Effects of Directed and Kinetic Energy Weapons on Spacecraft

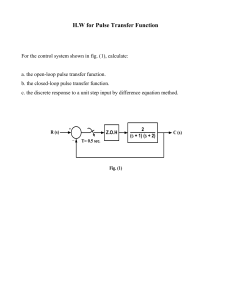

advertisement