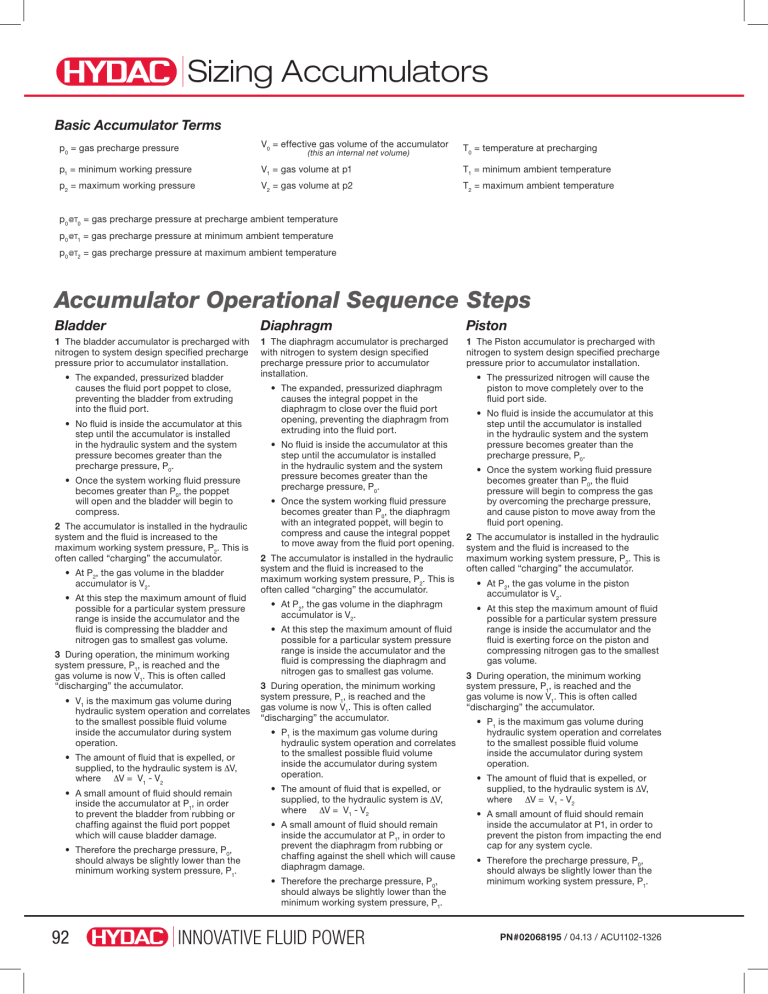

Sizing Accumulators Basic Accumulator Terms p0 = gas precharge pressure V0 = effective gas volume of the accumulator T0 = temperature at precharging p1 = minimum working pressure V1 = gas volume at p1 T1 = minimum ambient temperature p2 = maximum working pressure V2 = gas volume at p2 T2 = maximum ambient temperature (this an internal net volume) p0 @T0 = gas precharge pressure at precharge ambient temperature p0 @T1 = gas precharge pressure at minimum ambient temperature p0 @T2 = gas precharge pressure at maximum ambient temperature Accumulator Operational Sequence Steps Bladder Diaphragm Piston 1 The bladder accumulator is precharged with nitrogen to system design specified precharge pressure prior to accumulator installation. 1 The diaphragm accumulator is precharged with nitrogen to system design specified precharge pressure prior to accumulator installation. 1 The Piston accumulator is precharged with nitrogen to system design specified precharge pressure prior to accumulator installation. • The expanded, pressurized bladder causes the fluid port poppet to close, preventing the bladder from extruding into the fluid port. • No fluid is inside the accumulator at this step until the accumulator is installed in the hydraulic system and the system pressure becomes greater than the precharge pressure, P0. • Once the system working fluid pressure becomes greater than P0, the poppet will open and the bladder will begin to compress. 2 The accumulator is installed in the hydraulic system and the fluid is increased to the maximum working system pressure, P2. This is often called “charging” the accumulator. • At P2, the gas volume in the bladder accumulator is V2. • At this step the maximum amount of fluid possible for a particular system pressure range is inside the accumulator and the fluid is compressing the bladder and nitrogen gas to smallest gas volume. 3 During operation, the minimum working system pressure, P1, is reached and the gas volume is now V1. This is often called “discharging” the accumulator. • V1 is the maximum gas volume during hydraulic system operation and correlates to the smallest possible fluid volume inside the accumulator during system operation. • The amount of fluid that is expelled, or supplied, to the hydraulic system is ∆V, where ∆V = V1 - V2 • A small amount of fluid should remain inside the accumulator at P1, in order to prevent the bladder from rubbing or chaffing against the fluid port poppet which will cause bladder damage. • Therefore the precharge pressure, P0, should always be slightly lower than the minimum working system pressure, P1. 92 • The expanded, pressurized diaphragm causes the integral poppet in the diaphragm to close over the fluid port opening, preventing the diaphragm from extruding into the fluid port. • No fluid is inside the accumulator at this step until the accumulator is installed in the hydraulic system and the system pressure becomes greater than the precharge pressure, P0. • Once the system working fluid pressure becomes greater than P0, the diaphragm with an integrated poppet, will begin to compress and cause the integral poppet to move away from the fluid port opening. 2 The accumulator is installed in the hydraulic system and the fluid is increased to the maximum working system pressure, P2. This is often called “charging” the accumulator. • At P2, the gas volume in the diaphragm accumulator is V2. • At this step the maximum amount of fluid possible for a particular system pressure range is inside the accumulator and the fluid is compressing the diaphragm and nitrogen gas to smallest gas volume. 