50 [mm], BS5169 specifies two possible options for the welding of the connections to the air receiver: full penetration or two fillet welds around the circumference of the welds. The double fillet weld option was chosen because it was believed to be simpler and potentially less expensive than a single full penetration weld. The flanges and branch pipes were chosen in accordance with BS10 and BS5169. BS10 requires that a flange of the size required for exit pipe (200 [mm]) must be slipped on over the outside diameter of the pipe and welded on. Asmuss 366.6 [mm] Outer Diameter, 246 [mm] Nominal Bore, 20 [mm] wall thickness, schedule 160 steel pipe was chosen for the air exit pipe. The corresponding slip-on flange was selected from the same table and may be seen in Figure 12 of the appendices. The Flange will be welded 200 [mm] from the entry of the pipe into the receiver. Asmuss 120 [mm] Outer Diameter, 80 [mm] Nominal Bore, 10 [mm] wall thickness pipe was chosen for the air inlet. For logistical simplicity, the corresponding slip on flange (ASMUSS NB 100) was selected from the same supplier and may also be seen in Figure 12 of the appendices. The blind flange selected for the Manhole was selected as an ASME Class 600 NPS 16 Blind Flange. This will be welded on to the 95 [mm] protruding length of 20 [mm] wall thickness pipe. Calculations and decisions for manhole and inspection openings: The air receiver will have an inside diameter between 800 and 1500 [mm] and a cylindrical section between 0 and 2000 [mm], therefore the design needs to adhere to reference 4a of BS5169 Table 3. According to reference 4a of Table 3 of BS5169 and BS470 Table 2 and section 4.5, it is satisfactory for the air receiver to have a single manhole of 460 [mm] at one of the dished ends of the pressure vessel. Since one of ends will already be connected with pipework, the other end will have the manhole. A logical design for the manhole is a circular ‘blind flange’ that is sealed with a bolted plate when not open for access and inspection. According to BS5169 section 33, an air receiver with an opening greater than one third of the internal diameter may only be used if the design is confirmed by proof hydrostatic testing. Since the ratio of the proposed manhole diameter to the internal diameter of the receiver is greater than one third, the design must be proofed with hydrostatic testing before being used. Note that manhole neck length is limited as shown: BS5169 section 25.2.4 and BS470 section 2.7 were used to inform the manhole neck length. A flush attachment was chosen, as opposed to a projecting branch design, as it was though that a flush manhole would be easier for personnel to get in and out of. BS5169 section 25.2.4 specifies that the length of the manhole, shown in Figure 8 may not exceed 150 [mm]. The length of the hole was chosen as 120 [mm] as a compromise between safety and ease of access. Determine if compensation is required: The “Z” factor equations from section 33 of BS5169 were used to calculate the Z values for the air inlet, air outlet, drainage hole and manhole to determine to determine whether compensation was required. Figure 7: "Z" factor calculations from BS5169 to determine if compensation is required Since the ‘Z’ factor of the inlet, outlet and manhole are above 0.15, compensation calculations are required to ensure the receiver will not fail in service. The Z factor of the drainage hole is below 0.15 and thus does not compensation to be safe. BS5169 lists several options for compensation. The simplest of these is welding ‘compensation rings’ of additional material around the openings to increase the effective thickness of the shell. This approach is illustrated in Figure 10. However, if the compensation provided by the opening walls is sufficient to compensate for the area lost from the opening, then no compensation ring will be required. Figure 8: BS5169 figure 15 Compensation for