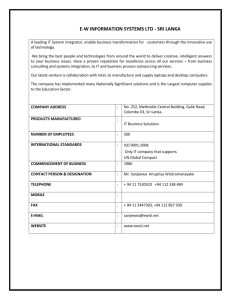

PREDICTIVE DATA MODEL FOR SUPPLY CHAIN DEMAND FORECASTING DOMINO’S PIZZA SRI LANKA FINAL YEAR PROJECT PROPOSAL - BSc (Hons) BUSINESS INFORMATION SYSTEM i Title Page Sponsoring Company: Jubilant Foodworks Lanka (Pvt) Ltd No.164, Galle Road, Dehiwala, Sri Lanka. Contact Person: Mr. Eranga Perera Head of Information Technology eranga_perera@jublfood.com +94 773563588 Project Carried Out by: M.G Ruchira Anuradha Senevirathne Ruchira.senevirathne@ipotenza.com +94 777192949 Date: 14th October, 2017 ii Executive Summery The intend of this project is to build a predictive data model for Jubilant Foodworks Lanka LTD to forecast the demand of supply chain department. The supply chain department of jubilant Foodworks Lanka ltd plays a critical role in the organization by catering to the needs of raw materials for the production environment. Therefore, it is a mandatory requirement to maintain a sufficient inventory throughout the year. If the supply chain department overestimates the demand, it will end up with more inventory than is necessary. This can incur a loss due to obsolescence of unsold inventory. In such a case, organization might need to sell inventory or product at a discount price or in some cases wasting the inventory without gaining a single cent out of it, which will reduce company's profit margins as well as creating considerable losses. This will affect the organization other way around also, if the department under estimate the demand, company’s entire production commissary and front-end restaurant will end up with shortage of end products. This will eventually lead the company to lost lose their customers and profits. A clear vision of the future demand will have a positive effect on planning, performance and profit of the organization The aim of this project is to build a predictive forecasting dashboard for Jubilant Foodworks Lanka to predict the demand for supply chain department, by extracting historical data (sales, inventory movements and purchasing) from the current supply chain department and restaurants operation department and then analyzing the same with data model based on a Statistical model and a Neural Network. After completing this project, the organization will be able to use the predictive data model and dashboard to forecast the demand of supply chain department more effectively. As a result of this forecast of the supply chain demand, the organization will be able to save a considerable amount of revenue by reducing wastage. iii Contents Title Page.................................................................................................................................................. Executive Summery............................................................................................................................... iii Contents ................................................................................................................................................ iv 1. Introduction to the Company ............................................................................................................ 1 2.Problem Statement ............................................................................................................................. 1 3.Background of the Study..................................................................................................................... 2 4.Aims & Objectives of the Study .......................................................................................................... 2 4.1 Academic Question ...................................................................................................................... 2 4.2Aims ............................................................................................................................................... 2 4.3Study Objectives ............................................................................................................................ 2 5.Scope ................................................................................................................................................... 3 5.1 Sample Data ................................................................................................................................. 3 5.2 Time Period for this project ......................................................................................................... 3 6. Limitations.......................................................................................................................................... 3 7. Technical Approach ............................................................................................................................ 3 7.1 Methodology Used ....................................................................................................................... 3 7.2 Performance evaluation ............................................................................................................... 4 8.Work Breakdown structure ................................................................................................................ 5 9.Gantt chart .......................................................................................................................................... 6 10.Deliverables ...................................................................................................................................... 6 10.1 Non-Technical Resources ........................................................................................................... 6 10.2 Technical Resources ................................................................................................................... 7 10.2.1 Hardware ............................................................................................................................. 7 10.2.2 Software .............................................................................................................................. 7 iv 1. Introduction to the Company Jubilant Foodworks Lanka (Pvt) Ltd is a subsidiary of Jubilant FoodWorks India which holds master franchise for Domino’s Pizza in India, Nepal, Sri Lanka and Bangladesh. Jubilant Foodworks is a part of Jubilant Bhartia Group. In Sri Lanka, Jubilant Foodworks Lanka (Pvt) Ltd has 25 restaurants island wide. Head office is located in Dehiwala area. Their main line of business is selling pizza products and they offer a wide variety of localized products in their menu. Front end restaurants act as quick serving restaurants while delivering pizza to the customer’s door steps is a main target of them. Central commissary serves all 25 restaurants by producing level 2 products such as dough balls, processed vegetables, etc. Further, it distributes raw materials for restaurants playing the role of main warehouse of Jubilant Food Works Lanka. Dominos Sri Lanka has been serving great quality products and services to Sri Lankan customers since 2011, becoming the main competitor for Pizza Hut, which has more than 20 years of experience and 50+ restaurants. 