3 During operation, the minimum working system pressure, P1, is reached and the gas volume is now V1. This is often called “discharging” the accumulator. • P1 is the maximum gas volume during hydraulic system operation and correlates to the smallest possible fluid volume inside the accumulator during system operation. • The amount of fluid that is expelled, or supplied, to the hydraulic system is ∆V, where ∆V = V1 - V2 • A small amount of fluid should remain inside the accumulator at P1, in order to prevent the diaphragm from rubbing or chaffing against the shell which will cause diaphragm damage. • Therefore the precharge pressure, P0, should always be slightly lower than the minimum working system pressure, P1. INNOVATIVE FLUID POWER • The pressurized nitrogen will cause the piston to move completely over to the fluid port side. • No fluid is inside the accumulator at this step until the accumulator is installed in the hydraulic system and the system pressure becomes greater than the precharge pressure, P0. • Once the system working fluid pressure becomes greater than P0, the fluid pressure will begin to compress the gas by overcoming the precharge pressure, and cause piston to move away from the fluid port opening. 2 The accumulator is installed in the hydraulic system and the fluid is increased to the maximum working system pressure, P2. This is often called “charging” the accumulator. • At P2, the gas volume in the piston accumulator is V2. • At this step the maximum amount of fluid possible for a particular system pressure range is inside the accumulator and the fluid is exerting force on the piston and compressing nitrogen gas to the smallest gas volume. 3 During operation, the minimum working system pressure, P1, is reached and the gas volume is now V1. This is often called “discharging” the accumulator. • P1 is the maximum gas volume during hydraulic system operation and correlates to the smallest possible fluid volume inside the accumulator during system operation. • The amount of fluid that is expelled, or supplied, to the hydraulic system is ∆V, where ∆V = V1 - V2 • A small amount of fluid should remain inside the accumulator at P1, in order to prevent the piston from impacting the end cap for any system cycle. • Therefore the precharge pressure, P0, should always be slightly lower than the minimum working system pressure, P1. PN#02068195 / 04.13 / ACU1102-1326 Sizing Accumulators Accumulators Bladder Diaphragm Piston Precharge Recommendations For energy storage: For shock absorption: For pulsation dampening: p0 = 0.9 x p1 p0 = (0.6 to 0.9) x pm p0 = (0.6 to 0.8) x pm p1 = minimum working pressure pm = median working pressure at free flow pm = median working pressure Temperature Effect Due to the Ideal Gas Laws, the precharge pressure of an accumulator is affected by the ambient temperature of the accumulator’s operating environment. Given the constant volume of an accumulator shell when the temperature rises, the gas pressure will increase and conversely as the temperature goes lower, the gas pressure decreases. This temperature effect on precharge gas pressure will affect operation of the accumulator in a hydraulic fluid system. Therefore it is critical to consider the precharge pressure at T2, maximum ambient temperature, and T1, the minimum ambient temperature, when sizing an accumulator to ensure that the accumulator is sized large enough to operate properly over the entire operating