openings Figure 9: Air Outlet compensation calculation In the case of the Air Outlet, the branch pipe itself provides sufficient compensation for the opening it creates. Thus, no additional compensation rings are required. Figure 10: Air inlet compensation calculation Again, since the cross-section area of the pipe work is greater than the missing area from the opening, the air inlet does not require any additional compensation. Figure 11: Manhole compensation calculation As in the case of the air inlet and outlet, the manhole cover does not require any additional compensation because the crosssectional given from the manhole side walls are sufficient to compensate for the lost area from the opening. Therefore, none of the openings in the air receiver require any additional compensation. Drainage design: BS5169 requires that an air receiver of Class II have at least one drainage hole of 15 [mm]. To satisfy this requirement, the receiver will have a 15 [mm] internal diameter drainage hole in the bottom of the cylindrical section. This will allow the water from hydrostatic tests and any condensation that forms to be drained. Stress analysis of vessel from first principles; hydrostatic pressure conditions: A first principles analysis of the stresses of the pressure vessel was conducted to as a check on the results given by the equations in BS5169. Thin walled analysis was considered justified because of the large size of the internal diameter (1195 mm) compared to the wall thickness (10 mm). Figure 12: Determination of the stresses in air receiver from first principles for the hydrostatic test pressure (16.5 bar) Figure 13: Elliptical end stress calculation for the hydrostatic test pressure (16.5 bar) The hoop and longitudinal stress in the air receiver are well below the yield stress of the cylindrical and end steel (235 MPa), with a factor of safety of 2.62 against yielding. Because of this, the selected wall thickness of 10 [mm] is acceptable and will be safe in practice. Since the ends are 12 [mm] thick will have a stress level below that of the hoop stress, their factor of safety will be higher than the cylindrical section and will therefore be safe from yielding. Saddle supports (BS 5276) or other supports: BS 5276 informed the design of the air receiver supports. For simplicity, the material of the supports and saddle plates was chosen to be the same as the shell – 40B mild steel plate. BS 5276 specifies that the supports be fabricated with continuous fillet welds on both sides of the plate with leg lengths of 6 [mm], and that the welds connecting the saddle plates to the air receiver have continuous fillet welds with 10 [mm] leg length. According to Figure 6 of BS 5276, the centre of the supports must be located within 250 [mm] to 299 [mm] of the connecting welds between the cylindrical section and the ends, for a receiver of internal diameter 1195 [mm]. The supports were chosen to be located 275 [mm] from the connecting welds to achieve a compromise between the stability of the receiver and preventing deflection of the cylindrical section. Thermal expansion and bending stresses; support design to allow for expansion: According to BS 5276, one support must be fixed using hold down bolts and the other must be restrained laterally, but free to move axially, to accommodate movement from thermal effects and axial strain. The weight of the cylindrical section(W) was calculated and compared to the load on each support (Wv) to see if low friction material (PTFE film) was required for the non-bolted support as according BS 5276 Section 6.1: Figure 14: Calculating whether the unbolted support will require anti-friction material Since the load exerted on each support will be greater than 0.1Wv, anti-friction material will be required in between the nonbolted support and the friction surface. Hold down bolts and configuration: BS 5276 specifies the hold down bolts for an air receiver of the