2. Problem Statement Supply chain department plays a vital role in the organization by maintaining the correct amount of stocks and supplies for the production needs. With new strategic initiatives of the marketing department, there is a need to maintain enough inventory to cater to the newly created demand and avoid shortages of raw materials. As a result, the supply chain department tend to stock excess raw materials to face such a situation. Under certain circumstances, forecasted results cannot be achieved through marketing campaigns. In such situations life time of food items and raw material expires before they are sold to customers. Therefore, Senior Management is very keen on finding a solution to reduce this wastage of food products by forecasting the correct demand for production. Management is in the view that they can forecast and minimize the over/under procurement situations by using a proper algorithm. 1 3. Background of the Study Even if there are number of software solutions available in the market to predict supply chain demand, none of them are specially designed to cater to the food and beverage sector. Most of the software solutions are designed to analyze previous purchasing history and inventory movements but not focus on sales patterns. Also these systems are very expensive and the organization is not ready to bear the cost at this stage. But, the requirement for a reliable forecasting model or a system is a key element to achieve less wastage and better demand handling in the organization. As a IT professional, I have seen this requirement as an opportunity to develop a predictive data model to support the decision making process of the supply chain department. Collecting historical data from different departments will be a challenging task during the initial stage of the project. By convincing the employees about the benefits and giving a clear picture of the deliverables of the project, we will be able to get the necessary support and the information required to complete this project successfully. 4. Aims & Objectives of the Study 4.1 • Academic Question How artificial intelligence (Neural Networks) & Statistical analysis methods can support the decision-making process in supply chain demand forecasting. 4.2 • Aims Aim of this project is to build a data model that can predict the demand of supply chain using advance algorithms & artificial intelligence like statistical data analysis and Neural networks. 4.3 Study Objectives • • • • • • • Gather historical data from relevant departments Chose correct samples for data manipulation process Create a data model using statistical analysis Create a data model using artificial intelligence – Neural Networks Develop a dashboard to identify the correct demand needs of the supply chain Test and verifying the accuracy of the model created Maintain the model to re-engineer after certain time period 2 5. Scope The scope of this project is to gather information, analyze information using an algorithm purpose developed to predict supply chain demand using historical data and sales operation data and present analysis output in an intelligible manner so that the management and relevant business user can make effective business decisions on supply chain operations. 5.1 Sample Data Two years of sample data will be collected from the departments for this analysis. The sample time period will be. 2015 November to 2017 November 5.2 Time Period for this project This project will be delivered to the client on 2018 May. Total day count of this project will be 132 Days 6. Limitations This project is only intending to develop a data model for supply chain department. All the predictions will be based on the accuracy of the data collected from the departments and this project will not be liable for the predictions if the data source is not reliable. 7. Technical Approach 7.1 Methodology Used The software development life cycle models (SDLC) are the various processes or methodologies that are being used for the development of the project depending on the project’s aims and goals. There are many software development life cycle models (SDLC) that have been developed in order to achieve different essential objectives. The life cycle models state the various stages of the process and the order which they should carried out. The selection of the correct SDLC model has very high impact on the project which is being carried out. SDLC model will define the what, where and when the correct processes should be done. There are various Software development models or methodologies available: 1. 2. 3. 4. 5. 6. 7. Waterfall model V model Incremental model RAD model Agile model Spiral model Prototype model 3 Waterfall Model is used for this project. The waterfall Model is a linear sequential design approach for developing a IT information system projects. This has been used widely in the software development industry to ensure the success of the projects. I have chosen this approach because of its clear visibility of the phases like, planning, analysis, design, deployment and maintenance. An inherent property of this model is that each step has a dependency on the previous step. This property is in line with the activity flow of the proposed algorithm development project. Based on waterfall method below steps are designed to archive the success of this project. 7.2 Performance evaluation Performance and accuracy of the outcome will be measured at the testing stage with the help of client and testing team. Accuracy of the data model predictions will be measured based on actual data (purchasing). 4 8. Work Breakdown structure 5 9. Gantt chart 10. Deliverables Below items will be delivered at this project completion • • • Dashboard system to access the predictive data Report downloading facility Actual vs predictive comparison portal 10. Required Resources 10.1 Non-Technical Resources ▪ ▪ Reliable Sample data from Supply chain department – purchasing and inventory movement Reliable sample data from operations department – sales data 6 10.2 Technical Resources 10.2.1 Hardware • Server PC - Dell R230 Power Edge o Intel® Xeon® processor E3-1200 o Intel C236 o 16GB DDR4 DIMM o 1 TB Hard Drive 10.2.2 Software • • • • • JetBrains PyCharm Community Edition 2017.1.3 R version 3.4.2 Microsoft Power BI Microsoft Excel and Word Microsoft SQL Server 2012 7