ambient temperature range. The formula below describes the ambient temperature and precharge pressure relationship to any temperature. Refer to the sizing example on page 95 to see how the formula is applied in the sizing calculation process. Fahrenheit p0 @T0 = p0 @Tx x T0 ( T0 + 460 Tx + 460 ) = precharge temperature in °F Celsius p0 @T0 = p0 @Tx x T0 ( T0 + 273 Tx + 273 ) = precharge temperature in °C = actual ambient operating temperature in °F, where Tx is Tx T1 ≤ Tx ≤ T2 = maximum operating temperature in °C, where Tx is Tx T1 ≤ Tx ≤ T2 p0 @T0 =gas precharge pressure at precharge ambient temperature p0 @T0 =gas precharge pressure at precharge ambient temperature p0 @Tx =gas precharge pressure at maximum ambient operating temperature, where Tx is T1 ≤ Tx ≤ T2 p0 @T2 =gas precharge pressure at maximum ambient operating temperature, where Tx is T1 ≤ Tx ≤ T2 PN#02068195 / 04.13 / ACU1102-1326 INNOVATIVE FLUID POWER 93 Sizing Accumulators Gas Behavior su es correction factor Ci correction factor Ca ( ) ( () ) ( ( ) ( ) ( ) (( )) (( ( ) ( ) ( ) ( ) ( ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) pr ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) g kin or xw ma ( ) ng ki or xw ma The compression and expansion processes Determine the following: Correction factor Ci Isothermal taking place in hydro-pneumatic accumulators change of condition are governed by the general gas laws. Necessary accumulator size, taking into The following applies for ideal gases: account the real gas behavior by using 1.7 correction factors p 0 x V0n = p1 x V1n = p2 x V2n 1.6 Calculate gas precharge pressure p0 at 68°F where the time related change of state is represented by the polytropic exponent “n”. (T0 ) For slow gas expansion and compression 1.5 Select accumulator size and type processes which occur almost isothermically, the polytropic exponent can be assumed to Solution: 1.4 be n = 1. Since it is a rapid process, the change of pr For rapid processes, the adiabatic change of es 1.3 condition of the gas can be assumed to be su re state can be calculated using n = k = 1.4 (for p2 adiabatic. =4 nitrogen as a diatomic gas) 00 1.2 ba r 1. Calculation for the required ideal gas volume: (58 For pressures above 3000 psi the real gas 30 00 p 0b si) ar ( behavior deviates considerably from the ideal 4 a) gas precharge pressure at T2: 1.1 350 200 psi) one, which reduces the effective fluid volume b ar (2900 p s i ) p0 @T2 = 0.9 x p1 = 0.9 x 1500 = 1350 psi ∆V. In such cases a correction is made which 1.0 takes into account an adiabatic exponent (k) 1 2 3 4 5 b) gas precharge pressure at T1: even greater than 1.4; n = k > 1.4. By using the pressure ratio p2/p1 T1 + 460 following formulas, the required gas volume V0 p0 @T1 = p0 @ T2 x can be calculated for various calculations. T2 + 460 Correction factor Ca Adiabatic For low pressure applications of less than 150 75 + 460 psi absolute gas pressures must always be change of condition = 1245 psi p0 @T1 = 1350 psi x used in the formulas. 120 + 460 ∆V 1.7 V0 = ∆V ∆V c) ideal gas volume: V0 = p0 1/n p0 1/n V0 = 1/n ∆V 1.6 1/n ∆V ∆V 0.714 0.714 V0, P 0 p , (T ) P0 p1 p2 = p , ( T ) V = ideal 0 1 0 1 0 V0 = ∆V 0.714 P1p 1/n P2p p1/n ∆V P0@(T1) 0.714 Calculation Formulas p2 V0 idealV0 =P0@(T1) 1.5 0 0 p0 1/n p0 1/n V =1 0 P 1 P p1 p2 p0, (T1) 0.714 p02, (T1) 0.714 p1∆V p2 p0, (T1) 0.714 p0, (T1) 0.714 re 1.4 p1 p2 p2 V0 = p1 15∆V p2 polytropic: = 40 ∆V p0 1/n p0 1/n 0b V=0 = 1.35 V a ∆V V0 = 0 r( 1.3 0.714 0.714 30 p1 p2 p0, (T1)0.714 p508, 0(0T1) 0.714 V0Videal = = 