diameter in question as M20 bolts with 26 [mm] diameter bolt holes. Linear interpolation from BS 5276 Table 1 gives a minimum tensile force of 2892 [N] per bolt, assuming no moments are exerted from the pipework on the receiver. Two countersunk bolts will be used at each end of the bolted support, as according to Figure 5 of BS 5276. Figure 15: BS5276 figure 1 displaying the construction of the air receiver supports Table 2: Dimensions and related quantities of the air receiver supports Specification P B C D E F G H J M X Dimension [mm] 1150 226 10 15 290 500 180 250 12.5 85 90 Y Diameter of bolt holes Size of bolts 12 26 M20 Heat treatment of air receiver: Since none of the air receiver plates exceed 20 [mm] in thickness, heat treatment is not required, as according to BS5169 section 24.1. Consider the need or otherwise of a full fatigue analysis, using BS 5500 Appendix C: Figure 16: Calculation as to whether a full fatigue analysis is required according to BS5500 Appendix C Since the total number of cycles over the required life of the air receiver (85,715) is much less than the limit given by BS5500 Appendix (3,000,000), the air receiver should be safe from fatigue over its 10-year expected life and a full fatigue analysis is not required Test and Inspection procedures: In the past, pressure vessel failures have led to significant injury and damage to property. To avoid these costly failures, the design and use of pressure vessels is subject to compliance and testing procedures designed to certify the design and allow any failures to occur in a controlled environment. The air receiver shall only be used after the following: The correct procedure regarding plate sample testing from BS5169 section 20 has been followed, and the appropriate testing authority has confirmed that the plate material is usable. Before any welding takes place, the documentation of the plate material and to be used in the receiver must be checked to ensure that the correct material is being used and that the plate is correctly certified. The same procedure should be followed for the ends of the receiver. The welder or welders for the fabrication of the receiver must be certified as according to section 18.1 of BS 5169. The procedure for testing whether samples of the receiver material conform to the specified limits must be followed as per BS 5169 section 20. Although inspection of receiver welds is not required for Class II vessels in BS 5169, at the bare minimum the welds of the receiver should be thoroughly visually inspected before any testing takes place. Ideally, full radiographic examination of the welds would be done, however where this is not possible all possible precautions should be taken to check the quality of the cylindrical seam weld and the circumferential end welds. The welds of the receiver must be tested as according BS 5169 section 19.2* The receiver must undergo a hydrostatic pressure test at 1.5 times the design pressure (16.5 bar), completed to the standard set out in section 36 of BS5169. The test must be witnessed by a qualified representative of the appropriate inspecting authority. Following the successful completion of the hydrostatic pressure test, a plate with the attributes listed in section 37 of BS5169 should be welded to the vessel After all tests and inspections are carried out, a signed and dated certificate of construction and test should be issued with the receiver, as according to section 38 of BS5169. Should the receiver fail any of the tests or inspections, the BS 5169 section 21 protocol for retests should be followed. If any repairs of the air receiver are required, the receiver should be retested as according to BS 5169 section 21 Although it is not required by BS 5169, the welds of the supports and the welds connecting the support saddle to the receiver should be inspected before the receiver is used. This could be done visually, or using radiographical examination. During