Cranwell - Experimental Organic Chemistry, 3rd Edition-Wiley (2017) (1)

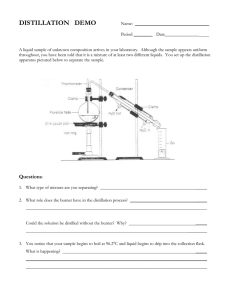

advertisement