3.95 gals. 0,ideal = 0 b 1150 V0 = 1150 p0 p0 ps 15 ar i) ∆V p p ( 15 1245 0.714 1245 0.714 4 2 350 1 0 P 0 P 1500 3000 p1 p2 ∆V V = 2 1.2 V0 = 0 00 V = psi ) V0 = 1500 3000 b ar 0 Pp1 P2 p isothermal: 1150 0.714 1150 0.714 (290 0.714 0 0 1150 0.714 0 ps1150 p0 p0 i) 1500 3000 1.1 p p (n=1) 1 2 1500 15 3000 p p2 ∆V 2. Calculation for the required real gas volume: 1 V0 = V0 = ∆V 0.714 1.0 a) Determine the adiabatic correction factor, Ca 1150 1150 0.714 p0 ∆V2 V 0 = p0 1 3 4 5 adiabatic: 0.714 0.714 p2 3000psi 1500 3000 V0 = pp1 0 p2 p0 = =2 0.714 ∆V ratio0.714 pressure p2/p1 (n = k = 1.4) 0 P 0 P p1 p∆V 1500psi p1 V0 = 2 V0 = P1p 0.714 P2p 0.714 0 0 From the correction factor for adiabatic p0 0.714 p0 0.714Sizing Example p1 p2 Correction factors to take into account change condition graph, using the 3000psi p1 ∆V the preal 2 T + 460 An additional operation is 0to be added to an gas behavior(2 T0 + 460 curve: V0 = T2 + 460 1.35 gallons p0 0.714 p0 0.714 existing machine which requires For isothermal change of condition: +460 460 CTa2T≈+0 1.16 of oil in 2.5 seconds for optimal operation. The T0 + 460 p1 p2 T + 460 V0,real = Ci x V0,ideal or 2 system must operate betweenT3000 psi and b) Real gas volume: + 460 2 + 460 1500 psi. The operating 68 ambient temperature ∆V0,real = ∆Videal 68 x+V460 =1.16 x 3.95 gal. V0, real = C 140 + 460 hydraulic a 0, ideal range is 75 to 120°F. The machine’s T0 + 460 120 460 Ci 68++gal. 460 = 4.6 fluid pump is sufficient to fully recharge the T2 +68 460 + 460 140 + 460 accumulator in the 8 second machine dwell for adiabatic change of condition: 3. Select actual accumulator size by rounding 140 + 460 time. Total machine cycle time = 10.5s. up to nearest nominal size accumulator V0,real = Ca x V0,ideal or listed in catalog: 68 + 460 Given: ∆Vreal = ∆ V0,ideal + 460 Selected size: 5 Gallon = 20 Liter maximum system working140 pressure Ca p2 = 3000 psi The Ci and Ca can be determined from the folminimum system working pressure 4. Calculation of gas precharge lowing Correction factor graphs. p1 = 1500 psi pressure p0 at 68°F: Calculate the ratio of Max/Min pressure, p2 /p1. required fluid volume of the system p 0 @ T0 = p 0 @ T 2 x On the graph find the intersection of p2 /p1 and T0 + 460 ∆V = 1.35 gallons the maximum working system pressure p2, = 1350 psi x T2 + 460 which is shown as a curve on the graphs for maximum ambient operating temperature = 1230 psi either an isothermal or adiabatic change of T2 = 120°F condition. 3. Selected: Size 20 (5 gallon) minimum ambient operating temperature Project the intersection point to the Y-axis to T = 75°F Recommended Model: SB330-20A1/112S1 determine the appropriate correction factor, 210C, Precharged to 1230 psi at 68°F C or C ) ( ) ( )) ( ( ( ( ) ) ( ) ) ) ( ( 94 ) ) ) ) ) ( ( ( ( ) ) ) ) ( i ( ) a. INNOVATIVE FLUID POWER PN#02068195 / 04.13 / ACU1102-1326 Sizing Accumulators Pulsation Dampeners & Suction Flow Stabilizers On the suction and pressure side of piston pumps almost identical conditions regarding non-uniformity of the flow rate occur. Therefore the same formulas for determining the effective gas volume are used for calculating the dampener size. That in the end two totally different dampener types are used is due to the different acceleration and pressure ratios on the two sides. V0 V0 Not only is the gas volume V0 a decisive factor but also the connection size of the pump has to be taken into account when selecting the pulsation dampener. In order to avoid additional cross section changes which represent reflection points