installation/commissioning, it should be checked that the correct bolts have been used in the flanges and supports (M20) *Note: since the receiver in question is Class II, the welds do not need to be radiographically examined (X-rayed), however it is recommended for additional safety Cost estimate: Table 3 displays the estimated costings of the components of a single pressure vessel. The fabrication labour cost of cutting, rolling, welding and other fabrication tasks was estimated as being approximately equal to the material cost. The costing estimate in Table 3 is indicative only, and should only be considered a guide to the actual cost. The cost estimate also excludes GST, thus if GST is to be paid, then 15% must be added to the displayed total. Weld gases have not been included because it is assumed that an established machine shop will have gases as part of normal operation. Table 3: Estimated costs in NZD of pressure vessel components excluding GST Item 10 [mm] 40B steel plate @ $290/m2 Dispatch and Garlick Ltd 1195 [mm] @ $1185 each 460 [mm] Internal Diameter Manhole Flange 80 [mm] Internal Diameter Air Inlet Flange 200 [mm] Internal Diameter Air Outlet Flange 500 [mm] diameter Steel pipe for Manhole 100 [mm] Steel pipe for Air inlet 246 [mm] Steel pipe for Air outlet Engineering consultant time @ $120/hour 3.2mm welding rod 350mm long Inspector callout time @ $350/hour 25 [mm] Diameter Steel drainage pipe Labour (cutting, rolling, welding etc) TOTAL Amount 17 m2 2 1 1 1 1m 1m 1m 83 hours 5 kg 8 hours 1m N/A Cost [NZD] 4930 2370 330 30 156 220 80 170 9960 56 2800 22 Approx. equal to material cost ~8362 29486 The brief mentioned that ten of the designed pressure vessels would be required. Because of economies of scale and/or special arrangements with suppliers it is potentially possible to reduce the cost on a per vessel basis. For example, the large quantities of plate required for ten vessels (170 m2) could potentially entice a supplier to accept a lower cost per square meter. Also, since the design of the vessel would not need to be redone, the substantial cost of the Engineering consultant time ($9960) could be distributed over multiple vessels. Also, the eight hours of Inspector callout time reflects that all ten of the requested pressure vessels would be tested one after the other on the same day during one callout. Pressure vessels from other projects could also be tested during this inspection time to further maximise cost savings. Due to the high cost of the inspection time, it is highly recommended that as much preparation as possible is completed prior to the inspection callout, to maximise the amount of inspection time that can be used for actual testing and examination. Part B: Heat exchanger A heat exchanger to keep the air inlet temperature below 70 [Deg C] was sized. The chosen design for the heat exchanger was a two-pass counter flow shell and tube exchanger, seen in Figure 23. The two-tube pass arrangement was chosen to make the exchanger as compact as possible. In the design of the heat exchanger it was assumed that tap water at 15 [Deg C] would be freely available at the site. The U value for the heat exchanger was taken as 125 [W/m2K] for an air – water exchanger with copper pipe with negligible wall thermal resistance, from Heat and Mass transfer 5th edition, Cengel, Ghajar, Table 11 – 1. Because the inlet and outlet temperatures were known, but the surface area was unknown the log mean temperature difference method was used to size the heat exchanger. The LMTD method allows the calculation of the heat exchanger area if the inlet and outlet temperatures are known. Figure 17: Compressor air exit temp calculation Assuming that the air acts as an ideal gas and is not cooled by the compressor, the heat exchanger will need to cool the air down from 281 [Deg C] to 70 [Deg C]. Figure 18: Heat Exchanger Sizing Calculations Part 1 Therefore, the heat exchanger