for vibrations, and also to keep pressure drops to a reasonable level, the connection cross section of the dampener has to be the same as the pipe line. The gas volume V0 of the dampener is determined with the aid of the formula for adiabatic changes of state. A simulation of the pressure performance can be carried out by means of a computer program for real pipe line conditions. V V0 (l) = 100 0.714 0.695 x 1 Formulas 100 + x 100 0.695 x 1100 100 + x 1- X (±%) = 1∆V (l) = X (±%) = V 0.695 x V0 100 1.4 V 0.695 x V0 1.4 0.714 - 100 - 100 pˆ - pm pm V V0 (in3) = 100 0.714 0.695 Types of Pump1 - 100 + X z Gear Pump 7 - 14 V 3 V0 (in ) = Pump 2 2.36 x π Piston - 11 0.13 3.15 100 10.714 4 0.695 1 3 e.g. V0 (in ) = 100 + X 1 0.714 100 2 0.695 1 100 +2 2.5 3 0.13 2.36 x π 3.15 4 3 4 V0 (in ) = 0.714 100 5 0.695 1 100 + 2.5 6 V 0.695 1 - x 100 = p - pm pm p̂ - pm = p̆ - pm = amplitude of pressure fluctuations V V0 (l) = X = residual pulsations 100 p̂ = max. working pressure 0.695 x 1 - 100 + x p̆ = min. working pressure 100 100 + X k 0.1 - 0.3 0.01 - 0.6 0.6 0.25 0.13 0.12 0.05 0.13 7 0.02 0.714 9 0.01 Calculation Example x 100 = required gas volume pˆ - pm p - pm x 100 = x 100 X (±%) = ∆V = fluctuating fluid p volume pm m q(l) = stroke volume per cylinder V0 pressure side V0 (in3) = kq ˆ X (±%) = ∆V ˆ V0 (l) = suction side 0.714 V Parameters: V0 (in3) = 2.362 x π 0.714 0.13 3.15 100 Single 3acting 3-plunger 4 0.695 1 - pump V (in ) = 100 + X 0 piston diameter 2.36 inches 0.714 100 piston stroke 3.15 0.695 1 100 +2 0.5 x π 3.15 rpm 0.13 2.36 370 464.44 gpm 3 flow rate V0 (in )= operating temp. 68°F 0.714 100 V 0.695 1 3 operating pressure V0 (in ) = 100 + 0.5 pressure side 3625 psi 100 0.695 1 suction side 58 psi 100 + X (60 mm) (80 mm) (244 l/min.) (20°C) 0.714 (250 bar) (4 bar) Required: 1 2 2.36 xpulsation π 3.15of ± 2.5% V • Suction stabilizer 0.13 for a residual 3 1Vflow D (in ) = 4 0 3 p x Vx0dampener )= 0.714 of 0.5% • Pulsation for a residual pulsation K E(inx e 100 0.714 100 0.695 1 0.695 1 - 100 + X Solution: 1 100 + 2.5 a) Determination of required 1 suction flow stabilizer 1 D 2.362 x π 3.15 px x 1 0.13 250 K Exe 980 x x 9 3 10 100 2.04 x 1011 4x 6.3 V1.62 )= 0 (in x X (±%) = - 100 0.714 100 1.4 V 1 P 0.695 11100 + 2.5 V (bar) 0.695 x V0 3 250 V (in1 )= 1 980 SB x 0330-4 (see 0.714 Selected: onx page 13) 9 xtable 11100 2 1.62 x 10 2.04 10 xp 6.3 0.714 m x v x0.695 0.4 1 p 1 D x100p+1 X 0.286 p x pxˆ - p 0 p2required pm p - pm K E xme b) Determination dampener 2 x p1 x of - 1 pulsation x 102 x 100 = x 100 X (±%) = p1 2 p 1 pm 2.36 xπ pm V p1 0.714 3.15 m 33x) = v2 x 0.40.13 V0 (in 4 1 D x 100 V0 (in ) = 0.714 p 0.714 px x p2 0.286 t (sec) 0.252 x π 0.695 110 - 2 1000 K2 E x e 2 x p x 1 x 980 x x 2000 x 2.452 0.4 0.714 100 + X 0.695 1 0.714 m x v x 0.4 1 p p 7 100 + 0.5 1 4 pˆ - pm x 1 p - pm x V0 (l) = 0.286 4.5 61) x2 100p=0 x 100 X (±%) = p1 0.286 11 Selected: SB 330 P-20 (see table on page 2 2 2 x p1 x -1pmx 10 2 x 7 x 1 x 10 2.36 x π 3.15 p m p0 0.13 7 0.252 x π 4 3 Vx0 (in ) =x 2.452 x 0.4 For assistance in sizing pulsationmdampeners, 2000 x v2 x 0.4shock absorbers, p 0.714 and suction stabilizers,980 x 7 0.714 0.714 4 please contact HYDAC. x 1 x 100 V0 (l) =the HYDAC Accumulator Group at 1-877-GO 0.695 1 p 0.286 0.286 4.5 0 p1 11 100 + 0.5 2 2 x p1 x -1 x 10 2x7x - 1 x 102 p0 7 PN#02068195 / 04.13 / ACU1102-1326 1 pm = pump flow rate or pressure in the suction line V V0 (l) = 100 = Coefficient of cyclic variation of the pump X (±%) = 100 100 -0.714 1.4 0.695 x cylinders 1V z =No. of