needs to be able to dissipate 1 [kW] of heat from the air. Figure 19: Heat exchanger Log mean temperature difference calculation Figure 20: Correction Factor F determination Figure 21: Heat exchanger Area sizing It is assumed that copper piping with negligible wall thermal resistance is used in the heat exchanger. Copper has very high thermal conductivity and it routinely used in heat exchangers. The air pipe diameter was taken as 0.05 [m] as it is a very common piping size and easily available. Figure 22: Determining the water mass flow rate Figure 23: Heat Exchanger Sketch Figure 24: Compressor, Heat exchanger and Pressure vessel setup sketch The minimum length of the air pipe inside the heat exchanger is 0.573 [m]. By making the air pipe pass through the heat exchanger, the overall length of the heat exchanger can be effectively halved. The length of the air pipe can be extended to decrease the air outlet temperature below 70 [Deg C] for additional safety. It should be noted that the temperature of the air coming of the compressor assumes that the compressor has no cooling mechanism for the outgoing air. Realistically, most compressors have cooling mechanisms to prevent overheating. Due to the uncertain on the correction factor F and the natural variability in the water inlet temperature, it is highly recommended that the heat exchanger be over built with dimensions greater than those suggested here. In other words, the air pipe pass should be made longer than 0.29 [m] and/or greater than 0.05 [m] diameter. The values suggested here are minimum values and under no circumstances should the heat exchanger have dimensions below their listed values. Table 4: Heat Exchanger values Q’ – Heat dissipated 1 [kW] As – surface area of air pipe 0.09 [m2] U – total heat transfer coefficient 125 [W/m2K[ F – correction factor 0.775 ∆Tlm – log mean temperature difference 116 [Deg C] mwater’ – mass flow rate of water 0.0044 [kg/s] mair’ – mas flow rate of compressor air 0.006 [kg/s] L – length of air pipe 0.573 [m] D – diameter of the air pipe 0.05 [m] P – correction factor chart x-axis value 0.21 R – correction factor chart curve value 3.84 Tair, inlet 281 [Deg C] Tair,outlet 70 [Deg C] Twater, inlet 15 [Deg C] Twater, outlet 70 [Deg C] *NOTE: apostrophe refers to the time derivative of the quantity Timesheet: Table 5: Timesheet table of assignment sections and time taken to complete (including revisions). Dated: 7/10/2020 Section Initial Design scoping of standard Receiver class Identify materials Joint factor Diameter/End selection Cylindrical length 4 pressures Shell thickness End thickness Weld specification Branch connections/pipe wall thickness Manhole calculations Drainage design supports First principles calcs Thermal expansion/bending stresses Hold down bolts Heat treatment calcs Fatigue analysis Inspection/Commissioning procedures Cost estimate Drawings Formatting/revisions Heat exchanger Total Time [hours] 5 1 2 3 2 3 2 3 2 2 2 3 3 2 4 4 2 4 1 2 4 4 16 4 3 83 Appendices: Figure 25: easysteel 40B steel plate table, 5800 [mm] by 1800 [mm] was in used in the design of the air receiver Figure 26: Blind Flange table used in selection of air inlet and exit pipe Figure 27: Pipe Schedule Table used for air exit/inlet/manhole DESCRIPTION ECO ASMUSS 100 [mm] Nominal Bore Flange 10.0 3 XXX 01JAN13 40.0 40.0 Manhole with blind flange cover (M20 bolts) ASME Class 600 NPS 16 Blind Flange 250.0 246.0 1219.0 DATE RELEASE ASMUSS 246 [mm] Internal Diameter Flange R607.5 APPROVED Air Inlet (from compressor) Air Outlet (to roller coaster) 20.0 REV. REV1 Weld line may be anywhere except intercepting Air inlet or drainage tap 100.0 2. GD&T AS PER ISO1101-2004. ZONE 74.6 1. ALL DIMENSIONS IN MILLIMETERS. REVISIONS NOTE: *FOR ALL WELD DETAILS SEE DRAWING 3 - WELD SPECIFICATIONS 140.0 10.0 NOTES - ( UNLESS OTHERWISE SPECIFIED ) 125.0 50 .0 1215.0 40.0 15.0 567.8 504.7 12.0 415.7 4° 1150.0 1180.0 1270.0 2 1800.0 12.5 ITEM NO. 1800.0 6 180.0 1 2698.4 Anti-Friction PTFE Material Between 2nd and 3rd Base Plate Layers (BS 5276 Figure 5 4 Bolted support 2x M20 bolts at each end 10.0 PART NUMBER DESCRIPTION QTY. Rolled/Welded Cylindrical Section 1 End with Air Outlet and Flange 1 1 Cylindrical Section 2 Air Outlet Flange end 3 Manhole end End with Manhole and Closed Flange 1 4 Bolted Support Sliding/Unbolted Support 1 5 Bolted Support Sliding Support 6 Air Receiver Base Plate Supporting Base Plate 1 THIRD ANGLE PROJECTION MATERIAL THIS DOCUMENT IS ISSUED IN STRICT CONFIDENCE ON CONDITION THAT IT IS NOT COPIED, REPRINTED, OR DISCLOSED TO A THIRD PARTY EITHER WHOLLY OR IN PART WITHOUT THE WRITTEN CONSENT OF UNIVERSITY OF CANTERBURY AIR RECEIVER PAINTED .X .1 .XX DECIMAL .03 mm .XXX DESIGN DWG NO. DRAWN PROJECT SUPERVISOR ISSUE DATE M.DURRANT TOLERANCE (UNLESS OTHERWISE SPECIFIED) .010 M.DURRANT ANG. 1 1 © UNIVERSITY OF CANTERBURY DEPARTMENT OF MECHANICAL ENGINEERING 40B 10 [mm] STEEL PLATE FINISH End Wall thickness 12 mm 5 Drainage Valve 25.0 K.ALEXANDER Drawing 1/3 REV ENME 311 AIR RECEIVER REV1 4/10/20 ENME 311 ASSIGNMENT 2 DRAWING NOT TO SCALE SHEET 1 OF 1 REVISIONS NOTES - ( UNLESS OTHERWISE SPECIFIED ) ZONE 2. GD&T AS PER ISO1101-2004. 460.0 DESCRIPTION REV1 RELEASE 104.6 11.0 DATE XXX 01JAN13 ASMUSS 120 [mm] out diameter 80 [mm] Nominal bore flange 10.0 12 [mm] END THICKNESS DETAIL B SCALE 1 : 9 50.0 10.0 10.0 12 [mm] END THICKNESS 134.6 15.0 25.0 11.0 201.1 C APPROVED 10.0 74.6 11.0 100.0 80.0 DETAIL A SCALE 1 : 9 A ECO ASME Class 600 NPS 16 Blind Flange 11.0 94.7 1. ALL DIMENSIONS IN MILLIMETERS. 500.0 REV. 200.0 246.0 DETAIL C SCALE 1 : 9 B NOTE: *FOR ALL WELD DETAILS SEE DRAWING 3 - WELD SPECIFICATIONS THIRD ANGLE PROJECTION MATERIAL D DETAIL D SCALE 1 : 9 ASMUSS 366.6 [mm] Outer Diameter 246 [mm] NB Flange THIS DOCUMENT IS ISSUED IN STRICT CONFIDENCE ON CONDITION THAT IT IS NOT COPIED, REPRINTED, OR DISCLOSED TO A THIRD PARTY EITHER WHOLLY OR IN PART WITHOUT THE WRITTEN CONSENT OF UNIVERSITY OF CANTERBURY AIR RECEIVER Drawing 2/3 40B 10 [mm] STEEL PLATE FINISH PAINTED .1 .XX DECIMAL .03 mm .XXX DESIGN DWG NO. DRAWN PROJECT SUPERVISOR ISSUE DATE M.DURRANT TOLERANCE (UNLESS OTHERWISE SPECIFIED) .X © UNIVERSITY OF CANTERBURY DEPARTMENT OF MECHANICAL ENGINEERING .010 M.DURRANT ANG. 1 K.ALEXANDER REV ENME 311 AIR RECEIVER REV1 4/10/20 ENME 311 ASSIGNMENT 2 DRAWING NOT TO SCALE SHEET 1 OF 1 REVISIONS NOTES - ( UNLESS OTHERWISE SPECIFIED ) ZONE 1. ALL DIMENSIONS IN MILLIMETERS. 2. GD&T AS PER ISO1101-2004. REV. DESCRIPTION REV1 RELEASE ECO APPROVED DATE XXX 01JAN13 .1 12.0 38.0 Slope decreases 1 [mm] either side over 10 [mm] Slope 1:10 3.0 16.5 3.0 10.0 10.0 Double sided butt joint with single "Vee" The same weld design is used to attach the Manhole and Air Outlet pipe/branch to the shell and the flange to the branch pipe .0 12 10.0 Circumferential dished end weld (BS 5169 Figure 8 b.) 12.0 Manhole and Air Outlet pipe attachement to shell and flange attachment to pipe weld (BS 5169 Figure 9 a.) 15.0 10.0 Longitudinal Shell Weld (BS 5169 Figure 1d.) 10.0 The same weld design is used to attach the Air inlet and Drainage pipe/branch to the shell and the flange to the Air inlet Air inlet and Drainge pipe attachment to shelland flange attachment to pipe weld (BS 5169 Figure 9 a.) THIRD ANGLE PROJECTION MATERIAL THIS DOCUMENT IS ISSUED IN STRICT CONFIDENCE ON CONDITION THAT IT IS NOT COPIED, REPRINTED, OR DISCLOSED TO A THIRD PARTY EITHER WHOLLY OR IN PART WITHOUT THE WRITTEN CONSENT OF UNIVERSITY OF CANTERBURY 40B 10 [mm] STEEL PLATE FINISH .1 .XX DECIMAL .03 mm .XXX 3/3 AIR RECEIVER Drawing Weld Details DESIGN PAINT DRAWN TOLERANCE (UNLESS OTHERWISE SPECIFIED) .X © UNIVERSITY OF CANTERBURY DEPARTMENT OF MECHANICAL ENGINEERING .010 ANG. 1 M.DURRANT M.DURRANT SUPERVISOR K.ALEXANDER DWG NO. ENME 311 AIR RECEIVER PROJECT REV REV 1 ENME 311 ASSIGNMENT 2 ISSUE DATE 7/10/20 DRAWING NOT TO SCALE SHEET 1 OF 1