compressions / effective per 100 + x revolution 1 factors for other types, i.e. gear, axial, 0.695 x and V0 radial piston pumps on request ˆ ˆ INNOVATIVE FLUID POWER px 1 D x K Exe 95 Sizing Accumulators Energy Storage Form Name Title Company E-mail Address Phone State Phone Fax Zip Please attach any special requirements or drawings to the fax or e-mail. Operation of Pump Continuous Operation Emergency Operation Maximum Operating Pressure (P2) PSI Minimum Operating Pressure (P1) PSI Precharge Pressure at 68˚F (20˚C) (P0) PSI Temperature Range of Environment (T) ˚F Temperature Range of Fluid or System (TF) ˚F Pump Flow Rate (QP) GPM Total Cycle Time of System (TE) Sec. Number of Actuators (cylinders, etc.) (NV) Actuator Time Schedule and Flow QVi = Required Actuator Flow (GPM) Ei = Actuator Start Time Ai = Actuator Shut Down Time (i = 1 for first actuator, i = 2 for second actuator, etc. up to NV) QV1 = E1 = A1 = QV2 = E2 = A2 = QV3 = E3 = A3 = QV4 = E4 = A4 = QV5 = E5 = A5 = Fluid Required Mounting Orientation Country of Final Installation (for country codes please see page 2) Required Quantity Annual Usage Target Price Competitor Quantity Additional Remarks 96 INNOVATIVE FLUID POWER PN#02068195 / 04.13 / ACU1102-1326 Sizing Accumulators Shock Applications Form Name Title Company E-mail Address Phone State Phone Fax Zip Please attach any special requirements or drawings to the fax or e-mail. What is the source of the shock? (i.e. valve closing, pump start, or other - please describe) At the instance the shock occurs what is the... Flow rate: GPM Normal Operating Pressure: PSI ; Maximum Spike Pressure: The system’s maximum allowable design pressure: PSI PSI Information is required on all piping from the shock source to the anticipated location of the shock absorber (accumulator) . Please continue to answer the following: Total Number of pipes: (up to 10 pipes) Starting at the shock source, please answer the following: Pipe Inner Length Diameter Pipe (feet) (inches) 1 6 2 7 3 8 4 9 5 10 Inner Diameter (inches) Length (feet) If the vertical height from the shock source to the anticipated location of the shock absorber is greater than 10 feet please state this distance. Vertical Height: feet Fluid Required Mounting Orientation Country of Final Installation (for country codes please see page 2) Required Quantity Annual Usage Target Price Competitor Quantity Additional Remarks PN#02068195 / 04.13 / ACU1102-1326 INNOVATIVE FLUID POWER 97 Sizing Accumulators Pulsation Dampening Form Name Title Company E-mail Address Phone State Phone Fax Zip Please attach any special requirements or drawings to the fax or e-mail. What type of pump is causing the pulsation? Please name or describe (ie piston pump, gear pump, etc.) What is the... Flow rate: Pump: GPM RPM Pump Piston Diameter: (inches) Pump Piston Stoke: (inches) Number of Rotating Elements: Operating Pressure: (3 piston, 13 tooth gear, etc) psi The system’s maximum allowable pressure: psi Line Size where pulsation dampener will be fitted into: (The I.D. of the line is what is really required) Note: A pulsation dampener should be always be installed as close to the pulsation source as possible to optimize its performance. A pulsation dampener should never be placed greater than 10 ft away from the pulsation source. Fluid Required Mounting Orientation Country of Final Installation (for country codes please see page 2) Required Quantity Annual Usage Target Price Competitor Quantity Additional Remarks 98 INNOVATIVE FLUID POWER PN#02068195 / 04.13 / ACU1102-1326